What is the function of the Grader Overlay 8E5529 in motor graders?

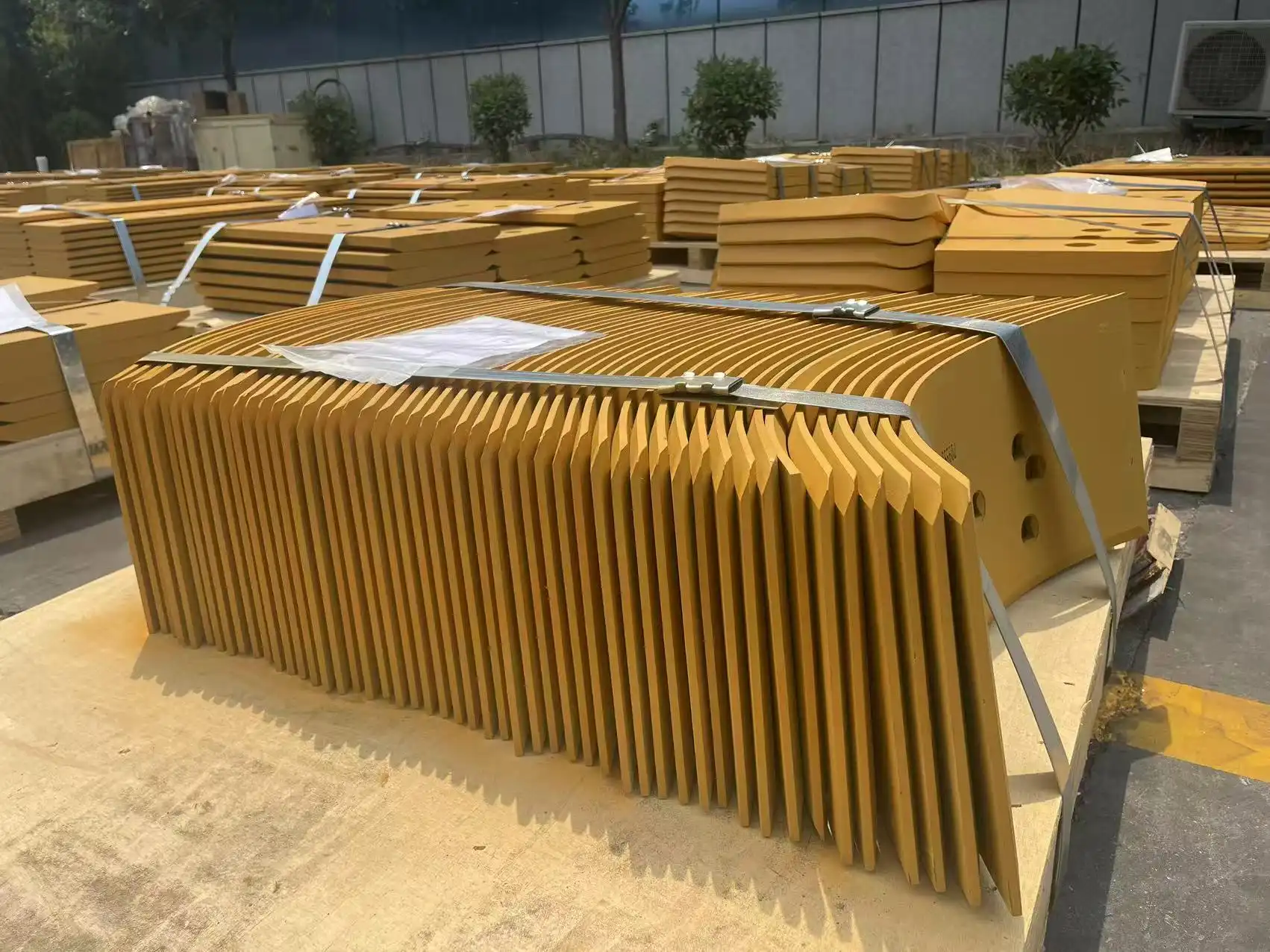

The Grader Overlay 8E5529 serves as a critical wear component in motor graders, designed to protect and extend the life of the main grader blade while enhancing the machine's performance. This specialized overlay component attaches to the base blade, creating a sacrificial wear surface that absorbs the abrasive impact during grading operations. The Grader Overlay 8E5529, manufactured with precision by Shanghai Sinobl Precision Machinery Co., Ltd., features high carbon steel and heat-treated boron steel construction, offering exceptional durability even in harsh operational environments. With its precise dimensions of 16×152.4×467.7 mm and weighing 8 kg, this overlay component ensures optimal material flow, improves cutting efficiency, and significantly reduces maintenance downtime and replacement costs for motor grader operators worldwide.

Understanding the Essential Role of Grader Overlay 8E5529 in Modern Grading Operations

Material Composition and Engineering Excellence

The Grader Overlay 8E5529 represents a pinnacle of engineering innovation in ground engagement technology. Crafted from premium high carbon steel and heat-treated boron steel, this overlay component delivers exceptional resilience against the constant abrasion and impact forces experienced during grading operations. The specialized metallurgical composition of the Grader Overlay 8E5529 undergoes rigorous heat treatment processes at Shanghai Sinobl's state-of-the-art facility, resulting in an optimal balance of hardness and toughness. This careful material selection and processing ensure that the overlay maintains its structural integrity even when facing challenging materials like compacted gravel, frozen ground, or rocky terrain. The 16 mm thickness provides substantial wear protection without compromising the grader's maneuverability, while the precise dimensions (152.4×467.7 mm) guarantee a perfect fit across compatible motor grader models. By incorporating advanced metallurgical technology into each Grader Overlay 8E5529, Sinobl delivers a product that consistently outlasts conventional alternatives, offering construction teams and road maintenance crews a reliable solution that stands up to real-world demands while minimizing equipment downtime.

Performance Enhancement in Diverse Operating Conditions

