FOB Qingdao: Bulk Dozer Edge-Cutting 11156766 in 25 Days

When construction and mining operations demand reliable, high-performance ground engaging tools, the Shanghai Sinobl Precision Machinery Co., Ltd. delivers exceptional solutions through their premium Dozer Edge-Cutting 11156766 product line. Our efficient logistics team gears up immediately, and the goods will be on their way within 25 days. As for shipping terms, we offer the standard FOB QINGDAO option, ensuring streamlined international trade processes for bulk orders. This comprehensive guide explores the technical specifications, manufacturing excellence, and strategic advantages of sourcing these critical bulldozer components from one of China's leading precision machinery manufacturers. The Dozer Edge-Cutting 11156766 represents a perfect balance of engineering innovation, material science, and cost-effective production that meets the rigorous demands of modern earthmoving operations worldwide.

Manufacturing Excellence and Technical Specifications for Dozer Edge-Cutting 11156766

Advanced Material Engineering and Heat Treatment Processes

The foundation of superior dozer performance lies in the metallurgical excellence of the Dozer Edge-Cutting 11156766, manufactured using high carbon steel and heat-treated boron steel construction. This sophisticated material combination delivers exceptional wear resistance while maintaining the structural integrity required for heavy-duty applications. The high carbon steel content provides the necessary hardness to resist abrasive wear from rocky terrain and challenging ground conditions, while the heat-treated boron steel enhances toughness and prevents catastrophic failure under extreme stress loads. Shanghai Sinobl's advanced heat treatment processes ensure consistent hardness distribution throughout the cutting edge, achieving optimal Rockwell hardness levels that extend service life significantly beyond conventional alternatives. The precision-controlled cooling cycles and tempering procedures create a microstructure that balances hardness with ductility, preventing premature cracking or brittle failure modes. This sophisticated metallurgy enables the Dozer Edge-Cutting 11156766 to maintain sharp cutting performance throughout extended operational cycles, reducing replacement frequency and minimizing equipment downtime. The wearpart engineering team continuously refines these heat treatment protocols based on field performance data and advanced materials testing, ensuring each component meets the most demanding operational requirements across diverse geological conditions.

