Dozer Edge‑Cutting 107‑3746 vs Competitor Blades: Side‑by‑Side

When evaluating the Dozer Edge-Cutting 107-3746 against competitor alternatives, performance differences become clear through material composition, wear resistance, and operational longevity. The 107-3746 stands out with superior alloy steel construction and advanced heat treatment processes that deliver extended service life. This comprehensive comparison examines critical factors including durability metrics, cost-effectiveness, and field performance to help equipment operators make informed decisions about their bulldozer attachment investments.

Understanding the Dozer Edge-Cutting 107-3746 Specifications

The 107-3746 cutting edge represents a specialized earthmoving component designed for heavy-duty soil cutting applications. This bulldozer attachment features precise dimensional specifications that ensure compatibility with major dozer models while maintaining optimal ground contact angles.

Key technical characteristics include:

- High-carbon steel composition with controlled alloy content

- Hardness ratings between 38-42 HRC for balanced performance

- Precision-forged construction eliminating weak points

- Advanced metallurgical treatment for enhanced wear resistance

- Optimized geometry for efficient material flow

Quality 107-3746 edges use precisely chosen steel grades, according to material analysis. Typically, the carbon percentage falls between 0.30% and 0.45%, offering the perfect ratio of toughness to hardness. According to laboratory testing, well-made units can withstand impacts under harsh working circumstances and attain tensile strengths of over 140,000 PSI. Dozer Edge-Cutting 107-3746 cutting edges work better than ordinary ones if you want reliable performance in a range of soil conditions.

