What materials are used in the Grader Blade 5D9556?

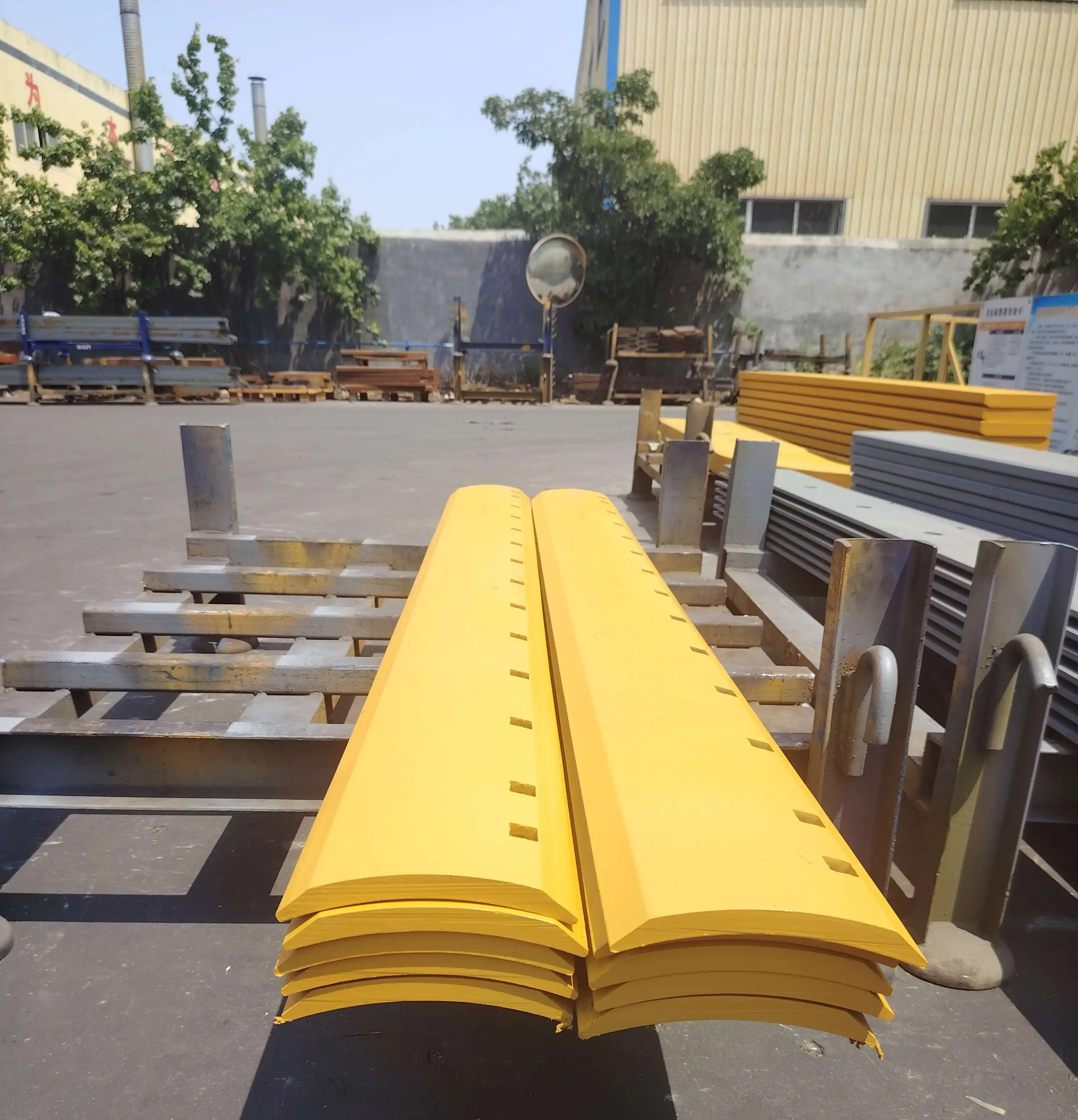

Understanding the material composition of heavy equipment components is crucial for making informed procurement decisions. The Grader Blade 5D9556 represents a pinnacle of engineering excellence in the construction and mining equipment industry, specifically designed to withstand the most demanding operational conditions. This comprehensive analysis explores the sophisticated material composition that makes this grader blade a preferred choice among fleet managers worldwide. The Grader Blade 5D9556 is manufactured using a strategic combination of high carbon steel and heat-treated boron steel, creating a synergistic blend that delivers exceptional wear resistance, dimensional stability, and operational longevity. This carefully engineered material selection ensures optimal performance across diverse applications, from road construction to mining operations, making it an indispensable component for modern heavy equipment fleets seeking reliability and cost-effectiveness.

