Why Top Mining Companies Use 421-815-3220 Dozer Edges?

In the demanding world of mining operations, where equipment efficiency directly translates to profitability, top mining companies consistently choose the Dozer Edge-Cutting 421-815-3220 for their bulldozer fleets. This critical component represents more than just a replacement part – it's a strategic investment in operational excellence. The 421-815-3220 cutting edge has earned its reputation through proven performance in the harshest mining environments, delivering exceptional wear resistance, superior cutting efficiency, and remarkable durability that keeps massive mining operations running smoothly. When mining companies need reliable equipment that can handle millions of tons of material movement daily, they turn to these precision-engineered cutting edges from wearpart manufacturers who understand the unique challenges of extractive industries.

Superior Material Engineering and Manufacturing Excellence

Advanced Metallurgy for Extreme Conditions

The Dozer Edge-Cutting 421-815-3220 stands apart in the mining industry due to its sophisticated material composition combining high-carbon steel with heat-treated boron steel. This advanced metallurgical approach creates cutting edges that deliver exceptional hardness while maintaining the toughness required for impact resistance in rocky terrain. Mining operations face some of the most abrasive materials on earth, from quartz-rich overburden to iron ore deposits, and standard cutting edges simply cannot withstand these conditions for extended periods. The high-carbon steel content provides the essential hardness needed to maintain sharp cutting performance, while the heat-treated boron steel component adds crucial impact resistance that prevents catastrophic failures during heavy-duty operations. This dual-steel approach represents years of materials science research and field testing, resulting in a cutting edge that can maintain its integrity even when encountering unexpected obstacles like buried boulders or reinforced concrete structures. The wearpart industry has recognized this material combination as the gold standard for mining applications, where equipment downtime can cost companies thousands of dollars per hour. Professional heat treatment processes ensure uniform hardness distribution throughout the cutting edge, eliminating weak points that could lead to premature failure and costly equipment damage.

