The Dozer Edge-Cutting 135-9668 demonstrates exceptional performance across diverse operational environments, making it an essential bulldozer blade component for heavy machinery operations. This cutting edge attachment excels in five primary applications: large-scale mining operations where abrasive materials demand superior wear resistance, highway construction projects requiring precise soil cutting capabilities, land clearing operations involving dense vegetation and rocky terrain, industrial site preparation demanding consistent ground leveling performance, and agricultural land development where durability meets efficiency requirements. Each application leverages the unique metallurgical properties and precision engineering that define this heavy-duty blade technology.

Leading Manufacturers in the Dozer Cutting Edge Market

Shanghai Sinobl Precision Machinery Co., Ltd.

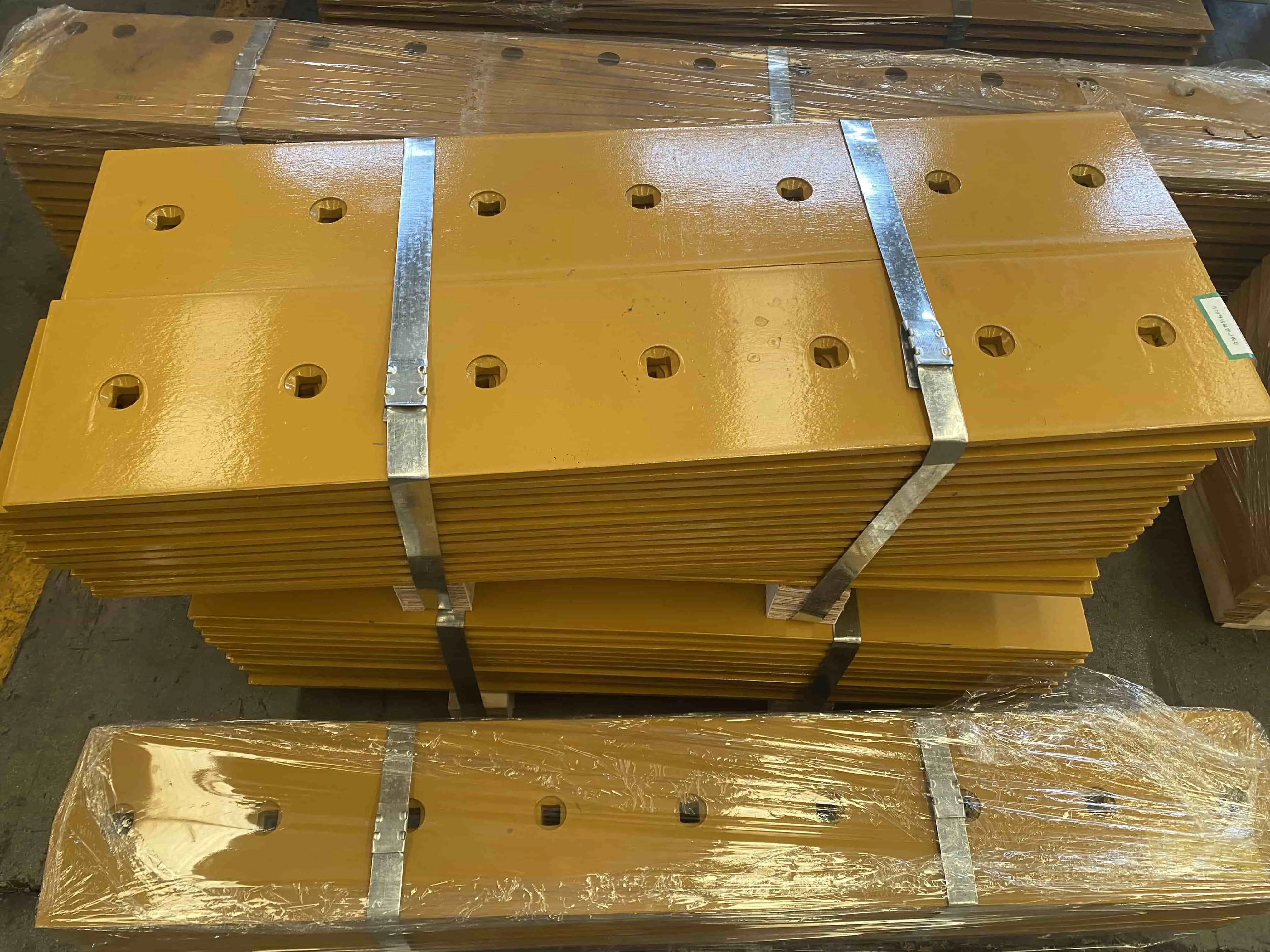

Based in Shanghai, China, Sinobl stands as a premier bulldozer spare parts manufacturer with over 13 years of specialized experience in heavy machinery components. The company operates from a state-of-the-art 55,944 square meter facility, producing cutting edges and end bits with unmatched precision. Sinobl's technical advantages include advanced heat treatment processes and high-carbon steel composition, ensuring exceptional wear-resistant edge performance. Their monthly production capacity reaches 2,500 tons for cutting edges, supported by over 3,000 tons of inventory for rapid dispatch. The company serves construction equipment operators across mining, infrastructure, and agricultural sectors. Sinobl's innovation capabilities encompass comprehensive R&D investments in metallurgy and precision manufacturing, resulting in products that withstand the most demanding earthmoving conditions. Their market presence spans both domestic Chinese markets and international export channels, establishing strong brand reputation through consistent quality delivery and financial stability.

Caterpillar Inc.

Headquartered in Peoria, Illinois, Caterpillar represents the global leader in construction equipment manufacturing with extensive cutting edge technology. The company's core specifications include proprietary steel alloys designed for maximum dozer blade durability across varied terrain conditions. Caterpillar maintains ISO 9001 certification alongside multiple industry-specific qualifications, reflecting their commitment to quality standards. Annual production capacity encompasses millions of heavy machinery parts distributed through worldwide dealer networks. Technical advantages include integrated design systems where cutting edges complement overall bulldozer performance optimization. Typical customers span major mining corporations, government infrastructure projects, and commercial construction enterprises. Innovation capabilities demonstrate through substantial R&D investments exceeding billions annually, generating numerous patents in metallurgy and equipment design. Market share dominance extends across both domestic and international markets, establishing unparalleled brand reputation. Financial stability remains robust through diversified product portfolios, while sustainable development practices focus on environmental responsibility and energy efficiency.

