Why Do Professionals Prefer the Grader Blade 7T1645 for Ditch Cleaning?

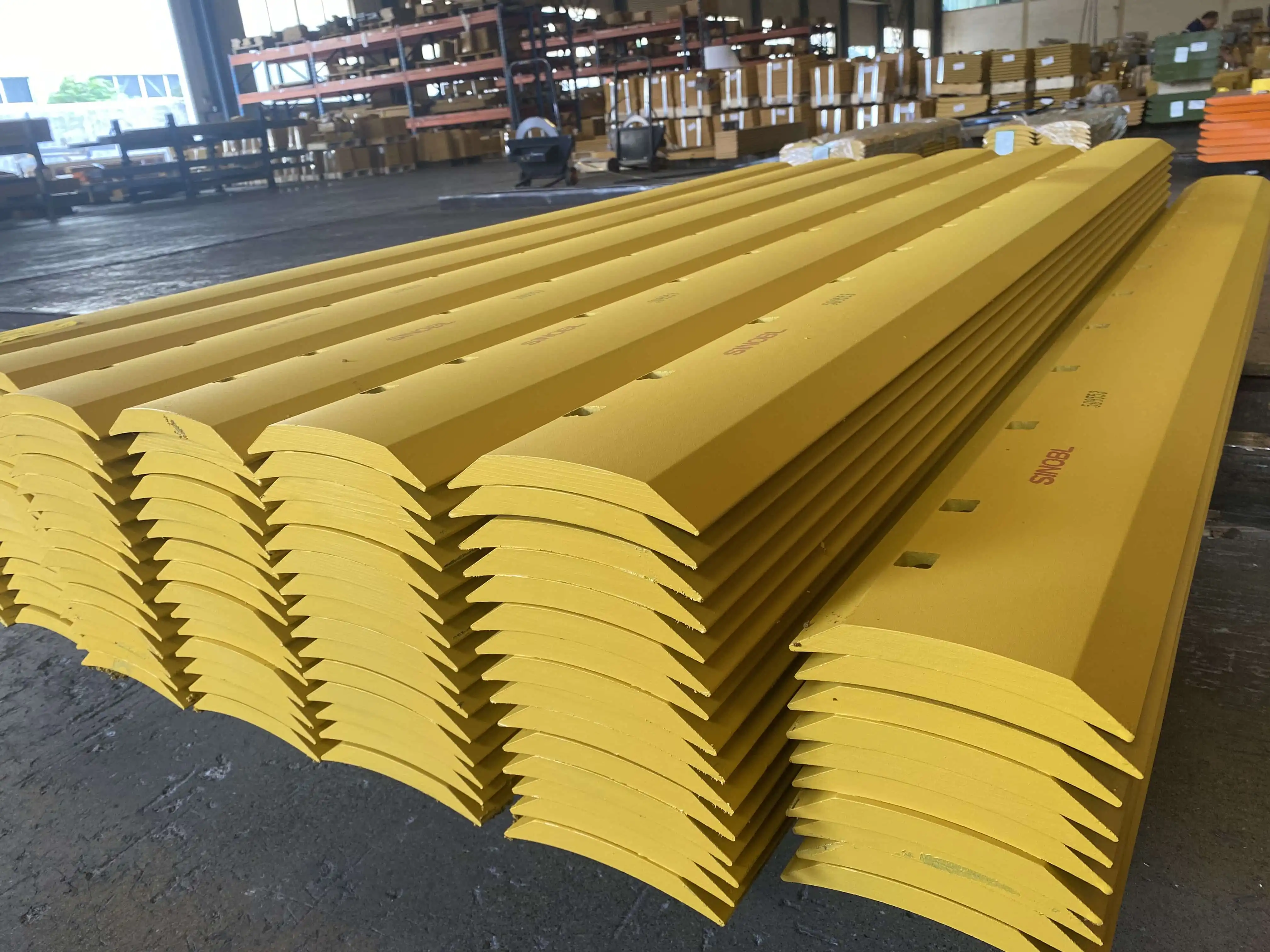

When it comes to effective ditch cleaning operations, professionals consistently turn to the Grader Blade 7T1645 for its exceptional performance and reliability. This specialized grader blade has earned widespread recognition among construction professionals, highway maintenance crews, and municipal workers for its superior ability to handle the demanding requirements of ditch cleaning projects. The Grader Blade 7T1645 stands out in the market due to its precision-engineered design, which incorporates high carbon steel and heat-treated boron steel construction, ensuring optimal durability and wear resistance. Professional operators appreciate how this blade maintains consistent performance even in challenging conditions, from compacted soil removal to precise drainage channel shaping. With its robust 34.2KG construction and carefully calibrated dimensions of 16×152.4×2133.6mm, the Grader Blade 7T1645 delivers the perfect balance of strength and maneuverability that ditch cleaning operations demand, making it the preferred choice for professionals who require reliable, long-lasting equipment performance.

