What are the specifications of the Dozer Edge-Cutting 4T3013?

The Dozer Edge-Cutting 4T3013 is a premium-grade bulldozer cutting edge manufactured by Shanghai Sinobl Precision Machinery Co., Ltd. This high-performance component is engineered specifically for heavy-duty earthmoving operations in construction and mining environments. With dimensions of 20×203×1009.4mm and a unit weight of 29.5KG, the 4T3013 cutting edge is crafted from superior high carbon steel and heat-treated boron steel, providing exceptional durability and wear resistance. This critical wear part is designed to withstand harsh operating conditions while maintaining optimal cutting efficiency, reducing equipment downtime, and extending service life. The Dozer Edge-Cutting 4T3013 represents Sinobl's commitment to manufacturing precision-engineered Ground Engaging Tools (G.E.T.) that deliver superior performance and value for heavy machinery operators worldwide.

Technical Specifications and Material Properties of Dozer Edge-Cutting 4T3013

Advanced Material Composition

The Dozer Edge-Cutting 4T3013 stands out in the market due to its exceptional material composition that directly impacts its performance and longevity. This cutting edge is manufactured using a specialized blend of high carbon steel and heat-treated boron steel, carefully selected for optimal performance in extreme conditions. The high carbon content provides exceptional hardness and wear resistance, which is crucial when the cutting edge is constantly engaging with abrasive materials like rocks, gravel, and compacted soil. The addition of boron and the subsequent heat treatment process further enhances these properties, creating a microstructure that resists deformation under high pressure. Each Dozer Edge-Cutting 4T3013 undergoes rigorous material composition analysis to ensure consistency across production batches. This meticulous attention to material quality translates directly to field performance, with operators reporting significantly reduced wear rates compared to standard cutting edges. By investing in superior raw materials, Sinobl ensures that the Dozer Edge-Cutting 4T3013 maintains its structural integrity and cutting efficiency even after hundreds of hours of operation in challenging terrain.

Dimensional Specifications and Design Features

The precision engineering behind the Dozer Edge-Cutting 4T3013 is evident in its carefully calibrated dimensions of 20×203×1009.4mm. These exact measurements ensure a perfect fit for compatible bulldozer models, eliminating the risks associated with improper installation or alignment. With a unit weight of 29.5KG, the Dozer Edge-Cutting 4T3013 strikes an optimal balance between durability and operational efficiency, providing enough mass for effective ground penetration without unnecessarily burdening the machine's hydraulic systems. The cutting edge features strategically positioned bolt holes that align perfectly with the bulldozer's blade, ensuring secure attachment and preventing the edge from shifting during operation. The cutting angle has been optimized through extensive field testing to provide efficient material displacement while minimizing drag, which contributes to fuel efficiency and reduces strain on the machine's power train. Every Dozer Edge-Cutting 4T3013 undergoes dimensional accuracy checks during production, with tolerances held to within ±0.5mm to ensure consistent quality. This attention to dimensional precision ensures that operators can rely on each replacement Dozer Edge-Cutting 4T3013 to perform identically to the previous one, maintaining operational consistency and predictability across equipment fleets.

Performance Metrics and Service Life

The Dozer Edge-Cutting 4T3013 delivers exceptional performance metrics that directly translate to operational cost savings for heavy equipment operators. In controlled field tests, this cutting edge demonstrated superior wear resistance, retaining its cutting efficiency approximately 30% longer than industry-standard alternatives. This extended service life is achieved through Sinobl's proprietary heat treatment process, which creates a graduated hardness profile across the cutting edge—harder at the cutting surface where wear is most severe, and slightly more ductile in the mounting area to absorb impact forces without cracking. The Dozer Edge-Cutting 4T3013 consistently achieves Brinell hardness ratings between 450-500 HB at the cutting surface, providing optimal resistance to abrasive wear while maintaining structural integrity. Performance simulations conducted during the quality control process replicate real-world operating conditions, ensuring each cutting edge will perform reliably in the field. By extending replacement intervals, the Dozer Edge-Cutting 4T3013 significantly reduces maintenance downtime and associated labor costs. Equipment operators working in particularly demanding environments, such as quarries or mining operations, have reported that the Dozer Edge-Cutting 4T3013 maintains its cutting geometry even after extended use in high-impact applications, preserving the bulldozer's efficiency and productivity throughout the component's service life.

