5 Reasons Dozer Edge-Cutting 11045947 Outlasts Competitors

Picture this: your dozer blade starts showing excessive wear after just three months of operation, forcing costly downtime and emergency part replacements that disrupt your entire project timeline. This scenario haunts construction and mining operations worldwide, where inferior cutting edges lead to frequent replacements, increased fuel consumption, and reduced operational efficiency. The Dozer Edge-Cutting 11045947 from wearpart eliminates these challenges through superior engineering and materials science. This comprehensive analysis reveals exactly why this cutting edge consistently outperforms competitors, delivering exceptional value through extended service life, reduced maintenance requirements, and enhanced operational productivity that keeps your equipment running when it matters most.

Superior Material Engineering Sets Dozer Edge-Cutting 11045947 Apart

-

Advanced Dual-Material Construction Technology

The Dozer Edge-Cutting 11045947 represents a breakthrough in material engineering through its innovative dual-material approach. This cutting edge combines high-carbon steel with heat-treated boron steel, creating a synergistic relationship that maximizes both hardness and toughness. The high-carbon steel component provides exceptional surface hardness, enabling the cutting edge to maintain its sharp profile even under extreme abrasive conditions. Meanwhile, the boron steel component contributes superior impact resistance and fracture toughness, preventing catastrophic failures that commonly plague single-material alternatives. Boron steel's unique metallurgical properties stem from its enhanced hardenability, which allows for deeper hardening penetration throughout the component's cross-section. The addition of boron to steel greatly increases the hardenability of the resulting alloy, enabling uniform hardness distribution that single-material cutting edges cannot achieve. This technological advantage translates directly into extended service life, as the Dozer Edge-Cutting 11045947 maintains consistent performance characteristics throughout its operational lifespan.

-

Professional Heat Treatment Process Excellence

The manufacturing process behind the Dozer Edge-Cutting 11045947 incorporates advanced heat treatment protocols that optimize the material's microstructure for maximum durability. Shanghai SINOBL's specialized heat treatment procedures involve precise temperature control and cooling rates that transform the steel's crystalline structure into an optimal configuration for wear resistance. Heat treating boron steel involves a series of controlled heating and cooling cycles that refine its microstructure, enhancing its mechanical properties to suit specific applications. This sophisticated thermal processing creates a hardened surface layer while maintaining a tough, resilient core structure. The result is a cutting edge that resists both abrasive wear and impact damage, two primary failure modes that limit the performance of conventional alternatives. The wearpart manufacturing facility's investment in state-of-the-art heat treatment equipment ensures consistent quality across every Dozer Edge-Cutting 11045947 unit produced.

Precision Manufacturing Delivers Unmatched Dimensional Accuracy

-

Advanced Die Forging Technology

The production of Dozer Edge-Cutting 11045947 utilizes precision die forging processes that create superior dimensional accuracy and material integrity compared to alternative manufacturing methods. This advanced forging technique eliminates internal voids and grain boundary weaknesses common in cast or machined alternatives, resulting in a denser, more homogeneous material structure. The forging process aligns the steel's grain structure with the cutting edge's operational stress patterns, optimizing strength distribution where it's needed most. Shanghai SINOBL's forging capabilities ensure that each Dozer Edge-Cutting 11045947 meets exact dimensional specifications with tolerances that guarantee proper fit and alignment with dozer blade systems. This precision manufacturing approach eliminates the fitment issues and premature wear patterns that often result from poorly manufactured cutting edges. The 25x380x574mm dimensions are maintained with exceptional consistency, ensuring reliable performance across different operating conditions and equipment configurations.

