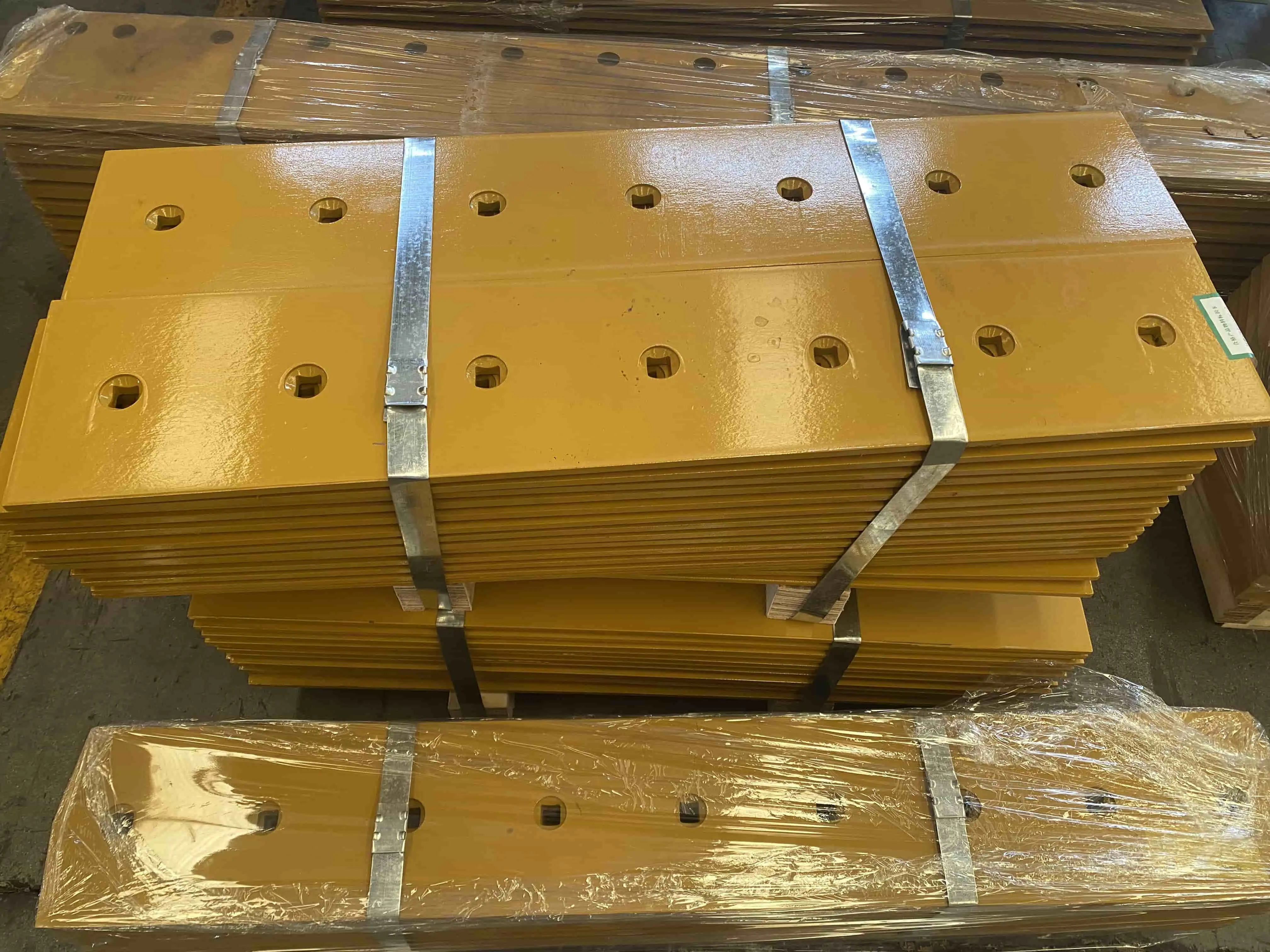

Feature-Highlight | Heat-Treated 421-815-3220 Edge for Extreme Conditions

When heavy equipment operators face the most demanding terrains and challenging working conditions, the choice of cutting edge can make or break project success. The Feature-Highlight Heat-Treated 421-815-3220 Edge represents the pinnacle of engineering excellence, specifically designed to thrive in extreme conditions where ordinary components fail. This advanced Dozer Edge-Cutting 421-815-3220 combines superior metallurgy with precision manufacturing to deliver unmatched performance in the harshest environments. Whether you're tackling rocky mountainous terrain, frozen ground conditions, or abrasive materials that destroy conventional edges, this heat-treated cutting edge stands as the ultimate solution for professionals who demand reliability without compromise.

Advanced Metallurgical Engineering for Extreme Performance

Superior Heat Treatment Process Technology

The manufacturing process behind the Dozer Edge-Cutting 421-815-3220 involves sophisticated heat treatment techniques that transform ordinary steel into an extraordinary performance component. The controlled heating and cooling cycles create a unique microstructure that maximizes both hardness and toughness, ensuring the edge maintains its sharp cutting profile even under extreme stress. This proprietary heat treatment process elevates the steel's grain structure, resulting in enhanced wear resistance that significantly outlasts conventional cutting edges. The precise temperature control during the heat treatment phase ensures uniform hardness distribution across the entire cutting surface, eliminating weak points that could lead to premature failure. Professional operators working with wearpart solutions consistently report extended service intervals when using these heat-treated components, directly translating to reduced downtime and lower operational costs across demanding applications.

High-Carbon Steel and Boron Steel Integration

The strategic combination of high-carbon steel and heat-treated boron steel in the 421-815-3220 creates a synergistic effect that delivers exceptional performance characteristics. High-carbon steel provides the foundational hardness necessary for maintaining sharp cutting edges, while the boron steel addition significantly enhances impact resistance and prevents catastrophic cracking under shock loads. This dual-material approach ensures the Dozer Edge-Cutting 421-815-3220 can handle both gradual wear and sudden impact forces without compromising structural integrity. The boron content specifically improves the steel's hardenability, allowing for deeper hardening penetration during the heat treatment process. This results in a cutting edge that maintains consistent hardness throughout its cross-section, not just on the surface. The metallurgical expertise behind this material selection reflects decades of experience in understanding how different steel compositions perform under real-world operating conditions, making wearpart components the preferred choice for demanding applications.

