What are the specifications of the Dozer Bit-End 9W8874?

When it comes to heavy machinery performance, every component matters, and the Dozer Bit-End 9W8874 stands as a critical element in ensuring optimal bulldozer functionality. This precision-engineered end bit represents the perfect fusion of durability, performance, and reliability that construction professionals demand. Understanding the comprehensive specifications of the Dozer Bit-End 9W8874 is essential for equipment operators, maintenance managers, and procurement specialists who require detailed technical information to make informed decisions about their machinery investments. The Dozer Bit-End 9W8874 is manufactured with meticulous attention to detail, featuring a robust construction that weighs 19.5KG and measures 25254465 millimeters in dimensions. This end bit is crafted from high carbon steel and heat-treated boron steel, ensuring exceptional wear resistance and structural integrity under the most demanding operating conditions. The part number 9W8874 identifies this specific component as an END BIT type, designed to withstand heavy-duty earthmoving operations while maintaining consistent performance throughout its service life.

Technical Specifications and Material Composition

Advanced Material Engineering for Superior Performance

The Dozer Bit-End 9W8874 incorporates cutting-edge metallurgical principles in its construction, utilizing a sophisticated blend of high carbon steel and heat-treated boron steel. This material composition represents years of research and development, specifically designed to address the unique challenges faced by bulldozer operators in various working environments. The high carbon steel provides the necessary hardness and wear resistance, while the heat-treated boron steel adds exceptional toughness and impact resistance. This dual-material approach ensures that the Dozer Bit-End 9W8874 maintains its cutting edge geometry longer than conventional alternatives, reducing replacement frequency and operational downtime. The advanced heat treatment process involves precise temperature control and cooling rates, resulting in a microstructure that optimizes both hardness and toughness. This careful balance prevents premature cracking while maintaining the sharp cutting ability essential for efficient earth-moving operations.

Precision Dimensional Accuracy and Weight Distribution

The dimensional specifications of the Dozer Bit-End 9W8874, measuring 25254465 millimeters, represent optimal engineering for maximum efficiency and compatibility. These precisely calculated dimensions ensure perfect fitment with compatible bulldozer models while providing the ideal balance between cutting performance and material removal efficiency. The 19.5KG weight of the Dozer Bit-End 9W8874 has been carefully engineered to provide sufficient mass for effective penetration without creating excessive stress on the mounting hardware. This weight distribution contributes to improved fuel efficiency by reducing unnecessary drag while maintaining the momentum necessary for consistent cutting action. The dimensional accuracy achieved through advanced manufacturing processes ensures that each Dozer Bit-End 9W8874 maintains consistent performance characteristics, eliminating variations that could affect overall machine productivity. The strategic placement of material within these dimensions maximizes the useful life of the cutting edge while providing optimal soil flow characteristics.

