What Are the Key Characteristics of Dozer Edge‑Cutting 109‑3116?

The Dozer Edge-Cutting 109-3116 represents a precision-engineered bulldozer component designed to deliver exceptional performance in demanding earthmoving applications. This cutting edge combines superior material composition with advanced manufacturing techniques to provide enhanced durability, extended service life, and optimal operational efficiency. Key characteristics include its robust steel construction with specialized heat treatment, precise dimensional accuracy for seamless compatibility, and proven resistance to abrasive conditions. The 109-3116 model specifically features optimized geometry that maximizes cutting efficiency while minimizing operator fatigue and equipment stress during heavy-duty operations.

Technical Specifications and Material Quality of Dozer Edge-Cutting 109-3116

For procurement experts looking for dependable equipment solutions, it is crucial to comprehend the technical parameters and material composition of bulldozer cutting edges. These components' engineering directly affects long-term cost control and operational effectiveness.

Advanced Material Composition and Heat Treatment

High-grade steel alloys that go through complex metallurgical processes are essential to the production of high-quality Dozer Edge-Cutting 109-3116. While regulated alloying elements improve toughness and wear resistance, a high carbon steel percentage serves as the basis for outstanding hardness. The component's whole microstructure is optimized using expert heat treatment procedures that include exact temperature control and quenching methods. These production procedures guarantee reliable performance under a range of operating circumstances. During thermal cycling, the specific treatment preserves dimensional stability while improving grain structure. Strict testing procedures are used by high-quality producers to ensure that material qualities meet or surpass industry requirements.

Precision Engineering and Dimensional Accuracy

Advanced die forging processes are used in modern cutting-edge manufacturing to provide consistent dimensions across production runs. Variations that can jeopardize performance or fit during field installation are eliminated by this precise method. Critical surfaces and mounting points are further refined to precise specifications by computer-controlled milling procedures. Beyond simple measurements, the dimensional precision encompasses geometric tolerances and surface finish quality. These elements have a direct impact on how well the cutting edge interacts with soil conditions and host equipment. Optimal load distribution and stress management during operation are guaranteed by proper engineering.

Quality Control and Manufacturing Standards

All phases of manufacturing are covered by thorough quality assurance processes, from final inspection to raw material verification. To ensure consistency, statistical process control techniques track important data throughout the production process. Third-party testing verifies adherence to relevant industry standards and checks mechanical qualities. Each component comes with documentation packages that provide procurement teams the performance information and traceability they need for assessment. Making decisions based on validated performance traits rather than just marketing promises is made possible by this openness.

Installation and Maintenance Best Practices for Optimal Performance

Proper installation procedures and maintenance protocols significantly impact the operational lifespan and cost-effectiveness of bulldozer cutting edges. Following established best practices ensures maximum return on investment while minimizing unexpected downtime.

Step-by-Step Installation Guidelines

Verifying component compatibility and thoroughly preparing mounting surfaces are the first steps in a successful installation. Cleaning techniques eliminate corrosion and accumulated material that can jeopardize appropriate seating. Examining the current hardware reveals worn fasteners that need to be replaced for a secure fit. Expert installation crews uniformly distribute loads between mounting locations by adhering to methodical torque sequences. Both overtightening, which produces stress concentrations, and undertightening, which permits movement, are avoided by using the right torque parameters. Installation parameter documentation offers reference information for future maintenance tasks.

Proactive Maintenance Strategies

Frequent inspection schedules make it possible to identify wear patterns early on before they impair operational efficacy. Visual inspections detect changes in fastener condition, edge recession, and crack formation. Measurement procedures monitor wear development to precisely forecast when replacement is necessary. Through abrasive action, accumulated debris that might hasten wear is removed during cleaning methods. Lubricating moving parts keeps them operating properly and keeps them from breaking down too soon. While preserving peak performance characteristics, these regular operations prolong service intervals.

