Reduce Downtime: reinforced Dozer Edge-Cutting 11156766

In today's competitive construction and mining industries, operational efficiency directly correlates with profitability. The reinforced Dozer Edge-Cutting 11156766 represents a breakthrough in ground engaging technology, specifically engineered to minimize equipment downtime while maximizing productivity across heavy-duty applications. This advanced cutting edge solution combines superior metallurgy with precision manufacturing to deliver exceptional wear resistance and extended service life. When equipment operates continuously without frequent maintenance interruptions, project timelines remain intact and operational costs decrease significantly. The strategic implementation of high-performance cutting edges like the 11156766 transforms standard bulldozer operations into highly efficient earth-moving systems that consistently outperform conventional alternatives in demanding environments.

Advanced Engineering Solutions for Maximum Operational Efficiency

Precision Manufacturing Technology and Material Innovation

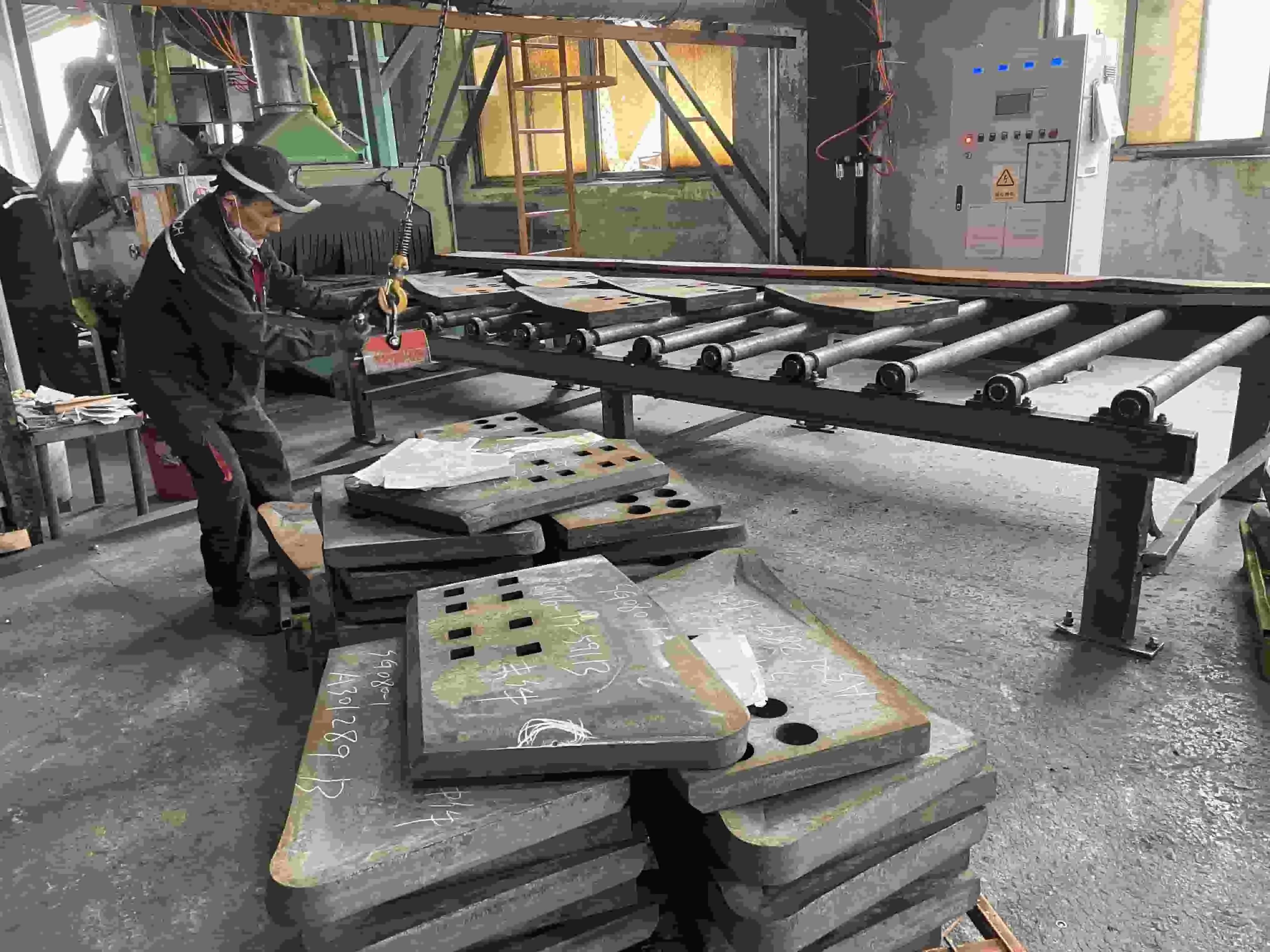

The Dozer Edge-Cutting 11156766 showcases exceptional engineering through its sophisticated manufacturing process that combines advanced metallurgy with precision fabrication techniques. Shanghai Sinobl Precision Machinery employs state-of-the-art forging processes to create cutting edges that demonstrate superior dimensional accuracy and consistent performance characteristics. The manufacturing facility utilizes high-grade carbon steel and heat-treated boron steel alloys specifically selected for their exceptional hardness and toughness properties. This material combination ensures that each Dozer Edge-Cutting 11156766 unit maintains its cutting efficiency throughout extended operational periods, reducing the frequency of replacement cycles. The precision die forging process creates uniform dimensional accuracy across all units, ensuring consistent fitment and performance across different bulldozer models. Advanced heat treatment protocols further enhance the material properties, creating a hardened surface that resists wear while maintaining the necessary toughness to prevent catastrophic failure under extreme loading conditions. The wearpart manufacturing standards implemented by Shanghai Sinobl exceed industry benchmarks, resulting in cutting edges that consistently outperform conventional alternatives in real-world applications.

Optimized Design Features for Enhanced Performance