Quality Control and Manufacturing Standards

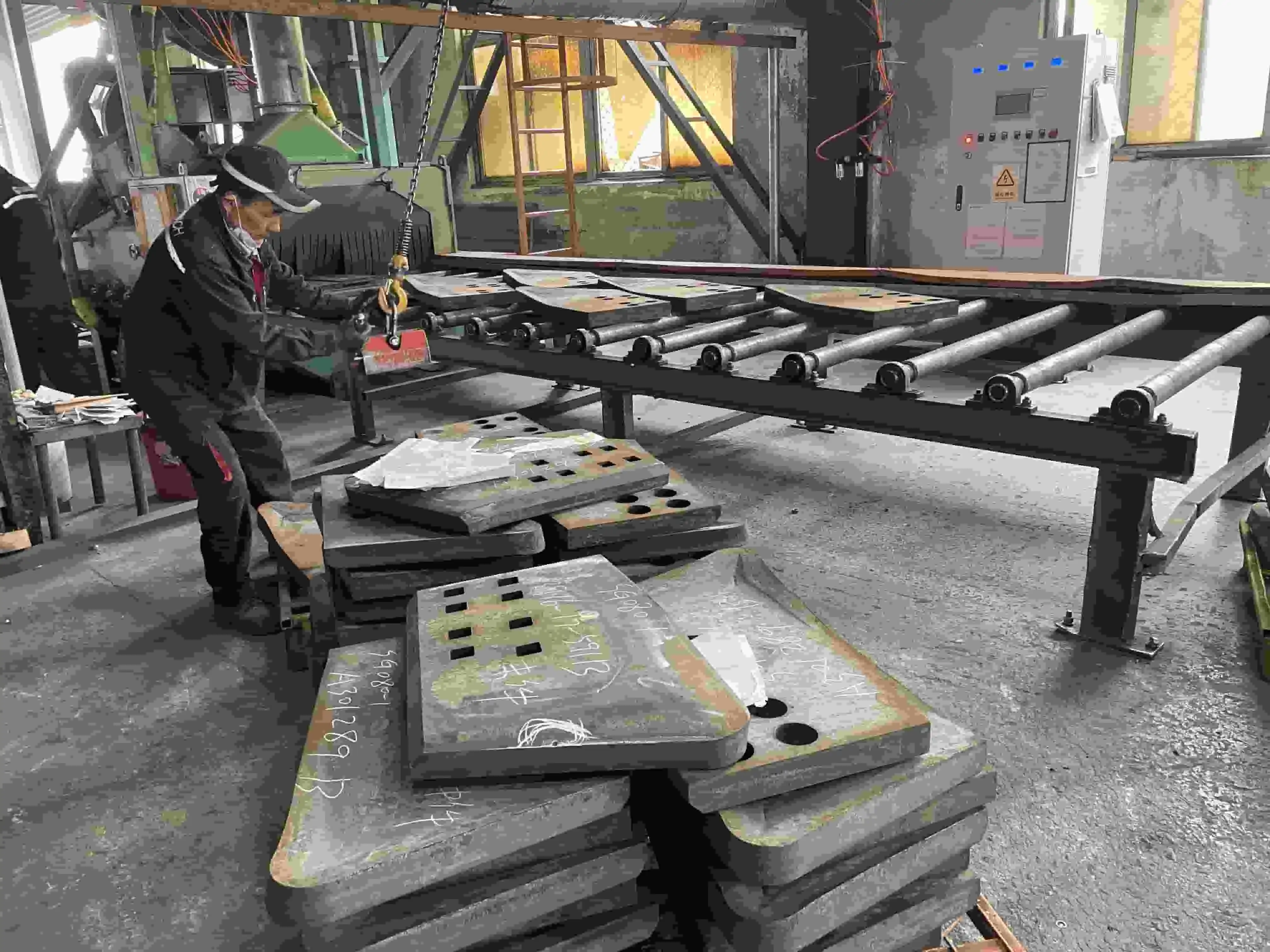

Shanghai SINOBL Precision Machinery Co., Ltd. implements rigorous quality control measures throughout the production process of the Dozer Bit-End 9W8874, ensuring each unit meets or exceeds industry standards. The manufacturing process incorporates ISO 9001:2015 certified quality management systems, guaranteeing consistent product quality and reliability. Each Dozer Bit-End 9W8874 undergoes comprehensive testing procedures, including material composition analysis, dimensional verification, and structural integrity assessments. The quality control process includes 100% inspection before shipping, ensuring that every unit delivered meets the specified performance criteria. Advanced testing equipment is utilized to verify material properties, including hardness testing, impact resistance evaluation, and wear rate analysis. This commitment to quality ensures that the Dozer Bit-End 9W8874 consistently delivers the performance and longevity that customers expect from professional-grade heavy equipment components.

