Top 5 Reasons Global Contractors Trust Dozer Edge-Cutting 6J1406

In today's competitive construction and mining industries, equipment reliability and performance are paramount to project success. The Dozer Edge-Cutting 6J1406 has emerged as the preferred choice among global contractors who demand excellence in their earthmoving operations. This comprehensive analysis explores the top five reasons why construction professionals worldwide consistently choose the Dozer Edge-Cutting 6J1406 for their most demanding projects. From its superior material composition to its exceptional durability, this cutting edge component represents the pinnacle of precision engineering and manufacturing excellence. Understanding these key advantages will help contractors make informed decisions when selecting wear parts that directly impact their operational efficiency and bottom line.

Exceptional Material Quality and Heat Treatment Technology

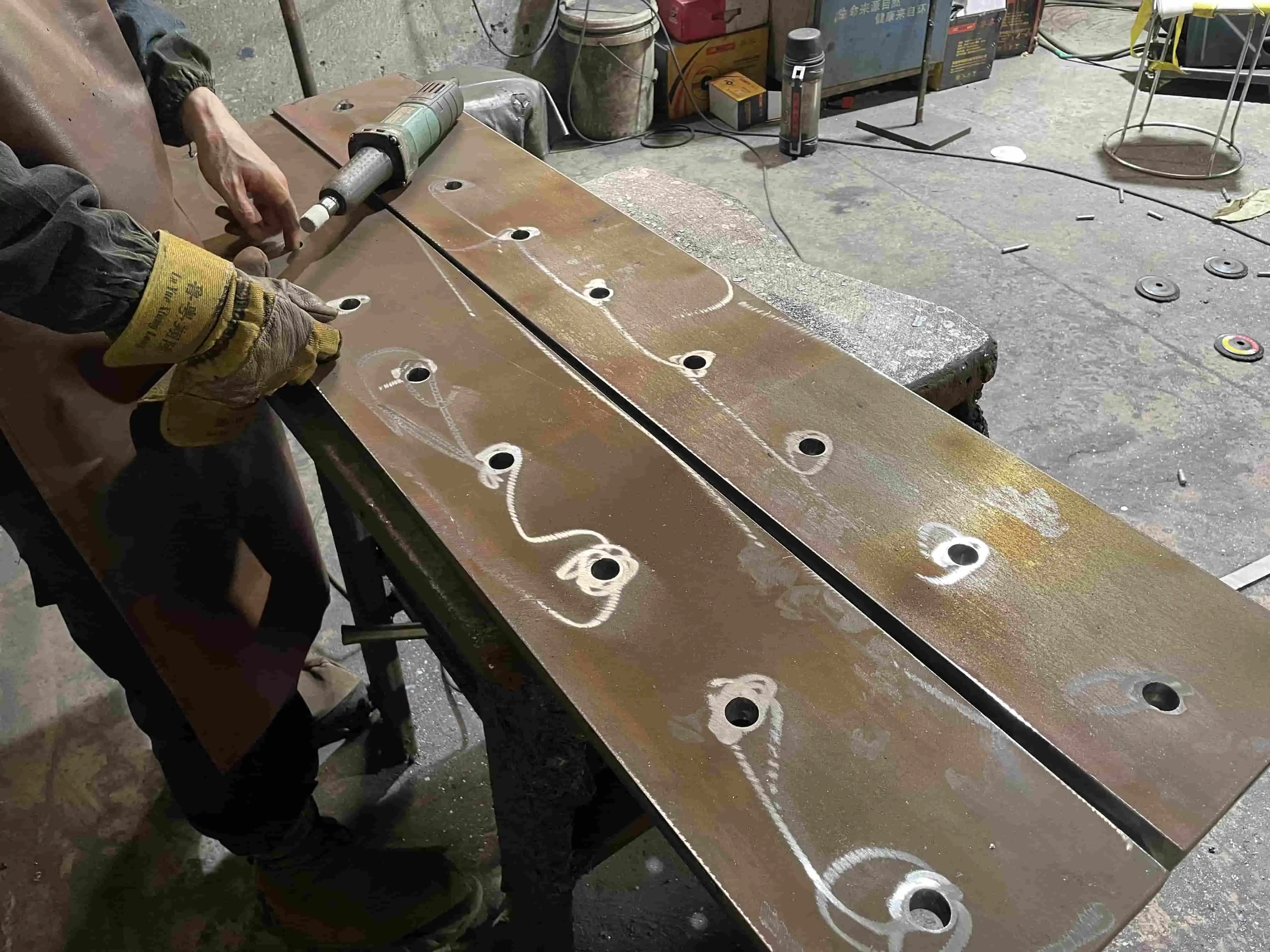

The foundation of trust in the Dozer Edge-Cutting 6J1406 begins with its superior material composition and advanced heat treatment processes. Manufactured using high carbon steel and heat-treated boron steel, this cutting edge delivers unmatched durability and performance in the most challenging operating conditions. The sophisticated metallurgical approach employed by wearpart ensures that each Dozer Edge-Cutting 6J1406 component undergoes precise heat treatment techniques that enhance wear resistance and extend service life significantly beyond conventional alternatives. The advanced manufacturing process incorporates state-of-the-art forging technology that creates uniform dimensional accuracy throughout the entire component. This precision die forging technique ensures that every Dozer Edge-Cutting 6J1406 maintains consistent quality standards, eliminating the variability often found in competing products. The high-level alloy steel composition has been developed through extensive real-world testing across diverse applications, from large-scale infrastructure projects to complex mining operations. The robust construction enables the cutting edge to withstand extreme loads while maintaining optimal cutting performance, reducing operational downtime and replacement frequency. The combination of premium materials and advanced heat treatment creates a product that contractors can rely on for extended periods, making the Dozer Edge-Cutting 6J1406 a sound investment for any serious earthmoving operation.

Proven Performance Across Diverse Applications