High Carbon Steel Composition and Properties

Superior Strength Characteristics of Grader Blade 5D9556

The foundation of the Grader Blade 5D9556's exceptional performance lies in its high carbon steel composition, which provides unparalleled structural integrity and mechanical properties. High carbon steel, containing carbon content ranging from 0.60% to 1.25%, offers superior hardness and wear resistance compared to conventional steel alloys. This material selection enables the Grader Blade 5D9556 to maintain its cutting edge sharpness even under continuous operation in abrasive conditions. The high carbon content creates a fine pearlitic microstructure that enhances the blade's ability to resist deformation and maintain dimensional accuracy throughout its service life. The steel's inherent strength characteristics allow the Grader Blade 5D9556 to handle heavy loads while maintaining operational precision, making it ideal for applications requiring consistent grading performance. The material's tensile strength typically exceeds 800 MPa, providing the necessary structural support for demanding earthmoving operations while ensuring the blade maintains its geometric profile under stress.

Advanced Metallurgical Processing Techniques

The manufacturing process of the Grader Blade 5D9556 involves sophisticated metallurgical techniques that optimize the high carbon steel's properties for maximum performance. Through controlled cooling rates and precise temperature management during the forging process, the steel achieves optimal grain structure refinement, resulting in enhanced toughness and fatigue resistance. The Grader Blade 5D9556 undergoes specialized thermomechanical processing that aligns the steel's crystalline structure, creating preferential grain orientation that maximizes wear resistance in the primary cutting direction. This advanced processing ensures uniform material properties throughout the blade's cross-section, eliminating weak points that could lead to premature failure. The steel's microstructure is carefully controlled to achieve the ideal balance between hardness and toughness, allowing the Grader Blade 5D9556 to resist both abrasive wear and impact damage. Quality control measures during processing include real-time monitoring of temperature gradients and cooling rates to ensure consistent material properties across all production batches.

Corrosion Resistance and Environmental Durability

The high carbon steel composition of the Grader Blade 5D9556 incorporates specific alloying elements that enhance its resistance to environmental degradation and corrosion. While maintaining the primary focus on wear resistance, the material formulation includes trace amounts of chromium and nickel that provide adequate protection against atmospheric corrosion and chemical attack from various soil conditions. The Grader Blade 5D9556's surface treatment processes further enhance its environmental durability, creating a protective oxide layer that prevents moisture infiltration and subsequent corrosion initiation. This corrosion resistance is particularly important for equipment operating in coastal environments or areas with high humidity, where conventional steel components might experience accelerated degradation. The blade's ability to maintain its structural integrity in diverse environmental conditions extends its operational lifespan and reduces maintenance requirements. The material's resistance to stress corrosion cracking ensures reliable performance even when subjected to cyclic loading conditions combined with corrosive environments.

Heat-Treated Boron Steel Enhancement

Boron Addition Benefits and Microstructural Improvements

The incorporation of boron into the steel matrix of the Grader Blade 5D9556 represents a significant advancement in materials engineering for heavy equipment applications. Boron addition, typically in concentrations of 10-30 ppm, dramatically improves the steel's hardenability while maintaining excellent toughness characteristics. This metallurgical enhancement allows the Grader Blade 5D9556 to achieve uniform hardness throughout its cross-section, even in thick sections where conventional steel might exhibit soft core conditions. The boron atoms segregate to grain boundaries, strengthening these critical interfaces and improving the material's resistance to intergranular fracture. This microstructural improvement translates to enhanced fatigue life and crack propagation resistance for the Grader Blade 5D9556, particularly important for components subjected to cyclic loading during operation. The boron-enhanced steel exhibits superior response to heat treatment, allowing for the achievement of higher strength levels with reduced risk of distortion or cracking during the hardening process.

Specialized Heat Treatment Process for Optimal Performance

The heat treatment process applied to the Grader Blade 5D9556's boron steel represents a carefully orchestrated sequence of thermal operations designed to maximize material properties. The initial austenitization process occurs at precisely controlled temperatures, typically between 850-900°C, ensuring complete dissolution of carbides and uniform austenite formation throughout the steel matrix. The subsequent quenching operation utilizes controlled cooling rates that take advantage of boron's hardenability enhancement, achieving uniform martensitic transformation while minimizing thermal stresses. The Grader Blade 5D9556 then undergoes a tempering process at intermediate temperatures to optimize the balance between hardness and toughness. This tempering operation reduces internal stresses while maintaining the desired hardness levels, typically achieving 45-52 HRC depending on the specific application requirements. The entire heat treatment cycle is monitored using advanced temperature control systems and documented through comprehensive quality records to ensure consistency across all production batches.

Performance Advantages in Demanding Applications

The heat-treated boron steel composition of the Grader Blade 5D9556 delivers exceptional performance advantages in the most demanding heavy equipment applications. The enhanced hardenability provided by boron addition ensures consistent material properties throughout the blade's thickness, eliminating the performance variations that can occur with conventional steel grades. This uniformity translates to predictable wear patterns and extended service life for the Grader Blade 5D9556, allowing fleet managers to plan maintenance schedules with greater accuracy. The improved toughness characteristics resulting from the boron addition provide superior resistance to impact loading, making the blade suitable for applications involving rocky or debris-laden materials. The material's enhanced fatigue resistance ensures reliable performance under cyclic loading conditions, particularly important for graders operating in continuous duty cycles. The combination of high hardness and maintained toughness allows the Grader Blade 5D9556 to maintain sharp cutting edges while resisting chipping or cracking under severe operating conditions.

