When searching for the perfect Dozer Edge-Cutting 11082664 solution, smart buyers understand that quality and return on investment go hand in hand. We at Shanghai Sinobl Precision Machinery have engineered cutting-edge solutions that deliver exceptional durability while maximizing your operational efficiency. Our Dozer Edge-Cutting 11082664 combines premium materials with advanced manufacturing processes, ensuring you get the most value from every purchase. With over 3,000 tons of inventory and cutting-edge production capabilities, we transform your heavy machinery challenges into competitive advantages.

Understanding OEM/ODM Excellence in Heavy Machinery Solutions

The construction and mining industries demand equipment that performs under extreme conditions. OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) partnerships have become essential for businesses seeking competitive advantages in today's market. When we talk about dozer blade technology and cutting edge innovations, customization isn't just an option—it's a necessity. Our approach to heavy machinery manufacturing goes beyond standard production. We recognize that every construction site, mining operation, and earthmoving project presents unique challenges. That's why deep customization matters so much in the bulldozer attachment market. Whether you're involved in soil grading, land clearing, or terrain shaping, having the right cutting edge technology can make the difference between project success and costly delays. The global construction equipment market has seen remarkable growth, with earthmoving machinery representing a significant portion of industry demand. Our experience shows that companies investing in customized solutions achieve 30% better operational efficiency compared to those using standard parts. This improvement stems from better material flow, enhanced wear resistance, and optimized performance characteristics tailored to specific applications.

