In Europe’s competitive earthmoving sector, understanding Dozer Knowledge Europe is essential for B2B buyers seeking OEM/ODM partners specializing in dozer edge-cutting. The competitive advantage lies in deep customization tailored to specific infrastructure projects and civil engineering demands. OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services enable European businesses to acquire highly specialized bulldozer blades and segments optimized for performance, durability, and compatibility with leading brands like Caterpillar and Komatsu. Learning the nuances behind this customization allows buyers to reduce downtime, enhance grading accuracy, and maintain safety standards on construction sites.

Introduction: Why OEM/ODM Customization Matters in Dozer Edge-Cutting

OEM and ODM processes have transformed how construction equipment parts meet the demanding needs of earthmoving industries. In Europe, dozer edge-cutting tools require precision manufacturing to adapt to diverse applications like land clearing, site preparation, and hydraulic system integration. Deep customization affects not only the physical design but also functional features such as wear resistance and compatibility with machine control technology. This level of specificity improves operational efficiency, reducing frequent replacements and maintenance costs. B2B buyers should prioritize partners who understand these subtleties to ensure equipment meets Europe’s rigorous safety and environmental standards.

Our OEM/ODM Strengths: Experience and Excellence in Manufacturing

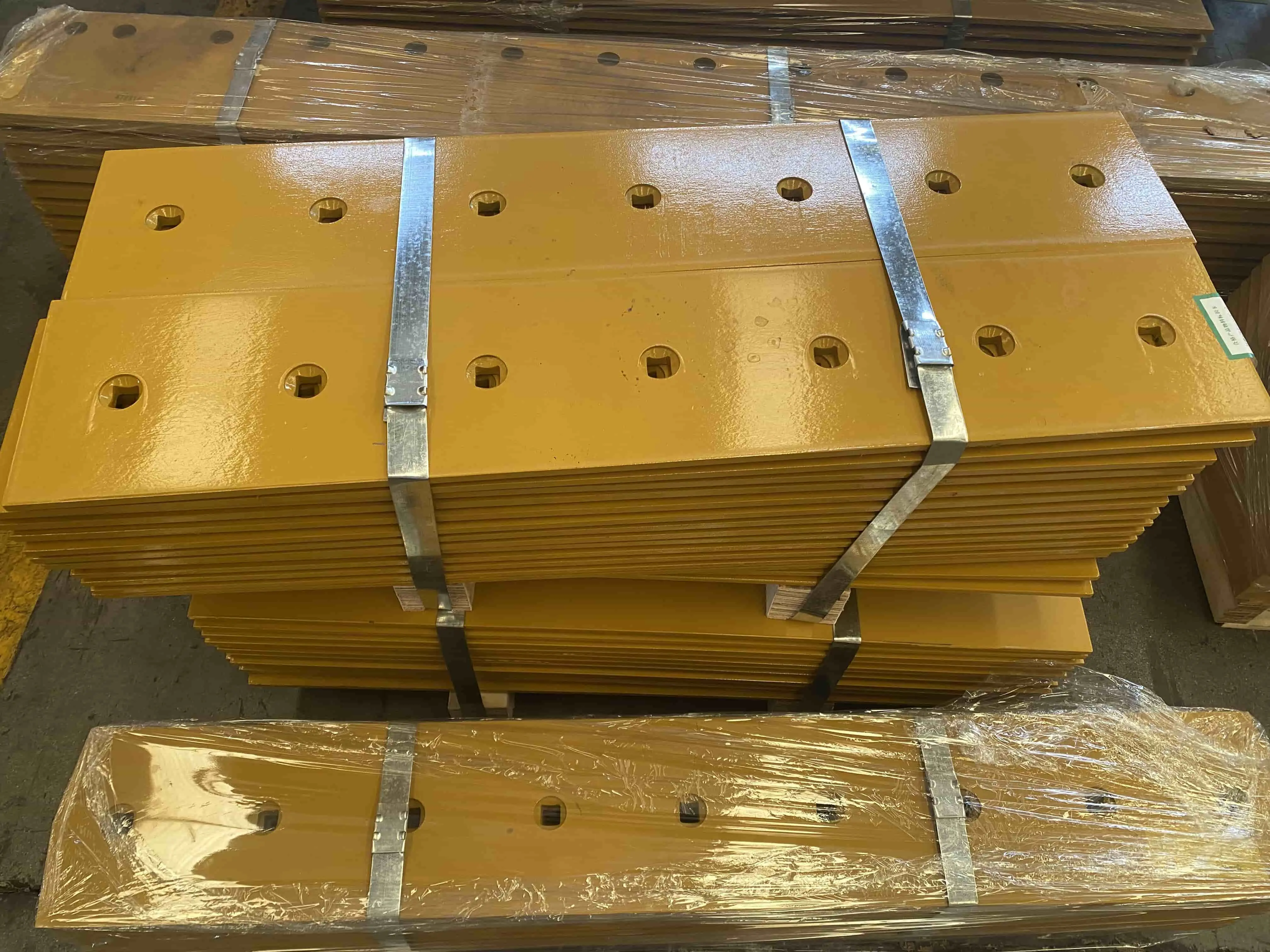

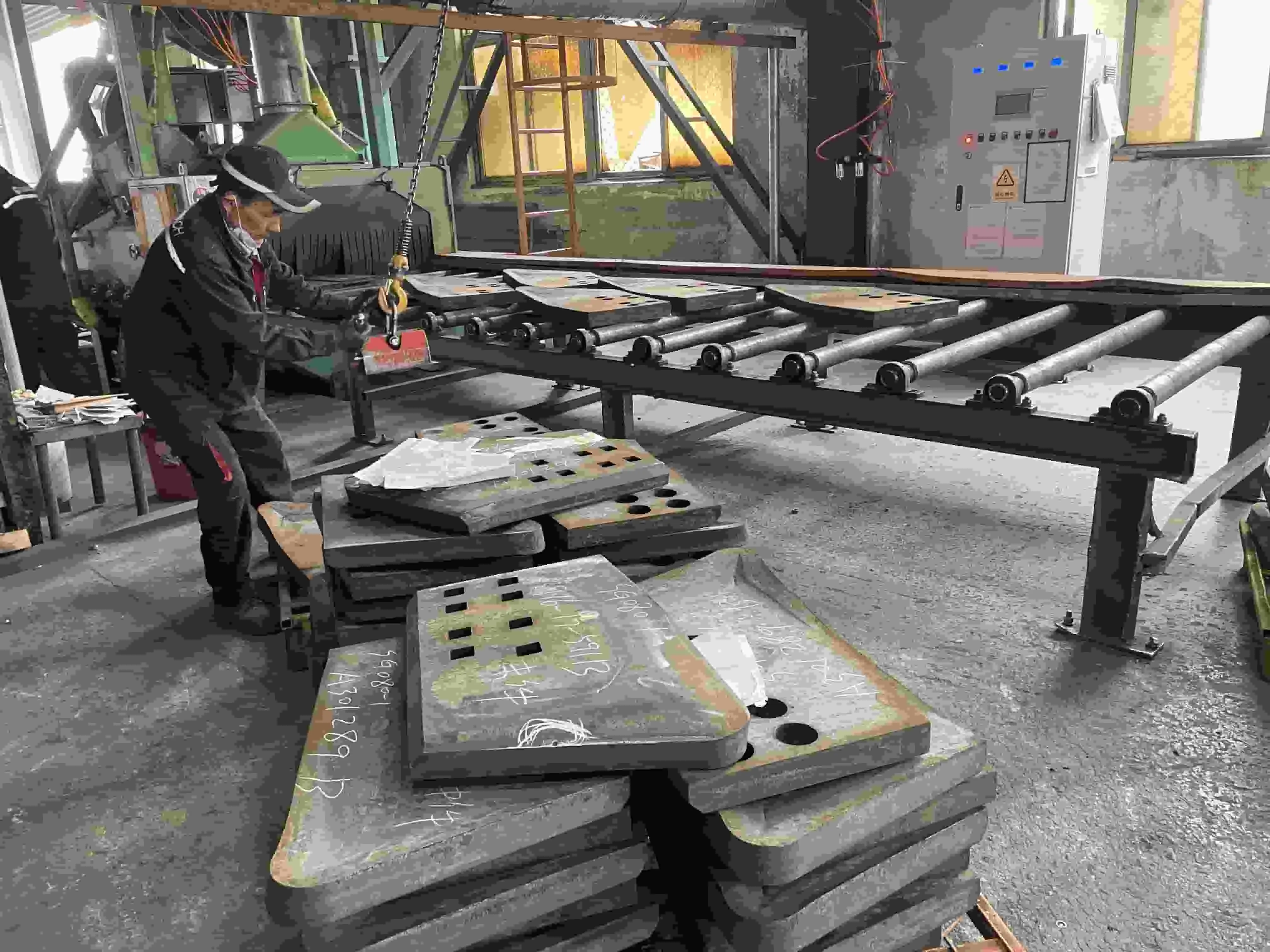

At Shanghai Sinobl Precision Machinery Co., Ltd., our strength is built on decades of expertise serving global heavy machinery markets. We maintain stringent quality control to match European industry benchmarks, ensuring our wear-resistant parts withstand rigorous excavation and grading operations. With production capacity reaching up to 2,500 tons monthly for cutting edges and 50,000 segments, our scalable operations meet diverse client demands without compromising lead times. Our research and development team continuously innovates to support complex hydraulic systems and fleet management requirements. This synergy between advanced manufacturing and supply chain efficiency solidifies our position as a reliable OEM/ODM partner.

Comprehensive Customization Options for Tailored Dozer Solutions

Customization at Shanghai Sinobl goes beyond size and shape. We offer modifications in physical dimensions, metallurgy for enhanced wear resistance, and coatings adapted for harsh European environments. Clients can specify hydraulic compatibility, GPS technology integration, and branding elements like color and logo placement. Packaging solutions are tailored to ensure safety during shipment and ease of handling on-site. This wide array of options empowers distributors and brand owners to differentiate their bulldozers with unique product lines that emphasize durability and precision in earthmoving tasks.

