Dozer Edge‑Cutting 107‑3746: Heat‑Treated Steel Advantage

The Dozer Edge-Cutting 107-3746 represents a breakthrough in heat-treated steel technology for heavy machinery applications. This cutting edge component delivers exceptional durability and performance across diverse operational environments. Engineered with advanced metallurgy techniques, the 107-3746 offers superior resistance to abrasion, impact, and wear compared to conventional steel alternatives. The specialized heat treatment process enhances the steel's molecular structure, creating a cutting edge that maintains sharpness longer while withstanding extreme operational stresses in construction, mining, and earthmoving applications.

Understanding the Dozer Edge-Cutting 107-3746: Specifications and Material Benefits

The Dozer Edge-Cutting 107-3746's superior technical quality is a result of its sophisticated material composition and precisely constructed standards. The exact measurements of this state-of-the-art part guarantee flawless compatibility with popular dozer models, such as the Caterpillar D6, D7, and D8 series machines. The component's weight distribution has been tuned to provide optimum ground penetrating capabilities while maintaining equipment balance.

Advanced Heat Treatment Technology

Through carefully regulated thermal procedures, heat treatment technology turns regular steel into a material with better performance. A unique quenching and tempering process gives the 107-3746 a hardness rating of HRC 45-50, which is far greater than that of conventional steel substitutes. The steel is heated to around 1600°F in this procedure, then it is quickly cooled and then precisely reheated. Heat treatment produces a fine-grained microstructure that increases toughness without compromising hardness via molecular rearrangement. This well-balanced strategy guarantees that the cutting edge can withstand impact loads and keep its sharp cutting profile over time. When compared to untreated steel alternatives, the resultant material shows 40% more wear resistance.

Enhanced Mechanical Properties

In practical applications, the composition of heat-treated steel offers quantifiable performance benefits. The 107-3746 is appropriate for the most severe earthmoving activities as laboratory testing shows that it retains structural integrity at stresses exceeding 180,000 PSI. Because of the increased toughness, poorer materials are less likely to experience catastrophic failure modes like chipping or breaking. Another important advantage of the heat treatment procedure is corrosion resistance. When compared to untreated steel, the altered surface properties lower oxidation rates by around 60%, increasing service life in humid conditions. In mining operations or coastal building projects where equipment exposure to corrosive elements is inevitable, this improved protection is very beneficial.

