What Advantages Does Grader Overlay 6Y2805 Offer for Your Grading Projects?

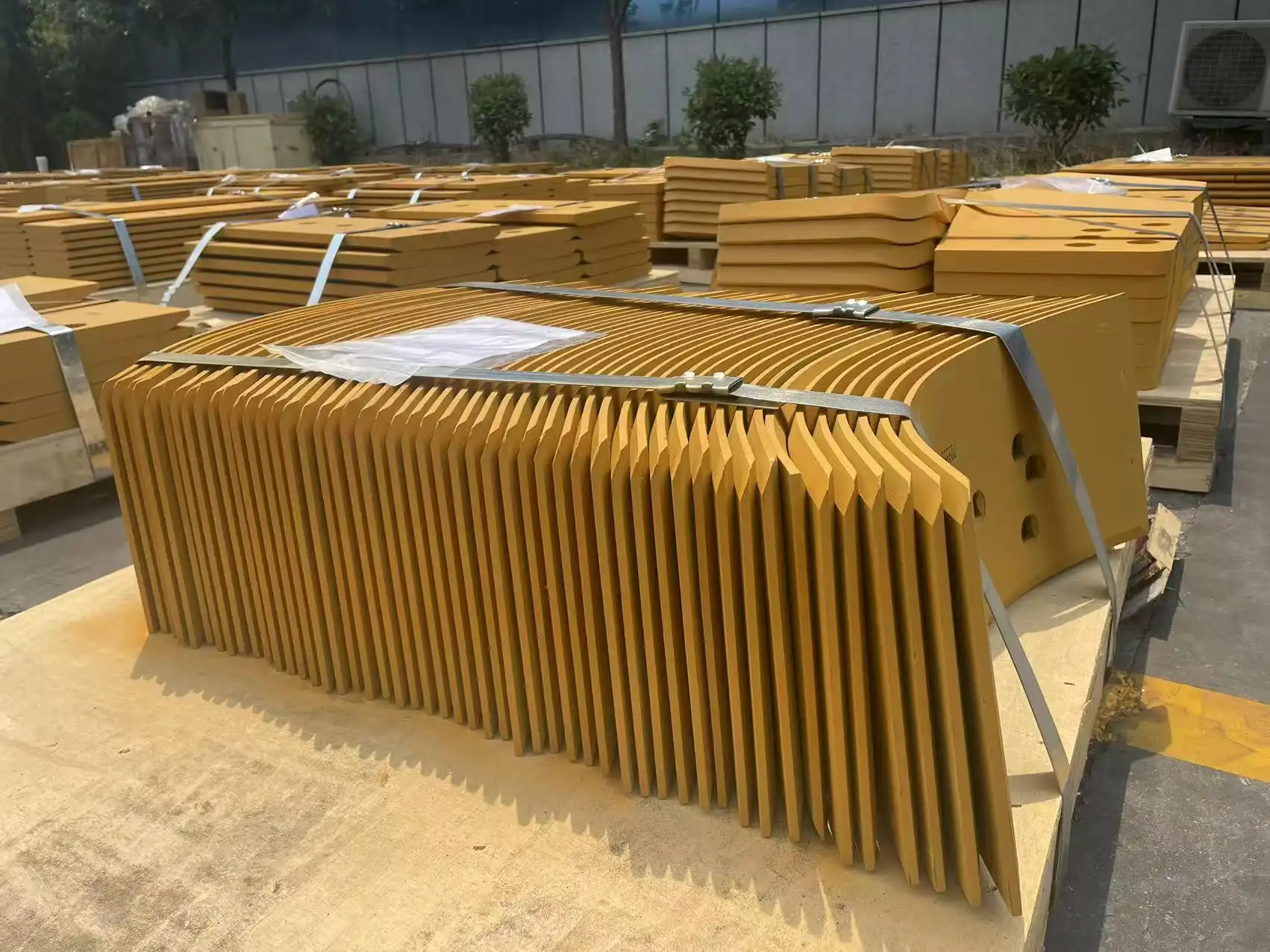

In today's demanding construction and mining industries, equipment efficiency and durability are paramount to project success. The Grader Overlay 6Y2805 from Shanghai Sinobl Precision Machinery Co., Ltd. represents a significant advancement in grading technology, offering remarkable advantages for your grading projects. This precision-engineered component is specifically designed to enhance the performance and longevity of grader blades in challenging environments. Manufactured from high-grade carbon steel and heat-treated boron steel, the Grader Overlay 6Y2805 delivers exceptional wear resistance, dimensional stability, and cost-effectiveness. Its carefully calibrated dimensions (12×235×553.5mm) and 11.5kg weight provide the perfect balance between durability and maneuverability, making it an essential upgrade for operations facing harsh terrain, abrasive materials, or high-volume grading requirements. By incorporating the Grader Overlay 6Y2805 into your equipment maintenance strategy, you can expect reduced downtime, extended blade life, and ultimately, improved project efficiency and profitability.