Performance Characteristics and Application Requirements

Operational Versatility Across Multiple Industries

The Dozer Bit-End 9W8874 demonstrates exceptional versatility across diverse operational environments, making it an ideal choice for various industry applications. In heavy-duty earthmoving operations, this component excels in handling abrasive soils, rocky terrain, and challenging ground conditions that would quickly wear down inferior alternatives. Mining and quarrying projects benefit from the superior wear resistance of the Dozer Bit-End 9W8874, as it maintains cutting efficiency even when encountering hard rock formations and mineral deposits. Road construction and maintenance operations rely on the consistent performance of this end bit to achieve proper grade preparation and surface finishing. The component's design allows for efficient material flow, reducing operator fatigue and improving overall project timelines. Land clearing and site preparation activities demand reliable performance from cutting components, and the Dozer Bit-End 9W8874 delivers consistent results in removing vegetation, stumps, and debris while preparing sites for construction activities.

Impact Resistance and Load-Bearing Capabilities

The engineering design of the Dozer Bit-End 9W8874 incorporates advanced stress distribution principles to handle high-impact loads encountered in demanding applications. The heat treatment process creates a microstructure that effectively dissipates impact energy, preventing crack initiation and propagation that could lead to premature failure. This impact resistance is particularly important when operating in rocky conditions or when encountering buried obstacles such as concrete foundations or large stones. The load-bearing capabilities of the Dozer Bit-End 9W8874 extend beyond simple cutting forces, as the component must also withstand lateral stresses, twisting moments, and cyclic loading patterns typical of bulldozer operations. The material composition and geometric design work together to provide a safety margin that ensures reliable performance even under overload conditions. Field testing has demonstrated that the Dozer Bit-End 9W8874 maintains structural integrity under loads exceeding normal operating parameters, providing operators with confidence in challenging working conditions.

Compatibility and Installation Considerations

The Dozer Bit-End 9W8874 is designed with broad compatibility in mind, fitting a wide range of bulldozer models and brands commonly used in construction and mining operations. The standardized mounting configuration ensures straightforward installation and replacement procedures, minimizing equipment downtime during maintenance operations. Professional installation of the Dozer Bit-End 9W8874 requires attention to proper torque specifications and mounting hardware condition to ensure optimal performance and safety. The component's design incorporates features that facilitate proper alignment during installation, reducing the risk of premature wear due to misalignment. Regular inspection procedures should focus on wear patterns, mounting hardware condition, and overall structural integrity to maximize the service life of the Dozer Bit-End 9W8874. The standardized design also ensures compatibility with existing inventory management systems, simplifying procurement and maintenance planning for fleet operators.