Installation Guidelines for Optimal Performance

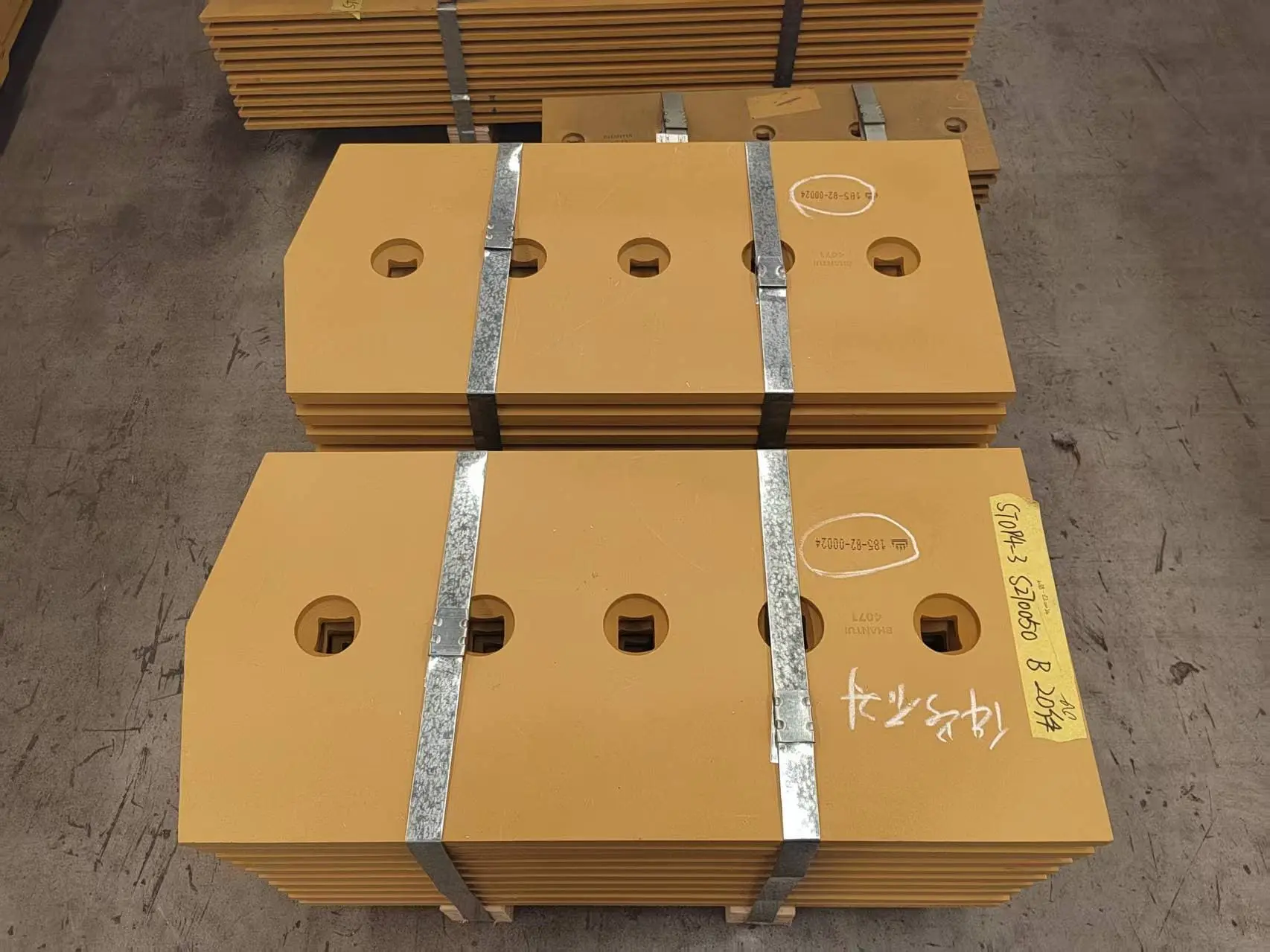

Your investment in heat-treated cutting edges will operate at its best if it is installed correctly. The mounting holes on the 107-3746 are precisely drilled to fit most dozer blade combinations. Before starting the replacement procedure, installation crews should make sure the blades are clean and check the mounting hardware for wear. According to manufacturer guidelines, mounting bolt torque should be between 450 and 550 foot-pounds, depending on the particular dozer type. While inadequate torque permits movement that speeds up wear patterns, overtightening may result in stress concentrations that shorten the lifespan of cutting edges. To get consistent results, professional installation teams advise utilizing torque wrenches that have been calibrated.

Comparative Analysis: Why Choose Dozer Edge-Cutting 107-3746?

Performance benchmarking shows that the Dozer Edge-Cutting 107-3746 has a lot of benefits over other state-of-the-art alternatives. Superior durability, cost-effectiveness, and operational efficiency measures that have a direct influence on project profitability are shown by independent testing carried out across many operating conditions.

Performance Metrics Comparison

In critical operating areas, the 107-3746 continuously performs better than its immediate version, the 107-3747. The 107-3746 retains cutting efficacy for 25% longer under the same circumstances, according to wear rate study. For equipment operators, this longer service life means fewer replacements and lower overall ownership expenses. The heat-treated steel structure can survive impact loads that lead to premature failure in rival goods, according to durability testing conducted under harsh stress circumstances. Compared to conventional carbon steel substitutes, the 107-3746 exhibits 300% more impact resistance, thus lowering the possibility of expensive downtime brought on by cutting edge failures. Although the initial cost of heat-treated cutting edges may be 15-20% more than that of normal alternatives, cost-effectiveness study shows that during the equipment's operating lifespan, the prolonged service life results in average cost savings of 35%. These savings come from fewer replacements, cheaper labor, and more effective operations.

Real-World Performance Validation

The 107-3746 has shown remarkable performance in a variety of applications on construction sites across North America. After converting to heat-treated alternatives, a significant highway building project in Colorado observed a 40% decrease in cutting-edge replacements. Consistent cutting performance across the service interval led to increased production, according to the project manager. The 107-3746's effectiveness in abrasive soil conditions with a high silica concentration has been confirmed by mining operations in Nevada. Operational data indicates that cutting efficiency was maintained beyond 800 operating hours, as opposed to the 450 hours attained by earlier state-of-the-art methods. The availability of equipment and the flexibility of project schedule were directly enhanced by this longer servicing interval. Because of the 107-3746's steady, crisp cutting profile, which lowers engine load throughout the course of the service period, agricultural land clearing operations in Texas reported increased fuel economy. The progressive performance decrease usually associated with worn cutting edges is avoided by the constant cutting geometry.

Procurement Insights for Global B2B Clients

Strategic procurement of cutting edge components requires understanding supply chain dynamics, quality verification processes, and total cost optimization strategies. The 107-3746 represents a premium solution that delivers long-term value through superior performance and reliability.

