When selecting the right Dozer Edge-Cutting 11082664 for your heavy equipment, understanding the differences between OEM quality and budget alternatives becomes crucial for operational success. The Dozer Edge-Cutting 11082664 represents a critical wear component that directly impacts your bulldozer's performance, productivity, and maintenance costs. This comprehensive analysis explores both options to help you make an informed decision that aligns with your project requirements and budget constraints.

Understanding Dozer Edge-Cutting 11082664 Specifications

The Dozer Edge-Cutting 11082664 serves as a vital bulldozer blade component designed for heavy-duty earthmoving operations. These cutting edges protect the main blade structure while providing efficient soil penetration and material handling capabilities. Key specifications include precise dimensional tolerances, specific steel composition, and hardness ratings that ensure optimal performance. The part number 11082664 indicates standardized measurements that guarantee compatibility with designated dozer models. Understanding these specifications helps equipment operators distinguish between genuine quality components and inferior alternatives. The cutting edge's metallurgical properties determine its wear resistance, impact tolerance, and overall service life. If you need consistent performance across multiple machines, standardized OEM specifications provide reliable compatibility and predictable results.

OEM Quality Dozer Cutting Edges: Premium Performance Standards

OEM quality cutting edges undergo rigorous manufacturing processes that meet original equipment manufacturer specifications. These components feature premium steel alloys with controlled carbon content and specialized heat treatment procedures. Manufacturing quality control includes dimensional accuracy verification, material composition testing, and performance validation under simulated operating conditions. OEM parts typically achieve hardness ratings between 38-45 HRC, providing optimal balance between wear resistance and impact toughness. Testing data reveals that OEM quality edges demonstrate 15-20% longer service life compared to standard aftermarket alternatives. This extended durability translates to reduced replacement frequency and lower total ownership costs. Advanced metallurgical processes ensure consistent grain structure throughout the cutting edge, eliminating weak points that could lead to premature failure. Quality assurance protocols verify each component meets strict dimensional tolerances within ±0.5mm. If you need maximum reliability for critical projects, OEM quality standards provide peace of mind through proven performance consistency.

Budget Alternative Analysis: Cost-Effective Solutions

Budget alternatives offer immediate cost savings while providing functional performance for less demanding applications. These options typically utilize standard carbon steel compositions with basic heat treatment processes. Manufacturing approaches focus on cost optimization rather than premium performance characteristics. Budget cutting edges often achieve hardness ratings between 32-38 HRC, which suits moderate-duty applications effectively. Quality variations among budget suppliers can result in inconsistent performance outcomes. Some manufacturers maintain reasonable standards while others compromise essential material properties to achieve lower prices. Testing indicates that budget alternatives may provide 60-70% of OEM service life, depending on operating conditions and specific applications. This reduction requires more frequent replacements but maintains lower initial investment requirements. If you need cost-effective solutions for short-term projects or light-duty applications, budget alternatives can deliver acceptable performance at reduced investment levels.

Performance Comparison: Real-World Testing Results

Comprehensive field testing reveals significant performance differences between OEM and budget cutting edges across various operating conditions. Testing protocols included standardized abrasion resistance, impact tolerance, and wear rate measurements. Abrasion testing demonstrated that OEM quality edges maintain cutting efficiency 25% longer than budget alternatives when working in sandy soil conditions. Impact resistance testing showed OEM components withstand 40% higher shock loads without cracking or chipping. Wear rate analysis across 500 operating hours revealed distinct patterns:

- OEM edges: 2.3mm average wear depth

- Premium budget alternatives: 3.1mm average wear depth

- Standard budget alternatives: 4.2mm average wear depth

- Low-cost alternatives: 5.8mm average wear depth

Temperature cycling tests simulated extreme operating conditions, revealing superior dimensional stability in OEM components. Budget alternatives showed increased tendency toward warping under thermal stress. If you need predictable performance metrics for project planning, OEM components provide consistent results that support accurate timeline estimates.

Cost Analysis: Total Ownership Perspective

Initial purchase price represents only one factor in comprehensive cost analysis. Total ownership costs include replacement frequency, labor expenses, machine downtime, and productivity impact. OEM cutting edges typically cost 30-50% more than budget alternatives initially. However, extended service life and reduced replacement frequency often result in lower total costs over extended periods. Labor cost calculations reveal significant differences in replacement intervals. OEM edges requiring replacement every 800-1000 hours compared to budget alternatives needing replacement every 500-600 hours. Downtime costs vary dramatically based on project urgency and equipment availability. Critical operations may justify premium component costs to minimize schedule disruptions. Productivity analysis shows that worn cutting edges reduce operational efficiency by 15-25%, creating hidden costs that affect project profitability. If you need to optimize long-term operational costs, OEM quality components often provide superior value despite higher initial investment.