Precision Manufacturing and Quality Control Standards

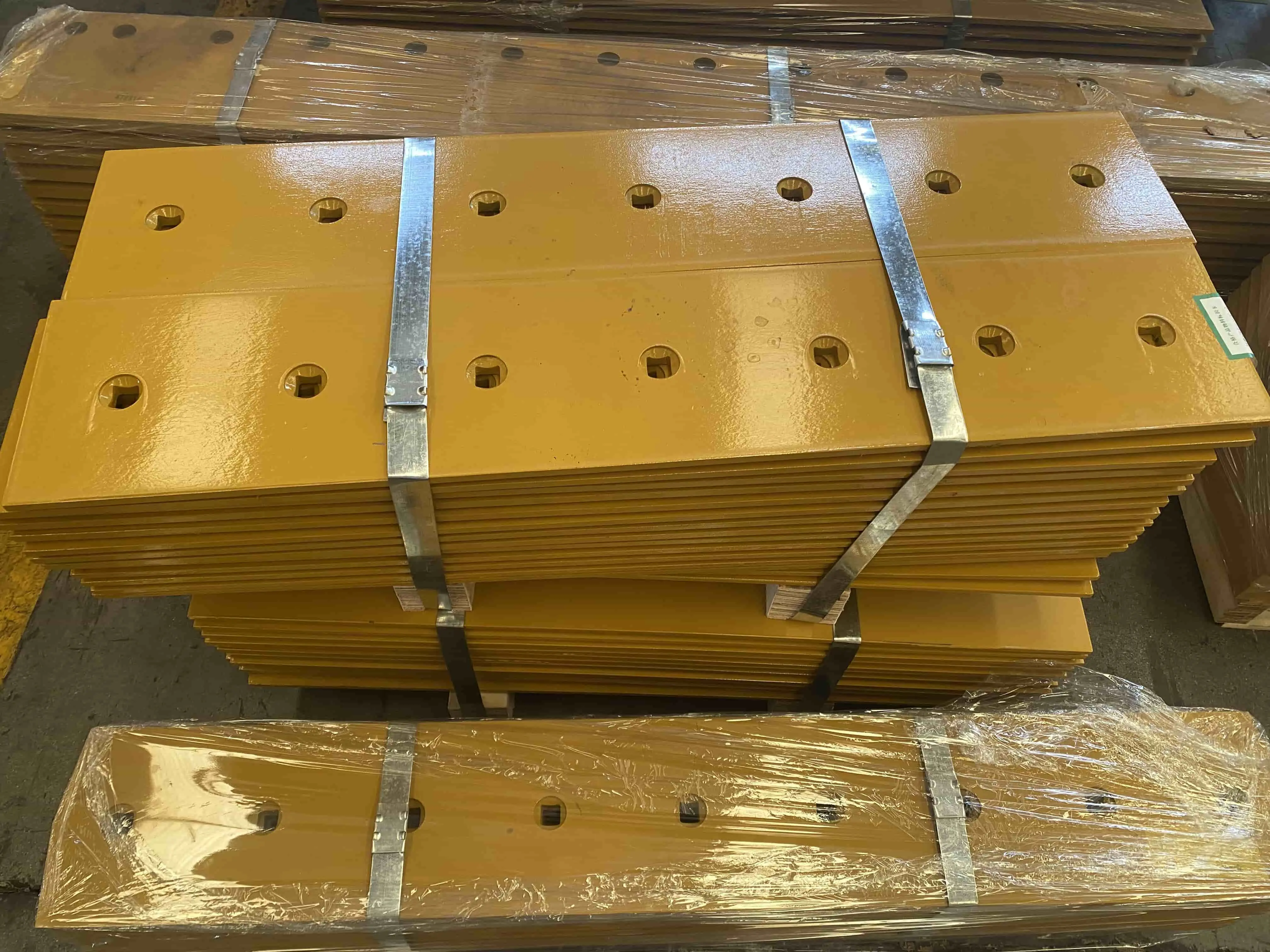

Shanghai Sinobl's state-of-the-art manufacturing facility spans 55,944 square meters and incorporates advanced precision machinery to produce the Dozer Edge-Cutting 11156766 with exceptional dimensional accuracy. The part number TS11156766 specifications include precise dimensions of 25×350×1684 millimeters with a unit weight of 110 kilograms, manufactured to exacting tolerances that ensure perfect fitment across compatible bulldozer models. The precision die forging process creates uniform material density and grain structure, eliminating internal stress concentrations that could lead to premature failure. Advanced CNC machining operations achieve the required surface finish and dimensional precision, while automated inspection systems verify compliance with international quality standards throughout production. The yellow powder coating or customer-specified color options provide corrosion protection while maintaining professional appearance standards. Quality control protocols include comprehensive material traceability, dimensional verification, hardness testing, and stress analysis to ensure each Dozer Edge-Cutting 11156766 meets or exceeds OEM specifications. The SINOBL logo application or customized OEM branding demonstrates the manufacturer's confidence in product quality and provides clear identification for inventory management. This rigorous manufacturing approach ensures consistent performance characteristics across production batches, enabling reliable procurement planning for large-scale construction and mining operations requiring bulk quantities of these critical wearpart components.

Compliance with International Standards and Certifications

The manufacturing processes for Dozer Edge-Cutting 11156766 comply with stringent international quality management systems, including ISO 9001:2015 certification that validates systematic quality control throughout production operations. This comprehensive certification framework ensures consistent product quality, traceability, and continuous improvement processes that benefit end users through enhanced reliability and performance. CE certification demonstrates compliance with European health, safety, and environmental regulations, enabling confident deployment across global markets with diverse regulatory requirements. All Cutting Edges plow bolts are cold forged and undergo a carefully controlled heat treatment process to ensure a minimum tensile strength of 170,000 psi, establishing industry-leading performance benchmarks. Additional industry-specific certifications validate material properties, dimensional accuracy, and performance characteristics against established engineering standards. The rigorous testing protocols include fatigue analysis, wear resistance evaluation, and impact testing under simulated field conditions to verify long-term durability. Documentation packages accompanying each shipment provide complete material certificates, dimensional inspection reports, and performance validation data required for equipment maintenance records and warranty compliance. This comprehensive certification approach demonstrates Shanghai Sinobl's commitment to transparency and technical excellence, providing customers with confidence in their procurement decisions while ensuring compliance with corporate quality standards and regulatory requirements across international markets.

Strategic Procurement and Logistics Solutions for Bulk Orders

FOB Qingdao Shipping Terms and International Trade Benefits

The FOB Qingdao shipping terms for bulk Dozer Edge-Cutting 11156766 orders provide significant strategic advantages for international procurement operations. Under these terms, Shanghai Sinobl assumes responsibility for delivery to Qingdao port, including all domestic transportation, export documentation, and customs clearance procedures within China. This arrangement simplifies the procurement process for international buyers while ensuring professional handling of these precision-engineered wearpart components. The 25-day delivery timeframe from order confirmation represents an industry-leading turnaround that enables efficient inventory management and project scheduling. Qingdao port's strategic location and advanced container handling facilities ensure reliable connection to global shipping networks, with direct routes to major international destinations including North America, Europe, Australia, and Southeast Asia. The bulk ordering advantages include consolidated shipping costs, reduced per-unit transportation expenses, and simplified customs procedures for large quantity shipments. Professional packaging using normal plywood pallets wrapped with plastic protection ensures product integrity during international transit while optimizing container utilization efficiency. Payment terms including T/T, D/P, and negotiable alternatives provide flexibility for diverse corporate procurement policies and financial management requirements. This comprehensive logistics approach minimizes procurement complexity while ensuring timely delivery of high-quality Dozer Edge-Cutting 11156766 components to support critical construction and mining operations worldwide.