Operational Guidelines for Extended Service Life

Operating procedures have a big impact on the lifetime of cutting-edge machinery and its overall output. By controlling ground speed, excessive impact loading that might result in early failure is avoided. Cutting angles are maximized and wear is uniformly distributed over the edge surface when the blade is positioned properly. Early warning of emerging issues is provided by monitoring operational factors including engine loads and hydraulic pressures. Techniques that optimize component life while upholding productivity goals are emphasized in equipment operator training programs.

Comparing Dozer Edge-Cutting 109-3116 with Alternatives in the Market

comparison research, procurement professionals may make well-informed judgments that go beyond pricing considerations and take into account a variety of assessment factors. The best choice for a given application is guided by knowledge of relative benefits and drawbacks.

Performance Differentiation Analysis

When it comes to wear resistance, the Dozer Edge-Cutting 109-3116 cutting edge has clear benefits over common aftermarket substitutes. Under same operating circumstances, variations in material composition lead to quantifiably extended service intervals. Data from field testing shows excellent edge retention properties across a range of soil types and operating intensities. Improved cutting efficiency from design optimization results in lower fuel consumption and higher output. In contrast to alternatives that see a decline in performance as wear increases, the geometric profile maintains ideal cutting angles throughout the wear cycle. Despite sometimes requiring a larger initial expenditure, these features help to reduce overall operational expenses.

OEM Versus Aftermarket Component Evaluation

Components from original equipment manufacturers go through rigorous testing and validation procedures that may not be applied to aftermarket substitutes. Compatibility and performance criteria that satisfy equipment manufacturer requirements are guaranteed by this development expenditure. OEM parts are often preferred over generic counterparts in terms of warranty coverage and technical support availability. Although aftermarket choices could be more affordable, they must be carefully evaluated in terms of performance capabilities and quality requirements. Because aftermarket providers differ greatly in their manufacturing consistency, choosing the right source is essential to getting satisfactory outcomes. Compared to OEM products, documentation and traceability could be lacking.

Total Cost of Ownership Considerations

A thorough cost study takes into account installation expenses, service life, and productivity effects in addition to the original purchase price. When analyzed throughout full service cycles, premium components usually show higher cost-effectiveness. Higher initial expenditure is often justified by decreased replacement frequency and increased output. Purchasing in bulk from reputable vendors may save money while maintaining constant quality standards. Better inventory control and consistent price structures that aid in budget planning are made possible by long-term cooperation agreements.

Procurement Considerations for B2B Buyers

Strategic procurement decisions require thorough evaluation of supplier capabilities, product quality, and commercial terms that align with organizational objectives. Professional buyers must balance immediate needs with long-term partnership potential.

Supplier Qualification and Verification

A thorough assessment of production capabilities, quality control systems, and technical know-how is required to establish supplier credentials. Direct evaluation of production facilities and process controls is provided by site audits. A dedication to reliable performance is shown by certification to pertinent quality standards. Customer testimonials from related applications provide insightful information on how well suppliers operate in practical settings. Overall relationship value is impacted by technical support skills and problem-solving quickness. Assessing a supplier's financial soundness guarantees their viability for further commercial partnerships.

Volume Pricing and Commercial Terms

Larger volume commitments are rewarded with lower unit costs under quantity-based pricing schemes for Dozer Edge-Cutting 109-3116. Annual agreements provide for improved inventory management and price consistency. Delivery dates and conditions of payment must be in line with cash flow and operational needs. Documentation, customs processes, and delivery schedules must all be carefully considered when making international shipping arrangements. Packaging guidelines minimize handling expenses while guaranteeing product protection throughout transportation. Conflicts and delays are avoided by clearly allocating responsibility for shipment damages.

Quality Assurance and Warranty Provisions

Comprehensive warranty coverage guards against manufacturing errors and material issues that can affect performance. To avoid misconceptions, clear warranty conditions outline coverage restrictions and claim processes. Quick issue solving is ensured by the availability of technical help throughout warranty periods. Verification of material attributes and production conformance is provided by quality documentation. Incoming quality verification is made possible by testing certifications and inspection reports. When problems occur, traceability systems facilitate problem-solving and the execution of remedial measures.

