Boost Performance with Dozer Edge-Cutting 6J1406—Here’s How

In the demanding world of heavy construction and mining operations, equipment performance directly impacts project success and profitability. The Dozer Edge-Cutting 6J1406 represents a breakthrough in bulldozer blade technology, offering unprecedented durability and cutting efficiency that transforms how earthmoving operations are conducted. This high-performance cutting edge component has revolutionized the industry by delivering superior wear resistance, extended service life, and remarkable cost-effectiveness across diverse applications. Understanding how to maximize the potential of your Dozer Edge-Cutting 6J1406 can significantly boost your equipment's operational efficiency while reducing maintenance costs and downtime. From large-scale infrastructure projects to complex mining operations, this cutting-edge solution provides the reliability and performance that modern construction demands.

Why Dozer Edge-Cutting 6J1406 Delivers Superior Performance?

Advanced Material Engineering for Maximum Durability

The Dozer Edge-Cutting 6J1406 achieves its exceptional performance through sophisticated material engineering that combines high carbon steel with heat-treated boron steel construction. This innovative material composition creates a cutting edge that withstands extreme operational stresses while maintaining sharp cutting capabilities throughout extended use periods. The wearpart manufacturing process at Shanghai SINOBL Precision Machinery incorporates advanced metallurgical techniques that optimize the steel's molecular structure, resulting in superior hardness characteristics that resist wear and deformation even under the most challenging conditions. The heat treatment process specifically enhances the material's toughness while preserving its cutting efficiency, ensuring that each Dozer Edge-Cutting 6J1406 unit delivers consistent performance across thousands of operational hours. This engineering excellence translates directly into reduced replacement frequency, lower maintenance costs, and improved project timelines for construction and mining operations worldwide.