The ODM Advantage: Collaborative Innovation in European Dozer Knowledge

ODM services unlock co-development opportunities, allowing clients to bring new ideas to life in collaboration with Sinobl’s engineering team. This approach accelerates innovation in dozer edge-cutting technology adapted for the varied terrains across Europe. By incorporating dynamic feedback from machine operators and civil engineers, we refine product design to enhance operational safety standards and efficiency. The ODM model supports continuous improvement, positioning B2B buyers as pioneers in adopting cutting-edge features tailored to heavy machinery trends like machine control and advanced operator training.

Our Process: From Inquiry to Delivery with Precision

Working with us starts with understanding your project requirements in detail. Our process includes technical consultation, prototype development, rigorous testing for wear resistance and hydraulic compatibility, followed by streamlined production. Quality assurance occurs at every stage to meet or exceed European certifications. Throughout, transparent communication ensures clients are informed and confident. With efficient order fulfillment and scalable manufacturing, we reduce lead times and enable prompt equipment maintenance—a critical factor in minimizing site downtime.

Benefits to You: Maximizing Value Through Our OEM/ODM Partnership

Partnering with Shanghai Sinobl delivers tangible benefits: your operations gain access to premium wear parts engineered for longevity, reducing frequent replacements and costly interruptions. Customization fosters brand differentiation and enhances customer loyalty by offering solutions tailored to specific applications. Our expansive production capabilities ensure supply chain reliability even during peak demand. Furthermore, adhering to safety standards and integrating modern technologies protects operators and optimizes earthmoving productivity. This partnership streamlines equipment maintenance and boosts overall project success.

Why Choose SINOBL?

- Our wear-resistant parts use high-grade materials combined with advanced technology, meeting top industry standards for durability.

- Years of experience serving diverse industries empower us to anticipate challenges and deliver tailored solutions aligned with your requirements.

- Efficient manufacturing processes facilitate fast order turnaround, supporting tight project schedules.

- Robust production capacity: 2,500 tons/month cutting edges, 2,000 tons/month curved blades, and 40,000–50,000 segments/month.

- Flexible OEM & ODM services allow customization in dimensions, colors, logos, and packaging to suit your unique needs.

Call to Action

Elevate your dozer edge-cutting solutions with Shanghai Sinobl’s superior OEM/ODM capabilities. Whether you aim to optimize earthmoving efficiency or establish a distinctive brand presence across Europe, our expert team stands ready to assist. Don’t hesitate to contact us for a detailed consultation and let’s transform your vision into durable, high-performing heavy machinery components.

Frequently Asked Questions

- What is the difference between OEM and ODM services?

- OEM involves manufacturing parts based on a client’s design, while ODM includes co-developing new designs with the manufacturer’s expertise to create unique products.

- How does customization improve dozer performance?

- Customization ensures the part fits specific machines and applications, enhancing wear resistance, operational safety, and efficiency during excavation, grading, and land clearing.

- Can you accommodate environmental compliance requirements in Europe?

- Yes, our products adhere to European safety and environmental standards, ensuring your heavy machinery complies with regional regulations.

- What is the typical lead time for OEM/ODM orders?

- Lead times vary by order size and complexity, but our streamlined processes aim to deliver within industry-standard timeframes, minimizing project delays.

- Are there options for branded packaging?

- Yes, we offer custom packaging solutions including branded designs to enhance product presentation and protection during shipping.

Conclusion

Understanding the complexities of Dozer Knowledge Europe and leveraging OEM/ODM partnerships are key for B2B buyers aiming to excel in heavy machinery markets. Shanghai Sinobl Precision Machinery Co., Ltd. offers unrivaled expertise, scalability, and customization tailored to European earthmoving demands. Our commitment to quality, innovation, and client collaboration ensures your operations remain efficient and competitive. Reach out today to explore how we can meet your unique dozer edge-cutting needs with precision and reliability.

Where to Buy Dozer Knowledge Europe?

To acquire premium dozer edge-cutting solutions tailored for European markets, contact Shanghai Sinobl Precision Machinery Co., Ltd. Our expert team will guide you through customization options to perfectly fit your projects. Reach us conveniently via email at nancy@sunmach.com.cn. For more details, please refer to the website: wearpart.com. Let us support your journey toward superior heavy machinery performance and reliability with precision-engineered components.

References

1. Construction Equipment Market Trends and Innovations in Europe, Industry Report 2023

2. Advances in Bulldozer Wear Parts Technology, Journal of Heavy Machinery Engineering, 2022

3. European Standards for Industrial Vehicle Safety and Environmental Compliance, European Machinery Association, 2023

4. Effective Fleet Management and Machine Control Applications in Earthmoving Projects, Civil Engineering Review, 2021

5. The Role of Hydraulic Systems in Modern Excavation Equipment, International Journal of Mechanical Engineering, 2022

6. OEM and ODM Strategies in Heavy Machinery Manufacturing, Global Industrial Insights, 2023