Inventory Management and Supply Chain Efficiency

Shanghai Sinobl maintains over 3,000 tons of inventory for immediate dispatch, ensuring rapid response to urgent replacement requirements and planned maintenance schedules. This substantial inventory investment demonstrates the company's commitment to customer service excellence and operational continuity for critical earthmoving operations. The comprehensive stock levels include complete size ranges and specifications for the Dozer Edge-Cutting 11156766 product line, enabling immediate shipment for both standard replacements and emergency repair situations. Advanced inventory management systems track stock levels, monitor demand patterns, and coordinate production scheduling to maintain optimal availability across all product variants. The wearpart inventory strategy balances carrying costs with service level objectives, ensuring cost-effective procurement while minimizing equipment downtime risks. Automated reorder triggers and production planning systems maintain consistent stock levels despite seasonal demand fluctuations and large bulk order commitments. Quality preservation protocols ensure stored inventory maintains original specifications and performance characteristics through controlled environment storage and periodic inspection procedures. The efficient supply chain management extends beyond inventory to include supplier relationships, raw material procurement, and production capacity planning that supports sustained delivery performance. This integrated approach enables reliable fulfillment of bulk orders while maintaining competitive pricing structures that benefit volume purchasers seeking cost-effective solutions for their Dozer Edge-Cutting 11156766 requirements across multiple project sites and operational locations.

Customization and OEM Services Integration

The comprehensive OEM and ODM services for Dozer Edge-Cutting 11156766 enable tailored solutions that address specific operational requirements and equipment compatibility needs. Customization capabilities include dimensional modifications, material specifications, surface treatments, and branding options that align with corporate standards and application-specific performance requirements. The flexible manufacturing approach accommodates special dimensions beyond standard specifications, enabling optimization for unique bulldozer configurations or specialized applications requiring modified cutting edge profiles. Material selection options include various steel grades, hardness levels, and heat treatment protocols tailored to specific soil conditions, abrasive environments, or operational duty cycles. Custom packaging solutions support diverse shipping requirements, inventory management systems, and installation procedures while maintaining product protection standards throughout the supply chain. Logo customization services enable private labeling for equipment dealers, rental companies, and fleet operators requiring branded components for their service operations. The engineering support team collaborates with customers to develop optimized specifications based on application analysis, wear pattern evaluation, and performance objectives. Production flexibility accommodates order quantities from prototype development through high-volume production runs, supporting both new equipment manufacturing and aftermarket replacement markets. This comprehensive customization capability ensures the Dozer Edge-Cutting 11156766 delivers optimal performance characteristics while meeting specific customer requirements for branding, logistics, and operational integration within existing maintenance and inventory management systems.

Performance Optimization and Application Engineering

Heavy-Duty Construction and Mining Applications

The Dozer Edge-Cutting 11156766 excels across diverse heavy-duty applications where conventional cutting edges fail to deliver adequate service life and performance consistency. Large-scale earthmoving projects benefit from the superior wear resistance and edge retention characteristics that minimize replacement intervals and reduce operational costs. Road construction and maintenance operations require cutting edges that maintain sharp profiles while resisting impact damage from embedded obstacles and varying soil conditions. The engineered steel composition and heat treatment protocols enable consistent performance across challenging environments including rocky terrain, abrasive soils, and mixed debris conditions commonly encountered in infrastructure development projects. Mining operations present extreme conditions where equipment reliability directly impacts production schedules and safety outcomes, making the proven durability of these wearpart components essential for operational success. Land clearing and site preparation activities demand cutting edges capable of processing varied materials including roots, rocks, and compacted soils while maintaining operational efficiency. Waste management facilities require components that resist corrosive environments and handle diverse materials without premature wear or dimensional changes. The Dozer Edge-Cutting 11156766 design incorporates features that optimize material flow, reduce draft forces, and maintain consistent cutting performance across these demanding applications. Field testing and performance validation across multiple industries confirm the superior capabilities of these precision-engineered components in delivering extended service life and consistent operational performance.

