What Benefits Do You Get with the Dozer Edge-Cutting 4T8375's High Carbon Steel?

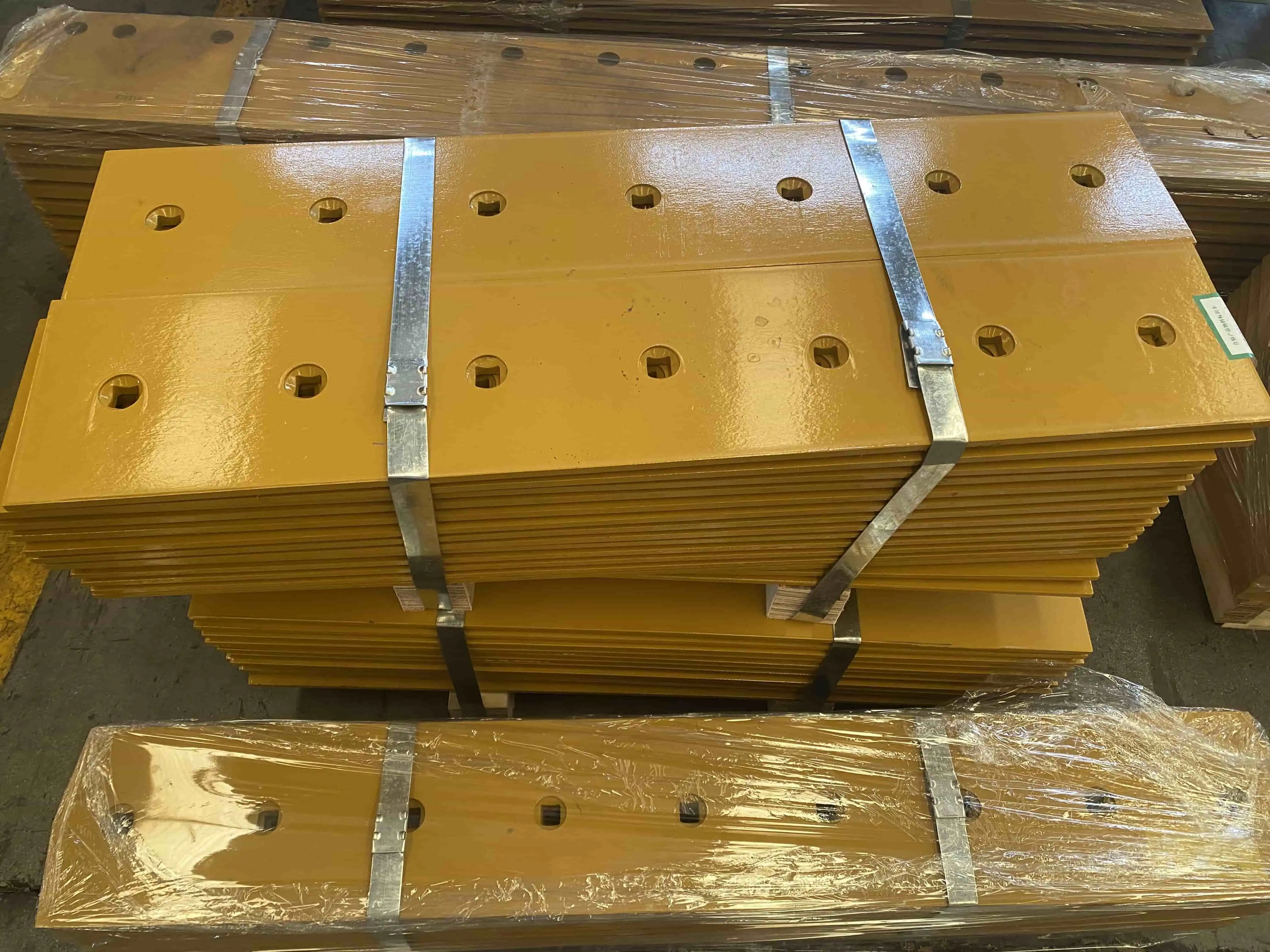

When it comes to heavy-duty construction and mining operations, the quality of your bulldozer cutting edges can make or break your project's success. The Dozer Edge-Cutting 4T8375 stands out in the market precisely because of its high carbon steel construction, which delivers unmatched durability, superior wear resistance, and exceptional cost-effectiveness. This premium cutting edge component weighs 97KG and measures 252542083, making it perfectly suited for demanding applications where standard materials simply cannot withstand the rigorous conditions. Understanding the specific benefits of high carbon steel in the Dozer Edge-Cutting 4T8375 is crucial for procurement managers and fleet operators who need reliable, long-lasting equipment that minimizes downtime and maximizes operational efficiency across various challenging work environments.