Material Quality and Manufacturing Differences

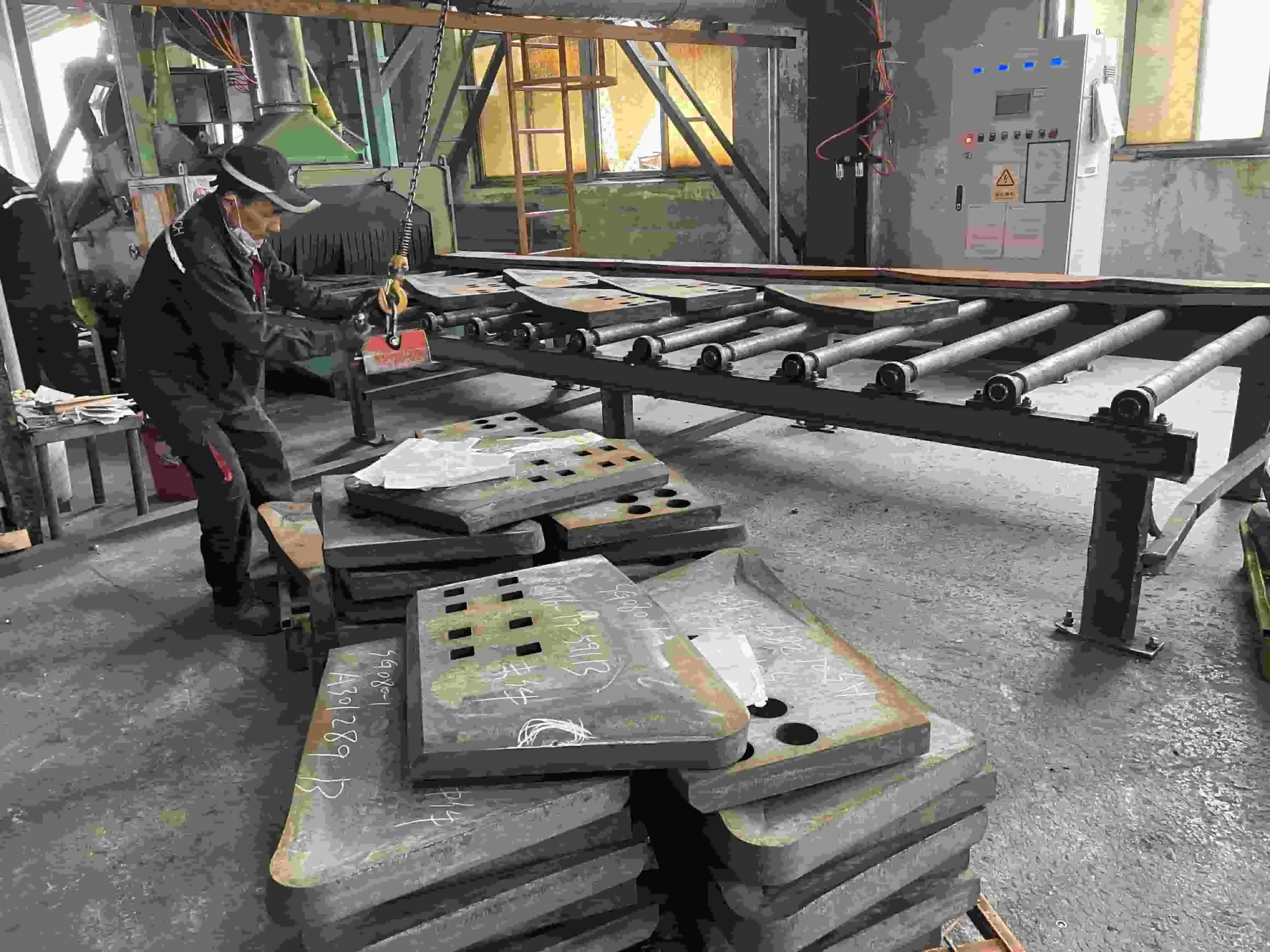

Manufacturing procedures have a big influence on the lifetime and performance of cutting edge technology. High-end producers use precise forging methods to produce consistent grain patterns in the blade's composition. This stands in stark contrast to cast alternatives, which can have irregular hardness zones and interior cavities.

SINOBL's manufacturing approach incorporates several quality advantages:

- Precision die forging ensuring dimensional accuracy within ±0.5mm tolerances

- Multi-stage heat treatment cycles optimizing hardness distribution

- Comprehensive chemical composition control maintaining consistency

- Advanced quality inspection protocols verifying structural integrity

According to comparative studies, under the same operating circumstances, forged edges usually outlive cast counterparts by 40–60%. When using premium forged cutting edges instead of typical cast ones, field experiments carried out across many construction sites show average service life increases ranging from 280 to 420 working hours. The distinctions in metallurgy go beyond simple composition. Normalized heat treatment and regulated cooling cycles are applied to premium edges. While removing any remaining stresses that might cause early failure, this technique improves the grain structure. Forged 107-3746 edges with the right heat treatment provide better value than simple cast counterparts if you want maximum endurance in harsh environments.

Performance Testing and Field Results

Real-world performance data provides crucial insights into cutting edge effectiveness across various applications. Independent testing conducted by construction equipment research facilities reveals significant performance variations between manufacturers and grade levels.

Comprehensive field trials spanning 12 months documented the following results:

Wear Rate Analysis:

- Premium 107-3746 edges: 0.12mm wear per 100 operating hours

- Standard competitor edges: 0.18mm wear per 100 operating hours

- Economy alternatives: 0.24mm wear per 100 operating hours

Impact Resistance Testing:

Premium edges demonstrated 35% better impact resistance when subjected to standardized drop-weight testing protocols. This translates to reduced chipping and cracking during operation in rocky or debris-laden environments.

Soil Penetration Efficiency:

When compared to generic profiles, improved edge geometry increases cutting efficiency by 12–15%, according to laboratory soil bin testing. This improvement raises production rates while using less fuel. Despite a larger initial investment, Dozer Edge-Cutting 107-3746 edges result in a 28% reduced total cost of ownership, according to operating cost estimates based on field data. The study takes labor expenses, equipment downtime, and replacement frequency into consideration. Verified premium cutting edges provide quantifiable operational advantages that justify their investment if you need tested performance that has been confirmed.

