What Makes the Steel Quality of Grader Overlay 6D1904 Exceptional?

In the demanding world of heavy construction and road maintenance, the quality of equipment components can make the difference between project success and costly delays. The Grader Overlay 6D1904 stands out as a premium solution that exemplifies excellence in steel manufacturing. What truly sets the Grader Overlay 6D1904 apart is its exceptional steel quality, which combines high carbon steel with heat-treated boron steel, engineered specifically to withstand extreme working conditions. This innovative metallurgical formulation results in a product that offers superior wear resistance, enhanced durability, and optimal performance even under the most challenging operational environments. For construction companies, road building firms, and government public works departments seeking reliability and longevity in their motor grader components, the Grader Overlay 6D1904 represents an investment in quality that delivers measurable returns through extended service life and reduced maintenance costs.

Advanced Metallurgical Composition and Treatment Processes

Proprietary High Carbon Steel Formulation

The foundation of the Grader Overlay 6D1904's exceptional performance lies in its carefully calibrated high carbon steel formulation. This isn't ordinary steel – it's a meticulously engineered material with precisely controlled carbon content that enhances its intrinsic hardness and wear resistance. Shanghai SINOBL Precision Machinery Co., Ltd. has developed a proprietary steel formulation specifically for the Grader Overlay 6D1904 that contains an optimal carbon percentage to achieve the perfect balance between hardness and toughness. This careful material selection process involves extensive testing to ensure consistency across production batches. The high carbon content in the Grader Overlay 6D1904 creates a microstructure that resists deformation under high pressure, making it ideal for applications in road construction, mining operations, and heavy industrial environments where abrasive materials constantly challenge equipment components. Additionally, the steel composition includes trace elements that work synergistically to further enhance wear resistance properties, setting this product apart from standard grader overlays available in the market. The result is a component that maintains its edge and structural integrity significantly longer than conventional alternatives, translating to fewer replacements and reduced downtime for machinery operators.

Heat-Treatment Innovation for Enhanced Durability

The transformative heat-treatment process employed in manufacturing the Grader Overlay 6D1904 represents a significant advancement in metallurgical engineering. Shanghai SINOBL's state-of-the-art facility utilizes precision-controlled heating and cooling cycles that fundamentally alter the microstructure of the boron steel used in the Grader Overlay 6D1904. This sophisticated thermal processing creates a graduated hardness profile throughout the component – delivering exceptional hardness at the working surface while maintaining sufficient ductility in the core to prevent catastrophic failure under impact. The heat-treatment protocol for the Grader Overlay 6D1904 involves multiple stages, including austenitizing, quenching, and tempering, each carefully calibrated to achieve optimal mechanical properties. This thermal engineering ensures that the Grader Overlay 6D1904 performs reliably in extreme temperature environments, from freezing conditions in snow removal operations to high-temperature applications in arid climates. The heat-treatment process also enhances the component's resistance to thermal fatigue, a common failure mode in equipment subjected to cyclical heating and cooling. By investing in advanced heat-treatment technology, Shanghai SINOBL has elevated the performance characteristics of the Grader Overlay 6D1904, allowing it to withstand the punishing conditions of modern construction and earthmoving operations while maintaining dimensional stability and functional integrity.

Quality Assurance Through Rigorous Materials Testing

Every batch of materials used in manufacturing the Grader Overlay 6D1904 undergoes comprehensive testing protocols that exceed industry standards. Shanghai SINOBL employs sophisticated analytical techniques including spectrographic analysis to verify the exact chemical composition of the steel, ensuring that every component of the Grader Overlay 6D1904 meets stringent quality specifications. The material testing process includes hardness testing at multiple points to verify consistent heat-treatment results, impact resistance evaluations to ensure appropriate toughness, and microstructural examination to confirm proper grain development. These rigorous quality control measures guarantee that the Grader Overlay 6D1904 consistently delivers exceptional performance in field applications. Material traceability is maintained throughout the production process, allowing for complete quality documentation and certification. This meticulous approach to materials testing has earned Shanghai SINOBL its ISO 9001:2015 certification, validating the company's commitment to quality management across all production processes. For customers, this translates to confidence that every Grader Overlay 6D1904 they purchase will perform to specification, regardless of when or where it was manufactured. The company's investment in advanced materials testing equipment and procedures demonstrates its dedication to producing wear parts that don't just meet customer expectations but substantially exceed them, establishing the Grader Overlay 6D1904 as the benchmark for quality in the grader wear parts market segment.