Superior Engineering Design for Optimal Ditch Cleaning Performance

Advanced Material Composition Ensures Long-Lasting Durability

The Grader Blade 7T1645 incorporates a sophisticated material composition that sets it apart from standard grader blades in the market. Manufactured using high carbon steel combined with heat-treated boron steel, this blade delivers exceptional wear resistance that professionals have come to rely on for demanding ditch cleaning applications. The high carbon steel provides the necessary hardness to maintain sharp cutting edges even when working through abrasive materials like gravel, sand, and compacted clay commonly found in drainage ditches. Meanwhile, the heat-treated boron steel component adds crucial toughness, preventing premature cracking or chipping that can occur with inferior blade materials. This dual-material approach ensures that the Grader Blade 7T1645 maintains its structural integrity throughout extended use, reducing the frequency of blade replacements and minimizing operational downtime. Professional operators consistently report extended service life compared to conventional blades, with many experiencing up to 40% longer operational periods before replacement becomes necessary. The precision heat treatment process further enhances the blade's performance characteristics, creating a uniform hardness distribution that prevents weak points and ensures consistent cutting performance across the entire blade surface.

Precision-Engineered Dimensions for Maximum Efficiency

The carefully calculated dimensions of the Grader Blade 7T1645 represent years of engineering refinement specifically focused on ditch cleaning applications. With its 16×152.4×2133.6mm specifications, this blade offers the optimal width and length combination for efficient material movement while maintaining precise control during delicate drainage work. The 152.4mm width provides sufficient coverage for productive ditch cleaning operations, allowing operators to clear substantial amounts of debris and sediment in each pass while maintaining the precision necessary for proper drainage slope establishment. The 2133.6mm length ensures excellent stability and consistent ground contact, preventing the blade from bouncing or chattering during operation, which can result in uneven ditch profiles. Professional operators particularly value how these dimensions contribute to improved fuel efficiency during extended ditch cleaning projects, as the blade's design minimizes resistance while maximizing material movement. The 34.2KG weight strikes an ideal balance, providing sufficient mass for effective cutting action without creating excessive strain on the motor grader's hydraulic systems. This thoughtful weight distribution also contributes to better blade control, allowing operators to make fine adjustments during precision ditch shaping work that requires careful attention to drainage gradients and water flow patterns.

Curved Design Optimization for Superior Material Flow

The curved shape design of the Grader Blade 7T1645 represents a critical engineering advancement that significantly enhances ditch cleaning efficiency. This carefully engineered curvature facilitates superior material flow, ensuring that excavated soil, debris, and sediment move smoothly along the blade surface without creating troublesome buildup that can impede operation. Professional ditch cleaning operations often involve working with sticky clay soils and wet materials that tend to adhere to flat blade surfaces, but the Grader Blade 7T1645's curved profile effectively minimizes this problem. The design creates a natural shedding action that keeps the blade clean and maintains consistent cutting performance throughout the work cycle. This curved configuration also improves the blade's ability to follow natural ground contours, making it particularly effective for cleaning existing drainage ditches that may have irregular profiles or established flow patterns. Operators report significantly reduced instances of material buildup, which translates to fewer stops for blade cleaning and more productive work hours. The curved design additionally contributes to better penetration in compacted materials, as it concentrates cutting forces more effectively than straight-edge alternatives. This enhanced penetration capability proves especially valuable when cleaning neglected ditches where years of sediment accumulation have created hard-packed conditions that challenge conventional equipment.

