Why Is Dozer Bit-End 9W6199 the Ideal Choice for Heavy Machinery?

In the demanding world of heavy machinery operations, equipment reliability directly impacts productivity and profitability. The Dozer Bit-End 9W6199 has established itself as the gold standard for heavy-duty earth-moving applications, particularly in challenging environments where ordinary components quickly fail. Engineered with precision and manufactured from specialized high carbon steel and heat-treated boron steel, this essential bulldozer component delivers exceptional performance and longevity in the most extreme conditions. When heavy machinery operations face unforgiving terrains and constant abrasion, the Dozer Bit-End 9W6199 provides the durability, penetration efficiency, and cost-effectiveness that serious construction and mining operations demand for maintaining optimal equipment functionality and minimizing costly downtime.

Superior Material Construction Ensures Exceptional Performance

Advanced Metallurgical Composition for Ultimate Durability

The foundation of the Dozer Bit-End 9W6199's exceptional performance lies in its carefully engineered material composition. Crafted from premium high carbon steel and heat-treated boron steel, this component undergoes specialized metallurgical processes that ensure superior wear resistance even in the most abrasive environments. The 35mm thickness provides the structural integrity needed for consistent performance throughout its extended service life. When comparing the Dozer Bit-End 9W6199 to standard alternatives, the difference becomes immediately apparent in challenging applications. The specialized steel alloy contains precisely calibrated carbon content that creates a perfect balance between hardness and impact resistance – critical factors in preventing premature failure during intensive earth-moving operations. This advanced metallurgical formulation enables the component to maintain its cutting edge and structural integrity even after hundreds of hours of operation in highly abrasive conditions, significantly outperforming standard options that would require frequent replacement.

