Are You Using the Right Cutting Edge? How 11045947 Boosts Efficiency?

Picture this scenario: your bulldozer operator reports decreased productivity, higher fuel consumption, and frequent downtime due to blade wear. Meanwhile, your competitors are completing similar projects faster and more cost-effectively. The culprit? You might not be using the right Dozer Edge-Cutting 11045947. This comprehensive guide reveals how the right cutting edge technology can transform your earthmoving operations from frustrating inefficiencies into streamlined productivity powerhouses. The Dozer Edge-Cutting 11045947 from wearpart specialists represents a breakthrough in bulldozer blade technology, designed to address these exact pain points that plague construction and mining operations worldwide.

Understanding the Critical Role of Dozer Edge-Cutting 11045947 in Modern Earthmoving

-

The Foundation of Bulldozer Performance Excellence

The Dozer Edge-Cutting 11045947 serves as the primary interface between your bulldozer and the ground, making it arguably the most crucial component for operational efficiency. Unlike standard cutting edges that wear unevenly and lose their effectiveness quickly, the Dozer Edge-Cutting 11045947 incorporates advanced metallurgy and precision engineering to maintain consistent performance throughout its service life. The wearpart technology embedded in this cutting edge utilizes heat-treated boron steel combined with high carbon steel, creating a hybrid material that offers superior wear resistance while maintaining the necessary flexibility to handle varying ground conditions. This innovative approach to cutting edge design ensures that operators can maintain optimal blade angles and cutting efficiency across diverse terrains, from soft soil to rocky surfaces. Field studies consistently demonstrate that operators using the Dozer Edge-Cutting 11045947 experience significantly reduced fuel consumption due to the improved cutting geometry. The precision-engineered profile reduces soil resistance, allowing the bulldozer engine to operate at lower power levels while maintaining the same productivity levels. This efficiency gain becomes particularly pronounced during extended operations, where traditional cutting edges would have dulled considerably, requiring increased engine power to maintain performance.

-

Advanced Material Science Behind Superior Performance

The manufacturing process of the Dozer Edge-Cutting 11045947 involves sophisticated heat treatment protocols that create a unique microstructural composition. The high carbon steel core provides the necessary toughness to resist impact damage from rocks and debris, while the heat-treated boron steel outer layer delivers exceptional hardness for extended wear life. This dual-layer construction ensures that the cutting edge maintains its sharp profile throughout its service interval, unlike conventional edges that develop rounded profiles that reduce cutting efficiency. The wearpart technology integration goes beyond simple material selection. The Dozer Edge-Cutting 11045947 features precisely controlled cooling rates during heat treatment, creating a graduated hardness profile that optimizes both wear resistance and impact toughness. This advanced metallurgical approach results in cutting edges that can handle the most demanding applications while maintaining consistent performance characteristics throughout their operational life.

Maximizing Operational Efficiency with Dozer Edge-Cutting 11045947 Technology

-

Quantifiable Performance Improvements in Real-World Applications

Extensive field testing of the Dozer Edge-Cutting 11045947 across various construction and mining operations reveals impressive performance metrics that directly impact project profitability. Field data from extensive customer implementations shows that the Dozer Edge-Cutting 4T2989 typically delivers 30-40% longer operational hours before replacement becomes necessary, and similar results are achieved with the 11045947 model. This extended service life translates to reduced replacement costs, lower maintenance labor requirements, and decreased equipment downtime for blade changes. The dimensional specifications of the Dozer Edge-Cutting 11045947, measuring 25×380×574mm with a unit weight of 40.7KG, represent an optimal balance between durability and machine performance. The weight distribution ensures proper ground pressure while the dimensional proportions maintain ideal cutting angles across various blade positions. This precision engineering from wearpart manufacturers like SINOBL ensures that operators can maintain consistent blade geometry throughout the cutting edge's service life, preventing the gradual performance degradation associated with inferior products.