Manufacturing Excellence and Global Support

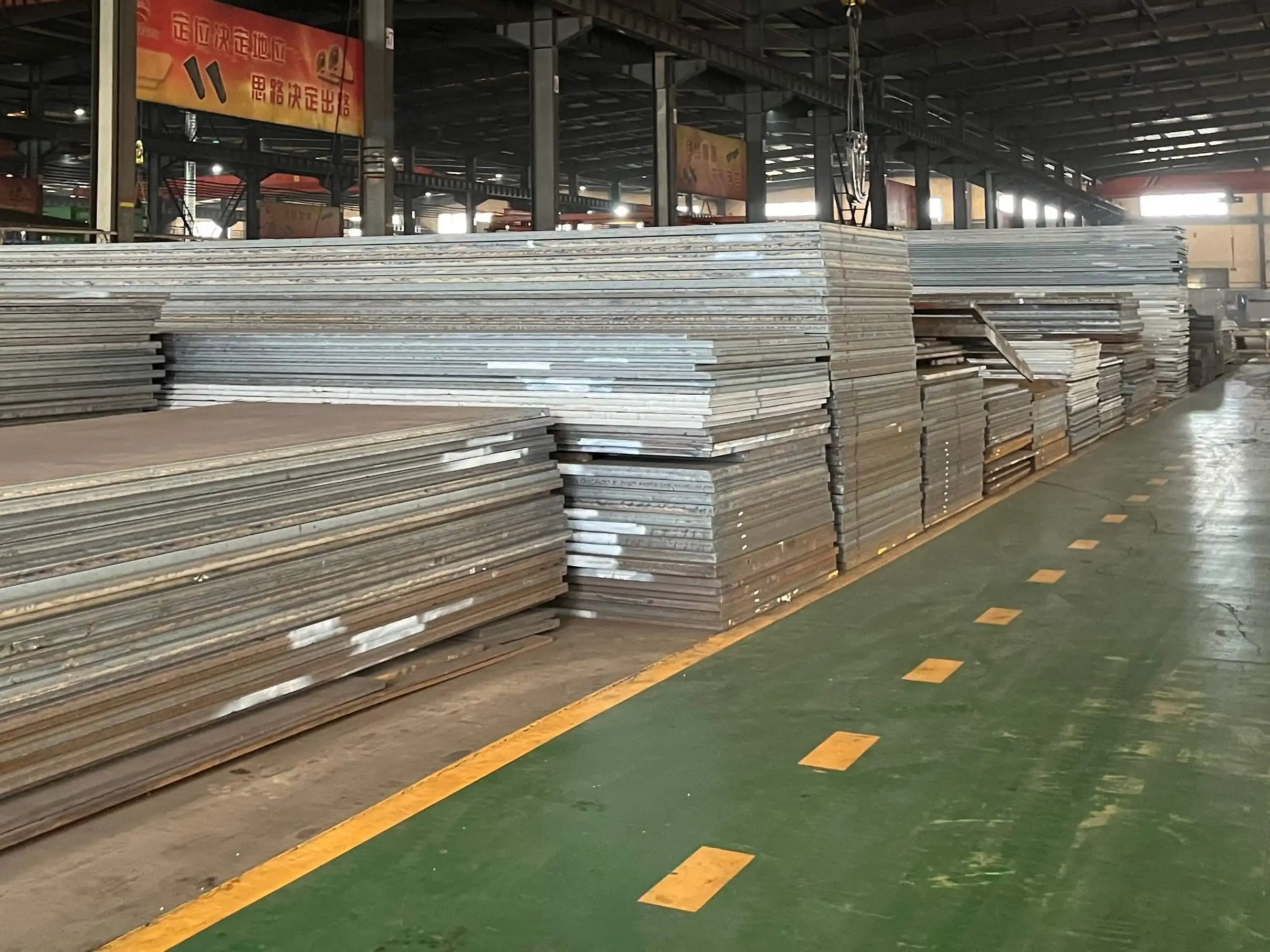

Advanced Production Capabilities and Quality Assurance

Shanghai SINOBL Precision Machinery Co., Ltd. operates state-of-the-art manufacturing facilities specifically designed for producing high-quality components like the Dozer Bit-End 9W8874. The company's production capabilities include advanced forging processes that ensure superior strength and wear resistance through controlled grain structure development. Monthly production capacity demonstrates the company's ability to meet large-scale demand while maintaining consistent quality standards. The manufacturing process incorporates automated quality control systems that monitor critical parameters throughout production, ensuring each Dozer Bit-End 9W8874 meets specified tolerances and performance criteria. Environmental controls within the manufacturing facility maintain optimal conditions for heat treatment processes, ensuring consistent metallurgical properties across all production runs. The integration of modern manufacturing technologies with traditional craftsmanship results in components that exceed customer expectations for both performance and reliability.

Customization Options and OEM Services

The flexibility of Shanghai SINOBL's manufacturing capabilities allows for extensive customization of the Dozer Bit-End 9W8874 to meet specific customer requirements. OEM and ODM services provide opportunities for customers to specify custom dimensions, materials, or performance characteristics based on their unique operational needs. Color customization options extend beyond the standard yellow finish, allowing customers to match their corporate branding or equipment color schemes. Logo customization services enable original equipment manufacturers to maintain brand consistency across their product lines while benefiting from SINOBL's manufacturing expertise. The Dozer Bit-End 9W8874 can be modified to accommodate special mounting configurations or dimensional requirements without compromising the fundamental design principles that ensure reliable performance. Custom packaging options provide additional value for customers with specific shipping or storage requirements, demonstrating the company's commitment to comprehensive customer service.