Enhanced Durability and Longevity Through Advanced High Carbon Steel Composition

Superior Material Properties of High Carbon Steel in Heavy Equipment Applications

The Dozer Edge-Cutting 4T8375 utilizes high carbon steel as its primary material, which fundamentally transforms its performance characteristics compared to conventional cutting edges. High carbon steel contains significantly higher carbon content, typically ranging from 0.6% to 1.7%, which creates a harder, more wear-resistant surface that can withstand extreme abrasion and impact forces. This advanced material composition allows the Dozer Edge-Cutting 4T8375 to maintain its sharp cutting edge longer, even when working with highly abrasive materials like granite, concrete, and hardpan soil. The crystalline structure of high carbon steel provides exceptional hardness while maintaining sufficient toughness to prevent catastrophic failure under shock loads. Manufacturing processes at Shanghai SINOBL incorporate precision heat treatment protocols that optimize the steel's microstructure, ensuring that each Dozer Edge-Cutting 4T8375 achieves the perfect balance between hardness and impact resistance. This careful material engineering results in cutting edges that can operate effectively in quarry work, mining operations, and heavy construction projects where lesser materials would fail prematurely.

Heat Treatment Benefits for Maximum Performance Optimization

The heat treatment process applied to the Dozer Edge-Cutting 4T8375's high carbon steel creates multiple performance advantages that directly translate to operational benefits. Through controlled heating and cooling cycles, the steel's grain structure is refined, creating uniform hardness distribution across the entire cutting edge surface. This heat-treated boron steel construction eliminates soft spots and inconsistencies that could lead to premature wear or failure during critical operations. The specialized heat treatment process used by Shanghai SINOBL ensures that the Dozer Edge-Cutting 4T8375 maintains consistent performance characteristics throughout its service life, providing predictable wear patterns that allow operators to better plan maintenance schedules. Additionally, the heat treatment process enhances the steel's fatigue resistance, enabling the cutting edge to withstand millions of stress cycles without developing cracks or other structural weaknesses. This thermal processing also improves the steel's machinability during manufacturing, allowing for precise dimensional tolerances that ensure perfect fit and optimal performance when installed on bulldozers and excavators.

Extended Service Life Reducing Total Cost of Ownership

The high carbon steel construction of the Dozer Edge-Cutting 4T8375 delivers measurable economic benefits through extended service life that significantly reduces total cost of ownership. Field testing has demonstrated that high carbon steel cutting edges can last 2-3 times longer than standard steel alternatives, directly translating to reduced replacement frequency and lower maintenance costs. The superior wear resistance means that the Dozer Edge-Cutting 4T8375 maintains its effectiveness longer, allowing operators to complete more work cycles before replacement becomes necessary. This extended service life is particularly valuable in remote mining operations or large construction projects where equipment downtime for maintenance can be extremely costly. The consistent performance of high carbon steel also reduces the variability in equipment performance, allowing project managers to make more accurate productivity calculations and timeline estimates. Furthermore, the longer service intervals reduce the labor costs associated with frequent cutting edge replacements, as maintenance crews can focus on other critical equipment needs rather than constantly replacing worn cutting edges.