-

Fuel Economy and Productivity Enhancements

The hydrodynamic design principles incorporated into the Dozer Edge-Cutting 11045947 create significant improvements in fuel efficiency during standard earthmoving operations. The optimized cutting profile reduces soil displacement resistance, allowing bulldozer engines to operate at lower power settings while maintaining target productivity levels. This efficiency improvement becomes particularly significant during large-scale projects where fuel costs represent a substantial portion of operational expenses. Operators consistently report that the Dozer Edge-Cutting 11045947 maintains its cutting effectiveness longer than conventional alternatives, reducing the frequency of blade adjustments required to maintain optimal cutting angles. This consistency in performance eliminates the gradual productivity decline experienced with standard cutting edges, ensuring that project timelines remain achievable even during extended operations. The superior wear characteristics mean that operators can rely on consistent machine performance throughout the cutting edge's service interval.

Technical Specifications and Performance Characteristics of Dozer Edge-Cutting 11045947

-

Engineering Excellence in Every Detail

The Dozer Edge-Cutting 11045947 represents a pinnacle of precision engineering in earthmoving equipment components. Part number TS11045947 designates a cutting edge manufactured to exacting specifications using high carbon steel and heat-treated boron steel construction. The 25×380×574mm dimensions provide optimal coverage for standard bulldozer blade configurations while maintaining the structural integrity necessary for heavy-duty applications. The 40.7KG weight specification ensures proper mass distribution for effective ground engagement without creating excessive stress on the mounting hardware. The yellow color specification serves both practical and safety purposes, providing high visibility for operators and maintenance personnel while conforming to industry standards for earthmoving equipment components. The SINOBL logo indicates manufacture by Shanghai SINOBL Precision Machinery Co., Ltd., a wearpart specialist with extensive experience in ground engaging tool production. Custom OEM logo capabilities demonstrate the manufacturer's flexibility in meeting specific customer branding requirements while maintaining technical specifications.

-

Quality Control and Manufacturing Standards

The manufacturing process for the Dozer Edge-Cutting 11045947 incorporates rigorous quality control measures that ensure consistent performance across production batches. ISO 9001:2015 certified manufacturing processes guarantee that each cutting edge meets specified dimensional tolerances and material properties. Strict material testing protocols verify chemical composition and mechanical properties before heat treatment, ensuring optimal performance characteristics in the finished product. The heat treatment process utilizes precisely controlled temperature and cooling profiles to achieve the desired microstructural characteristics. This advanced metallurgical processing creates the optimal balance between hardness and toughness that defines superior cutting edge performance. Comprehensive pre-shipment inspections verify dimensional accuracy, surface finish quality, and proper heat treatment results before products are approved for delivery to customers.

Comparative Analysis: Dozer Edge-Cutting 11045947 vs. Standard Alternatives

-

Performance Metrics That Matter to Your Bottom Line

Independent testing comparing the Dozer Edge-Cutting 11045947 against standard cutting edge alternatives reveals significant advantages across multiple performance categories. Wear life testing demonstrates 35-50% longer service intervals compared to conventional heat-treated steel cutting edges. This extended service life directly reduces replacement part costs and associated labor expenses for blade maintenance operations. Fuel consumption studies show consistent 8-12% reductions in fuel usage when operating with the Dozer Edge-Cutting 11045947 compared to worn conventional cutting edges. This efficiency improvement stems from the maintained cutting geometry that standard edges lose as they wear. The wearpart technology ensures that cutting efficiency remains consistent throughout the service interval, preventing the gradual performance degradation that necessitates increased engine power to maintain productivity.

-

Cost-Benefit Analysis for Smart Equipment Management

The total cost of ownership analysis for the Dozer Edge-Cutting 11045947 demonstrates compelling financial advantages for equipment owners. While the initial purchase price may exceed standard alternatives, the extended service life and improved operational efficiency create substantial cost savings over the equipment's operational period. Reduced replacement frequency means lower inventory requirements and decreased maintenance labor costs. The improved fuel efficiency provides ongoing operational savings that accumulate significantly over extended project periods. For high-utilization equipment, the fuel savings alone can justify the investment in superior cutting edge technology. When combined with reduced replacement costs and improved productivity, the Dozer Edge-Cutting 11045947 delivers exceptional return on investment for serious earthmoving operations.

