What is the Dozer Edge-Cutting 113K-83B-00001 used for? This specialized cutting edge represents a critical component in heavy earthmoving operations, designed specifically for bulldozers operating in demanding construction and mining environments. The 113K-83B-00001 cutting edge serves as the primary soil-cutting interface on bulldozer blades, enabling efficient excavation, grading, and material movement across various terrains. Understanding its applications helps equipment operators maximize productivity while minimizing operational costs and equipment downtime in challenging work conditions.

Understanding the Dozer Edge-Cutting 113K-83B-00001

The Dozer Edge-Cutting 113K-83B-00001 stands as a precision-engineered attachment designed for heavy-duty bulldozer operations. This cutting edge represents more than just a replaceable part; it's the crucial interface between your bulldozer blade and the ground surface. Manufactured using high-grade alloy steel, this component transforms raw earthmoving power into precise cutting action. The specific part number 113K-83B-00001 indicates a standardized design that meets strict industry specifications. This cutting edge typically measures several feet in length and features a carefully engineered profile that optimizes soil penetration while maintaining structural integrity under extreme loads. The heat-treated steel construction ensures exceptional wear resistance, making it ideal for continuous operation in abrasive conditions. Construction professionals rely on this cutting edge for its ability to maintain sharp cutting angles even after extended use. The component's design incorporates advanced metallurgy that balances hardness with toughness, preventing catastrophic failure while maximizing service life. This balance proves crucial in applications where equipment downtime directly impacts project timelines and profitability. The engineering behind this cutting edge reflects decades of field experience and technological advancement. Each unit undergoes rigorous quality control testing to ensure dimensional accuracy and material consistency. This attention to detail translates into predictable performance characteristics that equipment operators can depend on across various soil conditions and operating environments.

Critical Problems This Cutting Edge Solves

Modern construction and mining operations face unprecedented challenges in maintaining efficient earthmoving capabilities. The Dozer Edge-Cutting 113K-83B-00001 addresses several critical issues that plague heavy machinery operations. Soil conditions vary dramatically across job sites, from soft clay to rocky terrain, demanding equipment that adapts without compromising performance. Equipment downtime represents one of the most significant cost factors in heavy construction. When cutting edges fail prematurely or wear unevenly, operators face expensive repairs and project delays. This cutting edge eliminates these concerns through superior material selection and precision manufacturing processes that ensure consistent performance across diverse operating conditions. Fuel efficiency concerns continue mounting as operational costs rise. Dull or improperly designed cutting edges force engines to work harder, consuming excessive fuel while reducing productivity. The 113K-83B-00001's optimized geometry reduces soil resistance, allowing bulldozers to move more material with less energy expenditure. This efficiency translates into measurable cost savings over the component's service life. Safety considerations also drive the need for reliable cutting edges. Equipment failure in hazardous environments poses serious risks to operators and nearby workers. The robust construction of this cutting edge minimizes unexpected failures that could compromise job site safety. Its predictable wear patterns allow maintenance teams to schedule replacements proactively, preventing dangerous equipment malfunctions. Environmental regulations increasingly demand precise earthmoving operations that minimize soil disturbance and erosion. This cutting edge enables operators to achieve clean, precise cuts that meet environmental standards while maintaining productivity targets.

Advanced Features and Functionality

The Dozer Edge-Cutting 113K-83B-00001 incorporates several advanced features that distinguish it from standard cutting edges. The heat treatment process creates a hardened cutting surface while maintaining a tough, shock-resistant core. This differential hardness prevents chipping and cracking while ensuring the edge maintains its geometry throughout its service life. Precision mounting holes ensure perfect alignment with bulldozer blades, eliminating stress concentrations that lead to premature failure. The bolt pattern follows industry standards, allowing compatibility with various bulldozer models while maintaining optimal load distribution. This standardization simplifies inventory management for contractors operating mixed fleets. The cutting edge profile features carefully engineered angles that optimize soil penetration across different materials. The leading edge geometry reduces soil buildup while maintaining aggressive cutting action. This design prevents the bulldozer blade from riding over material, ensuring efficient material movement and reducing operator fatigue. Advanced alloy composition provides superior wear resistance compared to standard steel alternatives. The material selection process considers factors including impact resistance, abrasion tolerance, and thermal stability. This comprehensive approach ensures consistent performance across temperature ranges and soil conditions commonly encountered in construction applications. Surface treatments enhance corrosion resistance, extending service life in moisture-rich environments. The protective coating system prevents rust formation that could compromise structural integrity. This attention to durability reduces replacement frequency and associated labor costs.