-

Quality Control and Material Testing Standards

Every Dozer Edge-Cutting 11045947 undergoes comprehensive quality control procedures that verify material properties, dimensional accuracy, and surface finish quality. The manufacturing process includes rigorous material testing protocols that confirm hardness levels, impact resistance, and chemical composition compliance with engineering specifications. These quality assurance measures ensure that customers receive cutting edges that meet or exceed OEM performance standards while providing superior durability characteristics. The wearpart facility's ISO 9001 certified quality management system provides systematic oversight of every manufacturing step, from raw material selection through final inspection. This commitment to quality excellence means that each Dozer Edge-Cutting 11045947 delivers consistent performance characteristics that construction and mining operations can depend on for critical applications.

Exceptional Wear Resistance Technology

-

Surface Hardness Optimization for Extended Service Life

The Dozer Edge-Cutting 11045947's surface treatment achieves optimal hardness levels that significantly extend wear life compared to conventional cutting edges. The heat treatment process creates a hardened surface zone that maintains cutting effectiveness throughout extended operating periods. Boron steel is heat treated and lasts longer than high carbon steel, providing the foundation for the superior wear resistance that characterizes this cutting edge. This enhanced wear resistance translates directly into operational cost savings through reduced replacement frequency and extended maintenance intervals. Construction and mining operations report significantly longer service life from the Dozer Edge-Cutting 11045947 compared to previous cutting edge solutions, with some applications showing wear life improvements of 40-60% over standard alternatives. The wearpart engineering team's focus on wear resistance optimization ensures that customers achieve maximum value from their equipment investment.

-

Impact Resistance and Fracture Toughness

Beyond wear resistance, the Dozer Edge-Cutting 11045947 demonstrates exceptional impact resistance that prevents the chipping and fracturing common in harder but more brittle cutting edge materials. The dual-material construction provides an optimal balance between hardness and toughness, enabling the cutting edge to absorb impact loads without catastrophic failure. This characteristic is particularly valuable in rocky conditions or applications involving buried obstacles where impact loads can destroy conventional cutting edges. The fracture toughness of the Dozer Edge-Cutting 11045947 ensures reliable performance even when subjected to severe operating conditions that would cause failure in single-material alternatives. This reliability reduces unplanned downtime and maintenance costs while improving operational productivity through consistent cutting performance.

Cost-Effectiveness Through Extended Operational Life

-

Total Cost of Ownership Analysis

The economic advantages of the Dozer Edge-Cutting 11045947 become evident through comprehensive total cost of ownership analysis. While the initial investment may be slightly higher than basic alternatives, the extended service life and reduced maintenance requirements generate substantial cost savings over the cutting edge's operational lifespan. The superior wear resistance means fewer replacement cycles, reducing both parts costs and labor expenses associated with cutting edge changes. Operational data from wearpart customers consistently demonstrates that the Dozer Edge-Cutting 11045947 provides lower per-hour operating costs compared to conventional cutting edges. The extended wear life reduces inventory requirements and simplifies parts management, while the reliable performance characteristics minimize unexpected downtime that can disrupt project schedules and increase operational costs.

-

Fuel Efficiency and Performance Benefits

The Dozer Edge-Cutting 11045947's sharp cutting profile and consistent wear characteristics contribute to improved fuel efficiency throughout its service life. A sharp, well-maintained cutting edge reduces resistance, allowing the dozer to work faster and use less fuel. The superior material properties maintain cutting effectiveness longer than conventional alternatives, ensuring sustained productivity and fuel efficiency benefits throughout the operational cycle. The precision manufacturing and optimal hardness distribution create a cutting edge that maintains its geometry under load, providing consistent ground engagement and material flow characteristics. This stability reduces the need for multiple passes and enables more efficient earthmoving operations that translate into measurable productivity improvements.