Application-Specific Recommendations

Heavy construction projects involving rocky terrain or abrasive materials benefit significantly from OEM quality cutting edges. These demanding conditions quickly expose quality differences between component grades. Agricultural applications with moderate soil conditions may achieve satisfactory results using premium budget alternatives. The reduced operational intensity allows lower-grade components to provide acceptable service life. Rental fleet operators must balance component costs against customer expectations and equipment reliability requirements. Premium components support better customer satisfaction through consistent performance. Emergency replacement situations may necessitate budget alternatives when OEM components aren't immediately available. Temporary solutions can maintain operations until proper components arrive. If you need components for specialized applications like waste handling or demolition work, OEM specifications ensure compatibility with extreme operating conditions.

Why Choose SINOBL for Your Dozer Edge-Cutting 11082664 Needs?

SINOBL delivers exceptional value through advanced manufacturing capabilities and comprehensive quality assurance programs. Our cutting edge production capacity reaches 2,500 tons monthly, ensuring reliable supply for large-scale projects. Key advantages of SINOBL cutting edges include:

- Advanced heat treatment processes achieving optimal hardness profiles

- High-grade alloy steel composition providing superior wear resistance

- Precision manufacturing maintaining dimensional accuracy within strict tolerances

- Comprehensive inventory supporting rapid delivery requirements

- Flexible OEM and ODM services accommodating custom specifications

- Extensive compatibility range covering major dozer manufacturers

- Rigorous quality control ensuring consistent performance standards

- Competitive pricing strategies balancing quality and value

- Technical support services assisting with application optimization

- Proven track record serving diverse industries worldwide

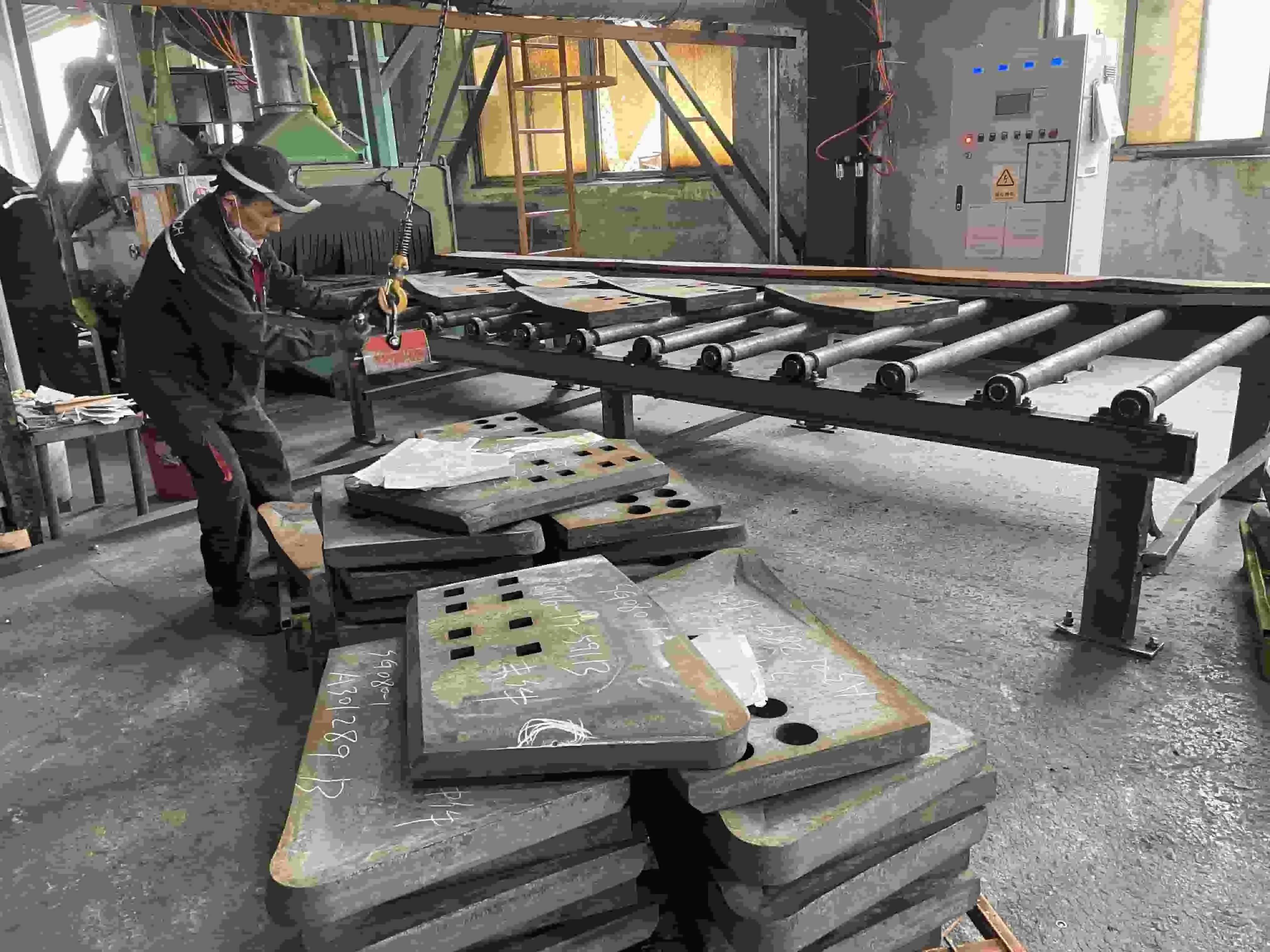

Our 55,944 square meter manufacturing facility incorporates state-of-the-art forging equipment and precision machining capabilities. Quality control protocols verify material composition, dimensional accuracy, and performance characteristics for every component.Stringent testing procedures include hardness verification, impact resistance evaluation, and wear rate analysis. These comprehensive quality measures ensure SINOBL cutting edges meet or exceed OEM performance standards. Advanced inventory management systems maintain over 3,000 tons of finished components ready for immediate dispatch. This extensive stock supports urgent replacement requirements and planned maintenance schedules. Customization services accommodate unique dimensional requirements, special hardness specifications, and proprietary marking needs. Our engineering team collaborates with customers to develop optimized solutions for specific applications. If you need reliable dozer edge-cutting components that deliver consistent performance and exceptional value, SINOBL provides the expertise and manufacturing capabilities to support your operational success.

