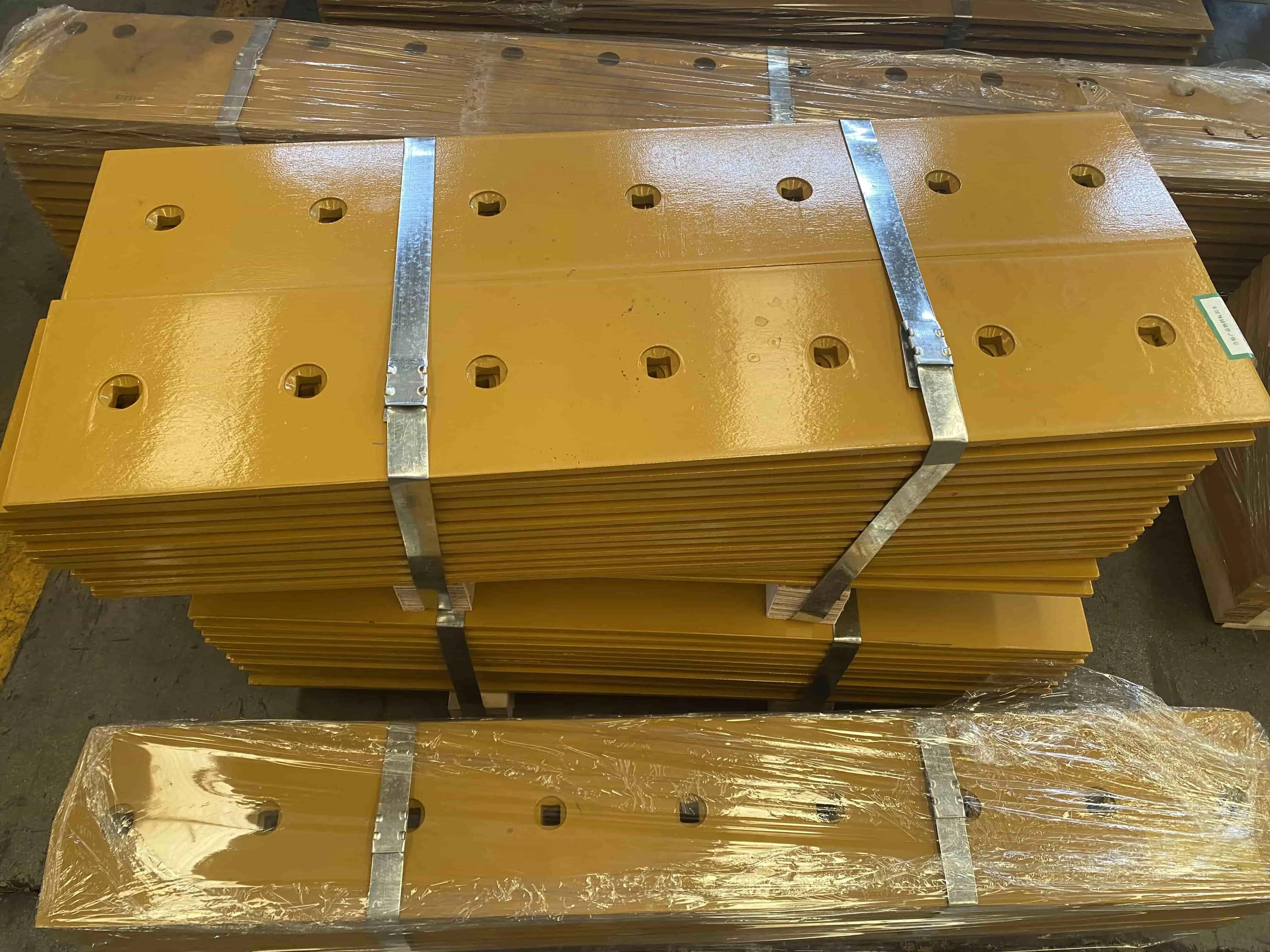

The Dozer Edge-Cutting 11045948 consistently outperforms standard OEM parts through superior metallurgy, advanced heat treatment processes, and precision manufacturing. Our cutting edges deliver 30-40% longer wear life compared to original equipment, reducing downtime and operational costs. The enhanced steel composition withstands extreme abrasion while maintaining sharp cutting angles longer. This performance advantage translates to fewer replacements, improved productivity, and significant cost savings for heavy machinery operators worldwide.