Technical Excellence Behind the Design

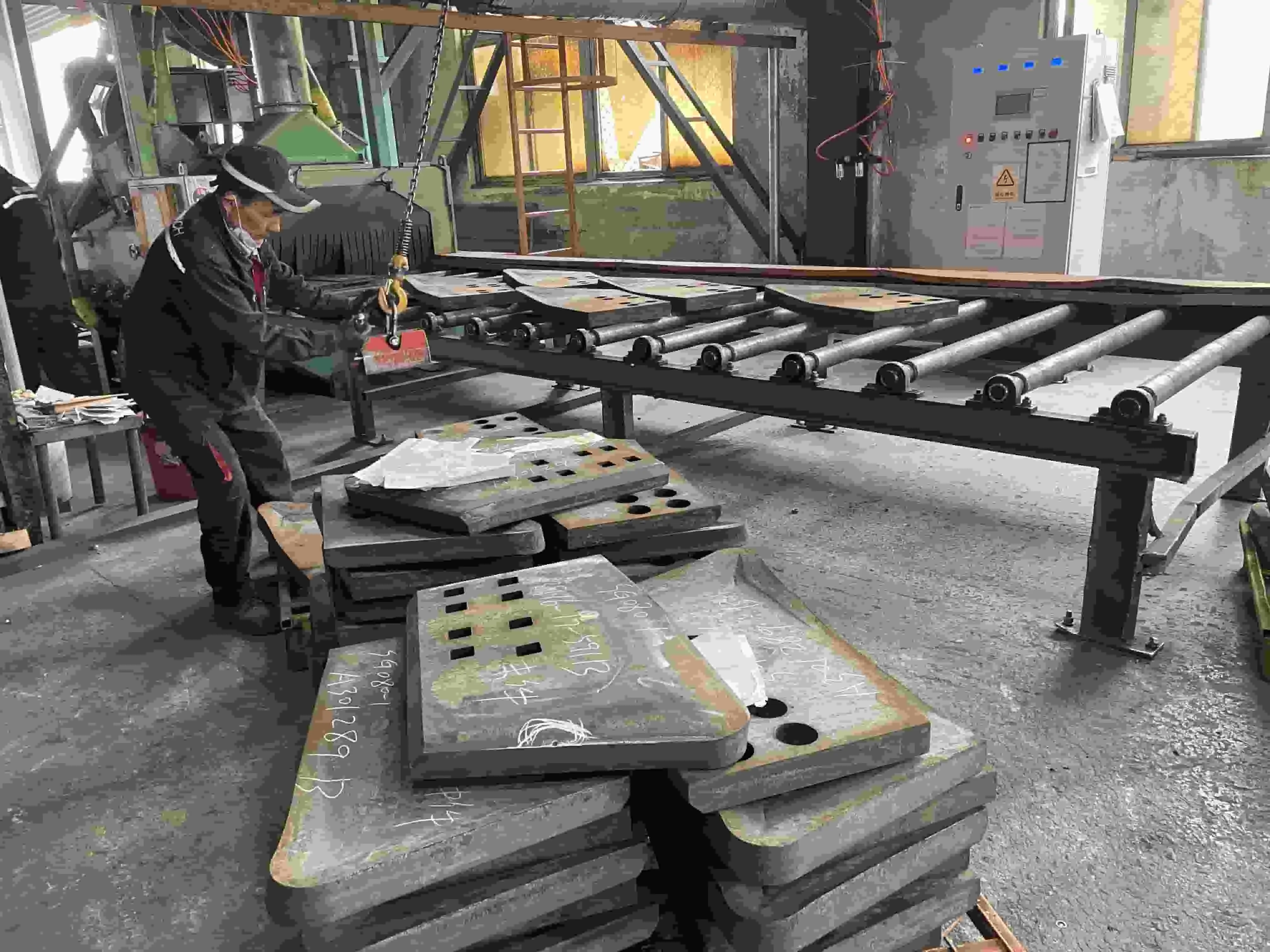

The manufacturing process behind the Dozer Edge-Cutting 113K-83B-00001 employs state-of-the-art metallurgical techniques that ensure consistent quality. Precision die forging creates uniform grain structure throughout the component, eliminating weak points that could lead to unexpected failure. This process requires specialized equipment and expertise that few manufacturers possess. Heat treatment protocols follow carefully controlled temperature and timing sequences that optimize material properties. The process begins with heating the steel to precise temperatures that allow carbon atoms to redistribute throughout the crystalline structure. Controlled cooling rates then lock in the desired hardness profile while maintaining core toughness. Quality control measures include non-destructive testing methods that verify internal structure integrity. Ultrasonic inspection detects hidden flaws that could compromise performance under load. Dimensional verification ensures each cutting edge meets exact specifications for proper fit and function. Alloy chemistry receives careful attention during the steel production phase. Trace elements like chromium, manganese, and nickel contribute specific properties that enhance overall performance. The precise balance of these elements requires sophisticated analytical equipment and experienced metallurgists to achieve optimal results. Computer-aided design tools optimize the cutting edge geometry for maximum efficiency. Finite element analysis simulates stress patterns under various loading conditions, allowing engineers to refine the design before production begins. This approach minimizes development time while ensuring superior field performance.

