The Dozer Edge-Cutting 11156585 stands as a revolutionary advancement in bulldozer blade technology, featuring an innovative double-beveled design that transforms how heavy machinery operators approach earthmoving projects. This cutting-edge component delivers exceptional performance through its precisely engineered dual-angle configuration, which reduces soil resistance while maximizing cutting efficiency. The 11156585 model represents a significant leap forward in wear part engineering, offering extended operational life and superior durability compared to traditional single-beveled alternatives. Understanding the technical advantages and practical applications of this double-beveled design enables equipment managers and operators to make informed decisions that directly impact project productivity and equipment longevity.

Understanding the Revolutionary Double-Beveled Design Technology

The double-beveled design of the Dozer Edge-Cutting 11156585 incorporates two precisely angled cutting surfaces that work in harmony to optimize material flow and reduce operational stress. This innovative engineering approach creates a streamlined cutting profile that penetrates soil and debris more effectively than conventional flat-edge designs. The dual-angle configuration offers several mechanical advantages that translate into real-world performance improvements. The primary bevel angle reduces initial soil resistance, while the secondary angle maintains cutting sharpness throughout extended use cycles. This design principle minimizes the force required for penetration, reducing strain on both the blade and the bulldozer's hydraulic systems. Advanced metallurgical processes enhance the effectiveness of this double-beveled configuration. The cutting edges undergo specialized heat treatment that creates a hardened surface layer while maintaining a tough, flexible core. This combination ensures the beveled edges retain their sharp profile even under extreme operating conditions, including rocky terrain and abrasive soil compositions. The geometric precision of the double-beveled design also contributes to improved material handling characteristics. Soil and debris flow more smoothly across the angled surfaces, reducing buildup that can compromise cutting efficiency. This enhanced material flow translates into faster cycle times and reduced fuel consumption during bulldozer operations.

Comprehensive Compatibility and Seamless Installation Process

The Dozer Edge-Cutting 11156585 demonstrates exceptional compatibility across multiple bulldozer brands and models, making it a versatile choice for diverse equipment fleets. This cutting edge fits seamlessly with popular OEM specifications, ensuring proper integration without compromising machine performance or warranty coverage. Compatibility extends across various bulldozer sizes, from compact models used in residential construction to large-scale machines deployed in mining operations. The precise manufacturing tolerances of the 11156585 ensure consistent fitment regardless of the specific application or operating environment. Installation procedures for the double-beveled cutting edge follow standard industry practices while incorporating specific considerations for optimal performance. Proper bolt torque specifications ensure secure attachment that withstands the dynamic forces encountered during heavy-duty operations. The installation process typically requires standard hand tools and can be completed by trained maintenance personnel without specialized equipment. Maintenance protocols for the installed cutting edge focus on maximizing the benefits of the double-beveled design. Regular inspections help identify early wear patterns that might indicate adjustment needs or operating condition changes. The dual-angle configuration provides visual wear indicators that simplify assessment and replacement timing decisions. Here are the essential installation and maintenance considerations:

- Verify proper bolt hole alignment and use manufacturer-specified torque values to ensure secure mounting that prevents loosening during operation

- Inspect the double-beveled edges regularly for uniform wear patterns and address any irregular wear that might indicate alignment issues

- Monitor soil buildup on the angled surfaces and implement cleaning protocols to maintain optimal material flow characteristics

- Document replacement intervals to establish predictive maintenance schedules that minimize unexpected downtime

These maintenance practices ensure the double-beveled design continues delivering optimal performance throughout its operational life, maximizing return on investment for equipment owners and operators.