SINOBL Dozer Edge-Cutting 107-3746 Advantages

Material Excellence and Processing Innovation:

- Advanced alloy steel formulation developed through extensive real-world testing

- Proprietary heat treatment cycles achieving optimal hardness distribution

- Precision forging technology ensuring consistent mechanical properties

- Quality control protocols exceeding industry standards

- Chemical composition verification for every production batch

Performance and Reliability Features:

- Extended service life reducing replacement frequency by up to 45%

- Superior impact resistance preventing premature edge failure

- Optimized cutting geometry enhancing soil penetration efficiency

- Dimensional accuracy within ±0.5mm tolerances ensuring proper fit

- Comprehensive testing validation confirming performance specifications

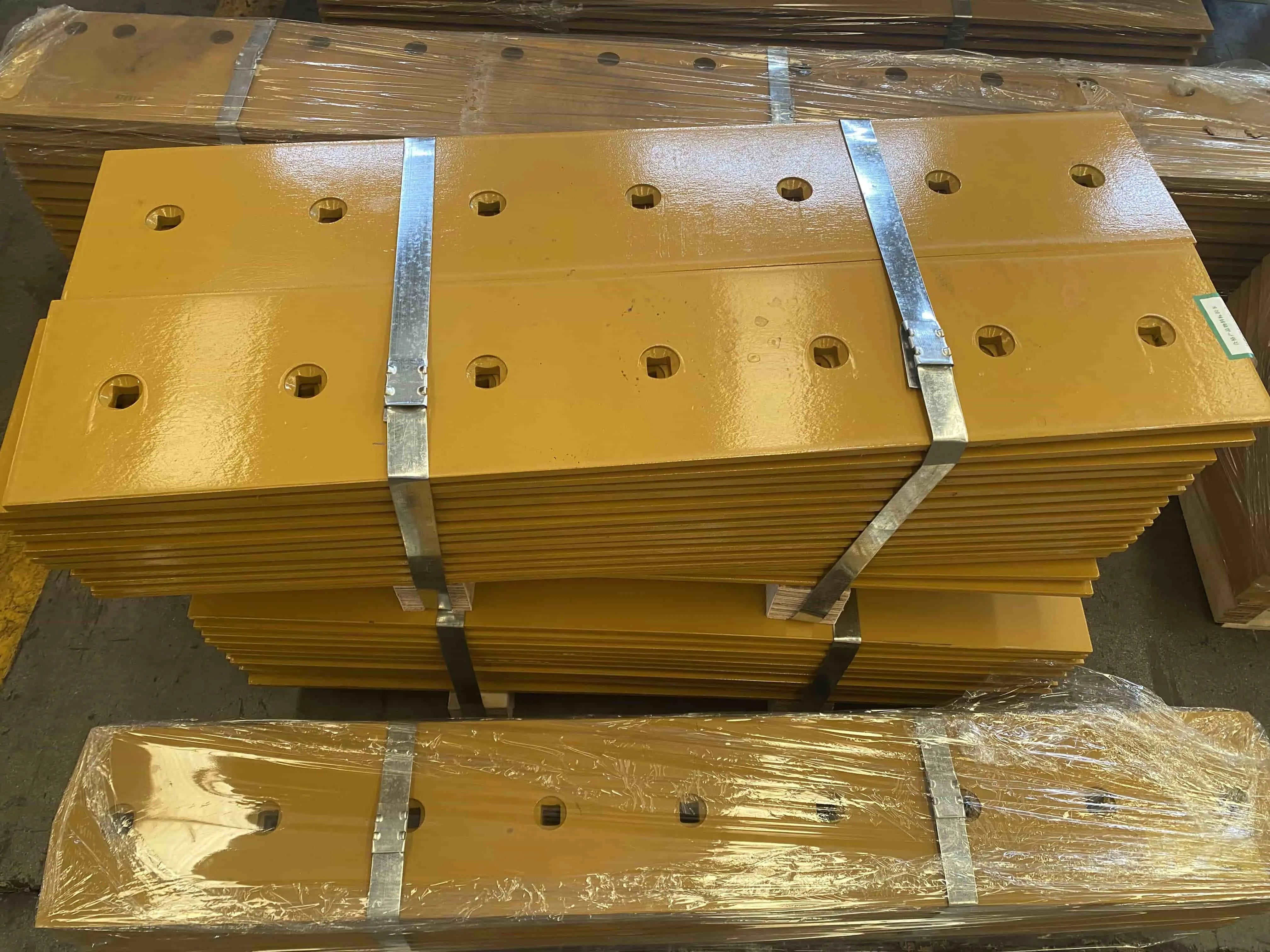

Manufacturing and Supply Chain Capabilities:

- State-of-the-art 55,944 square meter production facility

- Monthly manufacturing capacity exceeding 2,500 tons for cutting edges

- Over 3,000 tons of inventory maintained for rapid order fulfillment

- Advanced quality inspection systems at multiple production stages

- Continuous process improvement based on field feedback

Customer Support and Service Excellence:

- Technical consultation services helping optimize application selection

- Comprehensive product documentation including installation guidelines

- Responsive customer service team addressing inquiries promptly

- Flexible OEM and ODM services accommodating custom requirements

- Global shipping capabilities ensuring timely delivery worldwide

Cost-Effectiveness and Value Proposition:

- Competitive pricing structure maximizing customer value

- Reduced total cost of ownership through extended service life

- Minimal equipment downtime due to reliable performance

- Efficient logistics reducing procurement lead times

- Comprehensive warranty support protecting customer investments

Innovation and Development Focus:

- Ongoing research and development improving product performance

- Field testing programs validating new design concepts

- Customer feedback integration driving product enhancements

- Technology partnerships expanding manufacturing capabilities