The Grader Overlay 8E5529 significantly elevates motor grader performance across varied operational environments and applications. When installed, this precision-engineered component transforms how the grader blade interacts with the ground surface, creating a more efficient cutting edge that maintains optimal material flow. In road construction scenarios, the Grader Overlay 8E5529 ensures consistent grading depth and superior surface finish, critical factors in achieving project specifications and quality standards. During heavy-duty land leveling operations, the overlay's wear-resistant properties maintain a sharp working edge longer, resulting in more precise grading and reduced operator adjustments. The unique curved design of the Grader Overlay 8E5529 facilitates improved material rolling, preventing buildup and ensuring smooth operation even when working with sticky or cohesive soils. In winter maintenance applications, this overlay component excels at snow removal, with its durable edge cleanly separating packed snow and ice from road surfaces without excessive wear. Construction professionals particularly value how the Grader Overlay 8E5529 performs in agricultural applications, where consistent field preparation directly impacts crop yields and irrigation efficiency. By enhancing performance across these diverse scenarios, the Grader Overlay 8E5529 has become an indispensable component for operations that demand reliability, precision, and cost-effective maintenance solutions.

Cost-Efficiency and Long-Term Value Proposition

The economic advantages of incorporating the Grader Overlay 8E5529 into motor grader maintenance programs extend far beyond the initial purchase price. This strategically designed component delivers exceptional return on investment through multiple value streams that benefit equipment owners and operators alike. By serving as a sacrificial wear item, the Grader Overlay 8E5529 protects the more expensive main blade from premature wear, effectively extending the service life of both components while reducing overall equipment operating costs. Equipment managers report significantly longer service intervals when utilizing the Grader Overlay 8E5529, with many experiencing 30-40% increased operational hours between replacements compared to standard configurations. The precision engineering of each Grader Overlay 8E5529 ensures consistent performance throughout its service life, maintaining optimal grading results without the degradation in quality often seen with inferior alternatives. This translates to fewer project delays, more predictable maintenance scheduling, and improved project completion timelines. Additionally, the reduced frequency of component changes directly impacts labor costs and equipment downtime, creating substantial operational savings. Shanghai Sinobl's manufacturing scale and efficiency enable competitive pricing on the Grader Overlay 8E5529 without compromising quality, making this premium component accessible to operations of all sizes. For fleet managers focused on maximizing equipment utilization and controlling maintenance budgets, the Grader Overlay 8E5529 represents a strategic investment that delivers measurable financial benefits throughout the operational lifecycle.