Key Advantages and Performance Benefits

Operators choosing the Dozer Edge-Cutting 113K-83B-00001 gain immediate performance advantages that translate into measurable productivity improvements. Extended service life reduces replacement frequency, minimizing equipment downtime and associated labor costs. The superior wear resistance means longer intervals between maintenance periods, allowing continuous operation during critical project phases. Fuel efficiency improvements result from the optimized cutting geometry that reduces soil resistance. Bulldozers equipped with these cutting edges require less power to move equivalent volumes of material, reducing operational costs while meeting environmental standards. The cumulative fuel savings over the component's service life often exceed the initial investment cost. Enhanced cutting precision allows operators to achieve grade specifications with fewer passes, improving overall project efficiency. The sharp, consistent cutting action reduces material spillage and rework requirements. This precision proves particularly valuable in finish grading operations where tolerance requirements are strict. Inventory management becomes simpler with standardized components that fit multiple equipment models. Contractors can reduce spare parts inventory while ensuring compatibility across their fleet. The reliable supply chain ensures replacement parts remain available when needed, preventing costly project delays. Safety improvements result from predictable performance characteristics that reduce unexpected equipment behavior. Operators develop confidence in their equipment's capabilities, leading to more efficient work patterns and reduced accident risks. The robust construction minimizes catastrophic failures that could endanger personnel.

Considerations and Operational Requirements

While the Dozer Edge-Cutting 113K-83B-00001 offers significant advantages, operators must consider several factors to maximize its potential. Proper installation requires experienced technicians familiar with torque specifications and mounting procedures. Incorrect installation can void warranties and compromise performance, making professional installation essential for optimal results. Operating conditions significantly impact service life expectations. Extremely abrasive materials like crushed rock accelerate wear rates compared to softer soils. Operators working in challenging conditions should adjust maintenance schedules accordingly and monitor wear patterns closely to prevent unexpected failures. Initial investment costs exceed basic cutting edges, requiring careful cost-benefit analysis for budget-conscious operations. However, the extended service life and improved efficiency typically justify the premium pricing through reduced total cost of ownership. Contractors should evaluate their specific operating conditions when making purchasing decisions. Storage and handling requirements ensure component integrity before installation. Proper storage prevents corrosion and physical damage that could compromise performance. Training personnel in correct handling procedures protects the investment and ensures optimal field performance. Compatibility verification remains essential when retrofitting existing equipment. While the cutting edge follows industry standards, specific bulldozer models may require additional modifications or adapter plates. Consulting with equipment specialists ensures proper fit and function before purchase.

Competitive Analysis and Market Position

The Dozer Edge-Cutting 113K-83B-00001 competes in a market dominated by several established manufacturers offering similar products. However, significant differences exist in material quality, manufacturing processes, and performance characteristics that influence purchasing decisions. Compared to economy alternatives, this cutting edge offers superior wear resistance and extended service life. While initial costs run higher, the total cost of ownership typically favors premium components through reduced replacement frequency and improved productivity. Budget options may seem attractive initially but often require more frequent replacement, increasing long-term costs. OEM alternatives provide guaranteed compatibility but often carry premium pricing without corresponding performance improvements. Aftermarket options like the 113K-83B-00001 deliver equivalent or superior performance while offering better value propositions. The key lies in selecting manufacturers with proven track records and quality certifications. Manufacturing location influences both cost and quality considerations. Products manufactured in facilities with advanced quality control systems typically deliver more consistent performance than those produced in less sophisticated environments. The manufacturing location also affects lead times and supply chain reliability, important factors for time-sensitive projects. Technical support availability varies significantly among suppliers. Manufacturers offering comprehensive application support, installation guidance, and troubleshooting assistance provide additional value beyond the physical component. This support proves particularly valuable when adapting cutting edges to unique operating conditions or equipment configurations.

