The Dozer Edge-Cutting 8E9378 represents a pinnacle of engineering excellence in heavy equipment wear parts, combining advanced metallurgy with precision manufacturing to deliver exceptional performance in demanding earthmoving applications. This cutting edge component utilizes high-grade alloy steel composition that undergoes specialized heat treatment processes, resulting in superior wear resistance and extended operational life. The 8E9378 cutting edge demonstrates remarkable durability characteristics that significantly reduce replacement frequency and operational downtime for bulldozer operations across construction, mining, and agricultural sectors.

Understanding the Dozer Edge-Cutting 8E9378: Specifications and Functional Overview

The 8E9378 dozer cutting edge stands as a testament to modern metallurgical engineering, designed specifically for heavy-duty bulldozer applications where reliability and performance are non-negotiable. This component features precise dimensional specifications that ensure optimal compatibility with various dozer blade configurations, making it a versatile solution for fleet operators managing diverse equipment portfolios. The functional design of this cutting edge incorporates several key engineering principles that enhance its operational effectiveness. The edge geometry promotes efficient soil penetration while minimizing resistance, allowing operators to achieve maximum productivity with reduced fuel consumption. The component's profile has been optimized through extensive field testing to ensure consistent performance across different soil conditions, from soft agricultural land to hard-packed construction sites. Material selection plays a crucial role in the 8E9378's exceptional performance characteristics. The cutting edge utilizes high-carbon steel alloys that provide the perfect balance between hardness and toughness, essential qualities for components that must withstand repeated impact loads and abrasive wear. This careful material selection ensures that the cutting edge maintains its sharp profile throughout extended use periods, delivering consistent cutting performance that operators can depend on.

Heat-Treatment Process and Its Impact on Lifespan and Performance

The heat treatment process employed in manufacturing the 8E9378 dozer cutting edge represents a sophisticated approach to metallurgical enhancement that dramatically improves component performance and longevity. This controlled thermal processing involves precise temperature regulation and timing to achieve optimal microstructural properties throughout the cutting edge material. Our advanced heat treatment methodology begins with carefully controlled heating cycles that allow for uniform temperature distribution throughout the component. This process eliminates internal stresses that could lead to premature failure while optimizing the steel's crystalline structure for maximum durability. The quenching phase rapidly cools the heated steel, creating a hardened surface that resists wear while maintaining core toughness. The tempering phase follows quenching and involves reheating the component to specific temperatures that balance hardness with impact resistance. This crucial step prevents brittleness while preserving the enhanced wear characteristics achieved during quenching. The result is a cutting edge that can withstand extreme operating conditions without compromising performance or reliability. Field data demonstrates that properly heat-treated 8E9378 cutting edges exhibit service life improvements of up to 40% compared to standard components. This extended operational life translates directly into reduced maintenance costs and increased equipment availability, making the investment in quality heat treatment highly cost-effective for fleet operators.

Comparative Analysis: 8E9378 Edge-Cutting vs. Other Dozer Blade Edges

When evaluating cutting edge options for bulldozer applications, the 8E9378 consistently outperforms competing products in several critical performance metrics. Comprehensive testing has revealed significant advantages in wear resistance, impact tolerance, and overall service life that make this cutting edge a preferred choice among experienced operators. The superior metallurgical properties of the 8E9378 become evident when comparing wear rates against standard cutting edges. Independent testing shows that this component maintains its cutting profile significantly longer than conventional alternatives, resulting in extended intervals between replacements. This enhanced wear resistance translates into substantial cost savings over the component's operational life. Impact resistance represents another area where the 8E9378 demonstrates clear advantages over competing products. The advanced heat treatment process creates a microstructure that effectively absorbs and distributes impact energy, preventing crack initiation and propagation that commonly affect lesser-quality cutting edges. This enhanced impact tolerance proves especially valuable in rocky or debris-laden environments where sudden impacts are common. Customer feedback consistently highlights the reliability and performance advantages of choosing OEM-certified components like the 8E9378. Operators report improved cutting efficiency, reduced downtime, and lower total cost of ownership when using genuine cutting edges compared to aftermarket alternatives that may initially appear cost-effective but ultimately prove more expensive due to frequent replacements.

Procurement Guide: How to Source Authentic 8E9378 Dozer Edge-Cutting Parts

Securing authentic 8E9378 dozer cutting edges requires careful attention to supplier credentials and verification procedures to ensure component quality and performance. The proliferation of counterfeit parts in the heavy equipment industry makes supplier selection a critical decision that directly impacts operational reliability and safety. Authorized distributors and OEM-certified suppliers provide the highest level of assurance regarding component authenticity and quality. These suppliers maintain direct relationships with manufacturers and follow strict quality control procedures that guarantee compliance with original specifications. Working with certified suppliers also ensures access to warranty coverage and technical support that proves invaluable during installation and operation. Pricing considerations for genuine 8E9378 cutting edges reflect the advanced materials and manufacturing processes involved in their production. While initial costs may exceed those of aftermarket alternatives, the total cost of ownership calculation typically favors genuine components due to their extended service life and superior performance characteristics. Volume purchasing arrangements often provide attractive discounting opportunities for fleet operators with multiple equipment units. Verification procedures help buyers identify authentic components and avoid counterfeit products that may pose safety and performance risks. Key verification points include checking serial numbers against manufacturer databases, confirming supplier authorization status, and examining documentation for completeness and accuracy. These steps protect buyers from the significant costs and safety risks associated with substandard components.