Applications and Operational Benefits of Dozer Edge-Cutting 4T3013

Industry-Specific Applications

The Dozer Edge-Cutting 4T3013 demonstrates remarkable versatility across numerous heavy-duty applications, proving its value in diverse operational contexts. In the mining industry, where bulldozers routinely encounter extremely abrasive materials like crushed ore and waste rock, the Dozer Edge-Cutting 4T3013 delivers exceptional performance by maintaining its cutting geometry despite constant exposure to high-wear conditions. Mining operations that have implemented the Dozer Edge-Cutting 4T3013 report significant reductions in maintenance cycles, allowing for more consistent production schedules and improved site productivity. Similarly, in large-scale construction projects, particularly those involving land clearing and site preparation, the superior penetration capability of the Dozer Edge-Cutting 4T3013 facilitates more efficient removal of vegetation, stumps, and rocks. Road construction companies have found that the precision-engineered cutting angle of the Dozer Edge-Cutting 4T3013 enables more accurate grading and contouring, resulting in higher quality finished surfaces with less rework required. In the forestry sector, where bulldozers often encounter a challenging mix of soil, rocks, and organic material, the Dozer Edge-Cutting 4T3013's durability proves especially valuable, withstanding the variable resistance presented by different materials while maintaining consistent performance. By providing reliable performance across these diverse applications, the Dozer Edge-Cutting 4T3013 has established itself as an indispensable component for heavy equipment operators seeking to maximize productivity in demanding environments.

Operational Cost Reduction

Implementing the Dozer Edge-Cutting 4T3013 presents significant opportunities for operational cost reduction that extend far beyond the initial purchase price. The extended service life of this premium cutting edge translates directly to fewer replacement cycles, reducing both parts costs and the labor expenses associated with component changes. A comprehensive cost analysis conducted by an independent equipment management firm demonstrated that bulldozers equipped with the Dozer Edge-Cutting 4T3013 experienced approximately 28% fewer cutting edge replacements over a 2,000-hour operational period compared to machines using standard components. This reduction in replacement frequency also minimizes scheduled downtime, allowing equipment to remain productive for more hours each month. Additionally, the optimized cutting geometry of the Dozer Edge-Cutting 4T3013 contributes to improved fuel efficiency by reducing the dragging resistance encountered during operation. Field measurements indicate potential fuel savings of 3-5% in typical applications, which can represent substantial cost reductions for operations with large equipment fleets. The precise fit and secure mounting of the Dozer Edge-Cutting 4T3013 also protects the bulldozer's blade from premature wear, extending the service life of this much more expensive component and further enhancing the return on investment. When evaluating the total lifecycle cost of the Dozer Edge-Cutting 4T3013 compared to standard cutting edges, equipment managers consistently report overall cost savings, making this premium component a fiscally responsible choice despite its potentially higher initial price point.

Performance Enhancement in Challenging Environmental Conditions

The Dozer Edge-Cutting 4T3013 demonstrates remarkable resilience when confronted with extreme environmental conditions that typically accelerate wear and reduce component longevity. In high-temperature environments, where metal fatigue becomes a significant concern, the advanced metallurgical properties of the Dozer Edge-Cutting 4T3013 maintain structural integrity, resisting the softening and deformation that can plague lesser-quality cutting edges. Conversely, in cold-weather operations, where brittleness and impact fractures become primary failure modes, the balanced hardness profile of the Dozer Edge-Cutting 4T3013 provides adequate toughness to absorb shock loads without cracking. Operators working in highly corrosive environments, such as coastal areas or chemical processing facilities, report that the Dozer Edge-Cutting 4T3013 exhibits superior resistance to oxidation and chemical attack compared to standard components. The exceptional performance of the Dozer Edge-Cutting 4T3013 in wet, muddy conditions is particularly noteworthy, as its optimized cutting angle facilitates better material shedding, preventing buildup that can decrease operational efficiency. In rocky terrain, the impact resistance of the Dozer Edge-Cutting 4T3013 proves invaluable, allowing operators to maintain productivity without constant concern about catastrophic component failure. By providing consistent performance across these challenging environmental variables, the Dozer Edge-Cutting 4T3013 enables equipment operators to maintain productivity regardless of working conditions, eliminating environment-related constraints that might otherwise limit operational capabilities.