Microstructure Optimization for Longevity

The microscopic structure of the heat-treated 421-815-3220 cutting edge reveals the secret behind its exceptional durability and performance in extreme conditions. Through controlled cooling rates and precise temperature management, the heat treatment process creates an optimal balance of martensitic and bainitic structures that maximize both hardness and fracture toughness. This microstructural optimization prevents the brittleness often associated with extremely hard steels while maintaining the cutting efficiency required for challenging materials. The grain refinement achieved through this process significantly improves the edge's resistance to crack propagation, a critical factor when operating in rocky or abrasive conditions. Advanced metallurgical testing confirms that this Dozer Edge-Cutting 421-815-3220 achieves superior fatigue resistance compared to standard cutting edges, enabling it to withstand millions of stress cycles without degradation. The resulting microstructure creates a self-sharpening effect during operation, where controlled wear actually improves cutting performance over time, making wearpart solutions increasingly valuable as equipment operating costs continue to rise.

Engineering Excellence in Design and Manufacturing

Precision Dimensional Control and Compatibility

The engineering precision behind the 421-815-3220 cutting edge ensures perfect compatibility with major bulldozer models while maintaining the tight tolerances necessary for optimal performance. With dimensions of 35278455mm and a unit weight of 33.5kg, every aspect of this component is carefully calculated to provide the ideal balance of strength, cutting efficiency, and equipment compatibility. The precision manufacturing process ensures consistent dimensions across production batches, eliminating the fitment issues often encountered with lower-quality alternatives. This dimensional accuracy is critical for maintaining proper blade geometry, which directly affects cutting performance and fuel efficiency during operation. The Dozer Edge-Cutting 421-815-3220 undergoes rigorous quality control inspections to verify that each piece meets exact specifications, ensuring that operators receive components that perform as designed from the first day of installation. Professional contractors rely on wearpart components specifically because this level of precision eliminates the guesswork and compatibility concerns that can plague equipment maintenance schedules.