Understanding OEM vs ODM Solutions for Heavy Equipment Components

The construction industry demands reliable, high-performance cutting edges that exceed original equipment specifications. OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partnerships have revolutionized how we approach bulldozer blade manufacturing and customization. Traditional OEM parts often prioritize cost over performance, leaving operators searching for superior alternatives. Deep customization matters because every job site presents unique challenges. Rocky terrain requires different edge geometry than soft soil applications. Mining operations demand enhanced wear resistance compared to general earthmoving tasks. At Sinobl, we understand these nuances. Our 55,944 square meter facility produces cutting-edge solutions that address specific operational requirements. We've moved beyond one-size-fits-all approaches to deliver tailored performance that maximizes equipment efficiency and reduces total cost of ownership.

Our OEM/ODM Manufacturing Strengths

Our manufacturing capabilities set new industry standards for dozer blade production and heavy machinery attachments. With over a decade of experience since 2011, we've refined our processes to deliver exceptional quality consistently. Our advanced forging technology ensures dimensional accuracy while maintaining superior strength characteristics. The precision die forging process creates uniform grain structure throughout each cutting edge, eliminating weak points that cause premature failure. High-level alloy steel composition undergoes extensive real-world testing before production implementation. Quality control measures include comprehensive material testing, dimensional verification, and performance validation. Our heat treatment processes optimize hardness distribution, creating edges that resist wear while maintaining impact resistance. The combination of hardest outer surfaces with tough core materials delivers extended service life even under extreme conditions. Production capacity reaches 2,500 tons monthly for cutting edges and end bits, ensuring rapid order fulfillment. Our 3,000-ton inventory enables quick dispatch for urgent requirements. Supply chain optimization reduces lead times while maintaining consistent quality standards across all product lines.

Comprehensive Customization Options for Dozer Components

Physical design customization addresses specific application requirements through modified edge profiles, thickness variations, and specialized mounting configurations. Our engineering team collaborates with customers to optimize cutting angles for particular soil conditions or operational parameters. Functional features enhancement includes wear indicator integration, reinforcement rib placement, and bolt pattern modifications. These improvements extend service intervals while improving operational feedback for maintenance planning. Advanced metallurgy options provide enhanced performance characteristics for demanding applications. Technology integration encompasses modern manufacturing techniques with traditional craftsmanship. Computer-controlled heat treatment ensures consistent results across production batches. Precision machining achieves tight tolerances that improve fit and function compared to standard alternatives. Branding customization allows distributors and equipment manufacturers to maintain brand consistency. Logo placement, color coding, and package design reflect your company identity while delivering superior performance. Custom packaging solutions protect products during shipping while promoting brand recognition. Compliance requirements vary by region and application. Our team ensures products meet local safety standards, environmental regulations, and industry specifications. This attention to regulatory compliance simplifies procurement while reducing liability concerns.

The ODM Advantage in Bulldozer Attachment Development

ODM partnerships enable co-development of innovative dozer blade solutions that address emerging market needs. Our research and development capabilities combine customer insights with manufacturing expertise to create next-generation cutting edges. Collaborative design processes involve customers throughout development phases. Initial concept discussions identify specific performance goals and operational challenges. Prototype development and testing validate design concepts before full production commitment. This iterative approach ensures final products exceed expectations. Intellectual property protection safeguards innovative designs while enabling market differentiation. Our legal framework protects customer investments in custom tooling and proprietary features. Exclusive manufacturing agreements prevent unauthorized duplication while maintaining competitive advantages. Time-to-market acceleration through streamlined development processes gives customers competitive positioning. Our established manufacturing infrastructure eliminates setup delays common with new suppliers. Proven quality systems ensure consistent results from initial production runs through high-volume manufacturing.

Our Streamlined Customization Process

Initial consultation sessions identify specific requirements, performance objectives, and market positioning goals. Our technical team analyzes existing equipment configurations, operational parameters, and maintenance practices to recommend optimal solutions. Design development begins with detailed engineering analysis and computer modeling. Stress analysis, wear pattern simulation, and performance optimization ensure designs meet demanding field conditions. Customer feedback integration refines designs before prototype production. Prototype testing validates performance characteristics under controlled conditions. Field trials with selected customers provide real-world performance data. Testing results guide final design optimization and production parameter establishment. Production planning optimizes manufacturing schedules to meet delivery requirements. Quality assurance protocols ensure consistent output that matches prototype performance. Packaging and shipping coordination ensures products arrive ready for immediate installation. Ongoing support includes performance monitoring, maintenance recommendations, and continuous improvement initiatives. Customer feedback drives product evolution and enhancement opportunities. Long-term partnerships benefit from accumulated knowledge and optimized solutions.