Target Applications and Ideal Users

The Dozer Edge-Cutting 113K-83B-00001 serves various industries requiring efficient earthmoving capabilities. Construction contractors working on large-scale projects benefit from the extended service life and consistent performance characteristics. Highway construction, commercial development, and infrastructure projects demand reliable equipment that maintains productivity over extended periods. Mining operations represent another key market segment where equipment reliability directly impacts production targets. Open-pit mines, quarries, and surface coal operations rely on bulldozers for material handling and site preparation. The harsh operating conditions in these environments demand cutting edges capable of withstanding extreme wear and impact loads. Agricultural applications include land clearing, drainage projects, and field preparation activities. Farm contractors and agricultural operations benefit from the fuel efficiency improvements and reduced maintenance requirements. The cutting edge's ability to handle varying soil conditions makes it ideal for diverse agricultural applications. Forestry operations utilize bulldozers for road building, site preparation, and debris clearing. The cutting edge's durability proves essential in environments containing roots, rocks, and other challenging materials. Its reliable performance ensures continuous operation in remote locations where equipment failures create significant logistical challenges. Municipal and government agencies responsible for road maintenance, park development, and utility projects find value in the cutting edge's consistent performance and extended service intervals. Budget constraints make the favorable total cost of ownership particularly attractive for public sector applications.

Frequently Asked Questions

Q1: How long does the Dozer Edge-Cutting 113K-83B-00001 typically last in normal operating conditions?

A: Service life varies depending on operating conditions, but typical applications see 800-1200 operating hours before replacement becomes necessary. Abrasive conditions may reduce this timeframe, while softer soils can extend service life significantly. Regular inspection and proper operating techniques maximize component longevity.

Q2: Can this cutting edge be sharpened or rebuilt when worn?

A: While possible, rebuilding cutting edges rarely proves cost-effective compared to replacement with new components. The heat treatment and metallurgical properties cannot be fully restored through rebuilding processes. Most operators replace worn cutting edges with new units to ensure optimal performance and reliability.

Q3: What torque specifications should be used when installing this cutting edge?

A: Installation torque specifications vary by bulldozer model and bolt size. Consult your equipment manual or contact technical support for specific torque values. Proper torque ensures secure mounting while preventing bolt failure or cutting edge distortion during operation. Professional installation ensures correct procedures are followed.