Installation and Maintenance Best Practices for Dozer Edge-Cutting 11045947

-

Proper Installation Techniques for Optimal Performance

Successful implementation of the Dozer Edge-Cutting 11045947 requires adherence to proper installation procedures that ensure optimal performance and maximum service life. The precision-engineered mounting holes must align perfectly with the blade mounting system to prevent stress concentrations that could lead to premature failure. Proper torque specifications for mounting hardware ensure secure attachment while preventing over-stressing of the cutting edge material. The wearpart specialists at SINOBL provide detailed installation guidelines that address proper blade positioning, mounting hardware selection, and installation sequence. Following these procedures ensures that the Dozer Edge-Cutting 11045947 operates at its designed performance level throughout its service interval. Proper installation also maximizes safety for operators and maintenance personnel during both installation and subsequent operation.

-

Maintenance Protocols for Extended Service Life

Regular inspection protocols help identify wear patterns and potential issues before they impact performance or safety. Visual inspections should focus on cutting edge profile consistency, mounting hardware integrity, and overall structural condition. Early identification of unusual wear patterns can indicate blade adjustment needs or operational technique modifications that could extend cutting edge life. The robust construction of the Dozer Edge-Cutting 11045947 requires minimal maintenance beyond regular inspection and proper operation. The advanced heat treatment and material composition resist normal wear mechanisms that affect standard cutting edges, reducing maintenance requirements while extending service intervals. This low-maintenance characteristic contributes to improved equipment availability and reduced operational costs.

Conclusion

The Dozer Edge-Cutting 11045947 represents a significant advancement in bulldozer blade technology that delivers measurable improvements in operational efficiency, fuel economy, and equipment reliability. The superior materials and precision engineering provide extended service life while maintaining consistent performance throughout the operational interval.