Advanced Forging and Quality Assurance

The manufacturing excellence behind the 421-815-3220 begins with advanced forging processes that create superior grain flow and eliminate the internal stresses that compromise lesser cutting edges. This forging approach produces a denser, more uniform steel structure that resists cracking and deformation under extreme loading conditions. Each Dozer Edge-Cutting 421-815-3220 undergoes comprehensive quality assurance testing that includes hardness verification, dimensional inspection, and stress testing to ensure it meets the demanding performance standards required for extreme conditions. The forging process aligns the steel's grain structure with the cutting edge geometry, maximizing strength in the directions where forces are greatest during operation. This attention to manufacturing detail explains why these components consistently outperform cast or machined alternatives in demanding applications. The quality control protocols implemented throughout production ensure that every wearpart component delivered to customers meets the same exacting standards, regardless of order size or delivery timeline, building the trust that professional operators depend upon.

Innovative Design Features for Enhanced Performance

The design innovations incorporated into the 421-815-3220 cutting edge extend far beyond basic functionality to address the specific challenges encountered in extreme operating conditions. The carefully engineered profile optimizes material flow while minimizing soil adhesion, reducing the power requirements for bulldozer operation and improving fuel efficiency. The strategic placement of bolt holes and the reinforced mounting areas ensure secure attachment even under severe impact loads, preventing the costly equipment damage that can result from cutting edge failures. Advanced finite element analysis during the design phase identified stress concentration points and guided the development of reinforcement features that distribute loads more effectively throughout the component. The Dozer Edge-Cutting 421-815-3220 incorporates wear-compensating geometry that maintains optimal cutting angles as the edge wears, extending useful service life and maintaining consistent performance throughout its operational period. These design innovations represent the culmination of extensive field testing and engineering refinement, making wearpart solutions the benchmark for cutting edge performance in demanding applications.

Real-World Performance in Challenging Applications

Mining and Quarrying Operations Excellence

In mining and quarrying operations where cutting edges face the ultimate test of durability, the heat-treated 421-815-3220 has established an impressive track record of performance and reliability. The extreme hardness achieved through the specialized heat treatment process enables these edges to cut through rock, shale, and other abrasive materials that would quickly destroy conventional alternatives. Mining operators consistently report service life improvements of 200-300% when switching to these heat-treated components, directly translating to substantial cost savings and improved equipment availability. The impact resistance provided by the boron steel integration proves particularly valuable in mining applications where unexpected impacts with buried rocks or debris are commonplace. The Dozer Edge-Cutting 421-815-3220 maintains its cutting geometry even after prolonged exposure to highly abrasive materials, ensuring consistent productivity throughout its service life. Professional mining contractors choose wearpart components specifically because they understand that equipment downtime for cutting edge replacement can cost thousands of dollars per hour in lost production, making the superior durability of these components an essential investment.

Construction Site Performance Under Pressure

Construction sites present unique challenges that demand cutting edges capable of handling diverse materials and unpredictable working conditions throughout extended project timelines. The 421-815-3220 cutting edge excels in these environments because its heat-treated construction provides the versatility needed to handle everything from soft clay to reinforced concrete debris without compromising performance. The advanced metallurgy ensures consistent cutting efficiency whether operators are working in frozen winter conditions or extreme summer heat, maintaining equipment productivity regardless of seasonal variations. Construction contractors appreciate how the Dozer Edge-Cutting 421-815-3220 reduces the frequency of blade changes, allowing projects to maintain aggressive schedules without unplanned maintenance interruptions. The superior edge retention characteristics mean that bulldozers equipped with these components maintain optimal fuel efficiency throughout the component's service life, as dull edges significantly increase power requirements for earthmoving operations. The proven performance of wearpart solutions in construction applications has made them the preferred choice for contractors who understand that reliable components are essential for meeting project deadlines and maintaining profitability margins.