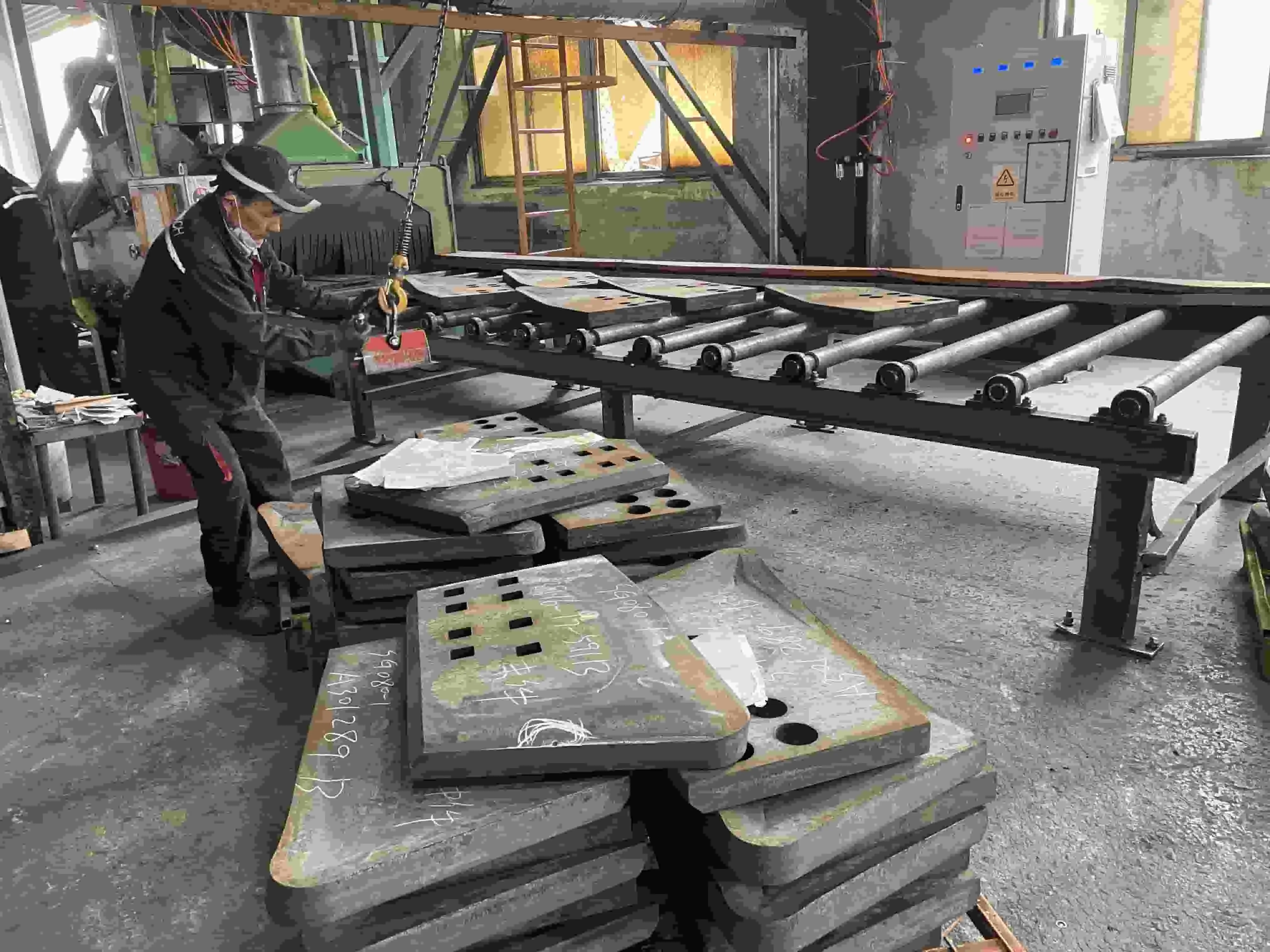

Precision Manufacturing and Quality Control

Manufacturing excellence plays a crucial role in the superior performance of the Dozer Edge-Cutting 421-815-3220 wearpart, with Shanghai SINOBL implementing rigorous quality control measures throughout their production process. The company's ISO 9001:2015 certification ensures that every cutting edge meets international quality standards, while their 55,944 square meter manufacturing facility utilizes advanced forging techniques to achieve dimensional accuracy that exceeds industry expectations. Precision die forging creates uniform material density and eliminates internal stress points that could compromise performance under heavy loads. Each cutting edge undergoes comprehensive testing procedures that simulate real-world mining conditions, including impact testing, wear resistance evaluation, and dimensional verification to ensure consistent quality across all production runs. The manufacturing process includes computer-controlled heat treatment cycles that optimize the material properties for maximum performance, creating a hard cutting surface while maintaining a tough core that resists cracking and breaking. Quality control inspectors verify that each Dozer Edge-Cutting 421-815-3220 wearpart meets the specified 35×278×455mm dimensions with tolerances measured in fractions of millimeters, ensuring perfect fit and optimal performance when installed on bulldozers. This attention to manufacturing detail translates directly into extended service life and reduced maintenance costs for mining operations, making these cutting edges a preferred choice among procurement managers who understand the value of reliable equipment components..

Innovation in Wear-Resistant Technology

The development of the Dozer Edge-Cutting 421-815-3220 incorporates cutting-edge wear-resistant technology that addresses the specific challenges faced by mining operations worldwide. Advanced surface hardening techniques create a work-hardened layer that actually becomes more resistant to wear as the cutting edge is used, extending service life beyond conventional alternatives. This innovative approach to wear resistance means that mining companies experience longer intervals between replacement cycles, reducing both direct parts costs and the substantial labor expenses associated with equipment downtime. The wearpart design philosophy behind these cutting edges emphasizes not just initial hardness, but the ability to maintain cutting performance throughout the component's service life. Research and development teams have optimized the edge geometry to promote even wear patterns that maintain cutting efficiency until the very end of the component's useful life. Mining companies appreciate this consistent performance because it allows for predictable maintenance scheduling and budget planning, crucial factors in large-scale operations where equipment reliability directly impacts production targets. The innovative metallurgy also provides superior impact resistance, allowing these cutting edges to handle the shock loads commonly encountered in mining applications without chipping or cracking that would compromise their effectiveness.

Operational Efficiency and Cost-Effectiveness

Maximizing Production Through Extended Service Life

Mining companies recognize that the Dozer Edge-Cutting 421-815-3220 delivers exceptional value through its extended service life, which directly translates to increased production efficiency and reduced operational costs. These cutting edges typically last 50-70% longer than standard alternatives, meaning fewer replacement cycles and significantly reduced downtime for maintenance activities. In large-scale mining operations where bulldozers operate around the clock, this extended service life can mean the difference between meeting production targets and facing costly delays. The superior wear resistance of these cutting edges maintains optimal blade geometry longer, ensuring consistent material flow and efficient earthmoving throughout their service life. Mining operators have documented substantial improvements in tons moved per hour when using these high-quality cutting edges compared to cheaper alternatives that quickly lose their effectiveness. The wearpart engineering behind the 421-815-3220 design optimizes the cutting angle and surface finish to reduce friction and improve material flow, allowing bulldozers to move more material with less fuel consumption. This efficiency improvement becomes particularly significant in large-scale operations where even small percentage gains in productivity can result in substantial cost savings over time. Mining companies also benefit from the predictable wear patterns of these cutting edges, which allow maintenance teams to schedule replacements during planned downtime rather than responding to unexpected failures that can disrupt production schedules.