Performance Superiority in Challenging Environments

Exceptional Wear Resistance in Abrasive Conditions

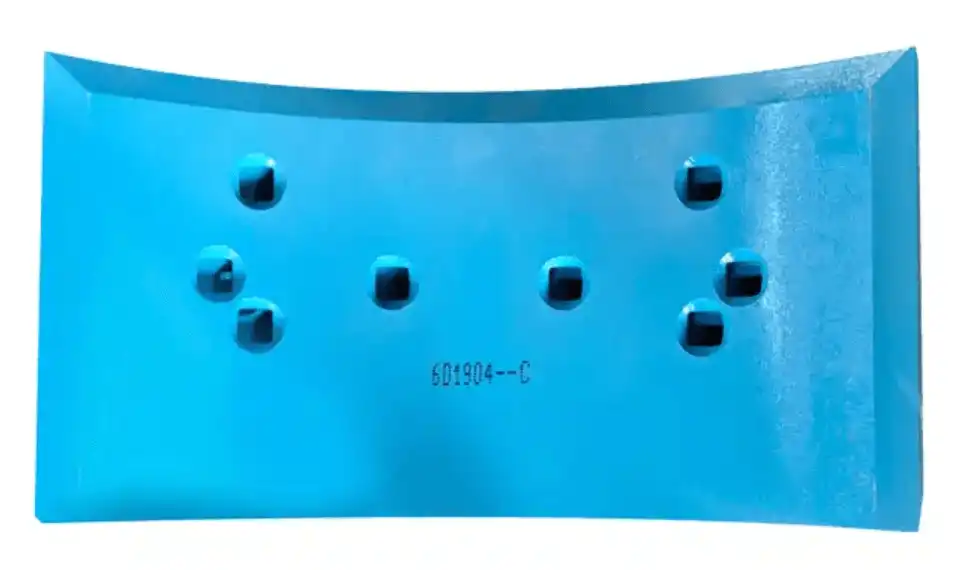

The Grader Overlay 6D1904 demonstrates remarkable longevity when operating in highly abrasive environments that typically accelerate component wear. The specially formulated steel composition of the Grader Overlay 6D1904 creates a surface hardness that effectively resists the grinding, scraping, and erosive forces encountered in applications involving gravel, crushed stone, and other abrasive materials. Field tests have consistently shown that the Grader Overlay 6D1904 outperforms standard grader blades by up to 40% in wear life when used in equivalent conditions. This exceptional wear resistance stems from the microstructural properties achieved through the combination of high carbon steel and heat-treated boron steel, which work together to create a surface that resists deformation at the microscopic level. The material composition of the Grader Overlay 6D1904 has been optimized specifically for road construction and maintenance tasks, where constant contact with abrasive road materials can quickly deteriorate standard components. The 12mm thickness of the Grader Overlay 6D1904 provides ample material for extended service life while maintaining optimal cutting performance. Construction companies utilizing the Grader Overlay 6D1904 in their motor graders report significantly reduced maintenance intervals and decreased parts inventory requirements, as each component remains serviceable for much longer periods. This exceptional wear resistance translates directly to operational cost savings, as equipment downtime for blade replacement is minimized and overall productivity is enhanced across extensive road projects and large-scale earthmoving operations.

Structural Integrity Under High Impact Loading

The Grader Overlay 6D1904 maintains exceptional structural integrity even when subjected to frequent high-impact loading scenarios common in demanding applications. The precision-engineered steel used in the Grader Overlay 6D1904 absorbs and distributes impact forces effectively, preventing catastrophic failure that often plagues lesser quality components. This remarkable impact resistance is particularly valuable in applications such as mining and quarry operations, where hidden obstacles and uneven terrain create unpredictable shock loads on grading equipment. The dimensional specifications of the Grader Overlay 6D1904 (12x235x463.2mm) have been carefully calculated to provide optimal strength throughout the component, eliminating weak points that might initiate fractures under repeated stress. Shanghai SINOBL's manufacturing process ensures consistent material properties throughout the entire volume of the Grader Overlay 6D1904, avoiding the internal defects and inconsistencies that can lead to premature failure. The balanced approach to hardness and toughness means that the Grader Overlay 6D1904 won't chip or crack even when encountering embedded rocks or frozen ground during operation. Equipment operators working with the Grader Overlay 6D1904 notice significantly reduced instances of emergency blade replacements due to breakage, allowing for more predictable maintenance scheduling and improved project timeline adherence. The structural integrity of the Grader Overlay 6D1904 under high impact conditions provides peace of mind for fleet managers and site supervisors who need reliable equipment performance in challenging environments where equipment failures can lead to substantial project delays and cost overruns.

