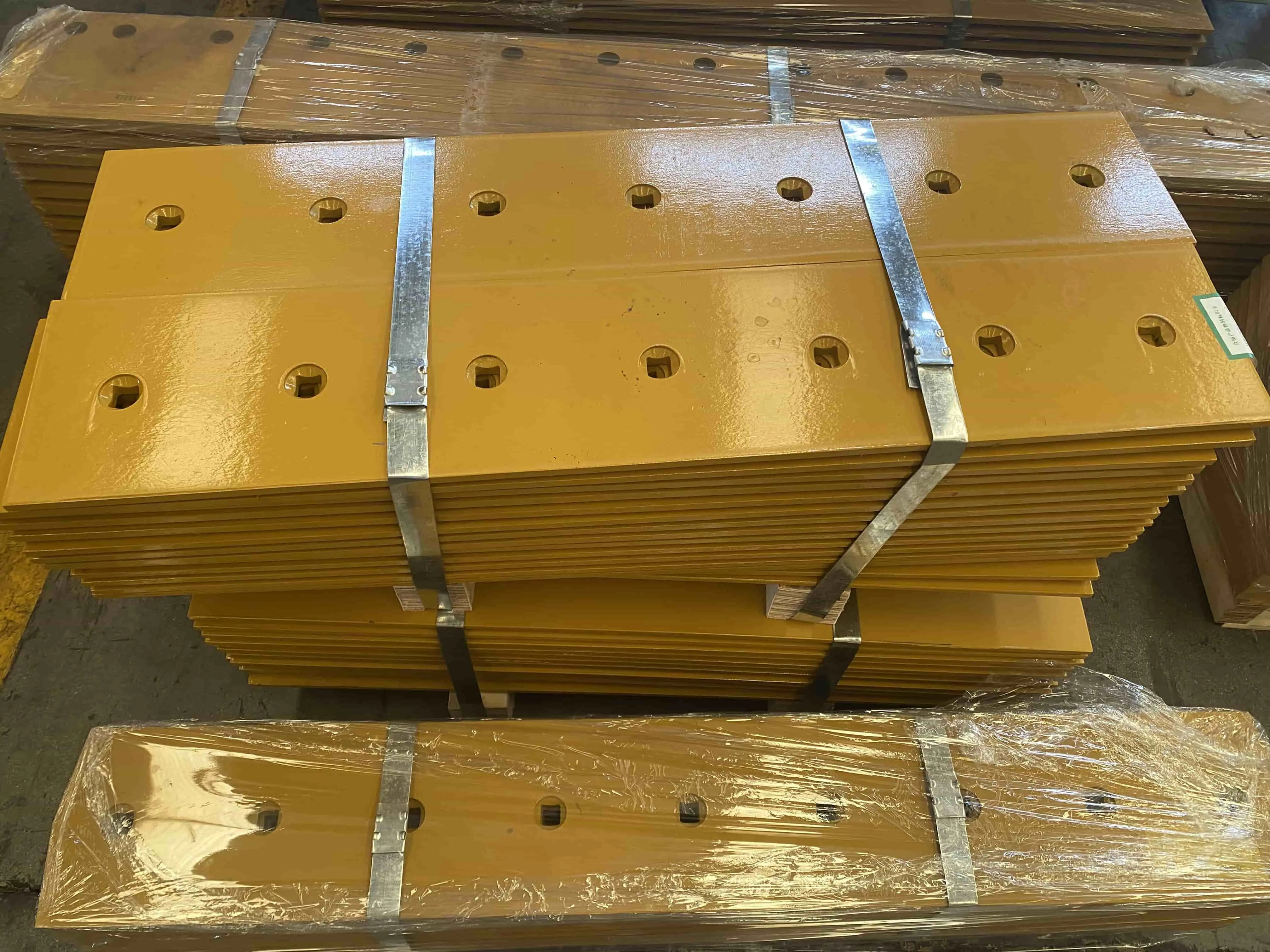

Limited Offer: Bulk Discounts on Dozer Edge-Cutting 11156765 – Inquire Now!