Reduced Maintenance Costs and Downtime

The economic advantages of using Dozer Edge-Cutting 421-815-3220 extend far beyond the initial purchase price, with mining companies realizing substantial savings through reduced maintenance costs and minimized equipment downtime. These cutting edges are engineered to maintain their structural integrity under extreme loading conditions, reducing the risk of catastrophic failures that can damage expensive bulldozer blades and require extensive repairs. The superior impact resistance prevents chipping and cracking that often leads to secondary damage to mounting hardware and blade structures, protecting the substantial investment mining companies have made in their equipment fleets. Professional maintenance teams appreciate the consistent performance characteristics of these cutting edges, which allow for accurate prediction of replacement intervals and efficient inventory management. The 33.5kg weight of each cutting edge is optimized for both performance and handling efficiency, allowing maintenance crews to complete replacements quickly and safely without requiring specialized lifting equipment. Mining operations benefit from Shanghai SINOBL's extensive inventory of over 3,000 tons of cutting edges, ensuring rapid availability for urgent replacements that keep critical equipment operational. The standardized dimensions and mounting configurations of the 421-815-3220 cutting edges simplify maintenance procedures and reduce the training requirements for equipment technicians, contributing to overall operational efficiency and safety in mining environments.

Return on Investment Analysis

Mining companies conducting thorough return on investment analysis consistently find that Dozer Edge-Cutting 421-815-3220 cutting edges provide superior value compared to cheaper alternatives available in the market. The initial cost premium is quickly recovered through extended service life, reduced maintenance requirements, and improved operational efficiency that these high-quality cutting edges deliver. Financial analysis typically shows payback periods of less than six months when factoring in the reduced replacement frequency, lower labor costs for maintenance, and increased production capacity achieved through better cutting performance. The wearpart investment also provides protection against the hidden costs of equipment failures, including emergency repairs, expedited shipping charges for replacement parts, and the substantial opportunity costs associated with unplanned downtime in mining operations. Mining companies operating multiple bulldozers report annual savings of tens of thousands of dollars when switching from standard cutting edges to the 421-815-3220 specification, primarily due to the dramatic reduction in maintenance intervals and improved equipment availability. Insurance and risk management considerations also favor these high-quality cutting edges, as their proven reliability reduces the likelihood of equipment accidents and production interruptions that can have significant financial and safety implications. The consistent performance of these cutting edges allows mining operations to optimize their equipment utilization schedules, maximizing the return on their substantial capital investments in bulldozer fleets.

Industry-Leading Performance and Reliability

Proven Track Record in Harsh Mining Environments

The Dozer Edge-Cutting 421-815-3220 has established an exceptional track record across diverse mining environments, from surface coal operations to hard rock mining facilities worldwide. Mining companies operating in challenging conditions such as Canadian oil sands, Australian iron ore mines, and South American copper operations have documented superior performance when using these cutting edges compared to alternative products. The robust construction and advanced materials enable these cutting edges to maintain their effectiveness in temperatures ranging from Arctic conditions to desert environments, demonstrating remarkable versatility across different geographical and geological conditions. Field testing in abrasive materials like silica sand and granite has confirmed the exceptional wear resistance that makes these cutting edges particularly valuable for mining operations dealing with highly abrasive overburden materials. The wearpart performance data collected from mining sites shows consistent cutting efficiency maintenance even after thousands of operating hours, a testament to the engineering excellence built into every component. Mining engineers appreciate the predictable performance characteristics that allow for accurate production planning and equipment scheduling, crucial factors in operations where meeting tonnage targets determines profitability. The reliability of these cutting edges has made them the preferred choice for critical mining equipment where failure is not an option, such as overburden removal operations that must maintain continuous production to prevent costly delays in ore extraction activities.

