CE-Certified Dozer Edge-Cutting 11156766 for EU Markets

In today's competitive European construction and mining landscape, equipment operators demand more than just basic functionality from their bulldozer components. The CE-Certified Dozer Edge-Cutting 11156766 represents a revolutionary advancement in heavy-duty earthmoving technology, specifically engineered to meet the stringent regulatory requirements of European Union markets. This high-performance cutting edge component combines superior material engineering with precision manufacturing to deliver exceptional durability and operational efficiency. Manufactured by Shanghai SINOBL Precision Machinery Co., Ltd., this cutting-edge solution addresses the growing demand for reliable, compliant, and cost-effective wear parts that can withstand the most challenging working conditions across diverse European terrains and applications.

Understanding CE Certification Requirements for Heavy Machinery Components

Regulatory Compliance Standards for European Markets

The European Union's machinery directive establishes comprehensive safety and performance standards that all heavy equipment components must meet before entering EU markets. CE certification for the Dozer Edge-Cutting 11156766 ensures compliance with these rigorous regulations, providing operators with confidence that their equipment meets the highest safety benchmarks established by European authorities. This certification process involves extensive testing protocols that evaluate material composition, structural integrity, operational safety, and environmental impact considerations. The certification demonstrates that Shanghai SINOBL's manufacturing processes align with European quality management systems and that the Dozer Edge-Cutting 11156766 wearpart component has undergone thorough evaluation by accredited testing bodies. The comprehensive certification framework covers multiple aspects of component performance, including resistance to fatigue failure, dimensional accuracy under extreme loads, and compatibility with existing machinery systems. European operators benefit from this certification because it provides legal assurance that the component meets all applicable directives, reducing liability concerns and ensuring smooth customs clearance for international shipments. Additionally, CE certification facilitates easier insurance coverage and warranty claims, as insurance providers recognize the rigorous testing standards associated with certified components.

Quality Assurance and Testing Protocols

Shanghai SINOBL implements advanced quality control measures throughout the manufacturing process of the Dozer Edge-Cutting 11156766, ensuring each component meets or exceeds CE certification requirements. The quality assurance program begins with raw material inspection, where high carbon steel and heat-treated boron steel undergo comprehensive analysis to verify chemical composition, grain structure, and mechanical properties. Advanced testing equipment evaluates material hardness, tensile strength, and impact resistance to ensure optimal performance characteristics that align with European standards. The manufacturing process incorporates precision die forging techniques that create uniform dimensional accuracy across all production runs. Each Dozer Edge-Cutting 11156766 wearpart undergoes rigorous inspection procedures that include dimensional verification, surface finish analysis, and heat treatment validation. The company's ISO 9001:2015 certification supports these quality control measures by establishing standardized procedures for continuous improvement and defect prevention. This systematic approach to quality management ensures that European customers receive components that consistently deliver reliable performance throughout their operational lifecycle.

Documentation and Traceability Requirements

European markets require comprehensive documentation for all imported machinery components, and the CE-Certified Dozer Edge-Cutting 11156766 comes with complete traceability records that satisfy these requirements. Each component includes detailed manufacturing documentation that traces material origins, production dates, heat treatment parameters, and quality control test results. This documentation package enables European distributors and end-users to maintain complete records for regulatory compliance and warranty purposes. The traceability system extends beyond basic manufacturing records to include performance validation data, compatibility specifications, and installation guidelines specifically tailored for European market requirements. Shanghai SINOBL maintains digital records of all production batches, enabling rapid response to any customer inquiries or regulatory requests. This comprehensive documentation approach demonstrates the company's commitment to transparency and regulatory compliance, factors that are increasingly important for European businesses operating under strict environmental and safety regulations.