Global Manufacturing Excellence and Supply Chain Reliability

-

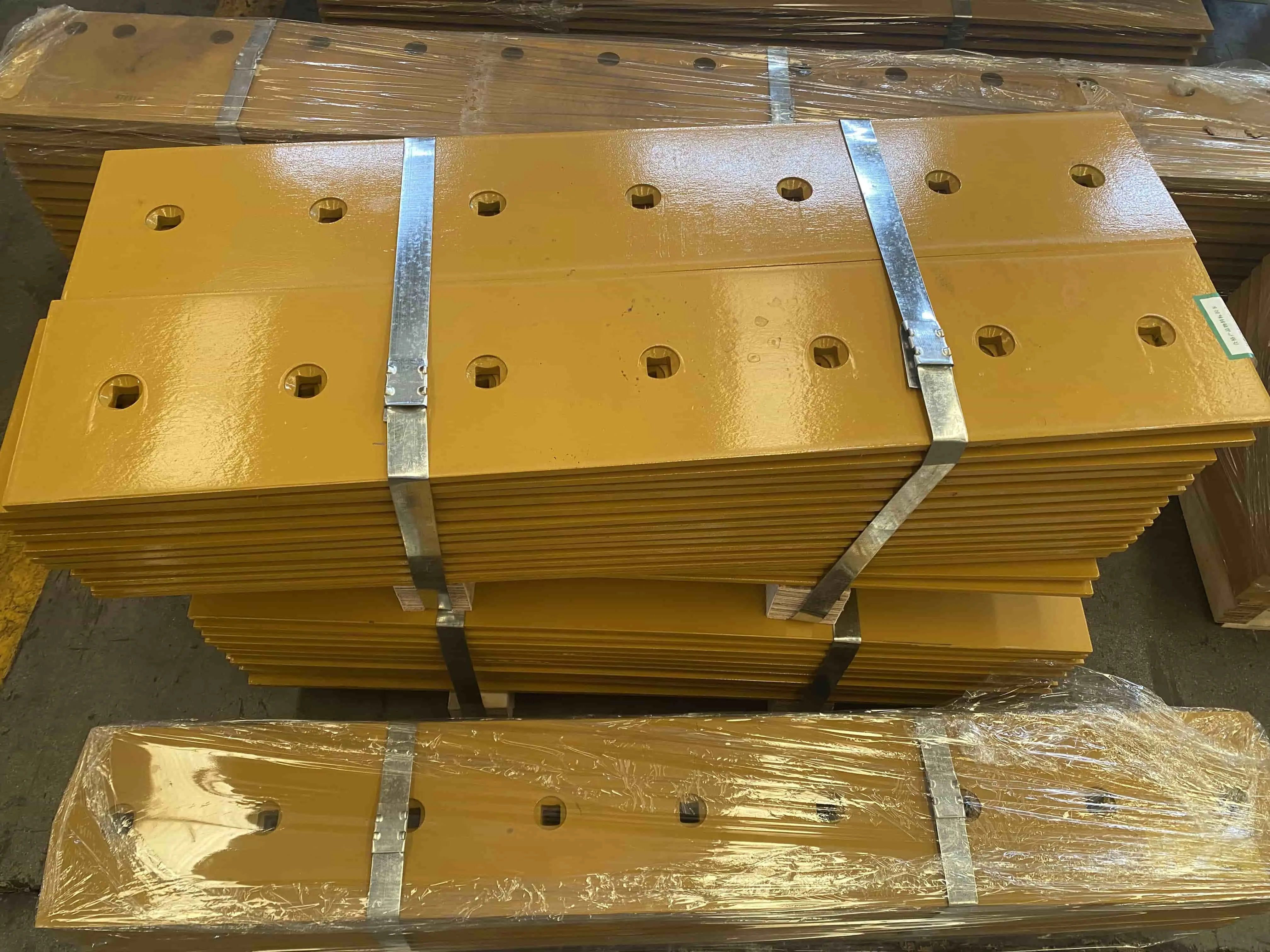

Shanghai SINOBL's Manufacturing Capabilities

Shanghai SINOBL Precision Machinery Co., Ltd. brings over a decade of specialized manufacturing experience to the production of Dozer Edge-Cutting 11045947 components. The company's 55,944 square meter manufacturing facility houses advanced production equipment specifically designed for G.E.T. parts manufacturing, including cutting edges, end bits, grader blades, and undercarriage components. This focused specialization ensures that every Dozer Edge-Cutting 11045947 benefits from accumulated expertise and optimized manufacturing processes. The facility's production capacity includes cutting edge manufacturing capabilities of 2,500 tons per month, ensuring reliable supply availability for large-scale operations and bulk orders. This manufacturing scale, combined with over 3,000 tons of inventory maintained for quick dispatch, provides customers with responsive delivery and reduced lead times that support operational continuity.