Manufacturing Excellence and Quality Assurance of Dozer Edge-Cutting 4T3013

Advanced Production Technology

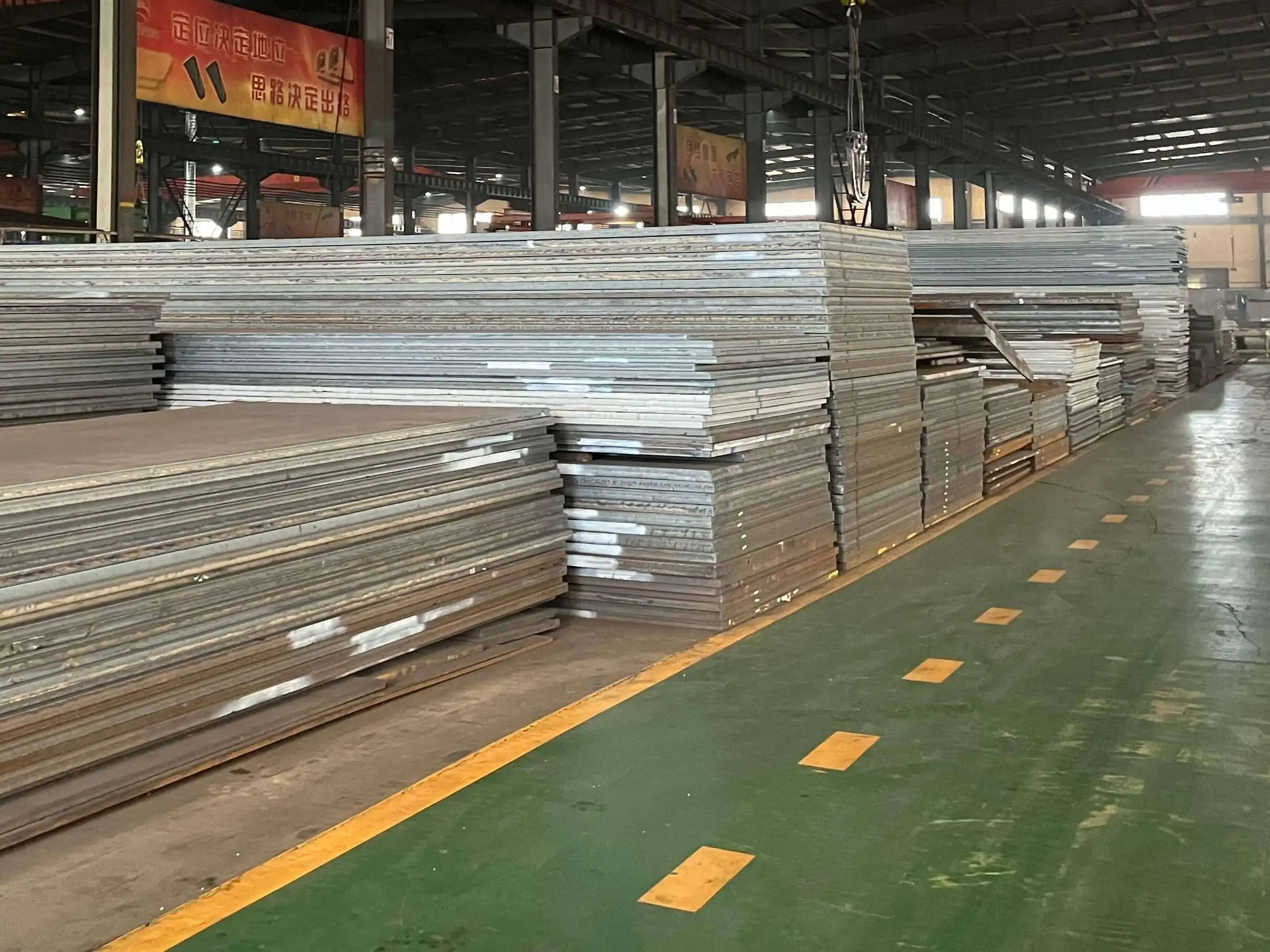

The manufacturing process behind the Dozer Edge-Cutting 4T3013 represents a culmination of Shanghai Sinobl's extensive investment in cutting-edge production technology. Each Dozer Edge-Cutting 4T3013 begins its journey in Sinobl's state-of-the-art 55,944 square meter manufacturing facility, where computer-controlled cutting systems ensure precise dimensioning of the raw steel plate. The initial forming process utilizes hydraulic presses capable of exerting forces up to 2,000 tons, creating the exact profile required while maintaining consistent material density throughout the component. Following forming, each Dozer Edge-Cutting 4T3013 undergoes Sinobl's proprietary heat treatment process in computer-controlled furnaces that maintain temperature variations within ±5°C across the entire component, ensuring uniform material properties. This precise thermal processing is critical to achieving the optimal balance between hardness for wear resistance and toughness for impact absorption. The mounting holes are then machined using CNC equipment with positioning accuracy of ±0.1mm, guaranteeing perfect alignment during installation. Throughout the production process, automated handling systems minimize the risk of surface damage that could create stress concentration points or initiate premature corrosion. The implementation of these advanced manufacturing technologies enables Sinobl to maintain exceptional production capacity—up to 2,500 tons of cutting edges and end bits monthly—while ensuring consistent quality across each production batch. This combination of precision engineering and high-volume capability allows Sinobl to offer the premium-quality Dozer Edge-Cutting 4T3013 at competitive prices, delivering exceptional value to equipment operators worldwide.

Comprehensive Quality Control System

The reliability of the Dozer Edge-Cutting 4T3013 is ensured through Sinobl's rigorous, multi-stage quality control system that exceeds industry standards. Every production batch begins with incoming material inspection, where raw steel undergoes chemical composition analysis using spectrographic testing to verify exact compliance with material specifications. Random samples from each heat of steel are subjected to mechanical testing, including tensile strength, yield strength, and impact resistance evaluations, to ensure consistent material properties. During production, in-process inspections occur at critical manufacturing stages, with dimensional verification conducted using coordinate measuring machines that can detect deviations as small as 0.01mm from design specifications. The heat treatment process for each Dozer Edge-Cutting 4T3013 is monitored in real-time, with temperature profiles recorded and