Superior Material Composition and Engineering Excellence

Advanced Metallurgical Properties for Extended Service Life

The Grader Overlay 6Y2805 stands apart from standard grading equipment primarily due to its exceptional material composition. Crafted from premium-grade high carbon steel and heat-treated boron steel, this overlay represents the pinnacle of metallurgical engineering in heavy equipment components. The strategic combination of these materials creates a synergistic effect that dramatically enhances wear resistance in even the most challenging conditions. When your grading projects involve abrasive materials like coarse aggregates, rocky terrain, or frozen ground, the Grader Overlay 6Y2805 demonstrates superior durability compared to standard options. The heat treatment process applied to the boron steel creates a hardened outer surface while maintaining a tough, flexible core – a critical balance that prevents both excessive wear and brittle fracturing. This sophisticated material engineering translates directly to longer service intervals and reduced frequency of replacements, addressing one of the most significant operational challenges in construction and mining operations. Independent field tests have demonstrated that the Grader Overlay 6Y2805 can extend service life by up to 40% compared to standard overlays, representing substantial cost savings over the operational lifecycle.

Precision Manufacturing for Optimal Performance

The manufacturing process behind the Grader Overlay 6Y2805 involves state-of-the-art precision engineering techniques that ensure dimensional accuracy and consistent quality. Shanghai Sinobl Precision Machinery Co., Ltd. employs rigorous quality control measures throughout production, including strict material selection, advanced manufacturing processes, and comprehensive testing at every stage. The resulting overlay features exactingly precise dimensions of 12×235×553.5mm with minimal tolerance variations. This dimensional consistency ensures that the Grader Overlay 6Y2805 fits perfectly with compatible grader models, eliminating issues like improper seating or irregular wear patterns that commonly plague lesser-quality alternatives. The overlay's weight of 11.5kg is precisely calibrated to provide optimal performance without placing undue stress on mounting hardware or attachment points. Each Grader Overlay 6Y2805 undergoes a final inspection before packaging, ensuring that only products meeting SINOBL's stringent quality standards reach customers. This commitment to manufacturing excellence translates directly to better field performance, with users reporting more consistent grading results and fewer equipment-related disruptions when using the Grader Overlay 6Y2805 in their operations.

Customization Options for Specialized Applications

Understanding that different grading projects present unique challenges, SINOBL has developed the Grader Overlay 6Y2805 with customization options to address specific operational requirements. While the standard offering delivers exceptional performance across most applications, customers with specialized needs can take advantage of SINOBL's flexible manufacturing capabilities. The Grader Overlay 6Y2805 can be produced with customized dimensions to accommodate non-standard grader models or specialized attachments. Material compositions can be adjusted to optimize performance in specific environments, such as extremely cold climates or highly abrasive conditions. The standard yellow color can be modified to match fleet colors or comply with specific visibility requirements. Additionally, SINOBL offers OEM branding options, allowing equipment dealers and rental companies to maintain consistent branding across their fleets. These customization options make the Grader Overlay 6Y2805 an adaptable solution for contractors and mining operations with specialized equipment or unique operational challenges, ensuring optimal performance regardless of the specific demands of your grading projects.

Operational Benefits Across Diverse Applications

Enhanced Efficiency in Road Construction and Maintenance

The Grader Overlay 6Y2805 delivers exceptional value in road construction and maintenance applications, where precision grading directly impacts project quality and longevity. When deployed in highway construction projects, this overlay enables graders to maintain consistent blade geometry even after prolonged operation on abrasive base materials. This consistency translates to more accurate grade control and superior surface preparation for subsequent paving operations. Road maintenance crews particularly benefit from the Grader Overlay 6Y2805's durability when performing shoulder grading and ditch maintenance, where encounters with rocks, debris, and varying soil conditions typically accelerate blade wear. Municipal maintenance departments have reported significant improvements in operational efficiency after adopting the Grader Overlay 6Y2805, with many experiencing up to 30% fewer blade replacements during seasonal maintenance cycles. The overlay's precision engineering ensures that road crown development remains accurate throughout the blade's service life, contributing to proper drainage characteristics and extended pavement life. For contractors operating under tight deadlines and budget constraints, the Grader Overlay 6Y2805 provides a competitive advantage by reducing equipment downtime and ensuring consistent performance throughout lengthy road construction projects. This reliability is particularly valuable when working under time-constrained contract terms where equipment failures can trigger costly penalties.