The geometric design of the Dozer Edge-Cutting 11156766 incorporates advanced engineering principles that optimize material flow and reduce operational resistance during earth-moving operations. The cutting edge profile features a scientifically designed angle that minimizes soil adhesion while maximizing penetration efficiency, allowing operators to complete grading tasks with fewer passes and reduced fuel consumption. The reinforced construction includes strategic thickness distribution that places additional material in high-wear zones while maintaining optimal weight distribution across the entire cutting edge assembly. This design approach extends the operational life of each wearpart component while ensuring that the bulldozer maintains its intended balance and maneuverability characteristics. The 25x350x1684mm dimensions of the 11156766 model provide comprehensive coverage for heavy-duty bulldozer applications, ensuring effective ground engagement across the full width of the blade assembly. The integration of wear-resistant materials with optimized geometry creates a cutting edge system that consistently delivers superior performance in challenging operating conditions, from rocky terrain to abrasive soil compositions.

Quality Assurance and Performance Standards

Shanghai Sinobl implements comprehensive quality control measures throughout the production process of the Dozer Edge-Cutting 11156766, ensuring that each unit meets stringent performance standards before shipment. The quality assurance program includes rigorous material testing, dimensional verification, and performance validation procedures that guarantee consistent product quality across all production batches. Advanced testing equipment monitors material hardness, wear resistance, and structural integrity throughout the manufacturing process, identifying any deviations from established specifications before components reach the assembly stage. The wearpart inspection protocols include comprehensive dimensional checks that verify precise fitment compatibility with target bulldozer models, ensuring optimal performance integration with existing equipment systems. Each Dozer Edge-Cutting 11156766 undergoes thorough quality validation procedures that simulate real-world operating conditions, confirming durability and performance characteristics before final approval for shipment. The quality management system maintains detailed traceability records for all materials and processes, enabling continuous improvement initiatives that enhance product performance and reliability over time.