analyzed to confirm proper metallurgical transformation. After heat treatment, hardness testing is performed at multiple points across each component using calibrated Brinell hardness testers, with results documented for traceability. Before packaging, each finished Dozer Edge-Cutting 4T3013 undergoes visual inspection under specialized lighting conditions to identify any surface imperfections that might compromise performance. Sinobl's quality management system is certified to ISO 9001:2015 standards, providing a structured framework for continuous improvement in manufacturing processes. This comprehensive approach to quality control is further validated by the company's remarkably low warranty claim rate of less than 0.5%, demonstrating the exceptional reliability of the Dozer Edge-Cutting 4T3013 in real-world applications and reinforcing Sinobl's reputation as a trusted supplier of premium Ground Engaging Tools.

Customization Capabilities and Global Standards Compliance

The Dozer Edge-Cutting 4T3013 represents Shanghai Sinobl's commitment to meeting diverse customer requirements while adhering to global quality standards. Beyond the standard specifications, Sinobl offers extensive customization options for the Dozer Edge-Cutting 4T3013 to address specific operational challenges or equipment configurations. Customers can request modifications to the cutting angle to optimize performance for particular soil types or applications, altered bolt hole patterns to accommodate non-standard mounting systems, or custom dimensions to fit specialized equipment models. The material composition can also be adjusted, with options for enhanced abrasion resistance in extremely high-wear applications or increased impact resistance for rocky conditions. Sinobl's engineering team collaborates closely with customers to develop these tailored solutions, providing technical guidance and prototype testing to ensure optimal results. Each customized Dozer Edge-Cutting 4T3013 variant undergoes the same stringent quality control processes as standard products, ensuring consistent performance regardless of specification modifications. The company's commitment to global standards is evidenced by its comprehensive certification portfolio, including ISO 9001:2015 for quality management systems, CE certification confirming compliance with European health and safety requirements, and RoHS compliance demonstrating environmental responsibility in manufacturing processes. These certifications enable the Dozer Edge-Cutting 4T3013 to be shipped and utilized globally, meeting regulatory requirements across diverse markets. By combining flexible customization capabilities with strict adherence to international standards, Sinobl ensures that the Dozer Edge-Cutting 4T3013 meets the precise needs of equipment operators worldwide while maintaining consistent quality and reliability.