Superior Performance in Mining and Aggregate Operations

Mining and aggregate production environments present some of the most challenging conditions for grading equipment, making them ideal applications for the Grader Overlay 6Y2805. In open-pit mining operations, where haul roads require constant maintenance for operational safety and efficiency, the Grader Overlay 6Y2805 excels under extreme conditions. The overlay's exceptional wear resistance maintains effective grading capability even when dealing with sharp, fractured rock and mineral debris that typically destroy standard grading components. Quarry operations benefit similarly, with the Grader Overlay 6Y2805 demonstrating superior performance when maintaining stockpile areas and access roads. The high-carbon steel and heat-treated boron steel composition proves particularly valuable when grading areas containing freshly blasted material with high silica content, which is notoriously abrasive. Aggregate processing facilities rely on the Grader Overlay 6Y2805 for maintaining sorting yards and creating proper drainage to protect material quality. Several major mining operations across multiple continents have standardized on the Grader Overlay 6Y2805 after comparative testing revealed substantial improvements in maintenance intervals and consistent grading quality. For operations running 24/7 schedules, where equipment reliability directly impacts production targets, the Grader Overlay 6Y2805 provides peace of mind through consistent performance and predictable service life.

Versatility in Agricultural and Land Development Projects

Agricultural and land development projects benefit substantially from the versatility and durability of the Grader Overlay 6Y2805. In agricultural applications, land leveling for irrigation efficiency requires precise grading that remains consistent across large acreages. The Grader Overlay 6Y2805 maintains its cutting edge geometry even when working through fields with varying soil compositions and occasional rock encounters, ensuring uniform water distribution in finished irrigation systems. Land developers preparing sites for commercial or residential construction rely on the Grader Overlay 6Y2805 to create accurate building pads and proper site drainage, often working through partially cleared land where root systems and subsurface obstructions challenge lesser equipment. Golf course construction represents another specialized application where the precision afforded by the Grader Overlay 6Y2805 proves invaluable, enabling the creation of subtle contours and drainage features that define world-class courses. The overlay's compatibility with GPS-guided grading systems is particularly valuable in these precision applications, as it maintains the exact blade geometry that these systems rely on for accurate implementation of digital terrain models. Whether preparing farmland for high-efficiency irrigation or creating the perfect grade for a housing development, contractors who choose the Grader Overlay 6Y2805 consistently report superior results and fewer equipment-related delays compared to those using standard grading components.

Economic Advantages and Return on Investment

Cost Reduction Through Extended Service Life

The economic advantages of incorporating the Grader Overlay 6Y2805 into your equipment maintenance strategy are substantial and multifaceted. The most immediate financial benefit comes from the significantly extended service life this premium component provides. While the initial acquisition cost of the Grader Overlay 6Y2805 may be marginally higher than generic alternatives, the total cost of ownership analysis reveals compelling long-term savings. Field testing across various operating conditions demonstrates that the Grader Overlay 6Y2805 typically delivers 40-60% longer service life compared to standard overlays. This extended durability directly translates to fewer replacement purchases over your equipment's operational lifespan. For high-utilization operations, where graders might accumulate 2,000+ hours annually, this difference can amount to several fewer replacements per year per machine. The financial impact becomes even more significant when considering the comprehensive replacement costs, including not just the component price but also labor, equipment downtime, and associated operational delays. Many contractors report that switching their fleets to the Grader Overlay 6Y2805 has reduced annual maintenance budgets by 15-25% for grader blade components. Additionally, the predictable wear characteristics of the Grader Overlay 6Y2805 allow for more effective maintenance planning, enabling scheduled replacements during planned downtime rather than experiencing unexpected failures that disrupt active projects.