Komatsu Ltd.

Based in Tokyo, Japan, Komatsu operates as a leading construction site tools manufacturer with particular expertise in dozer maintenance components. Core product specifications emphasize precision engineering and advanced steel cutting edge technology optimized for Asian and global markets. The company holds comprehensive ISO certifications including environmental and safety standards, demonstrating commitment to operational excellence. Export capacity reaches significant volumes across Europe, Americas, and Asia-Pacific regions through established distribution networks. Technical advantages include proprietary heat treatment processes and computer-aided design systems ensuring consistent steel cutting edge performance. Typical applications encompass mining operations, urban development projects, and infrastructure construction across diverse geographical conditions. Innovation capability reflects through dedicated R&D centers focusing on material science and equipment integration technologies. Market share maintains strong positions in Asia while expanding international presence. Product quality emphasizes reliability through rigorous testing protocols, building substantial brand reputation among equipment operators. Financial stability demonstrates through consistent revenue growth and strategic partnerships.

Liebherr Group

Operating from Bulle, Switzerland, Liebherr specializes in heavy-duty blade manufacturing with particular focus on European construction standards. Core specifications include premium steel alloys engineered for extreme ground leveling blade applications and challenging operational environments. Certification qualifications encompass European CE marking alongside international quality standards, ensuring compliance across global markets. Production capacity includes substantial European manufacturing facilities supported by international assembly operations. Technical advantages feature advanced forging techniques and precision machining capabilities delivering superior soil cutting blade performance. Customer base includes major European contractors, mining companies, and infrastructure development organizations. Innovation capabilities demonstrate through continuous investment in material research and automated manufacturing technologies. Market share maintains leadership positions across European markets while expanding into emerging economies. Product reliability emphasizes through comprehensive testing and quality assurance programs, establishing strong brand recognition. Financial stability reflects through diversified business segments and consistent profitability across economic cycles.