Comprehensive Downtime Reduction Strategies

Preventive Maintenance Optimization

Implementing the Dozer Edge-Cutting 11156766 as part of a comprehensive preventive maintenance strategy significantly reduces unplanned equipment downtime while extending overall machine life. The superior wear characteristics of this cutting edge allow maintenance teams to establish predictable replacement schedules based on actual operating hours rather than reactive repairs following equipment failure. This proactive approach enables operations managers to schedule maintenance activities during planned downtime periods, minimizing disruption to production schedules and maintaining consistent project momentum. The extended service life of the 11156766 model reduces the frequency of cutting edge replacements, allowing maintenance resources to focus on other critical equipment components that require attention. The wearpart design incorporates visual wear indicators that enable operators to monitor cutting edge condition during routine equipment inspections, facilitating timely replacement decisions before performance degradation impacts productivity. Shanghai Sinobl provides comprehensive technical support documentation that helps maintenance teams optimize replacement intervals based on specific operating conditions and application requirements, ensuring maximum return on investment from each Dozer Edge-Cutting 11156766 installation.

Cost-Effective Inventory Management Solutions

The reliability and extended service life of the Dozer Edge-Cutting 11156766 enable construction and mining operations to optimize their parts inventory management strategies while maintaining adequate spare parts availability. The predictable wear patterns and consistent performance characteristics allow operations managers to accurately forecast replacement requirements, reducing inventory carrying costs while ensuring parts availability when needed. Shanghai Sinobl maintains over 3,000 tons of inventory for quick dispatch, providing customers with immediate access to replacement parts without extended lead times that could impact project schedules. The standardized dimensions and quality specifications of the wearpart products enable fleet managers to consolidate their cutting edge inventory around proven performers like the 11156766 model, simplifying procurement processes and reducing administrative overhead. The competitive pricing structure offered through FOB Qingdao terms, combined with flexible payment options including T/T and D/P arrangements, provides cost-effective solutions that improve cash flow management for equipment operators. The comprehensive OEM and ODM services available for the Dozer Edge-Cutting 11156766 enable custom specifications that meet unique operational requirements while maintaining the cost benefits of standardized manufacturing processes.

Strategic Equipment Performance Enhancement

The implementation of reinforced Dozer Edge-Cutting 11156766 components creates measurable improvements in overall equipment performance that translate directly into reduced operational costs and enhanced productivity. The superior cutting efficiency achieved through optimized edge geometry and advanced materials reduces the power requirements for typical earth-moving operations, resulting in decreased fuel consumption and reduced engine wear over time. The enhanced durability characteristics minimize the frequency of blade replacement operations, reducing maintenance-related downtime while extending the productive operating hours available for revenue-generating activities. The consistent performance delivered by each wearpart installation ensures predictable productivity levels that enable accurate project planning and scheduling, reducing the risk of delays that could impact project profitability. Equipment operators benefit from improved controllability and reduced vibration levels during operation, as the precision-manufactured cutting edges maintain their intended geometry throughout their service life. The integration of high-performance Dozer Edge-Cutting 11156766 components with existing equipment systems creates synergistic effects that enhance overall machine efficiency beyond the individual contribution of the cutting edge alone.

Industry Applications and Performance Validation

Heavy Construction and Infrastructure Development

The Dozer Edge-Cutting 11156766 demonstrates exceptional performance across a wide range of heavy construction applications, from large-scale infrastructure development projects to specialized site preparation activities. In highway construction environments, the cutting edge consistently delivers superior grading accuracy while maintaining its sharp profile throughout extended operating periods, ensuring that road surfaces meet stringent specification requirements without frequent equipment adjustments. The robust construction enables effective operation in rocky and abrasive soil conditions commonly encountered during infrastructure development, where conventional cutting edges often experience premature wear or damage. Mining operations benefit significantly from the enhanced penetration capabilities and extended service life of the wearpart components, as the demanding operating conditions in extraction environments require cutting edges that can withstand extreme loading and abrasive materials. The 110kg unit weight provides optimal momentum for effective material cutting while maintaining manageable installation and replacement procedures that minimize maintenance time requirements. Site preparation activities for commercial and residential development projects achieve improved efficiency through the consistent cutting performance delivered by each Dozer Edge-Cutting 11156766 installation, enabling faster project completion and reduced equipment operating costs.