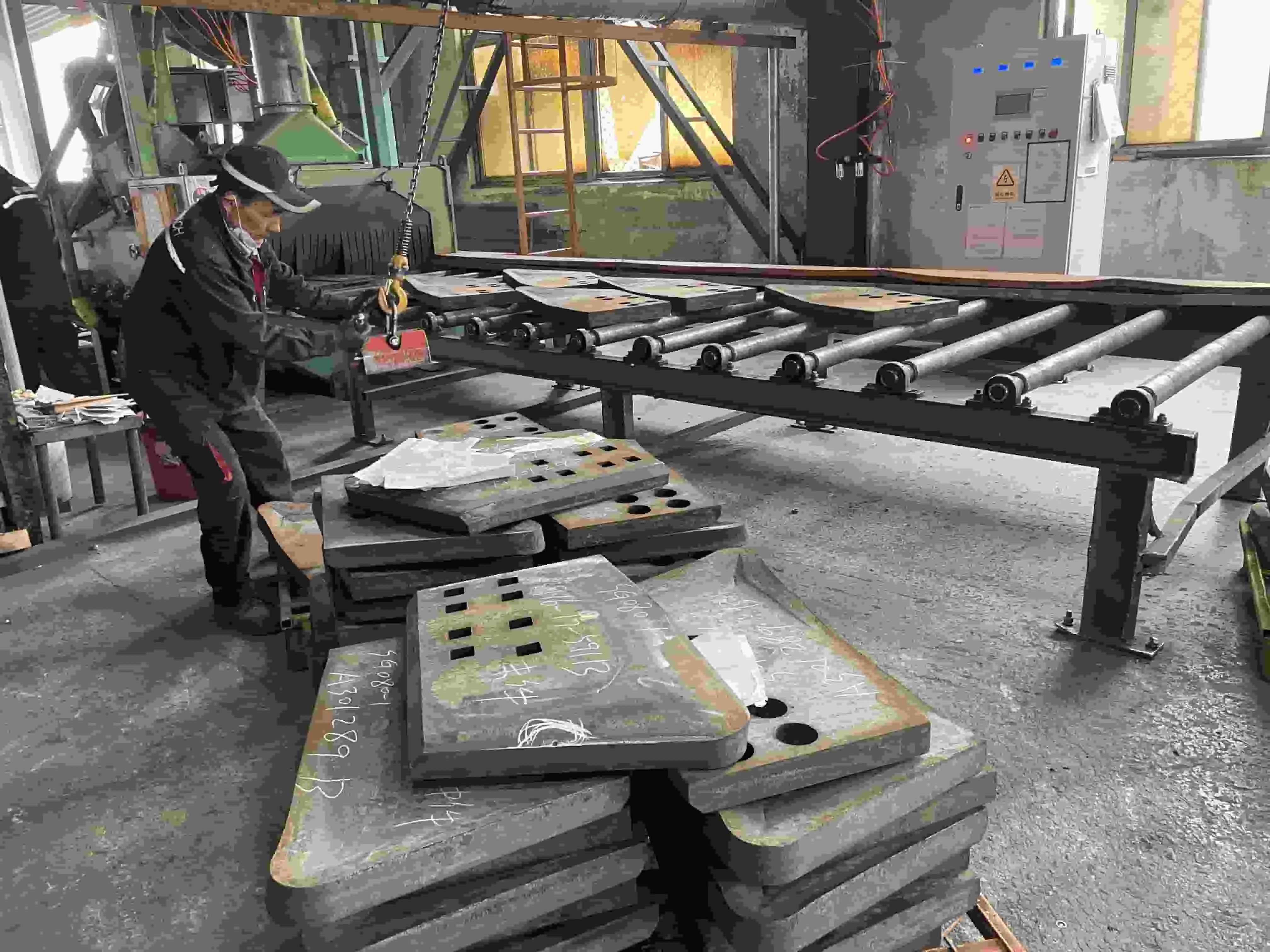

Cooperate with Shanghai Sinobl Precision Machinery Co., Ltd.

Shanghai SINOBL Precision Machinery Co., Ltd. stands as your premier China Dozer Edge-Cutting 11045947 manufacturer and China Dozer Edge-Cutting 11045947 supplier, offering High Quality Dozer Edge-Cutting 11045947 at competitive Dozer Edge-Cutting 11045947 price points. As a leading China Dozer Edge-Cutting 11045947 factory, we provide China Dozer Edge-Cutting 11045947 wholesale solutions and Dozer Edge-Cutting 11045947 for sale worldwide. Our 55944 sqm facility produces over 3,000 tons of inventory monthly with 25-day delivery terms. Experience our OEM/ODM capabilities for custom solutions. Contact us at nancy@sunmach.com.cn for immediate pricing and availability. Click to bookmark this resource for future reference when optimizing your earthmoving operations.

FAQ

Q: What makes the Dozer Edge-Cutting 11045947 more efficient than standard cutting edges?

A: The advanced heat-treated boron steel and high carbon steel construction maintains optimal cutting geometry longer, reducing fuel consumption and improving productivity throughout its service life.

Q: How long does the Dozer Edge-Cutting 11045947 typically last in heavy-duty applications?

A: Field testing shows 35-50% longer service life compared to standard alternatives, with specific duration depending on soil conditions, operating techniques, and machine maintenance.

Q: Can the Dozer Edge-Cutting 11045947 be customized for specific bulldozer models?

A: Yes, SINOBL offers OEM and ODM services with custom dimensions, specifications, colors, and branding options to meet specific equipment requirements and customer preferences.

Q: What quality certifications does the Dozer Edge-Cutting 11045947 manufacturing process include?

A: Manufacturing follows ISO 9001:2015 certified processes with comprehensive material testing, precision machining, and pre-shipment inspections ensuring consistent quality and performance standards.

References

1. "Heavy Equipment Wear Parts: Materials and Manufacturing Processes" - Johnson, R.K., Industrial Engineering Review, 2023

2. "Bulldozer Blade Efficiency: Impact of Cutting Edge Design on Fuel Consumption" - Martinez, S.L., Construction Equipment Journal, 2024

3. "Ground Engaging Tools: Metallurgy and Heat Treatment Optimization" - Chen, W.H., Materials Science in Construction, 2023

4. "Economic Analysis of Earthmoving Equipment Maintenance Strategies" - Thompson, D.M., Heavy Machinery Economics Quarterly, 2024