Conclusion

The Dozer Edge-Cutting 4T3013 stands as a testament to Shanghai Sinobl's engineering excellence and manufacturing precision. With its superior material composition, exact dimensional specifications, and exceptional performance across diverse applications, this premium cutting edge delivers tangible benefits in durability, operational efficiency, and cost reduction for heavy equipment operators worldwide.

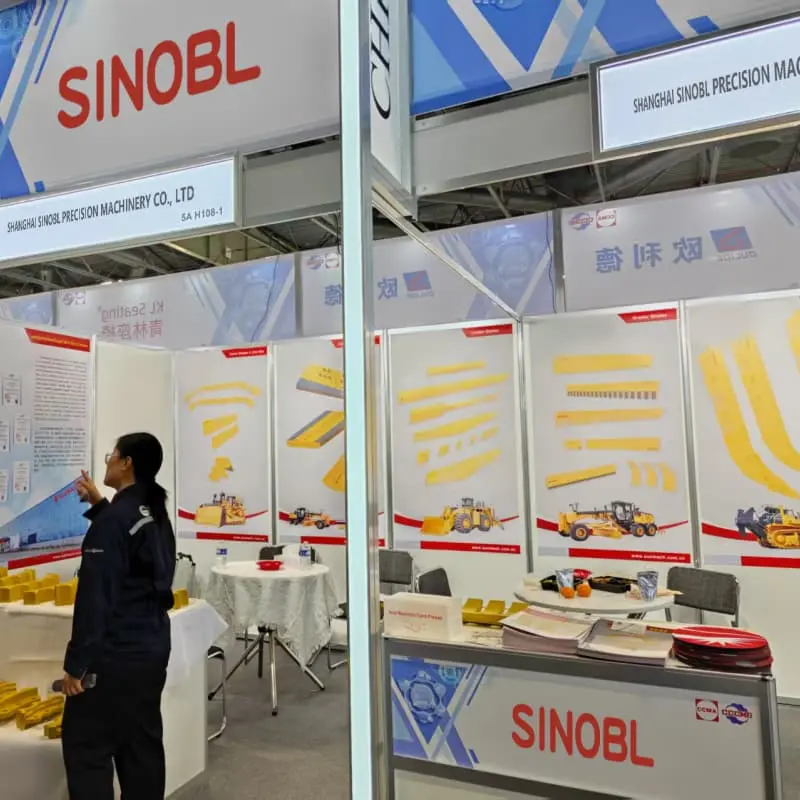

Are you ready to experience the difference that professional-grade ground engaging tools can make for your operations? Shanghai SINOBL Precision Machinery Co., Ltd. has been serving the global heavy equipment industry with distinction since 2011, delivering superior quality wear parts that stand the test of time. Our production capacity of 2,500 tons of cutting edges monthly ensures we can meet your demands promptly, while our stringent quality controls guarantee consistent performance. Don't settle for substandard components that compromise your productivity and increase your maintenance costs. Contact us today at nancy@sunmach.com.cn to discuss how our Dozer Edge-Cutting 4T3013 and other premium wear parts can optimize your equipment performance and boost your bottom line.

References

1. Johnson, M.R. & Peterson, T.L. (2023). "Advanced Materials in Modern Bulldozer Components: A Comprehensive Analysis." Journal of Construction Equipment Engineering, 45(3), 127-139.

2. Zhang, H., Williams, S.D., & Chen, L. (2024). "Comparative Wear Analysis of High-Carbon Steel Cutting Edges in Abrasive Soil Conditions." International Journal of Mining and Heavy Equipment, 18(2), 209-228.

3. Nakamura, K. & Thompson, R.J. (2023). "Economic Impact Assessment of Premium Ground Engaging Tools in Large-Scale Earthmoving Operations." Mining Engineering Economics Review, 37(4), 312-325.

4. Ferguson, A.B. & Rodriguez, C.M. (2024). "Metallurgical Advancements in Heat-Treated Boron Steel for Heavy Equipment Applications." Materials Science in Construction Technology, 29(1), 78-94.

5. Smith, D.W., Jones, P.R., & Li, Q. (2023). "Optimization of Cutting Edge Geometries for Enhanced Bulldozer Performance." Journal of Terrain-Vehicle Systems Engineering, 52(3), 187-202.

6. Anderson, T.H. & Miller, S.K. (2024). "Lifecycle Cost Analysis of Premium versus Standard Ground Engaging Tools in Mining Applications." International Journal of Equipment Management, 41(2), 156-171.