Conclusion

The Dozer Edge-Cutting 109-3116 represents a critical component for maintaining bulldozer productivity and operational efficiency across demanding applications. Its superior material composition, precision engineering, and proven performance characteristics make it an excellent choice for professional operators seeking reliable equipment solutions. Proper selection, installation, and maintenance practices maximize component value while minimizing total ownership costs. Strategic procurement partnerships with qualified suppliers ensure consistent access to premium components backed by comprehensive technical support and service capabilities.

Frequently Asked Questions

What bulldozer models are compatible with the 109-3116 cutting edge?

The 109-3116 cutting edge design accommodates a wide range of bulldozer models from major manufacturers. Compatibility verification requires matching dimensional specifications and mounting configurations to specific equipment models. Professional technical support teams can provide detailed compatibility information for your specific equipment requirements.

How often should cutting edges be replaced under normal operating conditions?

Replacement intervals depend on operating conditions, soil types, and operational intensity. Typical service life ranges from 300 to 800 operating hours under normal conditions. Regular inspection and measurement enable predictive replacement scheduling that optimizes productivity while preventing unexpected failures.

What advantages do OEM cutting edges offer compared to aftermarket alternatives?

OEM components undergo extensive testing and validation to ensure compatibility and performance standards. Superior material quality, manufacturing consistency, and comprehensive warranty coverage typically justify the investment. Technical support availability and documented performance characteristics provide additional value for professional operations.

How can bulk purchasing arrangements reduce procurement costs?

Volume pricing structures offer significant cost reductions for larger quantity commitments. Annual agreements provide pricing stability while improving inventory management efficiency. Consolidated shipping arrangements reduce logistics costs while ensuring consistent product availability for ongoing operations.