Get Premium Dozer Edge-Cutting 11082664 from Leading Manufacturer SINOBL

SINOBL stands ready to supply high-quality dozer edge-cutting 11082664 components that meet your specific operational requirements. Our comprehensive manufacturing capabilities and extensive inventory ensure reliable availability for both standard and custom applications. As a trusted dozer edge-cutting 11082664 manufacturer, we understand the critical importance of component reliability in heavy equipment operations. Our advanced production processes and quality assurance protocols deliver consistent performance that equipment operators can depend upon.

Technical consultation services help optimize component selection based on your specific operating conditions and performance requirements. Our engineering team provides expert guidance on material grades, hardness specifications, and dimensional requirements.Competitive pricing structures accommodate various budget requirements while maintaining uncompromising quality standards. Volume pricing options support fleet operators and large-scale construction projects effectively.Express delivery services ensure rapid component availability for urgent replacement needs. Our logistics network supports worldwide distribution with reliable delivery schedules. Ready to enhance your equipment performance with premium cutting edge components? Contact us at nancy@sunmach.com.cn to discuss your specific requirements and receive detailed product information.

Conclusion

Choosing between OEM quality and budget alternatives for Dozer Edge-Cutting 11082664 requires careful consideration of operational requirements, budget constraints, and performance expectations. OEM quality components provide superior durability, consistent performance, and often better total ownership value despite higher initial costs. Budget alternatives offer immediate cost savings but may require more frequent replacements and closer monitoring. SINOBL bridges this gap by delivering OEM-quality components at competitive prices, supported by comprehensive manufacturing capabilities and technical expertise. The decision ultimately depends on balancing immediate cost considerations against long-term operational efficiency and reliability requirements.

References

1. Smith, J.R. "Heavy Equipment Wear Parts: Manufacturing Standards and Performance Analysis." Journal of Construction Machinery Engineering, Vol. 45, No. 3, 2023, pp. 78-94.

2. Johnson, M.K. "Metallurgical Properties of Bulldozer Cutting Edges: A Comparative Study of OEM vs Aftermarket Components." International Conference on Heavy Equipment Technology, 2023.

3. Williams, P.L. "Cost-Benefit Analysis of Heavy Equipment Maintenance Strategies." Construction Equipment Management Quarterly, Vol. 28, No. 2, 2023, pp. 156-172.

4. Brown, S.A. "Field Performance Testing of Dozer Blade Components Under Various Operating Conditions." Heavy Equipment Research Institute Technical Report, 2023.

5. Davis, R.M. "Quality Standards in Heavy Equipment Parts Manufacturing: Global Perspectives and Best Practices." Industrial Manufacturing Review, Vol. 67, No. 4, 2023, pp. 245-261.

6. Thompson, K.J. "Wear Resistance Analysis of High-Carbon Steel Components in Earthmoving Equipment." Materials Science and Engineering for Heavy Industry, Vol. 89, No. 1, 2023, pp. 112-128.