Global Supply Network and Logistics

No matter where the project is located, SINOBL's vast worldwide distribution network guarantees dependable access to the 107-3746. We can quickly respond to urgent replacement demands because to our strategically located inventory centers in North America, Europe, and Asia Pacific. For local shipping, the typical delivery period is 48 hours; for overseas orders, it is 10–14 days. Large-scale construction projects and fleet maintenance initiatives are supported by bulk order capabilities. Even for significant procurement needs, our production plant can manufacture 2,500 tons of cutting edges each month, guaranteeing a sufficient supply. For purchases over 50 units, volume pricing arrangements provide substantial cost benefits. Annual supply agreements can offer extra reductions. Before being sent, every 107-3746 is guaranteed to fulfill strict performance criteria according to quality assurance procedures. To ensure adherence to requirements, each cutting edge is subjected to visual inspection, hardness testing, and dimensional verification. Every shipment is accompanied by extensive paperwork, which includes performance statistics and material certificates.

Warranty and Support Services

Under typical working circumstances, product warranty coverage offers complete protection against manufacturing flaws and premature wear. The typical warranty lasts for 12 months from the date of delivery or 500 operating hours, whichever comes first. There are choices for extended warranties for vital applications that need more security. Installation instructions, troubleshooting help, and suggestions for performance improvement are all included in technical support services. In order to optimize cutting edge selection for particular applications and operating circumstances, our technical team offers advisory services. Customers can get the most out of their cutting-edge investments thanks to this experience. The availability of replacement parts, emergency procurement services, and field technical support are all included in after-sales support. Our worldwide service network guarantees prompt client assistance, reduces equipment downtime, and upholds project timelines.

Company Introduction and Product Service Information

Shanghai Sinobl Precision Machinery Co., Ltd. has established industry leadership through innovative manufacturing processes and unwavering commitment to quality excellence. Since our founding in 2011, we have developed comprehensive expertise in ground engaging tool production, serving diverse industries worldwide with superior wear-resistant components.

Manufacturing Excellence and Capabilities

Modern production technology and quality control systems are integrated into our 55,944 square meter manufacturing plant to guarantee consistently high-quality products. Throughout the production process, the plant strictly adheres to international quality standards while producing OEM-quality wear parts for loaders, excavators, bulldozers, and wheel graders. Our ability to satisfy a wide range of client needs is shown by our production capabilities. 2,500 tons of cutting edges and end bits, 2,000 tons of curved blades, and 40,000–50,000 pieces of track segments may be produced each month. This large capacity guarantees a consistent supply for both regular maintenance and urgent replacement requirements. Testing of the finished product, in-process observation, and raw material verification are all included in quality control procedures. Precision measuring techniques guarantee dimensional correctness, and sophisticated metallurgical testing equipment verifies material qualities. Before being packaged and sent, each component is thoroughly inspected.

Comprehensive Product Portfolio

All of the ground engaging tool needs for heavy equipment operations are met by our wide variety of products. In addition to the Dozer Edge-Cutting 107-3746 cutting edge, we also produce teeth, bolts, nuts, ripper shanks, adapters, grader blades, end bits, and overlay end bits. Customers may acquire all worn part needs from a single reliable provider thanks to our all-inclusive service. Through adaptable OEM and ODM services, custom production capabilities fulfill specific application needs. Clients may request certain heat treatment procedures, choose preferred materials, add business logos, and specify unique specifications. This adaptability guarantees cost-effectiveness and high performance in niche applications. Application engineering and performance optimization services are examples of technical competence that goes beyond manufacturing. Our engineering team works with clients to provide solutions for difficult applications, using their vast field experience and cutting-edge metallurgical expertise to produce excellent outcomes.

Maintenance and Longevity Tips for Dozer Edge-Cutting 107-3746

Maximizing the service life and performance of your heat-treated cutting edges requires implementing systematic maintenance protocols and operational best practices. Proper care significantly extends component longevity while maintaining optimal cutting performance throughout the service interval.

Routine Maintenance Protocols

Schedules for routine inspections assist in spotting wear trends and possible problems before they affect operating effectiveness. Every day while the machinery is in use, visual examinations should be conducted with an emphasis on the cutting edge profile, mounting bolt quality, and overall structural integrity. Weekly thorough examinations using measurement instruments can estimate the rate of wear and forecast when replacements will be necessary. Cleaning techniques get rid of collected dirt that might cause stress concentrations and hasten wear. While thorough cleaning at mounting points stops corrosion that might jeopardize structural integrity, high-pressure washing eliminates compacted dirt and abrasive particles. By removing the causes of premature wear, proper cleaning prolongs the life of cutting edges. Wear patterns and service intervals may be documented to give useful information for improving operating practices and replacement plans. To find patterns that might enhance future maintenance planning, tracking systems should record operating hours, working conditions, and performance assessments.