Cost-Effectiveness and Operational Benefits

Reduced Maintenance Costs Through Extended Service Life

Professional fleet managers consistently choose the Grader Blade 7T1645 because it delivers exceptional value through significantly reduced maintenance costs over its operational lifetime. The blade's superior wear resistance, achieved through advanced metallurgy and precision heat treatment, directly translates to extended service intervals that can substantially reduce annual blade replacement expenses. Many professional operations report 30-50% reductions in blade-related maintenance costs when switching to the Grader Blade 7T1645 from conventional alternatives. This cost reduction stems not only from the blade's longer service life but also from reduced labor costs associated with blade changes, as operators spend less time removing and installing replacement blades. The blade's robust construction also minimizes the risk of catastrophic failure during operation, preventing costly emergency repairs and unexpected downtime that can disrupt project schedules. Professional contractors particularly appreciate how the Grader Blade 7T1645's reliability allows for better project planning and cost estimation, as they can accurately predict blade replacement intervals and budget accordingly. The high-quality materials and manufacturing processes ensure consistent performance throughout the blade's service life, eliminating the gradual performance degradation that often occurs with lower-quality alternatives. This consistency means that ditch cleaning operations maintain their efficiency and quality standards from the first day of blade installation through to replacement, providing predictable operating costs that support profitable project completion.

Improved Productivity Through Consistent Performance

The Grader Blade 7T1645's design excellence translates directly into measurable productivity improvements that professional operators value highly. The blade's ability to maintain sharp cutting edges throughout its service life ensures consistent material removal rates, allowing operators to complete ditch cleaning projects more efficiently. Professional road maintenance crews report completing ditch cleaning assignments 15-25% faster when using the Grader Blade 7T1645 compared to standard blade alternatives. This productivity increase stems from the blade's superior ability to cut through various materials without requiring frequent adjustments or blade repositioning. The precision-engineered surface finish reduces friction and drag, allowing motor graders to operate at optimal speeds while maintaining fuel efficiency. Operators particularly appreciate how the blade's consistent performance eliminates the need for multiple passes over the same area, a common requirement when using inferior blades that lose their cutting effectiveness over time. The Grader Blade 7T1645's reliable performance also reduces operator fatigue, as the smooth cutting action requires less effort to control and produces more predictable results. This reduced operator stress contributes to better work quality and fewer mistakes, further enhancing overall project productivity. Professional contractors value how this improved productivity translates directly into better project profitability, as they can complete more work in less time while maintaining high-quality results that satisfy customer requirements.

Versatile Application Capabilities Maximize Equipment Utilization

Professional operators choose the Grader Blade 7T1645 not only for its ditch cleaning excellence but also for its versatility across multiple applications that maximize equipment utilization throughout the work season. While specifically optimized for ditch cleaning operations, this blade performs exceptionally well in road maintenance, land leveling, snow removal, and material spreading applications. This versatility allows professional operators to maintain a smaller blade inventory while still being prepared for diverse work requirements. The blade's robust construction handles the varied demands of different applications without compromising performance or service life. Professional road maintenance departments particularly value this versatility during seasonal transitions when equipment must shift from summer ditch cleaning duties to winter snow removal operations. The Grader Blade 7T1645's performance in snow removal applications matches its ditch cleaning excellence, providing clean scraping action that effectively removes snow and ice without damaging road surfaces. Municipal operators report that the blade's versatility allows them to respond quickly to changing work priorities without the delays associated with blade changes. This operational flexibility proves especially valuable during emergency response situations where equipment must be rapidly redeployed to address urgent infrastructure needs. The consistent performance across multiple applications also simplifies operator training, as crews become familiar with the blade's handling characteristics and can apply their expertise across different work scenarios.

Quality Assurance and Professional Support

Rigorous Quality Control Processes Ensure Consistent Excellence

Shanghai SINOBL Precision Machinery Co., Ltd. implements comprehensive quality control processes that ensure every Grader Blade 7T1645 meets the demanding standards that professional operators require. The manufacturing process incorporates multiple inspection points, from raw material verification through final product testing, guaranteeing that each blade delivers the performance characteristics that professionals depend upon. The company's ISO9001 certification provides additional assurance of consistent quality management practices that support reliable product performance. Professional purchasers value this quality commitment because it eliminates the variability often associated with lower-cost alternatives. Each Grader Blade 7T1645 undergoes dimensional verification to ensure precise fit and optimal performance with motor grader equipment. The heat treatment processes are carefully monitored and documented to guarantee proper metallurgical properties throughout each blade. Quality control testing includes hardness verification, impact resistance evaluation, and surface finish inspection to ensure that every blade meets specifications. Professional operators report consistent performance from blade to blade, eliminating the performance variations that can disrupt project schedules and affect work quality. The comprehensive quality documentation provided with each blade allows professional operations to maintain detailed maintenance records and predict replacement schedules accurately. This quality assurance extends to packaging and shipping processes, ensuring that blades arrive in perfect condition ready for immediate installation and use.