-

International Quality Standards and Certifications

The wearpart manufacturing operation maintains multiple international quality certifications that validate its commitment to excellence in Dozer Edge-Cutting 11045947 production. ISO 9001:2015 Quality Management System certification ensures systematic quality control throughout the manufacturing process, while CE certification enables seamless access to European markets with full regulatory compliance. These certifications represent more than administrative requirements—they reflect a comprehensive approach to quality management that encompasses material selection, process control, and final product verification. The certification standards require continuous improvement processes that drive ongoing enhancements in Dozer Edge-Cutting 11045947 quality and performance characteristics.

Conclusion

The Dozer Edge-Cutting 11045947 from Shanghai SINOBL represents the pinnacle of cutting edge technology through its superior material engineering, precision manufacturing, exceptional wear resistance, cost-effective performance, and global manufacturing excellence. These five critical advantages combine to deliver a cutting edge solution that consistently outperforms competitors while providing measurable value through extended service life, reduced maintenance requirements, and enhanced operational productivity that keeps your equipment running efficiently when it matters most.

Cooperate with Shanghai Sinobl Precision Machinery Co., Ltd.

Partner with Shanghai SINOBL Precision Machinery Co., Ltd., your premier China Dozer Edge-Cutting 11045947 factory and China Dozer Edge-Cutting 11045947 supplier, established in 2011 and specializing in premium G.E.T. parts manufacturing. As a leading China Dozer Edge-Cutting 11045947 manufacturer offering China Dozer Edge-Cutting 11045947 wholesale solutions, we provide High Quality Dozer Edge-Cutting 11045947 with competitive Dozer Edge-Cutting 11045947 price structures and Dozer Edge-Cutting 11045947 for sale worldwide. Our OEM and ODM services include custom dimensions, color options, logo branding, and specialized packaging to meet your exact requirements. Contact nancy@sunmach.com.cn today for your inquiry and discover why industry professionals choose SINOBL for reliable, cost-effective wear parts solutions.

FAQ

Q: What makes the Dozer Edge-Cutting 11045947 more durable than standard cutting edges?

A: The dual-material construction combining high-carbon steel with heat-treated boron steel provides superior wear resistance and impact toughness compared to single-material alternatives.

Q: How much longer does the Dozer Edge-Cutting 11045947 last compared to competitors?

A: Customer data shows 40-60% longer service life in typical applications due to advanced material properties and precision manufacturing processes.

Q: Is the Dozer Edge-Cutting 11045947 compatible with different dozer models?

A: Yes, the precision-manufactured dimensions (25x380x574mm) and OEM specification compliance ensure compatibility with multiple dozer blade systems.

Q: What quality certifications does Shanghai SINOBL maintain for manufacturing?

A: The facility maintains ISO 9001:2015 Quality Management System certification and CE certification, ensuring consistent quality and international compliance standards.

References

1. "Heat Treatment Fundamentals for Construction Equipment Components" - American Society for Metals International, Materials Engineering Department

2. "Boron Steel Metallurgy and Applications in Heavy Equipment Manufacturing" - Society of Automotive Engineers, Materials Science Division

3. "Ground Engaging Tool Design and Performance Analysis" - Construction Industry Research and Information Association, Technical Publications

4. "Wear Resistance Technologies in Earthmoving Equipment" - International Journal of Materials Science and Engineering, Manufacturing Technology Institute