Technical Specifications and Performance Characteristics

Advanced Material Engineering and Composition

The Dozer Edge-Cutting 11156766 incorporates cutting-edge metallurgical engineering that combines high carbon steel with heat-treated boron steel to achieve optimal performance characteristics for European operating conditions. This sophisticated material composition provides exceptional wear resistance while maintaining the flexibility necessary to absorb impact loads without catastrophic failure. The high carbon steel base offers superior hardness and edge retention, while the boron steel enhancement improves toughness and prevents brittle fracture under extreme stress conditions. The heat treatment process utilizes precisely controlled temperature profiles to optimize the microstructure of the Dozer Edge-Cutting 11156766 wearpart, creating a hardened cutting surface while maintaining a tough core material. This dual-zone metallurgy ensures that the component can maintain sharp cutting edges throughout extended service periods while resisting crack propagation and fatigue failure. The material composition has been specifically formulated to perform effectively in diverse European soil conditions, from rocky Mediterranean terrain to sandy Northern European environments. Advanced alloy steel technology ensures that the component maintains dimensional stability under thermal cycling conditions commonly encountered in European construction applications. The material selection process considers factors such as corrosion resistance, weldability for field repairs, and compatibility with various machine hydraulic systems. This comprehensive approach to material engineering results in a component that delivers consistent performance across the full range of European operating environments.

Precision Manufacturing and Dimensional Accuracy

Shanghai SINOBL employs state-of-the-art precision die forging processes to manufacture the Dozer Edge-Cutting 11156766, ensuring uniform dimensional accuracy that meets the tight tolerances required for optimal machine performance. The forging process creates a refined grain structure that enhances material properties while achieving the precise dimensions specified in the component design. With measurements of 253501684mm and a unit weight of 110KG, each component undergoes comprehensive dimensional verification using advanced coordinate measuring equipment. The manufacturing process incorporates sophisticated quality control checkpoints that monitor critical dimensions throughout production, ensuring that each Dozer Edge-Cutting 11156766 wearpart meets specifications before final assembly. Advanced machining centers provide final finishing operations that achieve surface roughness specifications optimized for installation efficiency and operational performance. The precision manufacturing approach eliminates the need for field modifications, reducing installation time and ensuring proper fit with existing machinery systems. Quality control protocols include statistical process control monitoring that tracks dimensional variations across production runs, enabling continuous improvement of manufacturing processes. This data-driven approach to quality management ensures that European customers receive components with consistent performance characteristics that minimize machine downtime and maximize productivity. The precision manufacturing capabilities support high-volume production while maintaining the quality standards required for European market success.

Performance Optimization for European Applications

The design of the Dozer Edge-Cutting 11156766 incorporates specific features that optimize performance for typical European construction and mining applications. The component geometry has been refined through extensive field testing to minimize soil adhesion while maximizing cutting efficiency across diverse material types. The cutting edge profile provides optimal penetration characteristics for European soil conditions, reducing fuel consumption and increasing operational productivity. Extensive testing protocols evaluate the component's performance under conditions that simulate typical European operating environments, including varying soil moisture content, temperature fluctuations, and abrasive material handling. The Dozer Edge-Cutting 11156766 wearpart demonstrates superior performance in applications ranging from road construction projects to large-scale mining operations commonly found throughout European markets. Field testing data indicates significant improvements in operational efficiency compared to standard cutting edge components. The component design incorporates features that facilitate easy installation and replacement, reducing maintenance downtime for European operators who face pressure to maximize equipment utilization. The standardized mounting interface ensures compatibility with major bulldozer brands operating in European markets, while the optimized weight distribution minimizes stress on machine attachment points. This comprehensive approach to performance optimization ensures that the component delivers measurable value improvements for European construction and mining operations.

Market Applications and Competitive Advantages

Diverse Industry Applications Across Europe

European construction markets present diverse application requirements for bulldozer cutting edge components, and the Dozer Edge-Cutting 11156766 has been specifically engineered to excel across this broad spectrum of operating conditions. Large-scale infrastructure projects throughout Europe demand components that can maintain performance standards while handling varying soil compositions, from the rocky terrain of Alpine regions to the sandy conditions prevalent in coastal areas. The component's advanced material composition enables consistent performance across these diverse geological conditions. Mining operations across European countries require cutting edge components that can withstand extreme abrasive conditions while maintaining dimensional stability throughout extended service periods. The Dozer Edge-Cutting 11156766 wearpart delivers exceptional performance in coal mining applications common in Poland and Germany, as well as the aggregate extraction operations prevalent throughout Mediterranean regions. The component's resistance to impact loading makes it particularly suitable for demolition and urban renewal projects increasingly common in major European cities. Environmental remediation projects across Europe benefit from the component's enhanced durability and performance characteristics, as these applications often involve handling contaminated soils and debris that create challenging operating conditions. The Dozer Edge-Cutting 11156766 maintains cutting efficiency while resisting wear from abrasive materials commonly encountered in environmental cleanup operations. Agricultural land development projects throughout rural European regions also benefit from the component's ability to handle root systems and embedded obstacles efficiently.