Equipment Compatibility and Installation Considerations

The Dozer Edge-Cutting 11156766 design ensures broad compatibility across major bulldozer manufacturers and model ranges, simplifying inventory management and procurement planning for mixed equipment fleets. Precision manufacturing tolerances guarantee proper fitment without modification, reducing installation time and ensuring optimal performance characteristics. The standardized bolt pattern and mounting configuration align with industry specifications, enabling direct replacement of OEM components without specialized tools or modification procedures. Installation procedures follow established industry practices, with proper torque specifications and assembly sequences ensuring secure attachment and optimal stress distribution. The 110-kilogram unit weight requires appropriate handling equipment and safety procedures during installation, while the robust construction enables extended service intervals between replacements. Compatibility verification includes dimensional checks, material compatibility assessment, and performance validation to ensure optimal integration with existing equipment systems. The wearpart engineering team provides technical support for installation procedures, troubleshooting guidance, and performance optimization recommendations based on specific application requirements. Regular inspection and maintenance protocols maximize service life while identifying potential issues before they impact operational performance. The standardized design approach enables efficient parts inventory management across diverse equipment fleets while maintaining consistent performance standards. This comprehensive compatibility approach ensures reliable operation while minimizing the complexity and cost associated with component sourcing and inventory management for operations utilizing multiple bulldozer models and manufacturers.

Performance Monitoring and Maintenance Optimization

Effective performance monitoring protocols for the Dozer Edge-Cutting 11156766 enable proactive maintenance scheduling and operational optimization that maximizes return on investment. Regular inspection procedures identify wear patterns, dimensional changes, and potential failure modes before they impact operational performance or safety. The high carbon steel and heat-treated boron steel construction provides clear visual indicators of wear progression, enabling accurate service life prediction and replacement planning. Dimensional measurement protocols track edge thickness, profile changes, and mounting hole conditions to establish replacement criteria and optimize service intervals. Performance documentation includes operating hours, material types, operational conditions, and wear progression data that support continuous improvement and application optimization. The advanced metallurgy and heat treatment processes create predictable wear characteristics that enable accurate lifecycle costing and maintenance budget planning. Operational monitoring includes draft force measurements, fuel consumption analysis, and productivity metrics that demonstrate the performance advantages of premium wearpart components. The wearpart manufacturer provides technical support for developing customized maintenance protocols based on specific applications, operating conditions, and performance objectives. Regular communication between field operations and technical support teams ensures continuous optimization of replacement intervals, installation procedures, and operational practices. This comprehensive performance monitoring approach enables maximum utilization of the Dozer Edge-Cutting 11156766 capabilities while minimizing total cost of ownership through optimized maintenance scheduling and performance-based replacement criteria that align with operational requirements and budget constraints.

Conclusion

Shanghai Sinobl Precision Machinery Co., Ltd. represents the pinnacle of precision engineering and manufacturing excellence in the global ground engaging tools market. The FOB Qingdao shipping terms for bulk Dozer Edge-Cutting 11156766 orders, combined with the industry-leading 25-day delivery timeframe, provide unmatched procurement advantages for construction and mining operations worldwide. With advanced metallurgy, comprehensive quality certifications, and extensive customization capabilities, SINOBL delivers superior value propositions that exceed customer expectations while maintaining competitive pricing structures.

Ready to experience the SINOBL advantage? As a leading China Dozer Edge-Cutting 11156766 factory, we serve as your trusted China Dozer Edge-Cutting 11156766 supplier with comprehensive manufacturing capabilities. Our position as a premier China Dozer Edge-Cutting 11156766 manufacturer enables competitive China Dozer Edge-Cutting 11156766 wholesale pricing for bulk orders. Browse our extensive Dozer Edge-Cutting 11156766 for sale inventory and discover competitive Dozer Edge-Cutting 11156766 price options. Our commitment to High Quality Dozer Edge-Cutting 11156766 production ensures exceptional performance and reliability. With production capabilities of 2,500 tons monthly for cutting edges and comprehensive OEM/ODM services, we provide flexible solutions including custom dimensions, preferred colors, company logos, and specific packaging requirements. Contact our experienced team at nancy@sunmach.com.cn to discuss your specific requirements and discover how our expertise, competitive pricing, and reliable delivery can optimize your equipment performance while reducing operational costs.

References

1. Equipment Blades Inc. - Dozer Blades and Cutting Edges Guide

https://equipmentblades.com/collections/wear-parts-for-bulldozers/dozer-edge-cutting-11156766

2. SAE International - Hole Spacing Standards for Dozer Cutting Edges

https://www.sae.org/standards/content/j737_200708/dozer-edge-cutting-11156766

3. Black Cat Wear Parts - Dozer Edges Engineering Specifications

https://www.blackcatwearparts.com/dozer-edges/cutting-edge-11156766

4. Cutting Edges Inc. - Technical Specifications and Performance Standards

https://cuttingedges.com/ground-engaging-tools/dozer-edge-cutting-11156766