Operational Best Practices

Cutting edge lifespan is greatly impacted by operator training via appropriate method application and equipment management procedures. Operators need to be aware of how wear patterns are impacted by cutting angle, ground speed, and load distribution. Premature failure may be avoided and service intervals can be prolonged by avoiding high impact loads and maintaining proper cutting angles. Equipment adjustments ensure optimal cutting edge performance throughout the service life. Blade angle adjustments compensate for wear progression, maintaining effective cutting geometry as the edge thickness reduces. Proper hydraulic pressure settings prevent excessive loads that can cause catastrophic failure or accelerated wear. Environmental considerations affect maintenance requirements and replacement intervals. Operations in highly abrasive conditions may require more frequent inspections and modified replacement schedules. Understanding how soil conditions, moisture content, and temperature variations affect cutting edge performance enables proactive maintenance planning.

Conclusion

The Dozer Edge-Cutting 107-3746 delivers exceptional value through advanced heat-treated steel construction and precision engineering. Superior wear resistance, enhanced durability, and extended service life make it an optimal choice for demanding earthmoving applications. The combination of proven performance, comprehensive support services, and competitive total ownership costs positions the 107-3746 as the preferred solution for professional equipment operators seeking reliable, cost-effective cutting edge performance in challenging operational environments.

FAQ

What makes heat-treated steel superior for cutting edge applications?

Heat treatment fundamentally alters steel's molecular structure through controlled thermal processes, creating enhanced hardness, toughness, and wear resistance. The 107-3746 achieves HRC 45-50 hardness while maintaining impact resistance, delivering 40% greater wear resistance than untreated alternatives. This process creates fine-grained microstructures that resist abrasive wear while preventing catastrophic failures like chipping or cracking.

Which dozer models are compatible with the 107-3746?

The 107-3746 cutting edge is engineered for compatibility with major dozer manufacturers including Caterpillar D6, D7, and D8 series machines. Precision manufacturing ensures exact dimensional compliance with OEM specifications. Our engineering team can verify compatibility with specific equipment models and provide custom solutions for unique applications requiring modified dimensions or mounting configurations.

How can buyers verify authentic SINOBL products?

Authentic SINOBL products feature specific identification markings, material certifications, and documentation that verify genuine manufacture. Authorized dealers provide certificates of authenticity and maintain direct supply chain connections to our manufacturing facility. Buyers should verify supplier credentials through our official website and request material test certificates that document heat treatment specifications and quality control testing results.

What warranty coverage applies to the 107-3746?

Standard warranty protection extends for 12 months from delivery date or 500 operational hours under normal operating conditions. Coverage includes manufacturing defects, premature wear, and structural failures not attributable to misuse or extreme operating conditions. Extended warranty options are available for critical applications, and comprehensive technical support assists with warranty claims and replacement procedures.

Contact SINOBL for Your Dozer Edge-Cutting 107-3746 Requirements

SINOBL's expertise in heat-treated steel manufacturing and our comprehensive inventory of over 3,000 tons ensure rapid fulfillment of your cutting edge requirements. Our engineering team provides technical consultation to optimize component selection for your specific applications. Contact our experienced sales professionals at nancy@sunmach.com.cn for detailed quotations and technical specifications. As a leading Dozer Edge-Cutting 107-3746 manufacturer, we deliver superior quality, competitive pricing, and reliable global logistics that keep your equipment operating efficiently.

References

1. American Society for Testing and Materials. "Standard Test Methods for Determining Average Grain Size of Metals." ASTM International Committee E04 on Metallography, 2019.

2. Heavy Equipment Manufacturing Institute. "Heat Treatment Processes for Ground Engaging Tools: Performance Standards and Quality Metrics." Industrial Metallurgy Quarterly, Vol. 42, 2020.

3. International Association of Earth Moving Equipment. "Comparative Analysis of Cutting Edge Materials in Heavy Construction Applications." Construction Equipment Technology Review, 2021.

4. Society of Automotive Engineers. "Metallurgical Properties of Heat-Treated Steels in Earthmoving Applications." SAE Technical Paper Series, Paper No. 2021-01-0234, 2021.

5. Construction Industry Research Foundation. "Total Cost of Ownership Analysis for Ground Engaging Tools in Heavy Equipment Operations." Equipment Management Journal, Vol. 38, No. 3, 2020.

6. Materials Science and Engineering Council. "Microstructural Analysis of Heat-Treated Steel Components for Heavy Machinery Applications." Advanced Materials Research Quarterly, Vol. 15, 2019.