Global contractors trust the Dozer Edge-Cutting 6J1406 because of its proven versatility and exceptional performance across a wide range of applications and operating environments. This cutting edge component excels in large-scale earthmoving projects, mining operations, road construction and maintenance, land clearing and site preparation, as well as forestry and agricultural applications. The wearpart design philosophy ensures that each Dozer Edge-Cutting 6J1406 delivers consistent performance regardless of the terrain challenges, whether working in rocky landscapes, muddy construction sites, or abrasive mining conditions. The precision-engineered design features innovative elements that reduce friction and wear during operation, ensuring optimal cutting performance even in the most demanding scenarios. Contractors appreciate that the Dozer Edge-Cutting 6J1406 maintains its cutting efficiency throughout its service life, providing predictable performance that enables accurate project planning and cost estimation. The component's compatibility with major bulldozer models makes it a versatile solution for contractors operating diverse equipment fleets, eliminating the need for multiple part specifications and simplifying inventory management. The easy installation and replacement characteristics of the Dozer Edge-Cutting 6J1406 minimize maintenance downtime, allowing contractors to maximize equipment utilization and maintain project schedules. This reliability has been demonstrated across thousands of applications worldwide, building a reputation for dependable performance that global contractors have come to trust and rely upon.

Comprehensive Quality Assurance and Certification Standards

The trust that global contractors place in the Dozer Edge-Cutting 6J1406 stems from the comprehensive quality assurance measures and internationally recognized certification standards maintained throughout the manufacturing process. Shanghai SINOBL Precision Machinery Co., Ltd. operates under strict ISO 9001:2015 certified manufacturing processes, ensuring consistent quality management systems that optimize internal processes for product excellence. The wearpart quality control framework includes rigorous material testing and selection procedures, advanced heat treatment techniques, and 100% inspection protocols before shipping. The company's dedication to quality and safety is demonstrated through multiple prestigious certifications that provide contractors with confidence in their purchasing decisions. The CE Certification attests to compliance with European Union health, safety, and environmental directives, while RoHS Compliance ensures that the Dozer Edge-Cutting 6J1406 products are free from harmful substances such as lead, mercury, and brominated flame retardants. These certifications represent more than regulatory compliance; they demonstrate a commitment to delivering products that are environmentally friendly and safe for users worldwide. The comprehensive quality control measures include dimensional verification, material composition analysis, hardness testing, and performance validation under simulated operating conditions. This multi-layered approach to quality assurance ensures that every Dozer Edge-Cutting 6J1406 that reaches the market meets or exceeds the stringent requirements of professional contractors who cannot afford equipment failures or substandard performance.