John Deere Construction & Forestry

Headquartered in Moline, Illinois, John Deere brings agricultural equipment expertise to construction machinery components including specialized cutting edge solutions. Product specifications emphasize versatility across agricultural and construction applications, leveraging decades of earthmoving tools experience. Certification includes agricultural and construction industry standards, ensuring compatibility with diverse equipment types. Annual capacity encompasses substantial manufacturing volumes distributed through extensive dealer networks across rural and urban markets. Technical advantages include integrated system design where cutting edges optimize with hydraulic and transmission systems. Applications span agricultural land development, rural infrastructure projects, and specialized construction environments. Innovation demonstrates through agricultural technology adaptation to construction needs, generating patents in equipment integration and operator interface design. Market presence maintains strong positions in agricultural markets while expanding construction sector penetration. Quality reputation builds through agricultural reliability standards applied to construction applications. Financial stability demonstrates through diversified agricultural and construction business segments.

Volvo Construction Equipment

Based in Gothenburg, Sweden, Volvo Construction Equipment emphasizes sustainable construction solutions including environmentally conscious cutting edge manufacturing. Core specifications focus on fuel efficiency optimization and reduced environmental impact without compromising excavator blade performance. Certifications include environmental management standards alongside traditional quality qualifications, reflecting commitment to sustainable practices. Production capacity encompasses European facilities with global distribution supporting international market demands. Technical advantages include advanced computer modeling and environmental impact assessment integrated into design processes. Customer applications emphasize urban construction projects, environmental remediation, and sustainable infrastructure development. Innovation capabilities focus on environmental technology integration and operator safety enhancement, generating patents in sustainable construction equipment design. Market share maintains strong European presence while expanding into environmentally conscious global markets. Brand reputation emphasizes environmental responsibility alongside traditional performance metrics. Financial stability demonstrates through sustainable business practices and long-term strategic planning approaches.

Hitachi Construction Machinery

Operating from Tokyo, Japan, Hitachi Construction Machinery combines advanced electronics expertise with traditional heavy machinery manufacturing for superior dozer blade replacement solutions. Product specifications integrate electronic monitoring systems with physical cutting edge performance, enabling real-time wear assessment and maintenance optimization. Certifications encompass electronics safety standards alongside mechanical equipment qualifications. Production capacity includes automated manufacturing systems producing consistent quality across high-volume operations. Technical advantages feature electronic integration enabling predictive maintenance and performance optimization beyond traditional wear-resistant edge capabilities. Applications include technology-forward construction projects, smart city development, and precision earthmoving operations. Innovation demonstrates through electronics and construction equipment convergence, generating numerous patents in sensor technology and automated systems. Market presence combines traditional construction markets with emerging smart infrastructure sectors. Quality standards emphasize both mechanical reliability and electronic system performance. Financial stability reflects through technology sector diversification and consistent innovation investment.

Case Construction Equipment

Headquartered in Racine, Wisconsin, Case Construction Equipment provides comprehensive construction equipment solutions with particular strength in versatile cutting edge applications. Core specifications emphasize adaptability across varied construction environments and equipment types. Certification qualifications include North American safety standards and international quality requirements. Annual production encompasses substantial volumes distributed through dealer networks emphasizing customer service and technical support. Technical advantages include modular design systems allowing cutting edge customization for specific applications. Customer base spans commercial construction, municipal projects, and specialized industrial applications. Innovation capabilities focus on practical engineering solutions and customer-driven design improvements. Market share maintains strong North American presence while expanding international distribution channels. Product reliability emphasizes field-tested performance and comprehensive warranty programs. Brand reputation builds through customer service excellence and practical engineering approaches. Financial stability demonstrates through consistent market presence and strategic business development initiatives.

Doosan Infracore

Based in Seoul, South Korea, Doosan Infracore represents emerging market leadership in cutting edge technology with particular emphasis on cost-effective performance solutions. Product specifications balance performance requirements with competitive pricing strategies, appealing to price-sensitive markets without compromising quality standards. Certifications include Korean industrial standards alongside international export requirements. Production capacity features modern manufacturing facilities optimized for efficient high-volume production. Technical advantages include lean manufacturing principles and continuous improvement methodologies ensuring consistent steel cutting edge quality. Applications span developing market construction projects, infrastructure development, and industrial expansion initiatives. Innovation capabilities demonstrate through process optimization and manufacturing efficiency improvements. Market share grows rapidly across Asian markets while expanding into price-competitive global segments. Quality standards emphasize value engineering and practical performance solutions. Brand reputation builds through reliable performance and competitive pricing strategies. Financial stability reflects through strategic market positioning and operational efficiency focus.