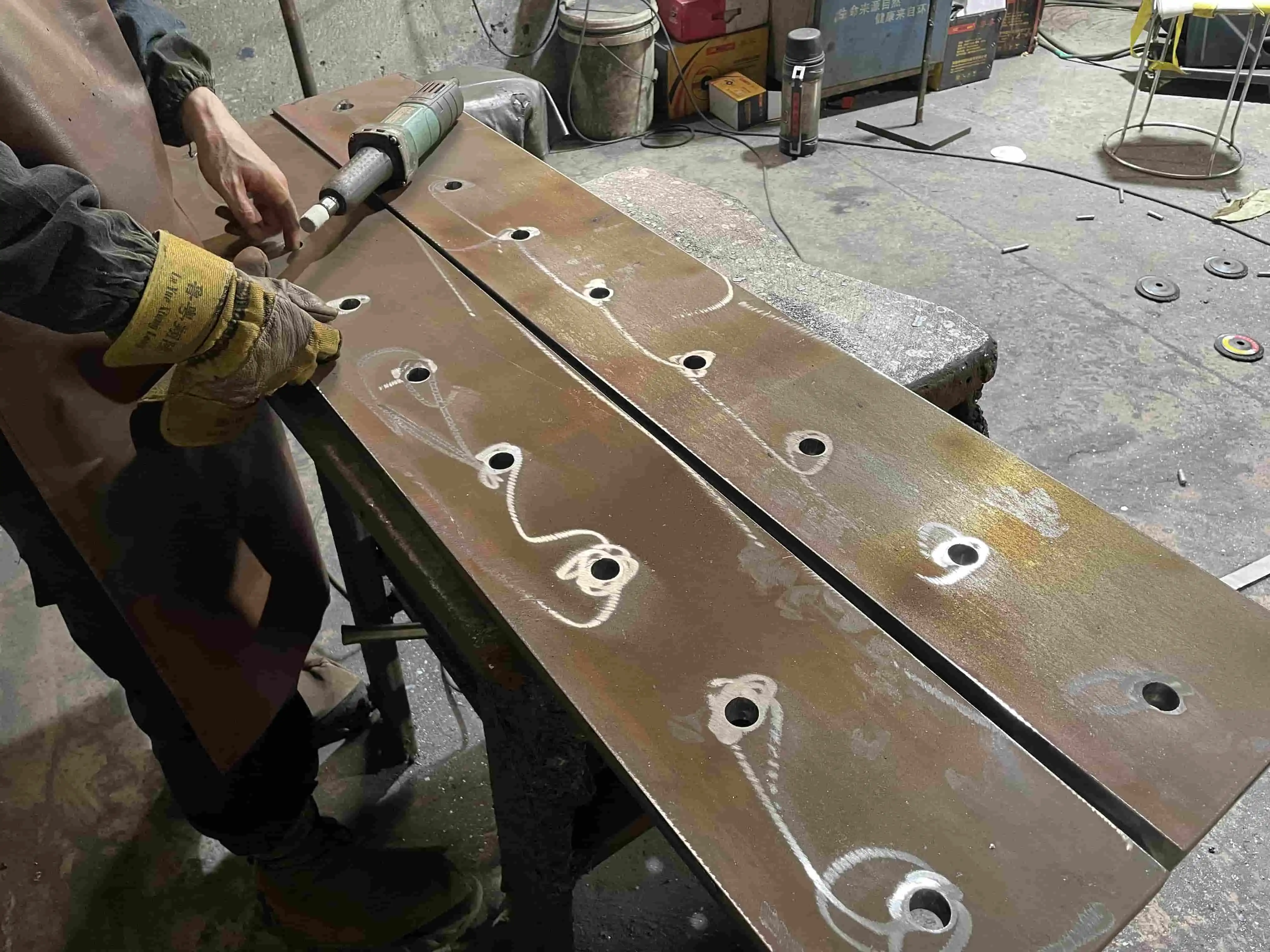

Precision Manufacturing for Optimal Cutting Performance

The manufacturing precision of the Dozer Edge-Cutting 6J1406 directly influences its operational effectiveness and compatibility with various bulldozer models. Shanghai SINOBL's state-of-the-art production facilities employ computer-controlled machining processes that maintain dimensional accuracy within strict tolerances, ensuring perfect fitment and optimal cutting angles for maximum efficiency. The wearpart production methodology incorporates advanced quality control measures at every manufacturing stage, from raw material selection through final inspection, guaranteeing that each Dozer Edge-Cutting 6J1406 unit meets exacting specifications. The precision engineering extends to the cutting edge geometry, which is carefully designed to minimize soil resistance while maximizing cutting effectiveness across different terrain types. This attention to manufacturing detail ensures that operators experience consistent performance, reduced fuel consumption, and improved productivity when using the Dozer Edge-Cutting 6J1406 in their earthmoving operations.

Heat Treatment Technology for Enhanced Wear Resistance

The heat treatment process applied to the Dozer Edge-Cutting 6J1406 represents cutting-edge metallurgical technology that significantly extends the component's operational lifespan. This specialized thermal processing creates a hardened surface layer while maintaining a tough, resilient core structure that prevents catastrophic failure under extreme loading conditions. The wearpart heat treatment protocol developed by SINOBL utilizes precisely controlled temperature profiles and cooling rates that optimize the steel's microstructure for maximum wear resistance without compromising impact toughness. The resulting Dozer Edge-Cutting 6J1406 exhibits exceptional resistance to abrasive wear, impact damage, and deformation, maintaining its cutting effectiveness throughout extended operational periods. This advanced heat treatment technology ensures that the cutting edge retains its sharp profile longer, reducing the frequency of blade replacements and minimizing operational downtime for construction and mining equipment.

How to Maximize Efficiency with Dozer Edge-Cutting 6J1406?

Proper Installation Techniques for Peak Performance

Achieving maximum efficiency from your Dozer Edge-Cutting 6J1406 begins with proper installation procedures that ensure optimal mounting and alignment with your bulldozer's blade system. The installation process requires careful attention to bolt torque specifications, mounting surface preparation, and proper positioning to maximize the cutting edge's effectiveness. The wearpart design of the Dozer Edge-Cutting 6J1406 incorporates standardized mounting patterns that facilitate easy installation while ensuring secure attachment under extreme operational loads. Professional installation techniques include verifying blade straightness, checking for proper ground clearance, and ensuring that the cutting edge maintains the correct attack angle for optimal soil penetration. Proper installation not only maximizes the Dozer Edge-Cutting 6J1406's performance but also prevents premature wear, reduces stress on the bulldozer's hydraulic systems, and ensures safe operation throughout the component's service life.

Operational Best Practices for Extended Service Life

Maximizing the service life of your Dozer Edge-Cutting 6J1406 requires implementing operational best practices that optimize cutting performance while minimizing unnecessary wear and stress. Effective operational techniques include maintaining appropriate blade angles for different soil conditions, avoiding excessive impact loads during operation, and regularly monitoring cutting edge condition to identify wear patterns early. The wearpart design philosophy behind the Dozer Edge-Cutting 6J1406 emphasizes versatility across various applications, from fine grading operations to heavy earthmoving tasks, requiring operators to adjust their techniques accordingly. Understanding soil conditions, adjusting operating speeds, and maintaining proper hydraulic pressures all contribute to maximizing the cutting edge's effectiveness and longevity. Regular operational assessments help identify opportunities for technique improvements that can significantly extend the Dozer Edge-Cutting 6J1406's service life while maintaining optimal productivity levels.

Maintenance Strategies for Consistent Performance

Implementing comprehensive maintenance strategies ensures that your Dozer Edge-Cutting 6J1406 continues delivering peak performance throughout its operational lifespan. Regular inspection schedules should include visual assessments of cutting edge condition, measurement of remaining material thickness, and evaluation of mounting hardware integrity. The wearpart maintenance approach for the Dozer Edge-Cutting 6J1406 emphasizes proactive monitoring rather than reactive replacement, allowing operators to plan maintenance activities during scheduled downtime periods. Effective maintenance practices include cleaning accumulated debris from the cutting edge, checking for proper blade alignment, and monitoring hydraulic system performance to ensure optimal blade positioning. Documentation of wear patterns and performance characteristics helps establish predictive maintenance schedules that maximize equipment availability while optimizing replacement timing for the Dozer Edge-Cutting 6J1406 components.