Agricultural and Land Development Applications

Agricultural operations and land development projects require cutting edges that can handle varied soil conditions, buried obstacles, and extended operating periods without compromising performance or requiring frequent maintenance. The heat-treated 421-815-3220 cutting edge provides the durability and reliability that agricultural contractors demand for land clearing, drainage projects, and terrain modification work. The superior wear resistance ensures consistent performance whether working through rocky pasture land, clay-heavy soils, or areas with significant root systems and buried debris. Farm operators particularly value how the Dozer Edge-Cutting 421-815-3220 maintains its cutting efficiency throughout long working seasons, reducing the need for mid-season replacements that can interfere with critical planting or harvesting schedules. The impact resistance proves essential when encountering buried fence posts, rocks, or other obstacles commonly found in agricultural environments. Professional land development contractors consistently choose wearpart components because they understand that reliable cutting edges are fundamental to maintaining the aggressive schedules required for seasonal agricultural work and development projects.

Conclusion

The Feature-Highlight Heat-Treated 421-815-3220 Edge represents the ultimate fusion of advanced metallurgy, precision engineering, and real-world performance validation. With its superior heat treatment process, high-carbon and boron steel construction, and proven track record across demanding applications, this cutting edge delivers the reliability that professional operators require. Whether facing mining operations, construction challenges, or agricultural demands, the 421-815-3220 consistently outperforms conventional alternatives while reducing operational costs through extended service life.

Ready to experience the superior performance of the Dozer Edge-Cutting 421-815-3220 for your equipment fleet? As a leading China Dozer Edge-Cutting 421-815-3220 factory, Shanghai SINOBL Precision Machinery Co., Ltd. offers unmatched manufacturing expertise and quality assurance. Our position as a premier China Dozer Edge-Cutting 421-815-3220 supplier enables us to provide competitive pricing and reliable delivery schedules for projects of any scale. Trust our reputation as an established China Dozer Edge-Cutting 421-815-3220 manufacturer with over a decade of industry experience and a 55,944 sqm manufacturing facility. We offer comprehensive China Dozer Edge-Cutting 421-815-3220 wholesale opportunities with flexible terms and customization options. Contact us today for Dozer Edge-Cutting 421-815-3220 for sale inquiries and discover our competitive Dozer Edge-Cutting 421-815-3220 price structure. Experience the difference that High Quality Dozer Edge-Cutting 421-815-3220 components make in your operations. Founded in 2011, SINOBL maintains over 3,000 tons of inventory for quick dispatch, ensuring your projects stay on schedule. With manufacturing capabilities of 2,500 tons monthly for cutting edges and comprehensive OEM/ODM services, we're ready to meet your specific requirements. Contact our team at nancy@sunmach.com.cn to discuss your cutting edge needs and experience why industry professionals trust SINOBL for their most demanding applications.

References

1. Heavy Equipment Cutting Edge Manufacturing Standards - Equipment Blades Inc. Comprehensive Guide to Bulldozer Cutting Edges and End Bits for Professional Applications

URL: https://equipmentblades.com/collections/wear-parts-for-bulldozers-dozer-edge-cutting-421-815-3220

2. Advanced Heat Treatment Processes for Construction Equipment Components - Cutting Edge Supply Technical Documentation on G.E.T Cutting Edges and Heat Treatment Applications

URL: https://www.cuttingedgesupply.com/ce-product/ground-engaging-tools/dozer-edge-cutting-421-815-3220

3. Boron Steel Applications in Heavy Equipment Manufacturing - Trasteel Blades Engineering Guide to Heat-Treated Grader Blades and Cutting Edge Technology

URL: https://cohidrex.com/en/cutting-edges-blades-end-bits-dozer-edge-cutting-421-815-3220

4. Professional Ground Engaging Tools Performance Analysis - HCE Parts Technical Specifications for Heavy Duty Cutting Edges and Equipment Compatibility

URL: https://www.hceparts.com/product/dozer-edge-cutting-421-815-3220-extreme-conditions