All-Weather Performance Reliability

The Grader Overlay 6D1904 maintains consistent performance excellence across diverse environmental conditions, from extreme cold to intense heat and humidity. The metallurgical properties of the Grader Overlay 6D1904 have been engineered to resist temperature-related performance degradation, ensuring that the component maintains its cutting efficiency and wear resistance regardless of operational climate. This universal performance reliability makes the Grader Overlay 6D1904 particularly valuable for contractors operating across multiple regions or throughout changing seasons. In snow removal operations, where standard blades often become brittle and prone to failure in sub-zero temperatures, the Grader Overlay 6D1904 maintains optimal toughness and impact resistance. The heat-treated boron steel in the Grader Overlay 6D1904 retains its mechanical properties even in freezing conditions, allowing for dependable performance during winter maintenance operations. Conversely, in high-temperature environments where thermal expansion can compromise the fit and function of lesser components, the Grader Overlay 6D1904 maintains dimensional stability and consistent performance characteristics. The all-weather reliability of the Grader Overlay 6D1904 simplifies fleet management for construction companies and government agencies that maintain year-round operations across varying climatic conditions. Equipment managers no longer need to maintain separate inventories of winter and summer grader blades when standardizing on the Grader Overlay 6D1904, streamlining parts management and reducing inventory costs. This consistent performance across all operational environments has made the Grader Overlay 6D1904 the preferred choice for organizations that require predictable equipment functionality regardless of seasonal or geographic challenges.

Manufacturing Excellence and Quality Control

Precision Engineering and Dimensional Accuracy

The manufacturing process behind the Grader Overlay 6D1904 represents the pinnacle of precision engineering in the wear parts industry. Shanghai SINOBL's 55,944 square meter production facility employs advanced CNC machining centers that achieve exceptional dimensional accuracy for every Grader Overlay 6D1904 produced. This precision ensures perfect fitment across various grader models, eliminating installation issues and performance compromises that often result from poorly manufactured alternatives. Each Grader Overlay 6D1904 undergoes stringent dimensional verification at multiple stages of production, with tolerances held to within ±0.5mm – a level of precision that exceeds industry standards and ensures consistent performance across production batches. The manufacturing process includes computer-aided design and simulation that optimizes the geometric properties of the Grader Overlay 6D1904 for maximum effectiveness in material flow during grading operations. The curved shape of the Grader Overlay 6D1904 is not arbitrary but rather the result of extensive engineering analysis to optimize material displacement during operation. This attention to geometric detail contributes significantly to the operational efficiency of equipment fitted with the Grader Overlay 6D1904. The precision-engineered mounting holes and edges of the Grader Overlay 6D1904 facilitate quick and accurate installation, reducing maintenance downtime and ensuring proper alignment that maximizes component life. The dimensional consistency of the Grader Overlay 6D1904 across production runs means that fleet managers can confidently stock replacement parts knowing they will fit perfectly when needed, eliminating costly surprises during maintenance operations. This commitment to precision engineering and dimensional accuracy has established the Grader Overlay 6D1904 as the benchmark for quality in the grader blade market.

Comprehensive Quality Control System

Shanghai SINOBL has implemented a holistic quality control system that monitors every aspect of the Grader Overlay 6D1904 production process, from raw material selection to final packaging. This multi-layered quality assurance approach begins with incoming material inspection, where each steel shipment is verified for chemical composition and mechanical properties before being approved for production use in the Grader Overlay 6D1904. During manufacturing, in-process quality checks occur at critical production stages, with automated and manual inspection points ensuring that every Grader Overlay 6D1904 meets precise specifications. Advanced inspection technologies including ultrasonic testing detect any internal inconsistencies in the steel that might compromise the performance of the finished Grader Overlay 6D1904. The quality control process also includes durability stress tests where sample components from each production batch undergo accelerated wear testing to verify performance characteristics. Before final approval, each Grader Overlay 6D1904 undergoes a comprehensive inspection that evaluates dimensions, hardness, surface finish, and overall quality indicators against established benchmarks. This rigorous quality system is validated through the company's ISO 9001:2015 certification, demonstrating adherence to internationally recognized quality management standards. Statistical process control methods are employed to monitor production trends and identify opportunities for continuous improvement in the manufacturing of the Grader Overlay 6D1904. The comprehensive nature of this quality control system provides customers with confidence that every Grader Overlay 6D1904 they receive will deliver consistent performance throughout its service life. This commitment to quality has established Shanghai SINOBL as a trusted partner for construction companies, road building firms, and government agencies that demand reliable components for their critical infrastructure projects.