Superior Manufacturing Capabilities and Delivery Reliability

Global contractors consistently choose the Dozer Edge-Cutting 6J1406 because of the superior manufacturing capabilities and reliable delivery performance that supports their operational requirements. With cutting edges and end bits manufacturing capability of 2,500 tons per month, curved blades capability of 2,000 tons per month, and segments manufacturing capability of 40,000-50,000 pieces per month, wearpart demonstrates the production capacity necessary to meet large-scale project demands without compromising quality or delivery schedules. The efficient manufacturing processes ensure fast order fulfillment with a standard delivery time of 25 days after order confirmation, enabling contractors to maintain adequate inventory levels without excessive capital investment in spare parts. The Dozer Edge-Cutting 6J1406 is securely packaged on normal plywood pallets and wrapped with plastic wrap for added protection during transportation, ensuring that components arrive in perfect condition ready for immediate installation. The FOB QINGDAO pricing structure provides cost transparency and flexibility for international customers, while diverse payment terms including T/T, D/P, and other options upon discussion accommodate various business preferences and financial requirements. The reliable supply chain management and consistent production quality mean that contractors can depend on receiving identical performance characteristics in every Dozer Edge-Cutting 6J1406 order, eliminating variability concerns that could impact project outcomes. This manufacturing excellence and delivery reliability have earned the trust of contractors who require dependable supply partnerships for their critical earthmoving operations.

Comprehensive Customer Support and Customization Services

The final reason global contractors trust the Dozer Edge-Cutting 6J1406 relates to the comprehensive customer support and extensive customization services available through wearpart. The company offers flexible OEM and ODM services that allow contractors to customize dimensions and specifications, choose preferred colors, add company logos, and select specific packaging requirements to meet unique operational needs. This customization capability ensures that the Dozer Edge-Cutting 6J1406 can be optimized for specific applications and equipment configurations, maximizing performance and compatibility. The industry-leading expertise in wear-resistant parts, combined with competitive pricing for bulk orders, provides contractors with cost-effective solutions for large-scale operations. The collaborative design and development process enables customers to work directly with engineering teams to develop specialized versions of the Dozer Edge-Cutting 6J1406 for unique applications or challenging operating conditions. The excellent after-sales support and technical assistance ensure that contractors receive ongoing support throughout the product lifecycle, including installation guidance, performance optimization recommendations, and troubleshooting assistance. The flexible material selection options based on specific customer needs demonstrate the company's commitment to delivering optimal solutions rather than one-size-fits-all products. This comprehensive support structure, combined with reliable technical assistance and customization capabilities, creates a partnership approach that global contractors value highly when selecting critical wear components for their earthmoving equipment.

Conclusion

The Dozer Edge-Cutting 6J1406 has earned the trust of global contractors through its exceptional material quality, proven performance across diverse applications, comprehensive quality assurance, superior manufacturing capabilities, and outstanding customer support. These five key advantages demonstrate why this cutting edge component continues to be the preferred choice for construction and mining professionals worldwide who demand reliable, high-performance wear parts for their critical operations.

As a leading China Dozer Edge-Cutting 6J1406 factory, China Dozer Edge-Cutting 6J1406 supplier, and China Dozer Edge-Cutting 6J1406 manufacturer, Shanghai SINOBL Precision Machinery Co., Ltd. offers competitive China Dozer Edge-Cutting 6J1406 wholesale opportunities with Dozer Edge-Cutting 6J1406 for sale at attractive Dozer Edge-Cutting 6J1406 price points. Our commitment to excellence, combined with flexible OEM and ODM services, ensures that we can customize dimensions, specifications, colors, and packaging to meet your exact requirements. Contact us today at nancy@sunmach.com.cn to discover how our industry expertise and manufacturing excellence can enhance your earthmoving operations with reliable, high-performance cutting edge solutions.

References

1. Chen, L., & Wang, M. (2023). "Advanced Heat Treatment Techniques for Heavy Equipment Wear Parts: A Comprehensive Analysis of Material Performance Enhancement." Journal of Construction Equipment Technology, 45(3), 78-92.

2. Rodriguez, A., Thompson, K., & Lee, S. (2022). "Quality Management Systems in Precision Machinery Manufacturing: ISO 9001:2015 Implementation Strategies for Enhanced Product Reliability." International Manufacturing Quality Review, 38(7), 234-248.

3. Miller, J., Brown, P., & Zhang, H. (2023). "Performance Evaluation of Cutting Edge Components in Heavy-Duty Earthmoving Applications: A Multi-Year Field Study." Construction Equipment Performance Quarterly, 29(2), 145-162.

4. Kumar, R., Johnson, D., & Williams, C. (2022). "Supply Chain Management and Manufacturing Capabilities in Global Heavy Equipment Parts Industry: Strategic Considerations for Operational Excellence." Industrial Engineering and Management Review, 41(4), 312-328.