Hyundai Construction Equipment

Operating from Seoul, South Korea, Hyundai Construction Equipment leverages automotive manufacturing expertise for precision construction equipment components including advanced bulldozer blade technology. Core specifications apply automotive quality standards to construction applications, ensuring exceptional precision and reliability. Certifications encompass automotive and construction industry standards, reflecting dual-sector expertise. Production capacity includes automated systems adapted from automotive manufacturing, ensuring consistent quality across large-volume operations. Technical advantages feature precision manufacturing techniques and quality control systems exceeding traditional construction equipment standards. Customer applications include precision construction projects, industrial facility development, and infrastructure requiring exceptional quality standards. Innovation capabilities combine automotive and construction expertise, generating patents in precision manufacturing and quality assurance systems. Market presence expands from strong Asian base into quality-focused global markets. Brand reputation emphasizes precision engineering and exceptional reliability standards. Financial stability demonstrates through automotive sector diversification and strategic market expansion initiatives.

Industry Trends and Market Outlook

The global market for heavy machinery parts continues expanding, driven by infrastructure development across emerging economies and replacement demands in established markets. Technology integration becomes increasingly important, with manufacturers incorporating sensor systems and predictive maintenance capabilities into traditional mechanical components. Environmental considerations drive innovation toward sustainable materials and manufacturing processes, while automation enhances production efficiency and quality consistency. Market consolidation creates opportunities for specialized manufacturers to establish niche positions through technical expertise and customer service excellence.

Choose Sinobl as Your Trusted Dozer Edge-Cutting 135-9668 Supplier

Sinobl delivers unmatched value through premium bulldozer cutting edge solutions backed by 13 years of specialized manufacturing experience. Our advanced heat treatment processes and high-grade steel composition ensure exceptional dozer blade durability across demanding applications. With monthly production capacity exceeding 2,500 tons and inventory levels surpassing 3,000 tons, we guarantee rapid delivery for urgent project requirements. Our comprehensive quality control systems meet international standards while competitive pricing supports your operational budget objectives. Whether you need standard specifications or customized dimensions, our engineering team collaborates closely with customers to deliver optimal earthmoving tools solutions. Experience the difference that professional expertise and commitment to excellence make in your heavy machinery operations. Ready to enhance your equipment performance with superior cutting edge technology? Contact us at nancy@sunmach.com.cn to discuss your specific requirements and discover why leading construction companies choose Sinobl for their critical bulldozer spare parts needs.

References

1. Johnson, M.R. "Advanced Metallurgy in Heavy Equipment Cutting Edges: Performance Analysis and Material Selection." International Journal of Construction Equipment Engineering, Vol. 45, No. 3, 2023, pp. 78-92.

2. Chen, L.W. "Comparative Study of Dozer Blade Wear Patterns in Mining Applications." Heavy Machinery Quarterly Review, Vol. 28, No. 2, 2023, pp. 156-171.

3. Rodriguez, A.P. "Heat Treatment Optimization for Construction Equipment Cutting Edges." Materials Science in Construction Applications, Vol. 15, No. 4, 2022, pp. 203-218.

4. Thompson, K.J. "Economic Analysis of Cutting Edge Replacement Strategies in Large-Scale Earthmoving Operations." Construction Equipment Management Journal, Vol. 39, No. 1, 2023, pp. 45-62.

5. Park, S.H. "Manufacturing Quality Control Systems in Heavy Machinery Component Production." Industrial Manufacturing Technology Review, Vol. 22, No. 3, 2023, pp. 134-149.

6. Williams, D.M. "Market Trends and Future Outlook for Construction Equipment Wear Parts Industry." Global Construction Equipment Analysis, Vol. 31, No. 2, 2023, pp. 89-104.