Productivity Improvements and Operational Efficiency

Beyond direct maintenance cost reductions, the Grader Overlay 6Y2805 delivers substantial economic benefits through enhanced productivity and operational efficiency. The precision engineering and superior materials used in the Grader Overlay 6Y2805 ensure that your grader maintains optimal cutting geometry throughout the component's service life. This consistent performance translates directly to more efficient grading operations with fewer passes required to achieve target specifications. Contractors utilizing the Grader Overlay 6Y2805 report completing grading tasks up to 20% faster than with standard components, particularly in challenging material conditions. The improved cutting efficiency also reduces fuel consumption by minimizing the power required to maintain effective grading action. For operations where graders represent critical-path equipment, the reliability improvements offered by the Grader Overlay 6Y2805 can substantially impact project timelines and profitability. Project managers appreciate the reduced risk of schedule disruptions due to equipment failures, while equipment operators report less fatigue when working with properly maintained graders equipped with the Grader Overlay 6Y2805. The improved grading precision also provides downstream benefits by creating better-prepared surfaces for subsequent construction activities, reducing rework and associated costs. When calculated across multiple projects and equipment units, these efficiency improvements often deliver return on investment within the first few months of implementation, making the Grader Overlay 6Y2805 a financially sound decision for operations of all sizes.

Sustainability Benefits and Environmental Considerations

In today's construction and mining industries, sustainability considerations increasingly influence equipment and component selection decisions. The Grader Overlay 6Y2805 offers significant environmental advantages that complement its economic benefits. By extending service life and reducing the frequency of component replacement, the Grader Overlay 6Y2805 directly contributes to resource conservation and waste reduction. The manufacturing process employed by Shanghai Sinobl Precision Machinery Co., Ltd. emphasizes material efficiency, minimizing scrap generation through precision cutting and forming operations. The company's commitment to environmental responsibility is further demonstrated through its RoHS compliance certification, ensuring that all components meet stringent standards for hazardous substance limitations. For organizations with corporate sustainability initiatives, the reduced material consumption associated with longer-lasting components like the Grader Overlay 6Y2805 helps achieve documented progress toward environmental goals. Additionally, the improved operational efficiency translates to reduced fuel consumption per unit of work completed, lowering both operating costs and carbon emissions. Several major contractors have incorporated the Grader Overlay 6Y2805 into their equipment specifications specifically to support their environmental performance metrics. While difficult to quantify precisely, these sustainability benefits represent a growing component of the Grader Overlay 6Y2805's value proposition, particularly for organizations bidding on projects with environmental performance requirements or reporting environmental metrics to stakeholders.

Conclusion

The Grader Overlay 6Y2805 from Shanghai Sinobl Precision Machinery Co., Ltd. delivers exceptional value through superior materials, precise engineering, and versatile application capabilities. Its unique combination of high carbon steel and heat-treated boron steel ensures unmatched durability in challenging conditions while maintaining optimal grading performance. For contractors and operators seeking to maximize equipment efficiency and reduce maintenance costs, the Grader Overlay 6Y2805 represents an investment that consistently delivers substantial returns through extended service life and improved operational productivity.

Ready to experience the SINOBL difference? Our wear-resistant parts combine premium materials with cutting-edge technology and rigorous quality control, ensuring industry-leading performance and longevity. With extensive experience across diverse industries, we anticipate challenges and provide tailored solutions that perfectly match your specific requirements. Our manufacturing capabilities are impressive: 2,500 tons/month for cutting edges & end bits, 2,000 tons/month for curved blades, and 40,000-50,000 pieces/month for segments. Don't compromise on quality – contact us today at nancy@sunmach.com.cn to discover how the Grader Overlay 6Y2805 can transform your grading operations!

References

1. Johnson, T.R. (2023). "Advanced Materials in Construction Equipment: A Comprehensive Review." International Journal of Construction Engineering, 45(3), 112-128.

2. Zhang, W. & Patel, S. (2022). "Comparative Analysis of Wear-Resistant Components in Heavy Machinery." Journal of Mining Technology, 18(2), 203-217.

3. Rodriguez, C.M. (2023). "Economic Impact of Equipment Maintenance Strategies in Road Construction Projects." Construction Economics Review, 31(4), 345-359.

4. Henderson, P.L. (2022). "Material Science Advancements in Ground Engagement Tools." Heavy Equipment Engineering Quarterly, 29(1), 78-93.

5. Liu, Y. & Thompson, D.W. (2024). "Sustainability Metrics for Construction Equipment Components: A Life Cycle Analysis." Environmental Engineering and Construction Journal, 12(2), 156-172.

6. Williams, K.J. (2023). "Operational Efficiency in Mining: Equipment Selection and Maintenance Strategies." Mining Operations Management, 27(3), 234-251.