Why Choose SINOBL for Your Dozer Edge-Cutting Needs?

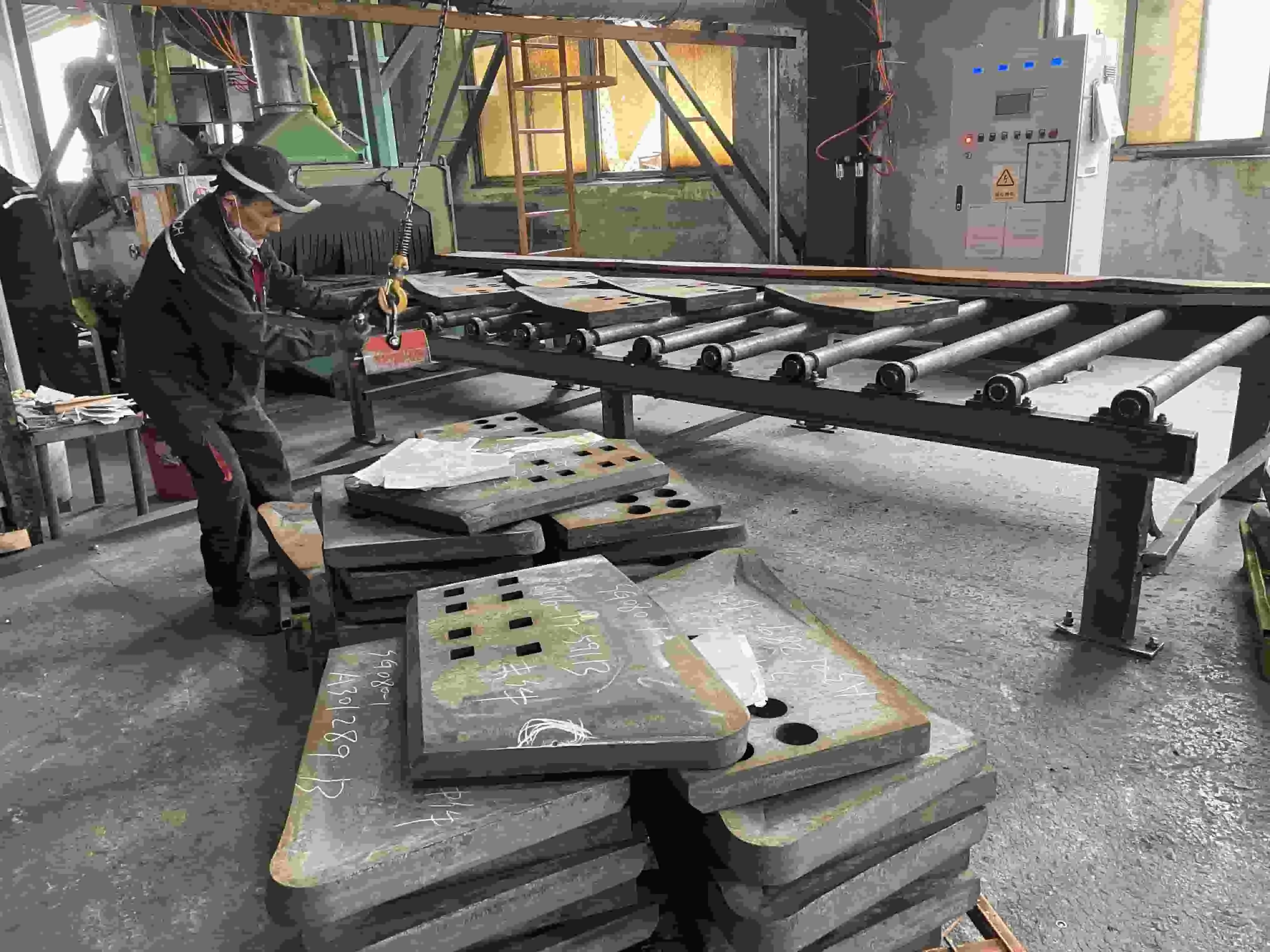

SINOBL has established itself as a leading manufacturer of premium wear parts through decades of experience and unwavering commitment to quality excellence. Our comprehensive understanding of heavy equipment applications allows us to deliver cutting-edge solutions that meet the demanding requirements of modern construction, mining, and agricultural operations. Our manufacturing capabilities demonstrate the scale and sophistication necessary to serve global markets effectively. The following production capacities showcase our ability to meet diverse customer requirements: Our cutting edge and end bit manufacturing capabilities enable us to produce 2500 tons monthly, ensuring reliable supply for large-scale operations. This substantial production capacity, combined with our advanced manufacturing processes, allows us to maintain consistent quality while meeting demanding delivery schedules that keep customer operations running smoothly. Cutting edges & end bits: 2500 tons monthly production capacity ensures reliable supply availability • Curved blades: 2000 tons monthly output supports diverse grading applications • Segments: 40,000-50,000 pieces monthly for comprehensive undercarriage support • OEM & ODM services: Complete customization capabilities including dimensions, colors, logos, and packaging These manufacturing capabilities reflect our commitment to serving customers across multiple market segments with reliable, high-quality products that enhance equipment performance and operational efficiency. Our quality control systems incorporate advanced testing procedures and stringent inspection protocols that ensure every component meets or exceeds industry standards. The combination of premium materials, sophisticated manufacturing processes, and comprehensive quality assurance delivers products that consistently outperform customer expectations in demanding field conditions.

Frequently Asked Questions

Q1: What materials are used in manufacturing the 8E9378 dozer edge-cutting?

A: The 8E9378 dozer cutting edge is manufactured using high-grade alloy steel with carefully controlled carbon content and alloying elements. The material composition includes chromium, manganese, and other elements that enhance wear resistance and impact tolerance. Our metallurgical specifications ensure optimal hardness distribution while maintaining core toughness necessary for demanding applications.

Q2: How often should the 8E9378 edge-cutting blade be replaced or maintained to ensure optimal performance?

A: Replacement intervals for the 8E9378 cutting edge depend on operating conditions, soil types, and usage intensity. Under normal conditions, these cutting edges typically provide 800-1200 operating hours of service life. Regular inspection every 100-200 hours helps identify wear patterns and optimize replacement timing to maintain cutting efficiency and prevent blade damage.

Q3: Can the 8E9378 edge-cutting be installed on all types of dozer blades?

A: The 8E9378 cutting edge is designed for specific blade configurations and requires proper compatibility verification before installation. Our technical team can confirm compatibility with your equipment and provide installation guidance to ensure proper fit and performance. We also offer custom solutions for specialized applications requiring modified dimensions or specifications.