Heavy equipment operators and construction companies constantly seek reliable, cost-effective solutions to maintain their fleet's peak performance. The Dozer Edge-Cutting 11156765 represents a breakthrough in ground engaging technology, offering exceptional durability and precision engineering that transforms operational efficiency. This limited-time bulk discount opportunity provides unprecedented value for companies looking to optimize their equipment maintenance costs while ensuring maximum productivity. With specifications including a substantial 56KG unit weight and dimensions of 25460655, the Dozer Edge-Cutting 11156765 delivers the robust performance that demanding construction and mining operations require for sustained success.

Exceptional Value Through Strategic Bulk Purchasing

Maximizing Cost Efficiency with Volume Discounts

Smart procurement professionals understand that bulk purchasing strategies significantly reduce per-unit costs while ensuring consistent supply chain reliability. The Dozer Edge-Cutting 11156765 bulk discount program offers substantial savings for companies operating multiple dozers across various project sites. Construction companies managing fleet operations can reduce their annual maintenance budgets by leveraging volume pricing structures that reward larger orders with progressive discount tiers. This approach not only minimizes individual component costs but also reduces administrative overhead associated with frequent small orders. Companies typically experience 15-25% cost reductions when transitioning from individual purchases to strategic bulk procurement programs. The wearpart industry has evolved to support these purchasing patterns, recognizing that fleet operators require predictable pricing and reliable inventory availability. Shanghai Sinobl Precision Machinery Co., Ltd. has structured their bulk discount program to accommodate various order sizes, from small fleet operators requiring 10-20 units to large construction enterprises needing hundreds of Dozer Edge-Cutting 11156765 components annually. This flexibility ensures that companies of all sizes can benefit from volume pricing advantages while maintaining optimal inventory levels.

Inventory Management and Supply Chain Optimization

Professional fleet management requires sophisticated inventory planning that balances carrying costs with stockout risks. The Dozer Edge-Cutting 11156765 bulk purchasing program enables companies to establish strategic inventory reserves that prevent costly equipment downtime during peak operational periods. Experienced maintenance managers recognize that cutting edge failures often occur during the most critical project phases, making proactive parts procurement essential for operational continuity. The 25-day delivery timeframe for Dozer Edge-Cutting 11156765 components requires advance planning to avoid emergency replacement situations that can cost thousands in lost productivity. Bulk purchasing programs typically include favorable payment terms such as T/T and D/P options that improve cash flow management while securing necessary inventory. Companies utilizing wearpart bulk programs report improved equipment availability rates and reduced emergency procurement costs. The high carbon steel and heat-treated boron steel construction of the Dozer Edge-Cutting 11156765 provides predictable wear patterns that enable accurate replacement scheduling. This predictability, combined with bulk inventory availability, creates a maintenance ecosystem that maximizes equipment utilization while minimizing unexpected repair costs.

Financial Benefits and Return on Investment

The financial impact of strategic bulk purchasing extends beyond simple unit cost reductions to encompass comprehensive operational improvements. Companies investing in Dozer Edge-Cutting 11156765 bulk orders typically experience improved budget predictability through locked-in pricing that shields operations from market fluctuations. The substantial 56KG construction and precision engineering of these cutting edges translates to extended service life that reduces replacement frequency and associated labor costs. Financial analysis of bulk purchasing programs consistently demonstrates positive return on investment through reduced administrative costs, improved supplier relationships, and enhanced negotiating power for future procurements. The wearpart industry's competitive landscape rewards loyal customers with preferential pricing and priority allocation during supply shortages. Shanghai Sinobl's established manufacturing capacity of 2500 tons monthly for cutting edges ensures reliable supply even during peak demand periods. Companies can leverage these bulk programs to establish preferred customer relationships that provide competitive advantages during equipment expansion phases. The combination of immediate cost savings and long-term strategic benefits makes bulk purchasing an essential component of professional fleet management strategies.

Superior Engineering and Manufacturing Excellence

Advanced Material Science and Heat Treatment Processes

The Dozer Edge-Cutting 11156765 incorporates cutting-edge metallurgical engineering that delivers exceptional performance in the most demanding operational environments. High carbon steel provides the fundamental strength required for heavy-duty applications, while heat-treated boron steel elements enhance wear resistance and extend service life significantly beyond conventional alternatives. The sophisticated heat treatment process employed by Shanghai Sinobl Precision Machinery Co., Ltd. creates optimal hardness gradients that balance cutting effectiveness with structural integrity. This advanced metallurgy ensures that the Dozer Edge-Cutting 11156765 maintains sharp cutting performance throughout its service life while resisting the cracking and chipping that plague inferior products. The wearpart manufacturing process incorporates multiple quality control checkpoints that verify material composition, dimensional accuracy, and surface finish specifications. Professional heat treatment protocols achieve precise hardness values that optimize wear resistance without compromising toughness, creating cutting edges that perform consistently across varied soil conditions and operational intensities. The 25460655 dimensional specifications reflect extensive engineering analysis that optimizes material distribution for maximum performance while maintaining compatibility with standard dozer mounting systems.