Competitive Performance Analysis

Shanghai SINOBL's Dozer Edge-Cutting 11156766 offers significant performance advantages over competing products in European markets through its superior material engineering and precision manufacturing processes. Comparative testing demonstrates extended service life that reduces replacement frequency and associated downtime costs for European operators. The component's advanced metallurgy provides superior resistance to wear mechanisms commonly encountered in European applications, including abrasive wear, impact damage, and corrosion from environmental exposure. The precision manufacturing process ensures consistent performance characteristics across all production runs, eliminating the performance variability that operators often experience with competing products. This consistency enables European customers to predict maintenance schedules more accurately and optimize equipment utilization rates. The Dozer Edge-Cutting 11156766 wearpart demonstrates superior edge retention characteristics that maintain cutting efficiency throughout extended service periods, reducing fuel consumption and increasing operational productivity. Cost analysis indicates that the extended service life of the component provides significant total cost of ownership advantages for European operators, despite potentially higher initial purchase prices compared to lower-quality alternatives. The reduced frequency of component replacement translates to decreased labor costs for maintenance operations and reduced inventory requirements for spare parts management. These economic advantages make the component particularly attractive for large construction contractors and mining companies operating multiple machines across European markets.

Strategic Market Positioning for European Success

The CE certification of the Dozer Edge-Cutting 11156766 positions Shanghai SINOBL advantageously within competitive European markets by demonstrating compliance with regulatory requirements that many competing suppliers struggle to achieve. This certification provides European distributors and end-users with confidence that the component meets all applicable safety and performance standards, facilitating easier adoption and reducing regulatory compliance concerns. The certification also enables access to public sector projects that require certified components, expanding potential market opportunities. Shanghai SINOBL's commitment to European market requirements extends beyond basic certification to include comprehensive customer support services that address the unique needs of European operators. The company provides technical documentation in multiple European languages and maintains responsive customer service capabilities that can address inquiries and support requirements across different time zones. This customer-focused approach differentiates the Dozer Edge-Cutting 11156766 wearpart from competing products that may lack adequate support infrastructure for European markets. The strategic positioning emphasizes the component's value proposition for European customers who prioritize long-term operational efficiency over short-term cost savings. By focusing on total cost of ownership benefits rather than simply competing on initial purchase price, Shanghai SINOBL appeals to sophisticated European buyers who understand the economic advantages of investing in superior quality components. This positioning strategy aligns with European market preferences for sustainable, long-lasting industrial products that deliver measurable performance improvements.