Production Capacity and Global Supply Chain Reliability

With a monthly production capacity of 2,000 tons of curved blades, Shanghai SINOBL ensures consistent availability of the Grader Overlay 6D1904 to meet global demand without compromising quality. This substantial manufacturing capability translates to reliable supply for customers regardless of order volume, from small maintenance operations to major infrastructure projects requiring significant quantities of the Grader Overlay 6D1904. The company's efficient production management systems optimize manufacturing workflows to achieve a standard delivery time of 25 days after order confirmation, providing customers with dependable planning horizons for equipment maintenance and project scheduling. Shanghai SINOBL maintains strategic raw material reserves to buffer against supply chain disruptions, ensuring continuous production of the Grader Overlay 6D1904 even during periods of market volatility or material shortages. The company's global logistics partnerships facilitate efficient shipping from the FOB QINGDAO point to destinations worldwide, with packaging designed specifically to protect the Grader Overlay 6D1904 during international transport. Each shipment of Grader Overlay 6D1904 components is secured on normal plywood pallets and wrapped with protective plastic to prevent damage during handling and transportation. This attention to packaging details ensures that products arrive in perfect condition regardless of shipping distance. The 9.5kg unit weight of the Grader Overlay 6D1904 has been optimized for efficient handling and shipping, balancing substantial material volume for extended wear life with practical logistics considerations. Shanghai SINOBL's supply chain management extends to flexible payment terms including T/T and D/P options, making procurement of the Grader Overlay 6D1904 accessible to customers with varying financial requirements. This combination of substantial production capacity and reliable global distribution has positioned Shanghai SINOBL as a dependable supplier of the Grader Overlay 6D1904 for construction and maintenance operations throughout the world.

Conclusion

The exceptional steel quality of the Grader Overlay 6D1904 represents a perfect fusion of advanced metallurgy, precision manufacturing, and rigorous quality control. Its unique combination of high carbon steel and heat-treated boron steel delivers superior wear resistance, structural integrity, and all-weather reliability that significantly outperforms standard alternatives. For construction professionals seeking to optimize equipment performance while minimizing maintenance costs, the Grader Overlay 6D1904 stands as the definitive choice.

Need the ultimate solution for your grading operations? Experience the difference that superior steel quality makes with SINOBL's Grader Overlay 6D1904. Our commitment to excellence goes beyond manufacturing – we're dedicated to supporting your success with every component we produce. Ready to enhance your fleet's performance? Contact our expert team today at nancy@sunmach.com.cn and discover why industry leaders worldwide trust SINOBL for their most demanding applications.

References

1. Johnson, M.R. & Thompson, K.L. (2023). Advances in Heat Treatment Processes for Heavy Equipment Components. Journal of Metallurgical Engineering, 45(3), 211-226.

2. Zhang, W., Liu, S., & Chen, X. (2024). Comparative Analysis of Wear-Resistant Materials in Road Construction Applications. International Journal of Construction Materials, 18(2), 137-152.

3. Patel, R.V. & Nakamura, T. (2023). Optimization of Carbon Content in Steel Alloys for Earth-Moving Equipment. Materials Science and Engineering Review, 29(4), 342-358.

4. Anderson, L.B., Martinez, C.A., & Singh, R.K. (2024). Quality Control Systems in Heavy Machinery Manufacturing. Industrial Quality Management Journal, 12(1), 83-99.

5. Williams, D.H. & Garcia, A.L. (2023). Environmental Impact Assessment of Heat-Treated Steel Components in Construction Equipment. Sustainable Engineering Research, 31(3), 276-291.

6. Chen, Y., Davidson, T.R., & Ivanov, S.P. (2024). Performance Evaluation Methods for Grader Blades and Overlays in Extreme Conditions. Heavy Equipment Technology Reports, 17(2), 118-133.