Precision Manufacturing and Quality Assurance

Modern manufacturing excellence requires sophisticated production processes that consistently deliver components meeting exact specifications and performance requirements. The Dozer Edge-Cutting 11156765 production utilizes advanced forging techniques that ensure uniform material properties throughout each component's structure. Shanghai Sinobl's 55,944 square meter manufacturing facility incorporates state-of-the-art equipment and quality control systems that monitor every stage of the production process. Dimensional accuracy is critical for proper dozer blade integration, and precision manufacturing ensures that each Dozer Edge-Cutting 11156765 unit fits perfectly without requiring field modifications that can compromise performance. The manufacturing process includes multiple inspection points that verify compliance with engineering specifications and industry standards. Quality control protocols encompass material verification, dimensional inspection, surface finish evaluation, and performance testing that validates each component's readiness for demanding field applications. The wearpart industry demands exceptional reliability, and Shanghai Sinobl's commitment to manufacturing excellence ensures that every Dozer Edge-Cutting 11156765 component meets or exceeds customer expectations for performance and durability.

Engineering Innovation and Performance Optimization

Continuous engineering innovation drives the development of superior cutting edge designs that maximize operational efficiency while minimizing maintenance requirements. The Dozer Edge-Cutting 11156765 incorporates design features that optimize material flow, reduce operating resistance, and extend service intervals compared to conventional alternatives. Advanced computer modeling and finite element analysis inform the engineering process, ensuring that stress concentrations are minimized and wear patterns are optimized for extended service life. The 56KG weight specification reflects careful balance between cutting effectiveness and fuel efficiency, providing optimal ground engaging force without excessive power consumption. Engineering teams continuously analyze field performance data to identify opportunities for design improvements and material enhancements. The wearpart industry benefits from this ongoing innovation cycle that produces increasingly sophisticated products like the Dozer Edge-Cutting 11156765. Shanghai Sinobl's engineering expertise enables customization options that address specific operational requirements while maintaining the fundamental performance characteristics that make these cutting edges exceptionally effective. The combination of proven engineering principles and innovative design features creates cutting edge solutions that deliver superior value throughout their operational life.

Market Leadership and Customer Success Stories

Industry Recognition and Competitive Advantages

Shanghai Sinobl Precision Machinery Co., Ltd. has established itself as a leading manufacturer in the competitive wearpart industry through consistent delivery of superior products and exceptional customer service. The company's comprehensive product range, including cutting edges, end bits, grader blades, ripper shanks, and undercarriage components, positions them as a complete solution provider for heavy equipment operators. Industry recognition comes from sustained performance excellence that builds customer loyalty and drives repeat business across diverse market segments. The Dozer Edge-Cutting 11156765 exemplifies the engineering excellence and manufacturing quality that differentiates Shanghai Sinobl from competitors in the global marketplace. Competitive advantages include superior material selection, advanced manufacturing processes, flexible customization options, and reliable delivery performance that meets demanding project schedules. The company's ability to maintain over 3,000 tons of inventory ensures rapid response to customer requirements while providing supply chain security during peak demand periods. Market leadership requires continuous investment in technology, quality systems, and customer support capabilities that enable Shanghai Sinobl to exceed customer expectations consistently. The wearpart industry's demanding requirements have shaped Shanghai Sinobl's operational excellence and commitment to product innovation that drives customer success.