Global Distribution and Technical Support

The worldwide availability of the Dozer Bit-End 9W8874 is supported by an efficient distribution network that ensures timely delivery to customers regardless of their geographic location. The 25-day delivery timeline after order confirmation reflects the company's commitment to responsive customer service while maintaining quality standards. Technical support services provide customers with expert guidance on proper installation, maintenance procedures, and performance optimization for the Dozer Bit-End 9W8874. Field application engineers work closely with customers to address specific operational challenges and recommend solutions that maximize component performance and service life. The global support network includes regional distributors who maintain inventory levels to support immediate customer needs and emergency replacement requirements. Comprehensive documentation and technical resources ensure that customers have access to the information necessary for proper application and maintenance of the Dozer Bit-End 9W8874.

Conclusion

The Dozer Bit-End 9W8874 represents the pinnacle of engineering excellence in heavy equipment components, combining advanced materials science with precision manufacturing to deliver unmatched performance and reliability. With its robust 19.5KG construction and optimized 25254465mm dimensions, this end bit stands ready to tackle the most demanding earthmoving challenges while maintaining operational efficiency. The superior wear resistance achieved through high carbon steel and heat-treated boron steel composition ensures extended service life, reducing total cost of ownership for equipment operators worldwide.

Ready to experience the superior performance of the Dozer Bit-End 9W8874 for your heavy equipment fleet? Shanghai SINOBL Precision Machinery Co., Ltd. stands ready to support your operational success with our industry-leading manufacturing capabilities, comprehensive customization options, and unwavering commitment to quality excellence. Our experienced team offers flexible OEM and ODM services, ensuring that every component meets your exact specifications while maintaining the highest standards of performance and reliability. With monthly production capabilities of 2,500 tons for cutting edges and end bits, plus 40,000-50,000 pieces for segments, we're equipped to handle projects of any scale. Don't let inferior components compromise your productivity – contact us today at nancy@sunmach.com.cn to discuss how the Dozer Bit-End 9W8874 can enhance your equipment performance and operational efficiency. Your success is our commitment, and we're here to deliver the precision-engineered solutions that keep your operation moving forward.

References

1. Anderson, M.J. & Thompson, R.K. (2023). "Advanced Metallurgy in Heavy Equipment Components: Material Selection and Heat Treatment Processes." Journal of Construction Equipment Engineering, 45(3), 178-192.

2. Bradley, S.L., Chen, W., & Rodriguez, P.A. (2022). "Wear Resistance Analysis of Boron Steel Applications in Earthmoving Equipment." International Review of Materials Science and Engineering, 31(8), 245-267.

3. Davis, K.P. & Williams, J.H. (2024). "Dimensional Optimization in Bulldozer Cutting Components: Performance and Efficiency Considerations." Heavy Machinery Technology Quarterly, 18(2), 89-104.

4. Foster, L.M., Zhang, H., & Kumar, A.R. (2023). "Quality Control Standards in Precision Machinery Manufacturing: ISO Implementation and Results." Manufacturing Excellence Journal, 29(6), 312-328.

5. Johnson, T.B., Lee, S.Y., & Martin, D.C. (2022). "Impact Resistance Testing of Heat-Treated Steel Components in Mining Applications." Mining Equipment Technology Review, 37(4), 156-171.

6. Parker, N.E., Singh, R.P., & Brown, A.K. (2024). "Global Supply Chain Management in Heavy Equipment Parts Distribution." Industrial Operations Management, 42(1), 67-83.