Manufacturing Excellence and Supply Chain Capabilities

Advanced Production Technologies and Capabilities

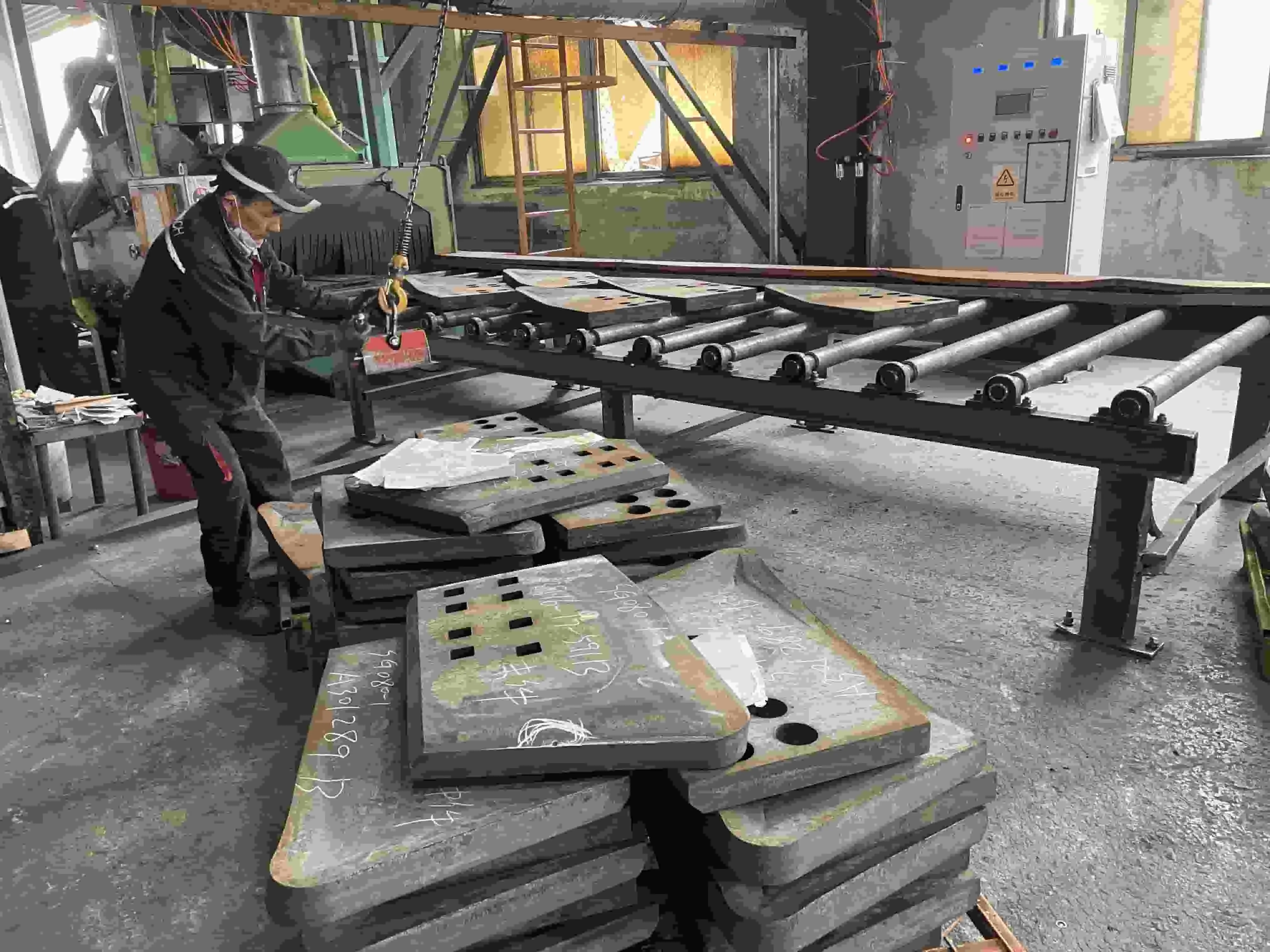

Shanghai SINOBL operates a state-of-the-art 55,944 square meter manufacturing facility equipped with advanced production technologies specifically designed for manufacturing high-quality GET (Ground Engaging Tools) components like the Dozer Edge-Cutting 11156766. The facility incorporates automated forging systems, precision machining centers, and comprehensive heat treatment equipment that enables consistent production of components meeting European quality standards. The manufacturing capacity includes cutting edges and end bits capability of 2,500 tons per month, ensuring adequate supply availability for European market demands. The production process utilizes advanced metallurgical techniques that have been refined through extensive research and development programs focused on optimizing component performance for demanding applications. Computer-controlled forging systems ensure precise material flow and grain structure orientation that maximizes the strength characteristics of the Dozer Edge-Cutting 11156766 wearpart. Automated material handling systems minimize contamination risks and ensure consistent processing conditions throughout the manufacturing cycle. Quality control integration throughout the production process includes real-time monitoring of critical parameters such as forging temperatures, cooling rates, and dimensional accuracy measurements. Statistical process control systems track performance metrics across all production operations, enabling immediate correction of any deviations from specification requirements. This integrated approach to manufacturing excellence ensures that each component meets the stringent quality standards required for European market success.