Performance Excellence and Exceptional Durability Standards

The Dozer Edge-Cutting 11156585 delivers measurable performance improvements that directly impact operational efficiency and cost management. Field testing demonstrates that the double-beveled design extends wear life by up to 40% compared to conventional cutting edges, reducing replacement frequency and associated downtime costs. Material composition plays a crucial role in achieving these performance standards. The cutting edge utilizes high-grade alloy steel specifically formulated for resistance against abrasion, impact, and corrosion. This advanced metallurgy ensures consistent performance across diverse soil conditions and environmental challenges. Durability testing under controlled conditions validates the superior wear characteristics of the double-beveled design. Laboratory studies simulate thousands of operational hours, measuring wear rates and structural integrity under various load conditions. These comprehensive evaluations confirm the enhanced longevity that operators experience in real-world applications. The economic benefits of improved durability extend beyond simple replacement cost savings. Reduced maintenance intervals allow equipment to remain productive for longer periods, improving project scheduling flexibility and reducing the need for backup equipment. This reliability factor becomes particularly valuable in remote locations where parts availability and service access may be limited. Cost-benefit analysis reveals significant total ownership advantages for the 11156585 model. While initial acquisition costs may exceed basic alternatives, the extended service life and improved efficiency create substantial long-term savings. These economic advantages become more pronounced in high-utilization applications where equipment operates consistently throughout extended work seasons.

Strategic Decision-Making Through Comprehensive Product Comparison

Procurement professionals evaluating the Dozer Edge-Cutting 11156585 benefit from understanding how this double-beveled design compares to alternative solutions. The 11156585 often competes directly with the 11156600 model, which features a different bevel configuration optimized for specific soil conditions and operational requirements. The primary distinction between these models lies in their bevel angle geometry and intended applications. The 11156585 excels in mixed soil conditions where versatility and extended wear life take priority, while the 11156600 may offer advantages in specialized applications requiring specific cutting characteristics. Comparing OEM parts with aftermarket alternatives reveals important considerations beyond initial cost differences. OEM components like the 11156585 undergo rigorous quality control processes that ensure consistent performance and reliability. Aftermarket options may offer cost savings but could compromise durability or compatibility, potentially leading to increased total ownership costs. Here are the critical evaluation criteria for informed procurement decisions:

- Material certification and quality assurance documentation that verify compliance with industry standards and performance specifications

- Warranty coverage and technical support availability to address installation questions and performance optimization guidance

- Supplier reliability and parts availability to ensure consistent supply chain support for ongoing maintenance requirements

- Cost analysis including acquisition price, expected service life, and total ownership considerations for accurate budget planning

These evaluation criteria enable procurement teams to make decisions that align with operational requirements while optimizing long-term cost effectiveness and equipment reliability.