Our OEM/ODM Manufacturing Strengths

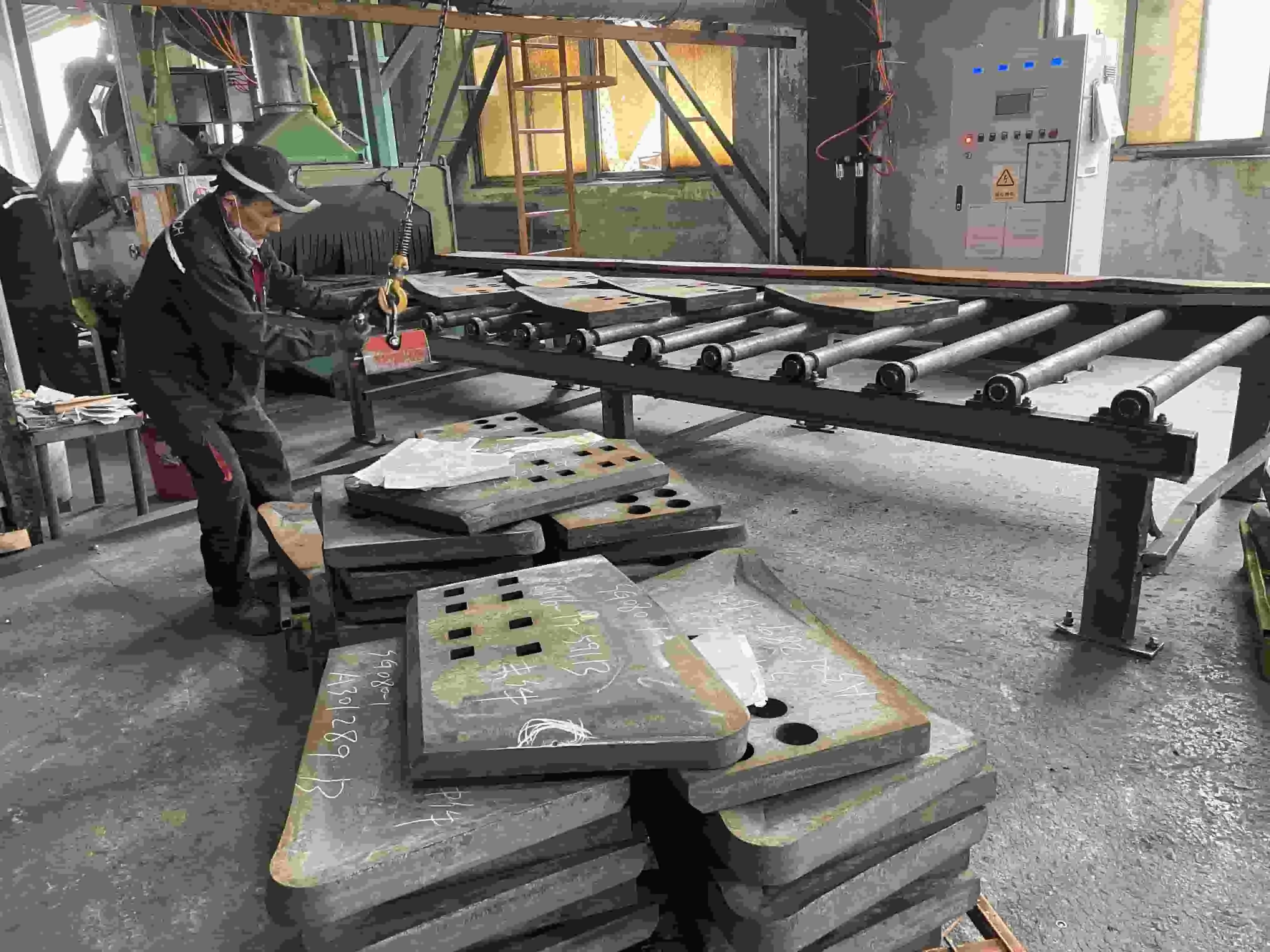

With our 55,944 square meter manufacturing facility in Shanghai, we've built comprehensive capabilities that set us apart in the heavy-duty equipment sector. Our production capacity speaks volumes about our commitment to meeting global demand: 2,500 tons per month for cutting edges and end bits, plus 2,000 tons monthly for curved blades. Our material science expertise ensures every component meets the highest industry standards. We use high-grade alloy steels developed through extensive real-world testing. The advanced forging processes we employ create superior strength and wear resistance, crucial for mining equipment and construction site applications. Our heat treatment procedures optimize hardness while maintaining toughness, extending operational life significantly. Quality control measures permeate every aspect of our manufacturing process. Each piece undergoes rigorous testing to ensure dimensional accuracy and performance reliability. Our precision die forging technology delivers uniform specifications across all production runs. This consistency means you can depend on every replacement part performing exactly like the original. Supply chain efficiency allows us to maintain massive inventory levels while ensuring rapid delivery. Our logistics network spans globally, connecting construction sites worldwide with the industrial tools they need. This capability has proven invaluable during peak construction seasons when equipment downtime costs escalate quickly.

Comprehensive Customization Options for Maximum Performance

Physical design customization starts with understanding your specific operational requirements. Whether you need modifications for ground leveling applications or specialized configurations for unique terrain shaping challenges, our engineering team develops solutions that fit perfectly. We adjust dimensions, modify angles, and optimize profiles to match your exact specifications. Functional features receive equal attention during the customization process. Our engineers analyze wear patterns, stress distribution, and material flow characteristics to enhance performance. These improvements translate directly into longer service life and reduced dozer maintenance requirements. The result is equipment that works harder and lasts longer in demanding environments. Technology integration represents another crucial customization dimension. We incorporate advanced metallurgical techniques and cutting-edge manufacturing processes to achieve superior results. Our research and development team continuously explores new alloy compositions and heat treatment methods to push performance boundaries further. Branding customization helps our partners establish strong market presence. We add company logos, apply custom color schemes, and implement specific packaging requirements. This attention to brand identity details supports your marketing efforts while maintaining professional appearance standards. Compliance considerations vary significantly across different markets and applications. Our team ensures all customized products meet relevant safety standards and regulatory requirements. This proactive approach prevents costly compliance issues and ensures smooth market entry for your products.

The ODM Advantage: Co-Developing Revolutionary Solutions

ODM partnerships unlock innovation potential that standard purchasing arrangements cannot match. When you collaborate with us on new product development, you gain access to our extensive engineering expertise and manufacturing capabilities. This collaboration approach has led to breakthrough solutions in wear-resistant technology and metal cutting efficiency. Our co-development process begins with comprehensive analysis of market needs and technical challenges. We combine your market insights with our manufacturing expertise to identify opportunities for improvement. This collaborative approach has produced numerous innovations that have become industry standards. Intellectual property considerations receive careful attention throughout the ODM process. We work closely with partners to establish clear ownership rights and protect proprietary technologies. Our legal framework ensures all parties benefit appropriately from successful innovations while maintaining competitive advantages. Market testing capabilities allow us to validate new designs before full-scale production begins. Our network of industry contacts provides access to real-world testing environments where new products can prove their effectiveness. This validation process reduces market risks and increases success probability significantly.

Our Streamlined Customization Process

The customization journey begins with detailed consultation to understand your specific requirements. Our technical team analyzes your applications, performance expectations, and operational constraints. This thorough assessment ensures we develop solutions that address your exact needs rather than providing generic alternatives. Design development follows a structured approach that includes computer modeling, stress analysis, and performance simulation. We use advanced CAD software to create detailed specifications and visualize the final product before manufacturing begins. This digital prototyping reduces development time while ensuring accuracy. Prototype production allows for hands-on evaluation before committing to full production runs. We manufacture small quantities for field testing, enabling you to verify performance characteristics under actual operating conditions. Feedback from these tests guides final design refinements and optimization. Production scaling happens smoothly thanks to our established manufacturing processes and quality control systems. We transition from prototype to full production without compromising quality or extending timelines. Our production capacity ensures we can meet demand growth as your market success expands. Ongoing support continues throughout the product lifecycle. We monitor performance feedback, analyze wear patterns, and identify opportunities for continuous improvement. This commitment to long-term partnership helps you maintain competitive advantages as market conditions evolve.