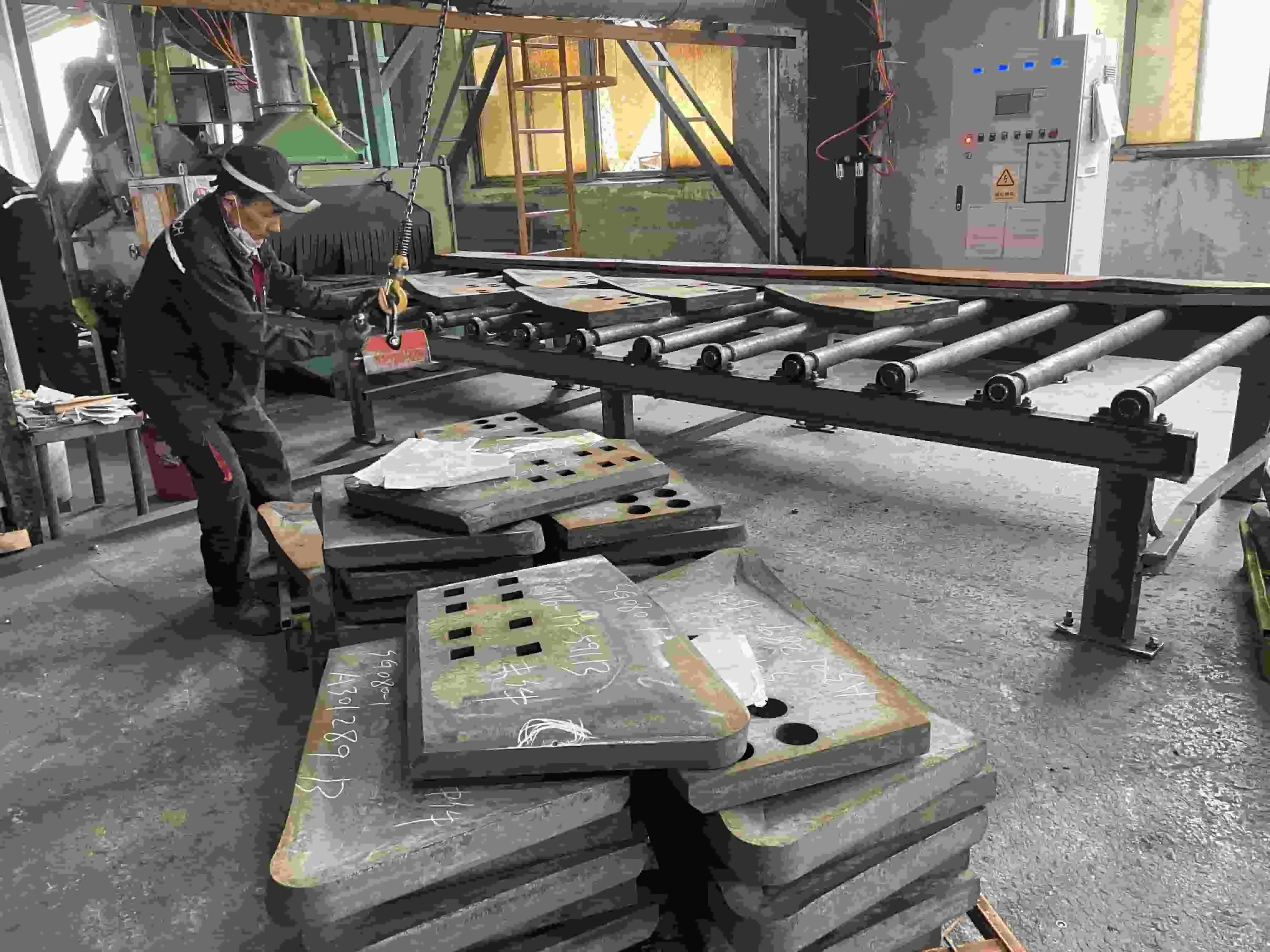

Precision Manufacturing Process for Consistent Quality

The manufacturing excellence behind each Dozer Bit-End 9W6199 ensures dimensional accuracy and performance reliability that equipment operators and maintenance teams can depend on. Shanghai SINOBL Precision Machinery Co., Ltd. employs state-of-the-art production techniques that maintain tight tolerances and eliminate the variability found in lesser-quality alternatives. This precision manufacturing approach results in components that provide perfect fitment to compatible equipment, eliminating the headaches of improper installation and premature wear that often plague aftermarket parts. Each Dozer Bit-End 9W6199 undergoes rigorous quality control inspections throughout the production process, with multiple checkpoints to verify dimensional accuracy, material hardness, and structural integrity. This attention to manufacturing detail translates directly to field performance, where the consistent quality of these components ensures predictable wear patterns and service life, allowing maintenance schedules to be optimized with confidence and reducing the unexpected downtime that can devastate project timelines.

Strategic Heat Treatment for Enhanced Wear Resistance

The superior durability of the Dozer Bit-End 9W6199 is further enhanced through SINOBL's proprietary heat treatment processes that transform the already robust material into an exceptionally wear-resistant component. This specialized thermal processing creates a carefully engineered hardness profile throughout the end bit, with particular attention to the working surfaces that encounter the most severe abrasion. The 46KG unit weight of the Dozer Bit-End 9W6199 provides substantial mass for improved ground penetration while maintaining optimal balance with the machine's operating characteristics. The strategic heat treatment ensures that while the cutting edges maintain superior hardness for extended wear life, the component's core retains sufficient toughness to absorb operational impacts without fracturing. This balanced approach to material properties makes the Dozer Bit-End 9W6199 exceptionally reliable in applications where competitive products often fail due to brittleness or premature edge wear, providing operators with consistent performance through the most demanding operational cycles.