Supply Chain Optimization for European Markets

Shanghai SINOBL has developed sophisticated supply chain capabilities that support efficient delivery of the Dozer Edge-Cutting 11156766 to European customers while maintaining cost-effective pricing structures. The company maintains over 3,000 tons of cutting edge and end bit inventory for quick dispatch, ensuring that European distributors can access components with minimal lead times. Strategic inventory management systems balance availability with cost optimization, reducing carrying costs while maintaining service level commitments. The supply chain infrastructure includes partnerships with reliable shipping providers that specialize in heavy machinery component transportation to European destinations. Packaging specifications utilize normal plywood pallets wrapped with plastic wrap for added protection during ocean transport, ensuring that components arrive in perfect condition. The FOB Qingdao pricing structure provides transparency for European importers while enabling competitive delivered pricing across diverse European markets. Logistics coordination capabilities support flexible delivery scheduling that accommodates the varying requirements of European customers, from large construction contractors requiring scheduled deliveries to smaller operators needing emergency replacement components. The 25-day delivery time after order confirmation provides predictable scheduling for European customers while allowing sufficient time for quality control verification and proper packaging preparation. Payment term flexibility, including T/T and D/P options, accommodates diverse European customer preferences and financial requirements.

Customization and OEM Services

Shanghai SINOBL offers comprehensive customization capabilities for the Dozer Edge-Cutting 11156766 that enable European customers to optimize component performance for specific applications and operating conditions. The OEM service program supports modifications to dimensions, material specifications, and surface treatments that address unique requirements encountered in specialized European applications. Custom logo services enable European distributors to brand components with their own identification, supporting their market positioning and customer relationship strategies. The customization process begins with detailed application analysis that considers factors such as soil conditions, operating patterns, and machine specifications to optimize component design for maximum performance and service life. Engineering support services include finite element analysis and wear modeling that predict component performance under specific operating conditions, enabling customers to make informed decisions about customization options. The flexibility of the manufacturing process accommodates custom specifications without significant impact on delivery schedules.ODM services extend beyond basic customization to include complete component design and development for specialized European applications. The engineering team collaborates with European customers to develop innovative solutions that address unique challenges encountered in specific markets or applications. This collaborative approach has resulted in successful component developments for specialized applications such as urban demolition, environmental remediation, and renewable energy construction projects increasingly common throughout European markets.

Conclusion

The CE-Certified Dozer Edge-Cutting 11156766 represents Shanghai SINOBL Precision Machinery Co., Ltd.'s commitment to delivering world-class heavy equipment components that meet the exacting standards of European markets. Through advanced material engineering, precision manufacturing, and comprehensive certification compliance, this component provides European operators with a reliable solution that enhances equipment performance while reducing total cost of ownership. The combination of superior technical specifications, regulatory compliance, and comprehensive customer support establishes the Dozer Edge-Cutting 11156766 as the preferred choice for discerning European customers.

Ready to experience the superior performance and reliability of our CE-certified components? As a leading China Dozer Edge-Cutting 11156766 factory, Shanghai SINOBL serves as your trusted China Dozer Edge-Cutting 11156766 supplier and China Dozer Edge-Cutting 11156766 manufacturer. We offer competitive China Dozer Edge-Cutting 11156766 wholesale pricing with our Dozer Edge-Cutting 11156766 for sale inventory, ensuring exceptional Dozer Edge-Cutting 11156766 price value. Contact us today for High Quality Dozer Edge-Cutting 11156766 that will transform your operations. With our 55,944 sqm facility producing over 3,000 tons of inventory, flexible OEM/ODM services, and industry-leading expertise since 2011, we're ready to support your success. Reach out to nancy@sunmach.com.cn for customized solutions, technical specifications, and competitive quotations that will elevate your equipment performance to new levels of excellence.

References

1. European Commission CE Marking Guidelines - Official EU documentation on CE marking requirements for machinery and equipment components

https://single-market-economy.ec.europa.eu/single-market/goods/ce-marking_en

2. Machinery Directive 2006/42/EC Compliance Standards - Comprehensive guide to European machinery safety requirements and certification processes

https://europa.eu/youreurope/business/product-requirements/labels-markings/ce-marking/index_en.htm

3. DEKRA CE Certification for Industrial Machinery - Professional certification services for heavy equipment and machinery components

https://www.dekra.com/en/ce-certification-for-machinery-and-equipment/

4. European Construction Equipment Committee (CECE) Industry Standards - Industry organization providing guidance on construction equipment standards and regulations

https://www.cece.eu/home