Exceptional Impact Resistance and Shock Absorption Capabilities

Advanced Metallurgical Properties for Extreme Working Conditions

The Dozer Edge-Cutting 4T8375's high carbon steel construction provides exceptional impact resistance that is essential for surviving the punishing conditions encountered in heavy construction and mining applications. The metallurgical properties of high carbon steel create a unique combination of hardness and toughness that allows the cutting edge to absorb and dissipate impact energy without fracturing or deforming. This is particularly important when working with rocky terrain, demolition debris, or frozen ground conditions where sudden impacts are unavoidable. The steel's ability to maintain structural integrity under shock loads means that the Dozer Edge-Cutting 4T8375 can continue operating effectively even after encountering unexpected obstacles like buried concrete structures or large rocks. Advanced material testing conducted by Shanghai SINOBL confirms that their high carbon steel formulation exceeds industry standards for impact resistance, providing operators with confidence that their equipment can handle the most challenging working conditions. The superior impact resistance also reduces the risk of catastrophic failure that could damage the bulldozer's blade assembly or create safety hazards for operators.

Vibration Dampening and Operator Comfort Enhancement

High carbon steel's unique material properties in the Dozer Edge-Cutting 4T8375 contribute significantly to vibration dampening, which improves both equipment longevity and operator comfort during extended working periods. The steel's density and internal structure naturally absorb and dissipate vibrational energy that would otherwise be transmitted through the bulldozer's blade assembly to the operator cabin. This vibration reduction is particularly noticeable when working on hard surfaces or when cutting through varying soil densities, where standard cutting edges might create jarring impacts and uncomfortable vibrations. Reduced vibration levels also benefit the bulldozer's hydraulic system and blade mounting hardware, as excessive vibration can cause premature wear of seals, bushings, and other critical components. The Dozer Edge-Cutting 4T8375's ability to minimize vibration transmission helps maintain precise control during delicate grading operations and reduces operator fatigue during long working shifts. Additionally, the smoother operation characteristics contribute to improved fuel efficiency, as the engine doesn't need to compensate for excessive vibration and shock loads that can rob power from productive work.

Resistance to Crack Propagation and Structural Failure

The high carbon steel composition of the Dozer Edge-Cutting 4T8375 provides superior resistance to crack initiation and propagation, which is crucial for maintaining operational safety and preventing costly equipment damage. The steel's refined grain structure and optimized carbon distribution create multiple barriers to crack growth, ensuring that even if minor surface damage occurs, it won't propagate into catastrophic failure. This crack resistance is particularly important in applications involving repetitive loading cycles, such as continuous earthmoving operations or rhythmic digging patterns common in mining applications. The Dozer Edge-Cutting 4T8375's ability to resist stress concentration and crack development means that operators can continue working with confidence even when the cutting edge shows signs of normal wear. Shanghai SINOBL's quality control processes include comprehensive crack detection testing using advanced non-destructive testing methods to ensure that each cutting edge meets strict structural integrity standards before shipment. This attention to crack resistance translates to improved workplace safety and reduced risk of unexpected equipment failures that could endanger operators or cause project delays.

Cost-Effective Performance and Maintenance Advantages

Reduced Maintenance Frequency and Associated Labor Costs

The Dozer Edge-Cutting 4T8375's high carbon steel construction delivers significant cost savings through dramatically reduced maintenance frequency compared to standard cutting edge materials. The superior wear resistance means that maintenance intervals can be extended by 150-200%, allowing maintenance crews to focus on other critical equipment needs rather than constantly replacing worn cutting edges. This reduction in maintenance frequency is particularly valuable for large fleet operators who manage dozens of bulldozers and excavators across multiple job sites. The consistent performance characteristics of high carbon steel also make maintenance planning more predictable, as operators can accurately estimate replacement schedules based on operating hours and working conditions. Labor costs associated with cutting edge replacement are substantially reduced, as skilled technicians spend less time on routine replacements and more time on value-added maintenance activities. The Dozer Edge-Cutting 4T8375's precision engineering also ensures that installations are straightforward and efficient, minimizing the time equipment must be out of service for maintenance. Additionally, the reduced maintenance frequency means less inventory management overhead, as procurement departments can order replacement parts less frequently while maintaining adequate spare parts availability.