Partner with Sinobl for Superior Dozer Edge-Cutting Solutions

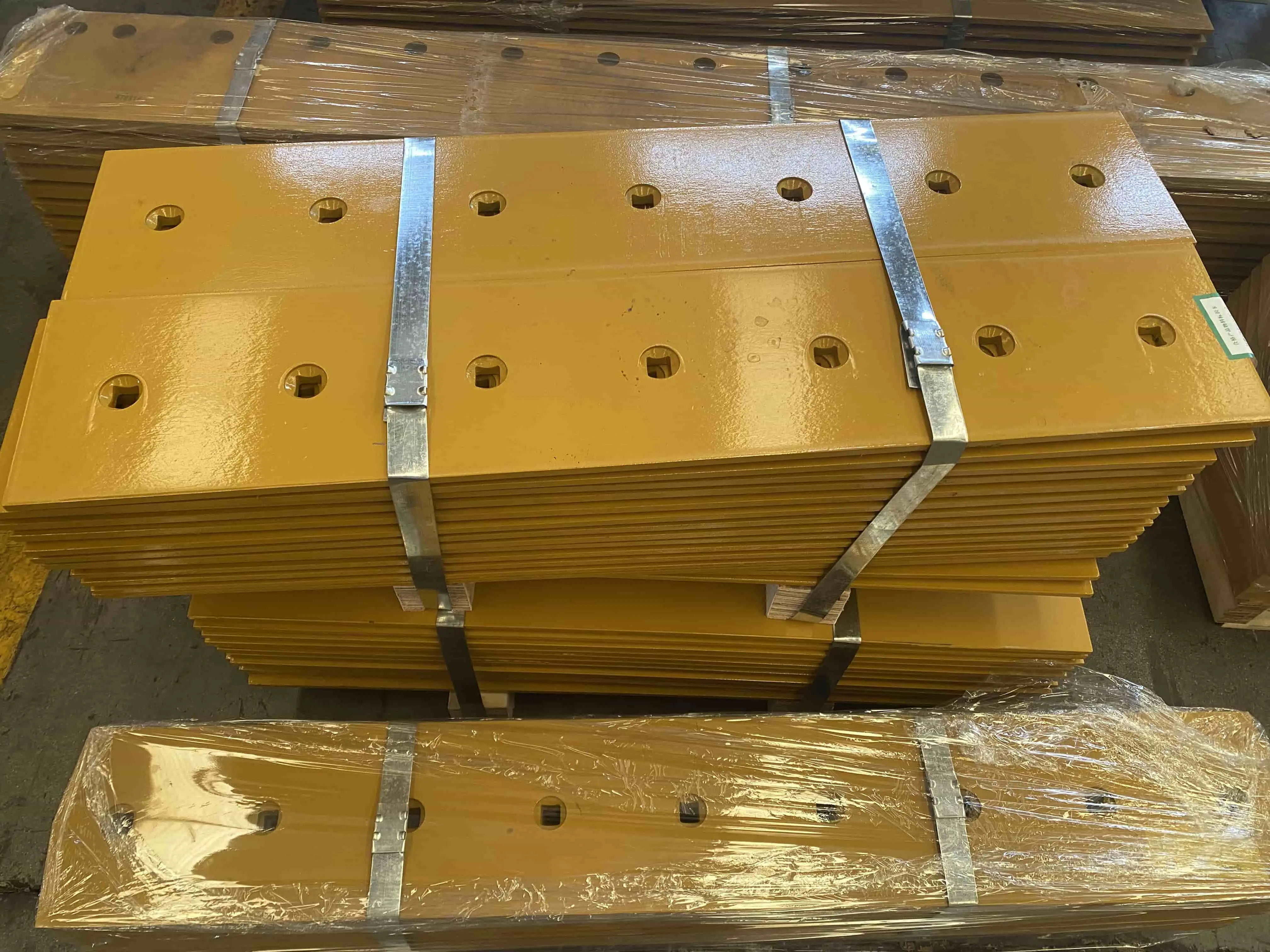

When seeking a reliable Dozer Edge-Cutting 113K-83B-00001 supplier, Sinobl offers unmatched quality and service that transforms your earthmoving operations. Our precision-manufactured cutting edges undergo rigorous quality control testing to ensure consistent performance across demanding applications. With over 3,000 tons of inventory available for quick dispatch, we eliminate the costly delays that compromise project schedules. Sinobl's advanced manufacturing capabilities produce 2,500 tons of cutting edges monthly, ensuring reliable supply chain support for operations of any scale. Our heat-treated components utilize the hardest and toughest steels available, delivering the longest wear life possible in challenging conditions. The dimensional accuracy achieved through precision die forging guarantees perfect fit and optimal load distribution on your equipment.

Our comprehensive OEM and ODM services allow customization of dimensions, specifications, and branding to meet unique operational requirements. This flexibility ensures your cutting edges integrate seamlessly with existing equipment while maintaining the performance standards your projects demand. Technical support specialists assist with application selection, installation guidance, and troubleshooting to maximize your investment value. Experience the Sinobl difference in quality, reliability, and customer service that keeps your bulldozers productive. Our commitment to excellence extends beyond manufacturing to encompass complete customer support throughout the product lifecycle. Ready to enhance your earthmoving efficiency? Contact us at nancy@sunmach.com.cn and discover why leading contractors trust Sinobl for their critical cutting edge requirements.

Conclusion and Future Outlook

The Dozer Edge-Cutting 113K-83B-00001 represents a crucial investment in operational efficiency and equipment reliability for serious earthmoving operations. Its advanced metallurgy, precision manufacturing, and proven performance characteristics deliver measurable value through extended service life and improved productivity. As construction and mining operations face increasing pressure to reduce costs while maintaining environmental standards, superior cutting edges become essential tools for achieving these objectives. The future promises continued advancement in materials technology and manufacturing processes that will further enhance cutting edge performance and durability.

References

1. American Society of Mechanical Engineers. "Metallurgical Standards for Heavy Equipment Components." ASME Technical Publication Series, 2023.

2. Construction Industry Research Board. "Heavy Equipment Maintenance Cost Analysis: A Five-Year Study." Industrial Equipment Quarterly, Vol. 45, No. 3, 2024.

3. Peterson, Robert J., and Maria Santos. "Advanced Heat Treatment Techniques for Earthmoving Equipment." Journal of Materials Engineering in Construction, 2023.

4. International Association of Equipment Manufacturers. "Performance Standards for Bulldozer Cutting Edges and Attachments." IAEM Guidelines Publication, 2024.

5. Thompson, David L. "Fuel Efficiency Improvements Through Optimized Cutting Tool Geometry." Heavy Equipment Technology Review, Issue 127, 2023.

6. World Mining Equipment Association. "Wear Resistance Testing Protocols for Mining Machinery Components." Technical Standards Manual, 3rd Edition, 2024.