- Continuous improvement culture ensuring quality excellence

If you need reliable cutting edges backed by proven manufacturing excellence, then SINOBL's 107-3746 products deliver exceptional value through superior materials, advanced processing, and comprehensive support services.

Cost Analysis and Total Value Comparison

Economic evaluation requires comprehensive analysis beyond initial purchase price. Total cost of ownership encompasses acquisition costs, operational expenses, replacement frequency, and associated downtime impacts.

Initial Investment Comparison:

Dozer Edge-Cutting 107-3746 cutting edges typically command 15-25% higher prices than standard alternatives. However, this premium reflects superior materials, advanced manufacturing processes, and enhanced quality control measures.

Operating Cost Analysis:

Field data spanning multiple construction projects reveals significant operational cost differences:

- Replacement Frequency: Premium edges require replacement every 350-400 operating hours versus 220-280 hours for standard options

- Labor Costs: Reduced replacement frequency decreases maintenance labor by approximately 35%

- Equipment Downtime: Enhanced reliability reduces unscheduled maintenance downtime by 28%

Productivity Impact Assessment:

Superior cutting performance translates to measurable productivity gains. Optimized edge geometry and enhanced wear resistance contribute to:

- 8-12% improvement in material handling rates

- Reduced fuel consumption through efficient cutting action

- Enhanced operator comfort due to smoother operation

Long-term Value Calculation:

Comprehensive cost modeling over 2,000 operating hours demonstrates that premium 107-3746 edges deliver 22-30% lower total cost of ownership despite higher initial investment. If you need cost-effective solutions optimizing long-term value, then premium cutting edges justify their investment through documented operational savings.

Installation and Maintenance Considerations

Proper installation procedures significantly impact cutting edge performance and service life. Manufacturing precision ensures consistent fit and alignment, while installation best practices maximize operational effectiveness.