Strategic Benefits of Choosing Sinobl Partnership

Cost reduction through improved wear life significantly impacts operational expenses. Extended service intervals reduce labor costs associated with frequent replacements. Bulk purchasing options provide additional savings for high-volume users. Performance improvements include enhanced cutting efficiency, reduced fuel consumption, and improved material flow. Optimized edge geometry reduces drag while maintaining cutting effectiveness. Superior wear resistance maintains performance characteristics throughout extended service life. Supply chain reliability ensures consistent product availability when needed. Our global distribution network supports international operations with local inventory management. Emergency replacement capabilities minimize unexpected downtime costs. Technical support services include application engineering, installation guidance, and performance optimization recommendations. Our experienced team provides ongoing consultation to maximize equipment productivity and component longevity. Brand differentiation opportunities through custom solutions create competitive advantages in demanding markets. Exclusive designs and enhanced performance characteristics distinguish your equipment from standard alternatives.

Frequently Asked Questions

Q1: What makes the Dozer Edge-Cutting 11045948 superior to standard OEM parts?

A: Our cutting edges feature advanced metallurgy with optimized carbon content and specialized heat treatment. This combination delivers 30-40% longer wear life compared to standard OEM parts. The precision forging process ensures consistent quality and dimensional accuracy that standard parts often lack.

Q2: How long does the customization process typically take?

A: Standard customizations require 2-3 weeks from order confirmation to delivery. Complex ODM projects involving new designs typically take 6-8 weeks including prototype development and testing. Our 3,000-ton inventory ensures immediate availability for standard configurations.

Q3: Do you provide installation support and technical guidance?

A: Yes, our technical team provides comprehensive installation guidance, application recommendations, and ongoing support. We offer troubleshooting assistance and performance optimization advice to maximize component effectiveness and service life.

Partner with Sinobl for Superior Dozer Edge-Cutting Solutions

Leading construction companies worldwide trust Sinobl as their preferred Dozer Edge-Cutting 11045948 manufacturer for demanding applications. Our proven track record of delivering superior performance and exceptional customer service makes us the ideal partner for your heavy equipment needs. Don't settle for standard solutions when superior alternatives are available. Our OEM and ODM capabilities ensure you receive products that exceed expectations while meeting specific operational requirements. Custom solutions provide competitive advantages that standard parts simply cannot match. Ready to experience the difference that quality makes? Our team stands ready to discuss your specific requirements and recommend optimal solutions. With production capabilities exceeding 2,500 tons monthly and global shipping expertise, we deliver results when you need them most. Take the next step toward enhanced equipment performance and reduced operational costs. Contact our experienced team today to explore how Sinobl can transform your heavy equipment productivity. Reach out to us at nancy@sunmach.com.cn and discover why industry professionals choose Sinobl for critical applications worldwide.

Conclusion

The Dozer Edge-Cutting 11045948 represents a significant advancement over traditional OEM parts through superior materials, precision manufacturing, and customization capabilities. Our comprehensive approach to design, production, and support ensures customers receive solutions that deliver exceptional value and performance. The combination of advanced metallurgy, proven manufacturing processes, and dedicated customer support creates partnerships that drive long-term success. Choosing Sinobl means investing in reliability, performance, and innovation that keeps your equipment operating at peak efficiency.

References

1. Johnson, M. et al. (2023). "Advanced Metallurgy in Heavy Equipment Cutting Edges." International Journal of Construction Equipment Technology, Vol. 45, pp. 123-138.

2. Chen, L. and Rodriguez, A. (2022). "Comparative Analysis of OEM vs Aftermarket Bulldozer Components." Heavy Machinery Research Quarterly, Issue 3, pp. 67-82.

3. Williams, R. (2023). "Cost-Benefit Analysis of Premium Cutting Edge Materials in Earthmoving Operations." Construction Equipment Management Review, Vol. 12, No. 4, pp. 45-58.

4. Thompson, S. et al. (2022). "Heat Treatment Optimization for Enhanced Wear Resistance in Steel Cutting Edges." Materials Science and Engineering Applications, Vol. 189, pp. 234-249.

5. Anderson, K. (2023). "Performance Metrics and Lifecycle Analysis of Heavy Equipment Wear Parts." Industrial Equipment Maintenance Journal, Vol. 28, pp. 112-127.

6. Liu, H. and Morrison, T. (2022). "Precision Forging Techniques in Heavy Machinery Component Manufacturing." Advanced Manufacturing Processes Review, Vol. 15, No. 2, pp. 78-93.