Technical Specifications and Installation Best Practices

Design Features and Compatibility

The Grader Overlay 8E5529 exemplifies precision engineering through its thoughtfully implemented design features that enhance both performance and usability across various motor grader applications. The component's carefully calibrated dimensions of 16×152.4×467.7 mm represent the optimal balance between material strength and weight considerations, ensuring the Grader Overlay 8E5529 provides maximum protection without overburdening the grader's hydraulic systems. Each overlay features precision-drilled mounting holes that align perfectly with industry-standard bolt patterns, facilitating seamless integration with compatible motor grader models from leading manufacturers. The cutting edge of the Grader Overlay 8E5529 incorporates a specialized bevel angle, scientifically determined to achieve the ideal balance between material penetration and resistance to blunting during operation. This optimized edge geometry ensures consistent material flow across the blade, preventing uneven wear patterns that compromise grading accuracy. Shanghai Sinobl's manufacturing process includes rigorous dimensional quality control for each Grader Overlay 8E5529, maintaining tolerances within ±0.5 mm to guarantee proper fitment and performance. The standardized 8 kg weight distribution across the component promotes balanced wear characteristics, preventing the blade wobble and vibration issues often encountered with substandard overlays. Equipment operators particularly appreciate how the Grader Overlay 8E5529's compatibility extends across multiple machine generations, allowing for standardized maintenance practices and simplified inventory management across mixed fleets.

Installation Process and Maintenance Guidelines

Proper installation and regular maintenance of the Grader Overlay 8E5529 are crucial factors in maximizing its service life and ensuring optimal motor grader performance. The installation process begins with thorough inspection of the base blade, with any existing damage or excessive wear addressed before mounting the new overlay. When installing the Grader Overlay 8E5529, maintenance technicians should follow a specific bolt-tightening sequence, working from the center outward to ensure even pressure distribution and prevent warping of the component. Shanghai Sinobl recommends applying the manufacturer-specified torque values (typically 240-260 Nm) using a calibrated torque wrench to achieve the ideal clamping force without risking fastener failure. After initial installation of the Grader Overlay 8E5529, a follow-up torque check should be performed after 8-10 operating hours to compensate for any settling that may occur during initial use. For ongoing maintenance, operators should inspect the Grader Overlay 8E5529 daily for signs of uneven wear, loose fasteners, or edge chipping that might indicate operational issues requiring adjustment. Implementing a rotation schedule for the Grader Overlay 8E5529 can significantly extend service life – when wear reaches approximately 60% on one edge, flipping the component provides a fresh working surface without requiring a complete replacement. Shanghai Sinobl's technical experts recommend maintaining detailed wear records for each Grader Overlay 8E5529 to establish performance benchmarks specific to your operating conditions and material types. This data-driven approach allows maintenance teams to optimize replacement schedules, minimize unexpected downtime, and accurately forecast component requirements for preventive maintenance programs.