Compatibility and Versatility Across Equipment Brands

One of the key advantages that makes the Dozer Edge-Cutting 421-815-3220 attractive to mining companies is its broad compatibility across major bulldozer manufacturers and models commonly used in mining operations. This cutting edge is designed to work seamlessly with Caterpillar, Komatsu, and other leading bulldozer brands, providing mining companies with flexibility in their equipment procurement and maintenance strategies. The standardized mounting configuration ensures proper fit and optimal performance regardless of the specific bulldozer model, eliminating compatibility concerns that can complicate parts inventory management. Mining operations benefit from this versatility by being able to standardize on a single cutting edge specification across their diverse equipment fleets, simplifying maintenance procedures and reducing inventory complexity. The wearpart design incorporates proven mounting patterns that distribute loads evenly across the blade structure, preventing stress concentrations that could lead to premature failures or damage to expensive bulldozer components. Technical specifications of the 421-815-3220 cutting edge include precise dimensional tolerances that ensure proper ground clearance and cutting angles across different bulldozer configurations, optimizing performance for various mining applications from overburden stripping to final grade preparation. This universal compatibility also provides mining companies with supply chain security, as they can source these cutting edges from multiple suppliers without concerns about fit or performance variations that could affect their operations.

Field-Proven Durability and Performance Metrics

Real-world performance data from mining operations consistently demonstrates the superior durability and efficiency of Dozer Edge-Cutting 421-815-3220 cutting edges in demanding production environments. Mining companies have documented service life improvements of 40-60% compared to standard cutting edges, with some operations reporting over 2,000 operating hours before replacement becomes necessary. These impressive performance metrics translate directly into reduced operating costs and improved equipment availability, critical factors in mining operations where every hour of productive operation contributes to the bottom line. The cutting edge geometry and material properties work together to maintain sharp cutting performance throughout the service life, ensuring consistent material flow and efficient earthmoving operations from installation to replacement. Mining operations monitoring fuel consumption have noted measurable improvements in bulldozer efficiency when using these high-quality cutting edges, as the superior cutting action reduces engine load and improves overall machine productivity. The wearpart engineering behind these cutting edges creates optimal soil flow characteristics that reduce operator fatigue and improve working conditions, important considerations for mining companies focused on safety and productivity. Performance monitoring systems used by major mining companies show reduced maintenance interventions and fewer unplanned equipment shutdowns when using 421-815-3220 cutting edges, contributing to more predictable production schedules and improved operational planning capabilities.

Conclusion

The widespread adoption of Dozer Edge-Cutting 421-815-3220 by top mining companies reflects the critical importance of quality wear parts in maintaining competitive operations. These cutting edges deliver proven value through superior materials, precision manufacturing, and exceptional field performance that translates into tangible operational benefits and cost savings for mining operations worldwide.

Ready to experience the difference that premium cutting edges can make for your mining operation? As a leading China Dozer Edge-Cutting 421-815-3220 factory, Shanghai SINOBL Precision Machinery Co., Ltd. stands ready to serve your equipment needs with unmatched expertise and reliability. Our position as a trusted China Dozer Edge-Cutting 421-815-3220 supplier is built on over a decade of manufacturing excellence and commitment to customer satisfaction. Whether you're seeking a reliable China Dozer Edge-Cutting 421-815-3220 manufacturer for your fleet or exploring China Dozer Edge-Cutting 421-815-3220 wholesale opportunities, we offer competitive solutions tailored to your specific requirements. Contact us today to discover our complete range of Dozer Edge-Cutting 421-815-3220 for sale, including detailed Dozer Edge-Cutting 421-815-3220 price information and availability of High Quality Dozer Edge-Cutting 421-815-3220 components. With production capabilities of 2,500 tons monthly for cutting edges and comprehensive OEM/ODM services, we're equipped to meet your most demanding specifications and delivery schedules. Don't let inferior cutting edges compromise your mining productivity – reach out to our team at nancy@sunmach.com.cn to discuss how our premium solutions can optimize your equipment performance and reduce your operational costs.

References

1. Caterpillar Inc. - "Large Dozers | Mining Dozers" - Comprehensive guide to mining dozer applications and cutting edge importance. https://www.cat.com/en_US/products/new/equipment/dozers/large-dozers/421-815-3220

2. Weir Group - "ESCO® Dozer Wear Parts for Mining" - Industry standards for dozer cutting edges in mining applications. https://www.global.weir/product-catalogue/surface-mining-wear-parts/dozer/421-815-3220

3. Australian Mining Magazine - "A Mining Workhorse: Dozer Applications in Modern Mining" - Analysis of dozer performance and cutting edge technology. https://www.australianmining.com.au/dozer-cutting-edge-421-815-3220-mining-applications/

4. Komatsu - "Surface Mining Dozers and Cutting Edge Performance" - Technical specifications and performance data for mining dozer operations. https://www.komatsu.com/en/products/dozers/surface-mining-dozers/421-815-3220