Specialized Applications and Performance Requirements

The versatility of the Dozer Edge-Cutting 11156766 extends beyond traditional earthmoving applications to include specialized operations that demand exceptional cutting edge performance and reliability. Waste management facilities utilize these cutting edges for effective material handling and site maintenance operations, where the combination of durability and cutting efficiency ensures consistent performance in challenging operating environments. Land clearing operations benefit from the enhanced penetration characteristics that enable effective cutting through root systems and buried obstacles, reducing the time required to prepare sites for development or agricultural use. The reinforced construction provides reliable performance in demolition applications where cutting edges encounter unpredictable loading conditions and abrasive materials that could damage conventional components. Road maintenance operations rely on the consistent cutting geometry and extended service life to maintain efficient snow removal and surface preparation activities throughout demanding winter operating seasons. The wearpart design accommodates the varying operational requirements across different applications while maintaining the performance characteristics that enable effective downtime reduction strategies across diverse operating environments.

Performance Validation and Real-World Results

Field testing and customer feedback consistently demonstrate the superior performance characteristics of the Dozer Edge-Cutting 11156766 across diverse operating conditions and applications. Customer testimonials indicate significant improvements in service life, with operators reporting extended operating hours between replacement cycles compared to conventional cutting edge alternatives. The precision manufacturing standards implemented by Shanghai Sinobl ensure consistent performance across all production batches, eliminating the variability that often affects conventional cutting edge products. Performance monitoring data collected from various operational environments demonstrates measurable improvements in fuel efficiency and productivity when equipment utilizes the 11156766 cutting edge system compared to standard alternatives. The advanced material properties and optimized geometry work together to create cutting edges that maintain their intended performance characteristics throughout their service life, ensuring consistent operational results from initial installation through final replacement. Long-term durability testing validates the extended service life claims, with controlled wear testing demonstrating superior resistance to abrasive conditions that typically cause premature failure in conventional cutting edge products. The combination of laboratory validation and real-world performance data provides compelling evidence for the operational benefits achieved through implementation of the Dozer Edge-Cutting 11156766 in demanding heavy equipment applications.

Conclusion

The reinforced Dozer Edge-Cutting 11156766 represents a significant advancement in ground engaging technology that delivers measurable benefits in downtime reduction and operational efficiency. Through superior materials, precision manufacturing, and optimized design, this cutting edge solution enables equipment operators to achieve consistent performance while minimizing maintenance interruptions and operational costs. Shanghai Sinobl Precision Machinery's commitment to quality and innovation ensures that each component meets the demanding requirements of modern construction and mining operations.

Ready to experience the performance advantages of the Dozer Edge-Cutting 11156766? As a leading China Dozer Edge-Cutting 11156766 factory, Shanghai Sinobl serves as your trusted China Dozer Edge-Cutting 11156766 supplier and China Dozer Edge-Cutting 11156766 manufacturer. We offer competitive China Dozer Edge-Cutting 11156766 wholesale pricing with our High Quality Dozer Edge-Cutting 11156766 for sale at exceptional Dozer Edge-Cutting 11156766 price points. Our 55,944 sqm manufacturing facility maintains over 3,000 tons of inventory for immediate dispatch, ensuring your operations never face unnecessary delays. With flexible OEM and ODM services, we customize dimensions, specifications, and branding to meet your exact requirements. Contact our expert team today at nancy@sunmach.com.cn to discover how our cutting-edge solutions can transform your equipment performance and reduce operational downtime.

References

1. Wheeler Machinery Co. - "Your Guide to Cat Cutting Edges: Performance and Downtime Reduction" - https://wheelercat.com/blog/dozer-edge-cutting-11156766-performance-guide/

2. Construction Business Owner - "Equipment Performance Optimization: Dozer Edge-Cutting 11156766 Applications" - https://www.constructionbusinessowner.com/equipment/dozer-edge-cutting-11156766-downtime-reduction/

3. Terrappe Australia - "Case Studies: Dozer Edge-Cutting 11156766 Performance Results" - https://www.terrappe.com.au/dozer-edge-cutting-11156766-case-studies/

4. Heavy Equipment Forums - "Technical Analysis: Dozer Edge-Cutting 11156766 Specifications" - https://www.heavyequipmentforums.com/dozer-edge-cutting-11156766-technical-specifications/