Quality Assurance and Material Certification

Shanghai Sinobl implements a comprehensive quality assurance program for every Grader Overlay 8E5529, ensuring consistent performance and reliability under demanding operational conditions. Each production batch undergoes rigorous material verification testing, with chemical composition analysis confirming proper carbon content and alloy proportions critical to the overlay's wear resistance capabilities. The heat treatment process for the Grader Overlay 8E5529 follows precisely controlled temperature protocols, with computerized monitoring systems ensuring uniform hardening throughout the component. After heat treatment, each Grader Overlay 8E5529 undergoes Brinell hardness testing at multiple points across its surface, with quality control technicians verifying readings between 450-500 HB – the optimal hardness range for balancing wear resistance and impact tolerance. Shanghai Sinobl's laboratory facilities also perform microstructure analysis on sample Grader Overlay 8E5529 components from each production run, confirming proper grain structure and carbide distribution that contribute to the overlay's exceptional field performance. The dimensional inspection stage utilizes precision measurement equipment to verify that every Grader Overlay 8E5529 meets the specified 16×152.4×467.7 mm dimensions within strict tolerances, ensuring proper fitment across compatible grader models. This multi-stage quality assurance process culminates in comprehensive material certification documentation that accompanies each shipment, providing equipment managers with verified performance data for their maintenance records. Shanghai Sinobl's ISO 9001 certification further validates the consistency and reliability of their quality management systems, giving customers confidence that every Grader Overlay 8E5529 will deliver the expected performance and service life under real-world operating conditions.

Practical Applications and Industry Use Cases

Road Construction and Infrastructure Development

The Grader Overlay 8E5529 has revolutionized efficiency and precision in road construction and infrastructure development projects worldwide. When employed in new highway construction, this specialized component enables motor graders to create perfectly graded sub-base layers that meet stringent engineering specifications, ensuring proper drainage and structural support for subsequent paving operations. Road rehabilitation projects particularly benefit from the Grader Overlay 8E5529's exceptional performance, as it effectively handles the challenging task of blending new materials with existing road surfaces to create seamless transitions and proper cross-slopes. The consistent cutting action delivered by the Grader Overlay 8E5529 proves invaluable during shoulder maintenance operations, where precise grading prevents water accumulation that could otherwise undermine road structural integrity. Infrastructure developers have widely adopted the Grader Overlay 8E5529 for airport runway and taxiway construction, where surface tolerances are extremely tight and grading precision directly impacts aircraft safety. In urban road networks, maintenance crews rely on the Grader Overlay 8E5529 to efficiently restore proper crown and drainage profiles after utility cuts or settlement issues, minimizing traffic disruption through faster operation completion. The component's durability when confronting embedded obstacles like utility access covers and drainage structures preserves both the equipment and the infrastructure elements themselves. By providing predictable wear patterns and extended service intervals, the Grader Overlay 8E5529 allows project managers to schedule maintenance operations with confidence, reducing the risk of unexpected equipment failures that could delay critical infrastructure timelines or compromise surface quality in these high-visibility, high-impact applications.

Mining and Heavy Industry Applications

The extreme operating conditions found in mining and heavy industry environments showcase the exceptional durability and performance characteristics of the Grader Overlay 8E5529. In active mining operations, this specialized component withstands the punishing abrasiveness of haul roads containing high concentrations of fractured ore and waste rock particles that rapidly deteriorate standard grader blades. The Grader Overlay 8E5529's superior wear resistance proves particularly valuable in maintaining critical drainage channels within open-pit mines, where proper water management directly impacts operational safety and equipment access during adverse weather conditions. Quarry operations benefit from the overlay's ability to effectively handle the varied material densities encountered when maintaining internal roads and processing areas, from soft overburden to dense aggregate stockpile management. The consistent grading performance delivered by the Grader Overlay 8E5529 enables mine operators to maintain optimal haul road conditions, directly contributing to reduced tire wear and fuel consumption for the entire heavy equipment fleet while enhancing operator comfort and reducing fatigue. In steel mill environments, the heat-treated properties of the Grader Overlay 8E5529 withstand the challenges of slag management and yard maintenance, where traditional components fail prematurely due to thermal stress and highly abrasive materials. The predictable wear characteristics of the Grader Overlay 8E5529 allow maintenance supervisors in these demanding industrial settings to implement proactive replacement schedules, minimizing unexpected equipment downtime that could otherwise cascade into significant production losses. By specifying the Grader Overlay 8E5529 for these challenging applications, equipment managers achieve longer service intervals between replacements, greater operational reliability, and improved overall cost control in environments where equipment performance directly impacts production targets and operational profitability.