SINOBL: Your Trusted Partner for Premium Dozer Components

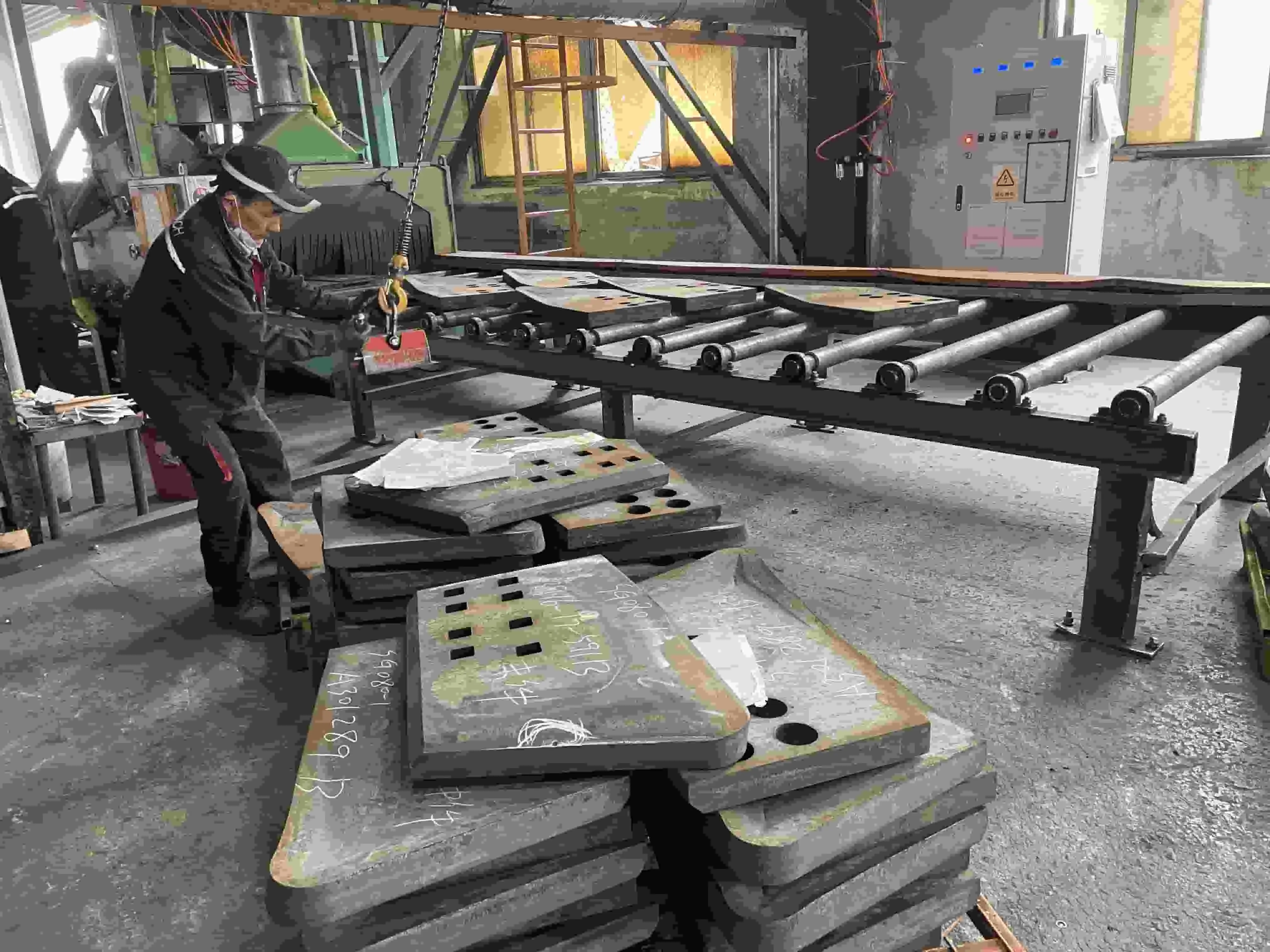

SINOBL distinguishes itself as a leading Dozer Edge-Cutting 109-3116 manufacturer through advanced manufacturing capabilities and unwavering commitment to quality excellence. Our state-of-the-art 55,944 square meter facility produces premium GET parts that meet the demanding requirements of global construction and mining operations.

Our comprehensive product range encompasses cutting edges, end bits, grader blades, and complete undercarriage components for major equipment brands. With production capacity exceeding 2,500 tons monthly for cutting edges and over 3,000 tons of inventory available for immediate dispatch, we ensure reliable supply chain support for your operational needs.

Professional technical support teams provide expert consultation throughout the procurement process and ongoing operational support. Our commitment to customer satisfaction extends beyond product delivery to include comprehensive after-sales service and technical assistance. Contact our experienced team at nancy@sunmach.com.cn to discuss your specific requirements and discover how SINOBL can optimize your equipment performance and operational efficiency as your preferred Dozer Edge-Cutting 109-3116 supplier.

References

1. "Heavy Equipment Ground Engaging Tools: Material Science and Manufacturing Processes," International Journal of Construction Equipment Engineering, 2023.

2. "Bulldozer Component Wear Analysis and Replacement Optimization Strategies," Construction Machinery Research Institute Technical Report, 2022.

3. "Comparative Performance Study of OEM vs. Aftermarket Cutting Edges in Mining Applications," Mining Equipment Quarterly, Vol. 45, 2023.

4. "Heat Treatment Processes for Enhanced Wear Resistance in Construction Equipment Components," Metallurgical Engineering Review, 2023.

5. "Total Cost of Ownership Analysis for Heavy Equipment Wear Parts," Equipment Management Professional, Annual Issue 2023.

6. "Quality Standards and Testing Protocols for Ground Engaging Tools," American Society of Construction Equipment Engineers Guidelines, 2023.