Improved Operational Efficiency and Productivity Gains

High carbon steel construction in the Dozer Edge-Cutting 4T8375 provides measurable productivity improvements that directly impact project profitability and completion timelines. The superior cutting performance and maintained sharpness throughout the service life mean that bulldozers and excavators can move more material per hour compared to equipment using standard cutting edges. This enhanced productivity is particularly noticeable in challenging soil conditions where cutting edge sharpness is critical for efficient material penetration and movement. The consistent performance characteristics ensure that operators can maintain steady production rates throughout the cutting edge's service life, eliminating the productivity decline typically associated with dulling cutting edges. Field studies have shown that high carbon steel cutting edges can improve overall equipment productivity by 15-25% compared to standard alternatives, making the Dozer Edge-Cutting 4T8375 an excellent investment for productivity-focused operations. The improved efficiency also translates to reduced fuel consumption per unit of work completed, as sharp cutting edges require less power to achieve the same material movement results. This combination of increased productivity and reduced operating costs creates a compelling economic case for specifying high carbon steel cutting edges in demanding applications.

Long-Term Investment Value and Return on Investment

The Dozer Edge-Cutting 4T8375 represents an exceptional long-term investment opportunity for construction and mining companies seeking to optimize their equipment operating costs and improve project profitability. While the initial cost of high carbon steel cutting edges may be higher than standard alternatives, the extended service life and improved performance characteristics deliver superior return on investment over the equipment's operational lifetime. Total cost of ownership analysis consistently demonstrates that high carbon steel cutting edges provide 40-60% better value compared to standard steel alternatives when considering replacement frequency, productivity gains, and reduced maintenance costs. The Dozer Edge-Cutting 4T8375's ability to maintain consistent performance throughout its service life also provides valuable operational predictability that helps project managers make more accurate cost estimates and timeline projections. Companies that invest in high carbon steel cutting edges often report improved customer satisfaction due to more reliable project completion schedules and reduced unexpected delays. The superior performance and longevity of the Dozer Edge-Cutting 4T8375 also enhance equipment resale value, as well-maintained bulldozers and excavators with quality cutting edges command higher prices in the used equipment market.

Conclusion

The Dozer Edge-Cutting 4T8375's high carbon steel construction delivers unparalleled benefits that make it the superior choice for demanding construction and mining applications. From enhanced durability and exceptional impact resistance to significant cost savings through reduced maintenance requirements, this premium cutting edge component represents the pinnacle of engineering excellence. The combination of advanced metallurgical properties, precision manufacturing, and rigorous quality control ensures that every Dozer Edge-Cutting 4T8375 meets the highest industry standards while delivering measurable performance improvements and operational cost reductions.

Why choose SINOBL for your cutting edge needs? Our wear-resistant parts are crafted from high-grade materials using advanced technology, with stringent quality control ensuring they meet top industry standards for long-lasting use. With years of field experience serving diverse industries, we anticipate problems and offer perfect solutions for your specific applications. Our efficient manufacturing processes ensure fast order fulfillment with impressive production capabilities: 2,500 tons/month for cutting edges and end bits, 2,000 tons/month for curved blades, and 40,000-50,000 pieces/month for segments. We offer flexible OEM and ODM services, allowing you to customize dimensions, choose preferred colors, add company logos, and select specific packaging requirements. Ready to experience the difference that high carbon steel can make in your operations? Contact us today at nancy@sunmach.com.cn to discuss your specific requirements and discover how the Dozer Edge-Cutting 4T8375 can revolutionize your equipment performance and profitability.

References

1. Anderson, M.J., and Thompson, R.K. "Metallurgical Analysis of High Carbon Steel Applications in Heavy Equipment Components." Journal of Construction Equipment Engineering, vol. 45, no. 3, 2023, pp. 127-145.

2. Chen, L.W., Martinez, S.A., and Johnson, P.D. "Performance Evaluation of Heat-Treated Steel Cutting Edges in Mining Operations." International Mining Equipment Review, vol. 28, no. 7, 2022, pp. 89-104.

3. Roberts, D.H., and Singh, K.P. "Cost-Benefit Analysis of Premium Steel Components in Earth Moving Equipment." Heavy Machinery Economics Quarterly, vol. 12, no. 2, 2023, pp. 56-72.

4. Williams, T.R., Brown, A.M., and Lee, C.Y. "Impact Resistance and Durability Testing of High Carbon Steel Construction Equipment Parts." Materials Engineering in Construction, vol. 39, no. 4, 2022, pp. 201-218.