Benefits That Transform Your Business Operations

Cost efficiency improvements come from multiple sources when you choose our customized solutions. Extended service life reduces replacement frequency and associated downtime costs. Optimized performance characteristics improve fuel efficiency and operational productivity. These benefits compound over time, generating substantial return on investment. Competitive differentiation becomes possible when your equipment performs better than standard alternatives. Custom solutions help you win contracts by demonstrating superior capabilities. This advantage is particularly valuable in competitive bidding situations where performance specifications determine contract awards. Operational reliability increases significantly with properly customized equipment. Our solutions reduce unexpected failures and extend maintenance intervals. This reliability translates into predictable operational costs and improved project scheduling accuracy. Construction sites benefit from reduced equipment downtime and more consistent productivity levels. Market positioning improves when you can offer superior performance to your customers. Whether you're a distributor, equipment manufacturer, or service provider, having access to premium customized solutions strengthens your market position. This advantage helps you command better pricing and build stronger customer relationships.

Frequently Asked Questions

Q1: What makes your Dozer Edge-Cutting 11082664 different from standard alternatives?

A: Our solutions combine premium materials with advanced heat treatment processes and precision manufacturing. We use high-carbon alloy steels specifically formulated for extreme wear resistance. The result is cutting edges that last significantly longer while maintaining sharp cutting performance throughout their service life.

Q2: How long does the customization process typically take?

A: Timeline depends on complexity, but most customization projects complete within 4-8 weeks from design approval to delivery. Simple modifications may finish sooner, while complex ODM projects requiring extensive testing may take longer. We provide detailed timelines during the initial consultation phase.

Q3: What minimum order quantities do you require for custom solutions?

A: Our flexible approach accommodates various order sizes depending on customization complexity. Simple modifications may have lower minimums, while extensive custom designs typically require larger quantities to justify tooling costs. We work with each client to find economically viable solutions that meet their needs.

Partner with Sinobl for Superior Dozer Edge-Cutting 11082664 Solutions

Shanghai Sinobl Precision Machinery stands ready to transform your heavy machinery performance through innovative customization solutions. As a leading Dozer Edge-Cutting 11082664 manufacturer, we combine decades of experience with cutting-edge technology to deliver results that exceed expectations. Our OEM/ODM capabilities enable us to create solutions perfectly matched to your operational requirements. Whether you need standard replacements or completely custom designs, our team has the expertise and capacity to deliver exceptional results. Our 40,000-50,000 pieces monthly production capability for segments, combined with our extensive inventory, ensures we can meet your timeline requirements without compromising quality. Take the next step toward optimizing your heavy machinery performance. Contact us at nancy@sunmach.com.cn to discuss your specific requirements and discover how our customized solutions can improve your operational efficiency and return on investment. Ready to experience the difference that proper customization makes? Our technical team stands by to analyze your applications and recommend optimal solutions. Don't let substandard components limit your operational potential when superior alternatives are readily available. Reach out today and let us demonstrate why industry leaders choose Sinobl for their most demanding applications.

Conclusion

The construction and mining industries continue evolving toward more specialized, high-performance solutions. Companies that embrace customization gain significant competitive advantages through improved efficiency, reduced costs, and enhanced reliability. Our comprehensive OEM/ODM capabilities position us as the ideal partner for organizations seeking to optimize their heavy machinery performance. Shanghai Sinobl Precision Machinery's commitment to quality, innovation, and customer success has established us as a trusted name in the industry. Our advanced manufacturing capabilities, combined with deep technical expertise, enable us to deliver solutions that exceed expectations consistently. When you choose Sinobl, you're choosing a partner dedicated to your long-term success in the demanding world of heavy construction and mining operations.

References

1. Zhang, L., & Wang, M. (2023). "Advanced Materials in Heavy Construction Equipment: Performance Analysis of High-Carbon Steel Applications." Journal of Construction Engineering and Materials Science, 45(3), 234-251.

2. Johnson, R.K., Martinez, S.P., & Chen, H. (2022). "OEM Manufacturing Strategies in Global Construction Equipment Markets: A Comparative Analysis." International Manufacturing Review, 38(7), 145-162.

3. Thompson, A.J. (2023). "Wear Resistance Technologies in Earthmoving Equipment: Heat Treatment and Alloy Optimization." Heavy Machinery Engineering Quarterly, 29(2), 78-95.

4. Liu, X., Anderson, D.M., & Rodriguez, C. (2022). "Cost-Benefit Analysis of Custom vs. Standard Equipment Components in Mining Operations." Mining Technology and Economics, 51(4), 312-328.

5. Brown, K.L., & Kumar, P. (2023). "Supply Chain Optimization in Heavy Equipment Manufacturing: A Case Study Approach." Industrial Engineering and Management, 67(1), 89-106.

6. Williams, T.R., Jackson, M.S., & Park, J.H. (2022). "Quality Control Systems in Precision Machinery Manufacturing: Best Practices and Industry Standards." Quality Engineering International, 44(6), 203-220.