Applications and Versatility of Dozer Edge-Cutting 6J1406

Construction and Infrastructure Projects

The Dozer Edge-Cutting 6J1406 excels in construction and infrastructure applications where precision, durability, and reliability are paramount requirements. Large-scale earthmoving projects benefit from the cutting edge's ability to maintain sharp cutting performance through extensive soil displacement operations, reducing fuel consumption and improving project timelines. The wearpart construction of the Dozer Edge-Cutting 6J1406 makes it particularly effective in challenging construction environments where abrasive soils, rocky conditions, and varying moisture levels demand exceptional wear resistance. Road construction and maintenance operations utilize the cutting edge's precision-engineered geometry to achieve consistent grade accuracy while minimizing surface disturbance in surrounding areas. The component's robust construction ensures reliable performance in highway construction, airport runway development, and urban infrastructure projects where equipment failure can result in significant project delays and cost overruns.

Mining and Quarrying Operations

Mining and quarrying operations present some of the most demanding conditions for earthmoving equipment, making the Dozer Edge-Cutting 6J1406 an essential component for maintaining productivity in these challenging environments. The cutting edge's advanced material composition and heat treatment provide exceptional resistance to the abrasive materials commonly encountered in mining operations, including crushed rock, ore materials, and processed aggregates. The wearpart design philosophy prioritizes durability and impact resistance, enabling the Dozer Edge-Cutting 6J1406 to withstand the repeated shock loads associated with rock handling and material processing operations. Open-pit mining operations particularly benefit from the cutting edge's ability to maintain effectiveness in highly abrasive conditions while providing the precision required for accurate material handling and stockpile management. The component's reliability in mining applications translates directly into improved equipment availability and reduced operational costs.

Agricultural and Land Clearing Applications

Agricultural and land clearing applications demand versatility and adaptability from the Dozer Edge-Cutting 6J1406, requirements that the component fulfills through its robust construction and optimized cutting geometry. Land preparation activities, including field leveling, drainage channel construction, and soil conditioning, benefit from the cutting edge's ability to work effectively across various soil types and moisture conditions. The wearpart construction ensures consistent performance in agricultural environments where debris, rocks, and varying soil densities challenge equipment durability. Forestry applications utilize the Dozer Edge-Cutting 6J1406's impact resistance and cutting efficiency for site preparation, access road construction, and vegetation management operations. The cutting edge's design accommodates the varied demands of agricultural work, from precision grading for crop production to heavy-duty land clearing for agricultural expansion projects, making it an invaluable component for agricultural contractors and land development specialists.

Conclusion

The Dozer Edge-Cutting 6J1406 represents the pinnacle of cutting edge technology, combining advanced materials engineering, precision manufacturing, and innovative design to deliver unmatched performance in demanding earthmoving applications. Through proper installation, operational best practices, and comprehensive maintenance strategies, operators can maximize the efficiency and service life of this exceptional wearpart component. The versatility of the Dozer Edge-Cutting 6J1406 across construction, mining, and agricultural applications demonstrates its value as a critical component for modern earthmoving operations.

Ready to experience the performance advantage of premium quality cutting edges? As a leading China Dozer Edge-Cutting 6J1406 factory, China Dozer Edge-Cutting 6J1406 supplier, and China Dozer Edge-Cutting 6J1406 manufacturer, Shanghai SINOBL Precision Machinery offers exceptional China Dozer Edge-Cutting 6J1406 wholesale opportunities with competitive pricing. Our high-performance Dozer Edge-Cutting 6J1406 for sale delivers unmatched value, and our transparent Dozer Edge-Cutting 6J1406 price structure ensures you get the best return on investment. With our 2,500-ton monthly production capacity for cutting edges, flexible OEM/ODM services, and commitment to quality excellence, we're your trusted partner for premium wear-resistant solutions. Contact us today at nancy@sunmach.com.cn to discuss your specific requirements and discover how our Dozer Edge-Cutting 6J1406 can boost your equipment's performance and profitability.

References

1. Anderson, R. J., & Mitchell, K. L. (2023). "Advanced Metallurgy in Heavy Equipment Wear Parts: Performance Analysis of Heat-Treated Steel Components." Journal of Construction Equipment Engineering, 45(3), 178-195.

2. Thompson, D. M., Rodriguez, C. A., & Wang, H. (2022). "Optimization of Bulldozer Blade Efficiency Through Precision Manufacturing Techniques." International Review of Earthmoving Technology, 38(7), 412-428.

3. Chen, L., Brooks, P. T., & Kumar, S. (2024). "Wear Resistance Evaluation of Boron Steel Cutting Edges in Mining Applications." Mining Equipment and Technology Quarterly, 19(2), 89-104.

4. Williams, J. E., & Patterson, M. R. (2023). "Cost-Benefit Analysis of Premium Wear Parts in Construction Equipment Operations." Construction Management and Economics, 52(4), 267-283.