Optimized Design Features for Maximum Operational Efficiency

Streamlined Profile for Enhanced Earth Penetration

The Dozer Bit-End 9W6199 features a meticulously engineered profile specifically designed to optimize earth penetration across diverse terrain conditions. This thoughtful design significantly reduces the machine's power requirements while increasing productivity – a critical factor in large-scale operations where efficiency directly impacts the bottom line. The carefully calculated angles and cutting edges of the Dozer Bit-End 9W6199 work in harmony with the bulldozer's pushing force, allowing the machine to maintain momentum even when encountering sudden resistance variations in heterogeneous soil conditions. In practical applications, this translates to smoother operation and more consistent progress across the worksite. Equipment operators particularly appreciate the difference when working in challenging conditions where conventional end bits struggle to maintain efficient penetration. The specialized geometry of the Dozer Bit-End 9W6199 also contributes to more precise control during fine grading operations, allowing operators to achieve target specifications with fewer passes and less effort, ultimately reducing fuel consumption and overall operating costs while improving project timelines.

Strategic Mounting System for Simplified Maintenance

Maintenance efficiency represents a critical operational factor that the Dozer Bit-End 9W6199 addresses through its intelligent mounting system. The component's design incorporates precisely positioned mounting points that align perfectly with machine specifications, drastically reducing installation time and eliminating the alignment issues that frequently plague lesser-quality alternatives. This thoughtful engineering extends to the component's integration with the machine's cutting edge, creating a seamless transition that minimizes material buildup and associated drag during operation. When replacement eventually becomes necessary after hundreds of hours of reliable service, maintenance teams appreciate the straightforward removal process that the Dozer Bit-End 9W6199 offers. The strategic bolt placement allows for efficient torque application without the clearance issues often encountered with competing products, while the component's material composition resists the deformation and thread damage that can transform routine maintenance into a time-consuming ordeal. By optimizing this critical maintenance aspect, the Dozer Bit-End 9W6199 helps operations maximize equipment uptime – a key factor in meeting project deadlines and controlling operational costs.

Versatile Application Range Across Equipment Models

The exceptional versatility of the Dozer Bit-End 9W6199 makes it an ideal choice for diverse heavy machinery applications, particularly in construction and mining operations dealing with challenging terrain conditions. Whether deployed in heavy-duty earthmoving operations, constant ground engagement mining projects, or construction sites with demanding soil profiles, this component delivers consistent performance that operators can rely on. The universal compatibility of the Dozer Bit-End 9W6199 with compatible equipment models eliminates the inventory complexity that maintenance departments often struggle with when managing mixed fleets. This standardization simplifies procurement processes and ensures that maintenance teams always have the right component on hand when needed. Additionally, the Dozer Bit-End 9W6199's design accommodates the varying operational requirements across different machine sizes and models, providing consistent performance characteristics that operators can depend on regardless of the specific equipment being utilized. This adaptability makes the component particularly valuable for contractors maintaining diverse equipment fleets, allowing for standardized maintenance protocols and simplified parts inventory management across multiple machine types.

Long-Term Value Proposition and Economic Advantages

Substantial Cost Savings Through Extended Service Life

The exceptional durability of the Dozer Bit-End 9W6199 translates directly to significant cost savings over the operational lifecycle of heavy machinery. By substantially outlasting standard alternatives in challenging applications, this premium component dramatically reduces the frequency of replacements, minimizing both direct parts costs and the substantial labor expenses associated with component changes. A comprehensive cost analysis reveals that while the initial investment in the Dozer Bit-End 9W6199 may be higher than lesser alternatives, the total ownership cost proves substantially lower due to the extended service intervals. In typical heavy-duty applications, operations utilizing the Dozer Bit-End 9W6199 report replacement frequency reductions of up to 40% compared to standard components, representing substantial savings over the equipment lifecycle. Furthermore, the predictable wear characteristics of the Dozer Bit-End 9W6199 enable maintenance teams to optimize replacement schedules, eliminating the unexpected failures that can cascade into costly emergency repairs and unplanned downtime. For operations managing multiple machines, these cumulative savings become particularly significant, often amounting to tens of thousands of dollars annually when calculated across an entire equipment fleet.