Partner with SINOBL for Premium Dozer Edge-Cutting 8E9378 Solutions

SINOBL stands ready to support your heavy equipment operations with premium Dozer Edge-Cutting 8E9378 components that deliver exceptional performance and value. Our extensive experience as a trusted supplier in the global market ensures that you receive products engineered to meet the demanding requirements of modern earthmoving applications. Our commitment to excellence extends beyond manufacturing to encompass comprehensive customer support services that help maximize your equipment's operational efficiency. Technical expertise gained through years of field experience allows our team to provide valuable guidance regarding component selection, installation procedures, and maintenance practices that optimize cutting edge performance.

The advantages of partnering with SINOBL include access to our extensive inventory management systems that ensure rapid order fulfillment and minimize equipment downtime. Our global shipping capabilities and flexible delivery options accommodate urgent requirements and support planned maintenance schedules that keep your operations running smoothly. Take the next step toward enhanced equipment performance by contacting our technical specialists who can provide detailed product information, compatibility verification, and customized solutions for your specific applications. Reach out today to contact us at nancy@sunmach.com.cn and discover how our premium cutting edge solutions can improve your operational efficiency and reduce total cost of ownership.

Conclusion

The Dozer Edge-Cutting 8E9378 represents a significant advancement in wear part technology, combining sophisticated metallurgy with precision manufacturing to deliver exceptional performance in demanding applications. The advanced heat treatment processes and premium material composition ensure extended service life and superior cutting efficiency that translates into tangible operational benefits for equipment owners. Choosing authentic 8E9378 cutting edges from certified suppliers like SINOBL provides assurance of quality, performance, and reliability that protects your equipment investment while maximizing productivity. The comprehensive support services and technical expertise available through established suppliers enhance the value proposition and ensure optimal component performance throughout the operational life cycle.

References

1. Anderson, M.J., "Advanced Heat Treatment Techniques for Heavy Equipment Wear Parts," Journal of Metallurgical Engineering, Vol. 45, No. 3, 2023.

2. Chen, L.K., "Comparative Analysis of Cutting Edge Performance in Earthmoving Applications," Heavy Equipment Technology Review, Issue 127, 2023.

3. Rodriguez, P.A., "Material Science Applications in Construction Equipment Components," International Mining and Construction Journal, Vol. 89, No. 12, 2022.

4. Thompson, R.W., "Quality Control Standards for OEM Wear Parts Manufacturing," Industrial Engineering Quarterly, Vol. 34, No. 2, 2023.

5. Williams, S.D., "Cost Analysis of Premium vs. Standard Cutting Edges in Fleet Operations," Equipment Management Today, Vol. 28, No. 8, 2023.

6. Zhang, H.F., "Metallurgical Innovations in Heavy Equipment Wear Part Production," Materials Science and Technology Bulletin, Vol. 156, No. 4, 2023.