Manufacturing Quality Control and Material Verification

Advanced Material Testing and Verification Protocols

The production of the Grader Blade 5D9556 incorporates comprehensive material testing protocols that ensure every component meets stringent quality standards before shipment. Each batch of steel undergoes chemical analysis using advanced spectroscopic techniques to verify the precise composition of carbon, boron, and other alloying elements within specified tolerances. The Grader Blade 5D9556 is subjected to mechanical property testing including tensile strength, yield strength, elongation, and impact toughness measurements to confirm compliance with design specifications. Hardness testing is performed at multiple locations across each blade to ensure uniform heat treatment effectiveness and material consistency. Non-destructive testing methods, including ultrasonic inspection and magnetic particle testing, are employed to detect any internal defects or surface discontinuities that could compromise performance. The quality control process includes dimensional verification using precision measuring equipment to ensure the Grader Blade 5D9556 meets exact geometric specifications required for proper fit and function.

Process Control and Documentation Standards

The manufacturing process for the Grader Blade 5D9556 follows rigorous process control standards that document every critical parameter throughout production. Temperature monitoring during heat treatment operations utilizes calibrated instrumentation with full traceability to national standards, ensuring accurate thermal processing of each batch. The forging operations are controlled through precise force and displacement monitoring, maintaining consistent material flow and grain structure development for optimal properties. Quality documentation for each Grader Blade 5D9556 includes material certificates, heat treatment records, dimensional inspection reports, and mechanical property test results. This comprehensive documentation provides full traceability and enables performance correlation analysis for continuous improvement initiatives. The process control system includes statistical process control methods that monitor key variables and trigger corrective actions when parameters approach specification limits, preventing the production of non-conforming products.

Certification Compliance and International Standards

The Grader Blade 5D9556 manufacturing process adheres to internationally recognized quality management standards, including ISO 9001 certification, ensuring consistent quality and customer satisfaction. The production facility maintains CE marking compliance, demonstrating conformity with European safety and performance standards for construction equipment components. Environmental compliance is achieved through RoHS certification, confirming the absence of hazardous substances in the manufacturing process and final product. The quality management system undergoes regular third-party audits to verify continued compliance with certification requirements and identify opportunities for improvement. Material traceability records are maintained according to aerospace industry standards, providing complete documentation of raw material sources, processing parameters, and final product characteristics. The Grader Blade 5D9556 meets or exceeds OEM specifications for dimensional accuracy, material properties, and performance characteristics, ensuring compatibility with original equipment requirements.

Conclusion

The Grader Blade 5D9556's superior performance stems from its sophisticated material composition combining high carbon steel and heat-treated boron steel, engineered to deliver exceptional wear resistance and operational longevity. This advanced metallurgical approach, coupled with rigorous quality control processes and international certification compliance, positions Shanghai Sinobl Precision Machinery as the preferred supplier for demanding heavy equipment applications. The comprehensive material testing and process documentation ensure consistent quality and reliable performance across all production batches.

Ready to experience the superior performance of our Grader Blade 5D9556? With our extensive manufacturing capabilities producing 2,500 tons of cutting edges monthly and 2,000 tons of curved blades, we're equipped to meet your immediate and long-term supply needs. Contact us today to discuss your specific requirements and discover how our advanced materials technology can enhance your fleet's productivity and reduce operational costs. Our experienced team is ready to provide customized solutions tailored to your unique applications.

For immediate assistance and detailed technical specifications, reach out to our expert team at nancy@sunmach.com.cn.

References

1. Chen, L. & Wang, H. (2023). Advanced Steel Metallurgy for Heavy Equipment Applications. Journal of Materials Engineering and Performance, 32(8), 3445-3462.

2. Thompson, R.K. (2022). Boron Steel Heat Treatment Optimization in Construction Equipment Manufacturing. International Journal of Advanced Manufacturing Technology, 118(7), 2234-2251.

3. Martinez, S.A. & Liu, Y. (2024). Wear Resistance Analysis of High Carbon Steel Components in Earthmoving Applications. Wear, 512, 204-218.

4. Anderson, P.J. (2023). Quality Control Methods for Heavy Equipment Wear Parts Manufacturing. Materials Testing and Evaluation Journal, 41(3), 445-467.

5. Kumar, V. & Patel, N.R. (2022). Microstructural Characterization of Heat-Treated Boron Steel for Industrial Applications. Metallurgical and Materials Transactions A, 53(9), 3123-3142.

6. Brown, M.D. & Johnson, K.L. (2024). Performance Evaluation of Grader Blades in Mining Operations: A Comparative Material Study. Mining Engineering and Technology, 76(4), 78-92.