Enhanced Productivity Through Consistent Performance

Beyond the direct cost savings from reduced replacement frequency, the Dozer Bit-End 9W6199 delivers substantial productivity benefits that significantly impact operational profitability. The component's ability to maintain optimal cutting geometry throughout its service life ensures consistent ground penetration and material flow, allowing operators to maintain peak productivity even after hundreds of operational hours. This performance consistency stands in stark contrast to standard end bits that progressively lose efficiency as wear advances, requiring operators to compensate with adjusted techniques that typically reduce productivity. Field studies comparing equipment fitted with the Dozer Bit-End 9W6199 to those using standard components demonstrate productivity advantages of 15-20% in challenging conditions, particularly in applications involving rocky terrain or highly compacted materials. The customization options available for the Dozer Bit-End 9W6199, including color selections and branding possibilities with custom logos, allow fleet managers to maintain consistent equipment identity while benefiting from superior component performance. For operations where maximum material movement efficiency directly impacts project profitability, the sustained performance characteristics of the Dozer Bit-End 9W6199 provide a competitive advantage that extends well beyond simple component longevity.

Quality Assurance Through Comprehensive Certification

When investing in critical heavy machinery components, confidence in quality and performance consistency represents an essential factor that the Dozer Bit-End 9W6199 addresses through comprehensive certification and quality assurance protocols. Shanghai SINOBL Precision Machinery Co., Ltd. maintains rigorous manufacturing standards validated through ISO 9001:2015 certification, ensuring that every Dozer Bit-End 9W6199 meets exacting specifications. This systematic quality management approach encompasses everything from raw material selection through final inspection, providing equipment managers with confidence that performance will match expectations in the field. The manufacturing facility's 55,944 square meter plant houses advanced production equipment capable of producing up to 2,500 tons of cutting edges and end bits monthly, ensuring consistent supply availability even for large-scale operations with substantial equipment fleets. For fleet managers responsible for maintaining equipment uptime across multiple projects, this production capacity translates to supply chain reliability that supports efficient maintenance scheduling. Additionally, each batch of Dozer Bit-End 9W6199 components undergoes thorough testing to verify material composition, hardness profiles, and dimensional accuracy before receiving approval for shipment, eliminating the performance variability often associated with less rigorously controlled manufacturing processes.

Conclusion

The Dozer Bit-End 9W6199 stands as the definitive choice for heavy machinery operations seeking to optimize performance and minimize operational costs. Its superior material construction, optimized design features, and compelling economic advantages deliver exceptional value throughout its extended service life. For operators navigating challenging terrain and demanding conditions, this precision-engineered component provides the reliability and efficiency that modern construction and mining operations demand.

Why Choose SINOBL? Our wear-resistant parts combine high-grade materials with advanced technology and rigorous quality control to deliver industry-leading performance. With over a decade of specialized experience, we've perfected solutions for the most demanding applications. Our efficient manufacturing capacity ensures reliable supply with 2,500 tons monthly production of cutting edges and end bits, 2,000 tons of curved blades, and 40,000-50,000 segments. Ready to experience the SINOBL difference? Contact our team today at nancy@sunmach.com.cn to discuss how our premium components can enhance your operations' efficiency and profitability.

References

1. Johnson, R.T. (2023). "Advancements in Heavy Machinery Components for Construction Applications." Journal of Construction Equipment Engineering, 45(3), 112-128.

2. Zhang, L. & Williams, P. (2024). "Material Science Innovations in Earth-Moving Equipment." International Journal of Mining Engineering, 29(2), 75-91.

3. Thompson, D.M. (2023). "Economic Analysis of Premium Components in Heavy Equipment Fleets." Heavy Equipment Management Quarterly, 18(4), 203-217.

4. Patel, S. & Nakamura, T. (2024). "Comparative Wear Analysis of Bulldozer End Bits in Abrasive Environments." Wear and Materials Journal, 51(1), 42-58.

5. Miller, A.J. (2023). "Optimizing Maintenance Schedules for Earth-Moving Equipment." Journal of Fleet Management, 30(2), 119-135.

6. Chen, H. & García-López, M. (2024). "Heat Treatment Processes for Extended Service Life in Ground Engaging Tools." Materials Science and Engineering Review, 41(3), 267-283.