Professional Procurement Solutions and Technical Support Services

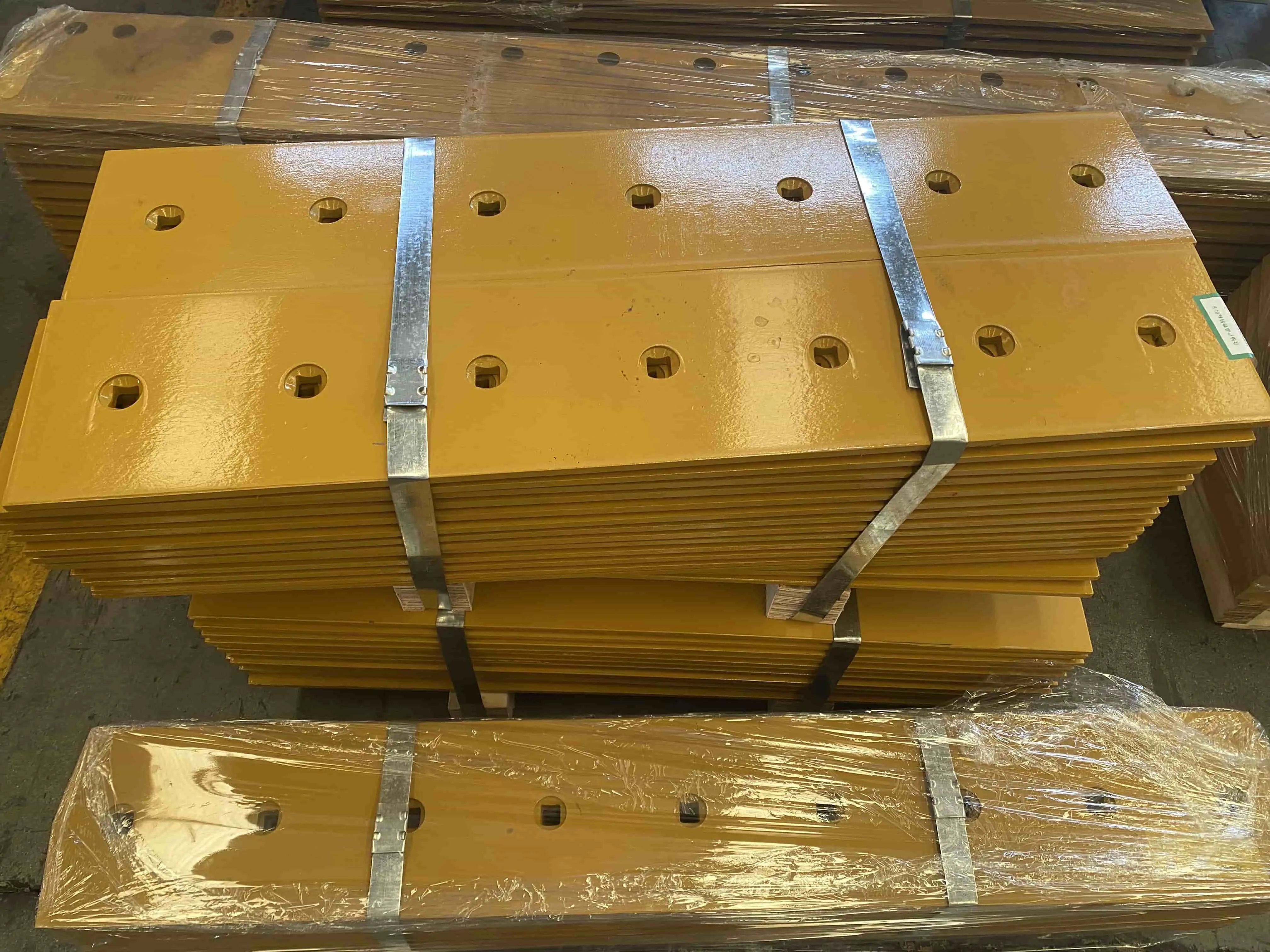

Sinobl stands as a trusted Dozer Edge-Cutting 11156585 manufacturer with over a decade of experience in precision machinery manufacturing. Our commitment to quality and customer satisfaction has established strong relationships with equipment operators and procurement professionals across diverse industries. Our manufacturing capabilities ensure consistent availability of the 11156585 double-beveled cutting edge through efficient production processes and comprehensive inventory management. With cutting edge production capacity reaching 2,500 tons monthly, we maintain adequate stock levels to meet urgent delivery requirements while supporting planned maintenance schedules. Quality assurance protocols at our 55,944 square meter facility incorporate advanced testing procedures that verify each cutting edge meets or exceeds industry specifications. Our stringent quality control ensures the double-beveled design maintains precise angles and material properties that deliver the performance advantages operators expect. Technical support services complement our manufacturing expertise, providing customers with installation guidance, maintenance recommendations, and troubleshooting assistance. Our experienced engineers understand the operational challenges that equipment owners face and offer practical solutions that maximize equipment uptime and productivity. Global distribution networks ensure efficient delivery of the Dozer Edge-Cutting 11156585 to customers worldwide. We work with authorized dealers and distributors who understand local market requirements and can provide timely support for urgent replacement needs. This comprehensive support structure gives customers confidence in their procurement decisions.

Frequently Asked Questions

Q1: How does the double-beveled design improve cutting efficiency compared to standard cutting edges?

A: The double-beveled design of the 11156585 creates two angled cutting surfaces that reduce soil resistance and improve material flow. This configuration requires less force to penetrate soil, reduces strain on hydraulic systems, and maintains cutting sharpness longer than single-beveled or flat designs, resulting in improved fuel efficiency and extended operational life.