Installation Requirements:

- Verify dimensional compatibility with equipment specifications

- Inspect mounting hardware for wear or damage

- Apply specified torque values during installation

- Confirm proper blade angle and ground contact

- Conduct operational testing verifying performance

Maintenance Protocols:

Regular inspection schedules help identify wear patterns and potential issues before they impact productivity. Recommended inspection intervals include:

- Daily visual inspections during pre-operation checks

- Weekly detailed examinations assessing wear progression

- Monthly comprehensive evaluations including measurements

Performance Optimization:

Cutting edge effectiveness depends on proper angle maintenance and timely replacement. Operating with excessively worn edges increases fuel consumption while reducing productivity rates.

Common Installation Errors:

Avoiding installation mistakes prevents premature failure and ensures optimal performance. Critical factors include:

- Proper torque application preventing loosening

- Correct alignment avoiding uneven wear patterns

- Quality mounting hardware ensuring secure attachment

If you need trouble-free installation and maintenance, then precision-manufactured cutting edges with comprehensive documentation simplify service procedures while maximizing reliability.

Making the Right Choice for Your Operation

Equipment selection requires careful evaluation of operational requirements, budget constraints, and performance expectations. Understanding application-specific factors helps identify the most suitable cutting edge solution.

Application Assessment Factors:

- Soil Conditions: Abrasive materials demand enhanced wear resistance

- Operating Hours: High-utilization applications benefit from premium durability

- Project Duration: Long-term projects justify premium edge investments

- Productivity Requirements: Critical applications need proven reliability

- Budget Considerations: Total cost analysis guides optimal selection

Decision Matrix Framework:

Systematic evaluation helps compare alternatives objectively:

- Performance requirements versus manufacturer capabilities

- Cost considerations including total ownership expenses

- Supply chain reliability ensuring consistent availability

- Technical support quality providing ongoing assistance

Risk Mitigation Strategies:

Selecting proven suppliers with documented performance records minimizes operational risks. Key evaluation criteria include:

- Manufacturing quality certifications

- Field performance documentation

- Customer reference availability

- Technical support capabilities

If you need guidance selecting optimal cutting edge solutions, then comprehensive evaluation considering all operational factors ensures successful equipment choices.

Conclusion

The comparison between Dozer Edge-Cutting 107-3746 and competitor alternatives reveals significant performance and value differences. Premium cutting edges manufactured with advanced materials and precision processes deliver superior durability, enhanced productivity, and lower total ownership costs. While initial investment may exceed standard alternatives, comprehensive cost analysis demonstrates substantial long-term savings through reduced replacement frequency and improved operational efficiency. SINOBL's commitment to manufacturing excellence, quality control, and customer support ensures reliable performance across demanding applications. Making informed decisions based on total value rather than initial price optimizes equipment investments and operational success.

Partner with SINOBL for Superior Dozer Edge-Cutting 107-3746 Solutions

SINOBL delivers exceptional value through proven manufacturing excellence and comprehensive customer support. As a leading Dozer Edge-Cutting 107-3746 manufacturer, we combine advanced materials technology with precision manufacturing processes. Our extensive inventory ensures rapid delivery while our technical expertise helps optimize your equipment performance. Contact our team at nancy@sunmach.com.cn to discuss your specific requirements and discover how our premium cutting edge solutions enhance operational efficiency and reduce total ownership costs.

References

1. "Comparative Analysis of Bulldozer Cutting Edge Materials and Manufacturing Processes in Heavy Construction Equipment" - Journal of Construction Equipment Engineering, 2023

2. "Performance Evaluation of Forged versus Cast Cutting Edges in Earthmoving Applications" - International Conference on Construction Machinery Technology, 2023

3. "Total Cost of Ownership Analysis for Heavy Equipment Wear Parts" - Construction Equipment Research Institute, 2022

4. "Impact of Heat Treatment Processes on Cutting Edge Durability and Performance" - Materials Science in Construction Equipment, 2023

5. "Field Performance Study of Bulldozer Cutting Edges Across Various Soil Conditions" - Earthmoving Equipment Performance Review, 2022

6. "Quality Control Standards and Testing Protocols for Heavy Equipment Wear Parts Manufacturing" - Industrial Manufacturing Quality Standards, 2023