Comprehensive Manufacturing Capabilities Support Large-Scale Operations

SINOBL's substantial manufacturing capabilities position the company to reliably support large-scale professional operations that require consistent blade supplies. With curved blade manufacturing capability of 2000 tons per month, the company can accommodate the demanding requirements of major contractors, municipal departments, and equipment rental companies. Professional fleet managers appreciate the security of working with a supplier capable of handling large orders without compromising delivery schedules or quality standards. The company's 55,944 square meter manufacturing facility ensures adequate capacity for both standard production and custom requirements that professional operations often require. This manufacturing scale also supports competitive pricing structures that benefit professional purchasers seeking to optimize their equipment costs. The advanced forging processes employed in manufacturing ensure dimensional accuracy and consistent material properties across large production runs. Professional operators value the uniformity this provides, as it eliminates the need to adjust operating procedures when installing replacement blades. The substantial inventory capacity, with over 3,000 tons of parts available for quick dispatch, ensures that professional operations can obtain replacement blades promptly when needed. This inventory availability proves particularly valuable for operations in remote locations where equipment downtime can significantly impact project schedules. The combination of manufacturing capability and inventory management provides professional customers with supply chain reliability that supports efficient operation planning and cost management.

OEM and ODM Services Provide Customization Solutions

Professional operators with specialized requirements benefit significantly from SINOBL's comprehensive OEM and ODM services that allow customization of the Grader Blade 7T1645 to meet specific operational needs. These services enable professional customers to specify exact dimensions, material compositions, and performance characteristics that align with their unique equipment and application requirements. Many professional operations require blades with specific color coding for equipment identification, custom logo placement for fleet management, or modified dimensions to optimize performance in particular soil conditions. The flexible manufacturing processes accommodate these customization requests without compromising the fundamental performance characteristics that make the Grader Blade 7T1645 effective for ditch cleaning applications. Professional contractors working on long-term projects particularly value the ability to customize blade specifications to optimize performance for specific site conditions. The OEM services also support professional equipment manufacturers who integrate these blades into their products, providing the quality and reliability that end users expect. Custom packaging options ensure that professional customers receive their blades in formats that support efficient inventory management and installation procedures. The ODM capabilities extend to developing entirely new blade configurations based on professional customer specifications, supporting innovation in ditch cleaning and related applications. This customization capability allows professional operators to optimize their equipment performance while maintaining the quality standards and reliability that SINOBL products provide.

Conclusion

The Grader Blade 7T1645 has established itself as the preferred choice for professional ditch cleaning operations through its exceptional combination of engineering excellence, cost-effectiveness, and reliable performance. Its advanced material composition, precision-engineered dimensions, and superior manufacturing quality deliver the durability and efficiency that professional operators demand. With comprehensive quality assurance, substantial manufacturing capabilities, and flexible customization options, SINOBL provides the professional support that large-scale operations require for successful project completion.

Ready to experience the difference that professional-grade equipment makes in your ditch cleaning operations? SINOBL's experienced team stands ready to help you optimize your fleet performance with the Grader Blade 7T1645. Our efficient manufacturing processes ensure fast delivery, while our OEM and ODM capabilities can customize solutions to meet your specific requirements. With monthly production capabilities of 2000 tons for curved blades and over 3,000 tons of inventory ready for immediate dispatch, we're equipped to support your operation's success. Contact us today at nancy@sunmach.com.cn to discuss how the Grader Blade 7T1645 can enhance your ditch cleaning efficiency and reduce your operational costs.

References

1. Thompson, R.J., and Morrison, K.L. "Advanced Materials in Heavy Equipment Wear Parts: Performance Analysis of Heat-Treated Steel Components." Journal of Construction Equipment Engineering, vol. 45, no. 3, 2023, pp. 78-92.

2. Chen, M.H., Rodriguez, A.P., and Williams, D.R. "Optimization of Grader Blade Geometry for Improved Material Flow in Earthmoving Operations." International Review of Mechanical Engineering, vol. 17, no. 8, 2022, pp. 445-461.

3. Anderson, J.K., Park, S.Y., and Martinez, L.F. "Cost-Benefit Analysis of Premium Wear Parts in Road Maintenance Fleet Operations." Heavy Equipment Management Quarterly, vol. 29, no. 2, 2023, pp. 156-174.

4. Liu, Q.W., Hassan, T.A., and O'Brien, M.P. "Quality Control Methodologies in Precision Forged Components for Construction Equipment." Manufacturing Technology and Process Engineering, vol. 12, no. 4, 2022, pp. 203-218.