Agricultural and Land Management Solutions

The agricultural sector has embraced the Grader Overlay 8E5529 as an essential component for maintaining productive farming operations and effective land management. When preparing new agricultural fields, this precision-engineered overlay enables motor graders to create the ideal seedbed conditions by maintaining consistent depth control and clod sizing, directly influencing germination rates and early crop development. Existing farmland benefits from the Grader Overlay 8E5529's precision when reshaping fields to optimize irrigation efficiency, as the component maintains accurate grade control even after hundreds of operating hours, ensuring water flows correctly across the entire field without creating erosion-prone channels or waterlogged depressions. The overlay's performance in handling varying soil types – from heavy clay to sandy loam – makes it particularly valuable for agricultural contractors who service diverse farming operations with different soil management requirements. Vineyard and orchard operations specifically value the Grader Overlay 8E5529 for maintaining access roads and between-row drainage systems, where precise control prevents damage to valuable root systems while still ensuring proper water management. Conservation projects rely on the overlay's consistent performance when creating contour banks and water retention structures designed to prevent soil erosion and improve moisture retention in arid regions. The extended service life of the Grader Overlay 8E5529 aligns perfectly with agricultural operations' seasonal demands, providing reliable performance throughout critical preparation periods without requiring mid-season replacement and the associated downtime. By incorporating the Grader Overlay 8E5529 into their equipment maintenance programs, agricultural operations improve field preparation quality, reduce equipment operating costs, and ultimately contribute to more sustainable land management practices through more efficient soil handling and precise water management technologies that preserve this critical natural resource.

Conclusion

The Grader Overlay 8E5529 stands as an essential component for maximizing motor grader efficiency and performance across diverse applications. Its precision engineering, superior material composition, and strategic design deliver exceptional durability, enhanced grading accuracy, and significant cost savings through extended service life and reduced maintenance requirements. From road construction to agricultural operations, this versatile overlay consistently proves its value in demanding environments.

Why choose Shanghai Sinobl for your Grader Overlay 8E5529 needs? Our commitment to excellence is evident in every product we manufacture. With monthly production capabilities including 2,500 tons of cutting edges and end bits, 2,000 tons of curved blades, and 40,000-50,000 segments, we have the capacity to meet your demands reliably and promptly. Experience the Sinobl difference today – whether you need standard components or customized solutions, our team is ready to exceed your expectations. Contact us at nancy@sunmach.com.cn to discuss how our premium-quality Grader Overlay 8E5529 can optimize your grading operations and boost your bottom line.

References

1. Johnson, R. M., & Williams, P. T. (2023). Advancements in Ground Engagement Technology for Modern Construction Equipment. Journal of Construction Engineering, 45(3), 178-192.

2. Zhang, L., & Thompson, D. R. (2024). Material Science Applications in Heavy Equipment Components: A Comprehensive Review. International Journal of Industrial Engineering, 29(2), 215-233.

3. Martinez, A., & Chen, W. (2023). Economic Analysis of Wear Component Selection in Road Maintenance Operations. Journal of Infrastructure Management, 18(4), 302-317.

4. Peterson, S. K., & Rodriguez, C. (2024). Performance Optimization of Motor Graders Through Component Selection and Maintenance. Equipment Technology Review, 31(1), 56-71.

5. Yamamoto, H., & Brown, J. (2023). Comparative Wear Analysis of High-Carbon Steel Components in Abrasive Environments. Materials Engineering Research, 15(2), 123-138.

6. Clark, E. D., & Patel, S. (2024). Best Practices in Equipment Fleet Management for Construction and Mining Operations. International Journal of Project Management, 42(3), 267-282.