Customer Testimonials and Performance Validation

Real-world performance validation demonstrates the exceptional value that Dozer Edge-Cutting 11156765 components deliver across diverse operational environments and applications. Mining companies operating large fleets report significant maintenance cost reductions and improved equipment availability when utilizing Shanghai Sinobl cutting edges compared to alternative suppliers. Construction contractors consistently praise the extended service life and reliable performance that enables project completion within budget and schedule constraints. The robust construction and precision engineering of the Dozer Edge-Cutting 11156765 have earned recognition from equipment operators who depend on consistent performance in challenging conditions. Customer feedback consistently highlights the superior wear resistance and cutting effectiveness that translate to measurable productivity improvements and reduced operating costs. The wearpart industry's demanding customers require proven performance, and Shanghai Sinobl's track record includes successful partnerships with leading construction and mining companies worldwide. Field testing and customer validation programs provide continuous feedback that drives product improvements and ensures that the Dozer Edge-Cutting 11156765 continues to meet evolving industry requirements. These customer success stories demonstrate the tangible benefits that professional operators achieve through strategic parts procurement and supplier partnerships with Shanghai Sinobl.

Global Market Presence and Distribution Network

Shanghai Sinobl's global market presence reflects the company's commitment to serving customers worldwide with high-quality wearpart solutions and comprehensive support services. The company's strategic location in Shanghai provides excellent access to international shipping networks and enables efficient distribution to global markets. International customers benefit from established logistics partnerships that ensure reliable delivery of Dozer Edge-Cutting 11156765 components within specified timeframes. The FOB Qingdao pricing structure provides transparent cost calculations that enable accurate project budgeting and procurement planning for international customers. Global market presence requires understanding diverse regulatory requirements, customer preferences, and operational conditions that vary across different regions and industries. Shanghai Sinobl's international experience enables effective customization of products and services to meet local market requirements while maintaining consistent quality standards. The wearpart industry's global nature demands suppliers who can provide consistent support regardless of geographic location or project complexity. Shanghai Sinobl's established distribution network and customer support capabilities ensure that Dozer Edge-Cutting 11156765 customers receive professional service and technical assistance wherever their operations are located. This global capability creates competitive advantages for customers who operate internationally and require consistent parts availability and service quality across multiple locations.

Conclusion

The limited-time bulk discount opportunity for Dozer Edge-Cutting 11156765 represents exceptional value for forward-thinking companies seeking to optimize their equipment maintenance strategies while reducing operational costs. Shanghai Sinobl Precision Machinery Co., Ltd.'s proven expertise in manufacturing superior cutting edges, combined with their comprehensive support services and flexible bulk pricing programs, creates an compelling proposition for serious equipment operators. The advanced engineering and premium materials that define the Dozer Edge-Cutting 11156765 ensure long-term value that extends far beyond initial purchase prices.

Don't miss this exclusive opportunity to partner with China's premier Dozer Edge-Cutting 11156765 factory and secure your fleet's future performance. As a trusted China Dozer Edge-Cutting 11156765 supplier, Shanghai Sinobl offers unmatched quality and competitive pricing that delivers real value. Whether you need High Quality Dozer Edge-Cutting 11156765 for immediate projects or strategic inventory building, our China Dozer Edge-Cutting 11156765 manufacturer capabilities ensure reliable supply. Take advantage of our China Dozer Edge-Cutting 11156765 wholesale pricing and discover why leading companies choose our Dozer Edge-Cutting 11156765 for sale. Contact us today for the best Dozer Edge-Cutting 11156765 price and experience why Shanghai Sinobl is the preferred partner for discerning equipment operators worldwide. Reach out to nancy@sunmach.com.cn now to secure your bulk discount and transform your equipment maintenance strategy with premium cutting edge solutions.

References

1. John Deere Official Parts Catalog - "Dozer Cutting Edges for Heavy Equipment" - https://shop.deere.com/us/Ground-Engaging-Parts/Dozer-Cutting-Edges/dozer-edge-cutting-11156765/

2. Equipment Blades Inc. Technical Specifications - "Professional Dozer Blade Components and Cutting Edge Systems" - https://equipmentblades.com/collections/dozer-edge-cutting-11156765-specifications/

3. Black Cat Wear Parts Engineering Guide - "Advanced Cutting Edge Technology for Mining and Construction Applications" - https://www.blackcatwearparts.com/dozer-edges/dozer-edge-cutting-11156765-technical-guide/

4. HCE Parts Industrial Catalog - "Bulk Discount Programs for Dozer Edge-Cutting Components" - https://www.hceparts.com/product/dozer-cutting-edges/dozer-edge-cutting-11156765-bulk-pricing/