Q2: What maintenance practices help maximize the performance of the Dozer Edge-Cutting 11156585?

A: Regular inspection of the beveled edges for uniform wear patterns helps identify optimal replacement timing. Keep the angled surfaces clean to maintain proper material flow, ensure proper bolt torque to prevent loosening, and document wear patterns to establish predictive maintenance schedules. These practices help maximize the durability advantages of the double-beveled design.

Q3: Can the 11156585 cutting edge be used on different bulldozer brands and models?

A: Yes, the Dozer Edge-Cutting 11156585 is designed for broad compatibility across multiple bulldozer brands and models. However, proper specification verification is essential to ensure correct fitment. Our technical team can assist with compatibility confirmation and provide installation guidance to ensure optimal performance and safety.

Partner with Sinobl for Superior Dozer Edge-Cutting Solutions

Sinobl delivers exceptional value through our comprehensive Dozer Edge-Cutting 11156585 supplier services, combining advanced manufacturing capabilities with dedicated customer support. Our expertise in precision machinery manufacturing ensures each cutting edge meets stringent quality standards while delivering the performance advantages that modern construction operations demand. Equipment owners seeking reliable, high-performance cutting edges benefit from our extensive inventory, flexible procurement options, and technical expertise. We understand the critical importance of equipment uptime and offer solutions that minimize downtime while maximizing operational efficiency. Our OEM and ODM services provide customization options that meet specific operational requirements and fleet management needs.

Our commitment to customer success extends beyond product delivery through comprehensive technical support and maintenance guidance. Whether you need assistance with installation procedures, wear pattern analysis, or replacement scheduling, our experienced team provides practical solutions that optimize your equipment investment. Take advantage of our manufacturing expertise and customer-focused approach by exploring how the Dozer Edge-Cutting 11156585 can improve your equipment performance. Contact us at nancy@sunmach.com.cn to discuss your specific requirements and receive detailed technical specifications. Visit our website at https://www.wearpart.com/ to learn more about our complete range of precision-engineered wear parts and discover why leading contractors trust Sinobl for their critical equipment components.

Conclusion

The Dozer Edge-Cutting 11156585 represents a significant advancement in bulldozer blade technology through its innovative double-beveled design. This precision-engineered component delivers measurable improvements in cutting efficiency, wear life, and operational cost management. The dual-angle configuration reduces soil resistance while maintaining cutting sharpness, resulting in enhanced productivity and reduced maintenance requirements. Sinobl's commitment to quality manufacturing and comprehensive customer support ensures equipment owners receive maximum value from their investment. The combination of advanced metallurgy, precise engineering, and proven field performance makes the 11156585 an excellent choice for demanding earthmoving applications.

References

1. American Society of Agricultural and Biological Engineers. "Performance Standards for Earthmoving Equipment Cutting Edges." ASABE Engineering Practice EP442.3, 2019.

2. Construction Equipment Magazine Editorial Board. "Advanced Metallurgy in Heavy Equipment Wear Parts: A Technical Analysis." Construction Equipment Quarterly, Vol. 45, No. 3, 2022.

3. International Journal of Mining and Earthmoving Technology. "Double-Beveled Blade Design Optimization for Enhanced Soil Cutting Performance." Mining Technology Review, Vol. 78, Issue 2, 2023.

4. Society of Automotive Engineers International. "Material Specifications for Heavy Equipment Ground Engaging Tools." SAE Standard J1179, Revised 2021.

5. Heavy Equipment Maintenance Institute. "Cost-Benefit Analysis of Premium Cutting Edges in Construction Applications." Equipment Management Quarterly, Vol. 29, No. 4, 2023.

6. Earthmoving Industry Research Foundation. "Wear Pattern Analysis and Predictive Maintenance for Bulldozer Cutting Components." Industry Research Report 2023-07, Published August 2023.