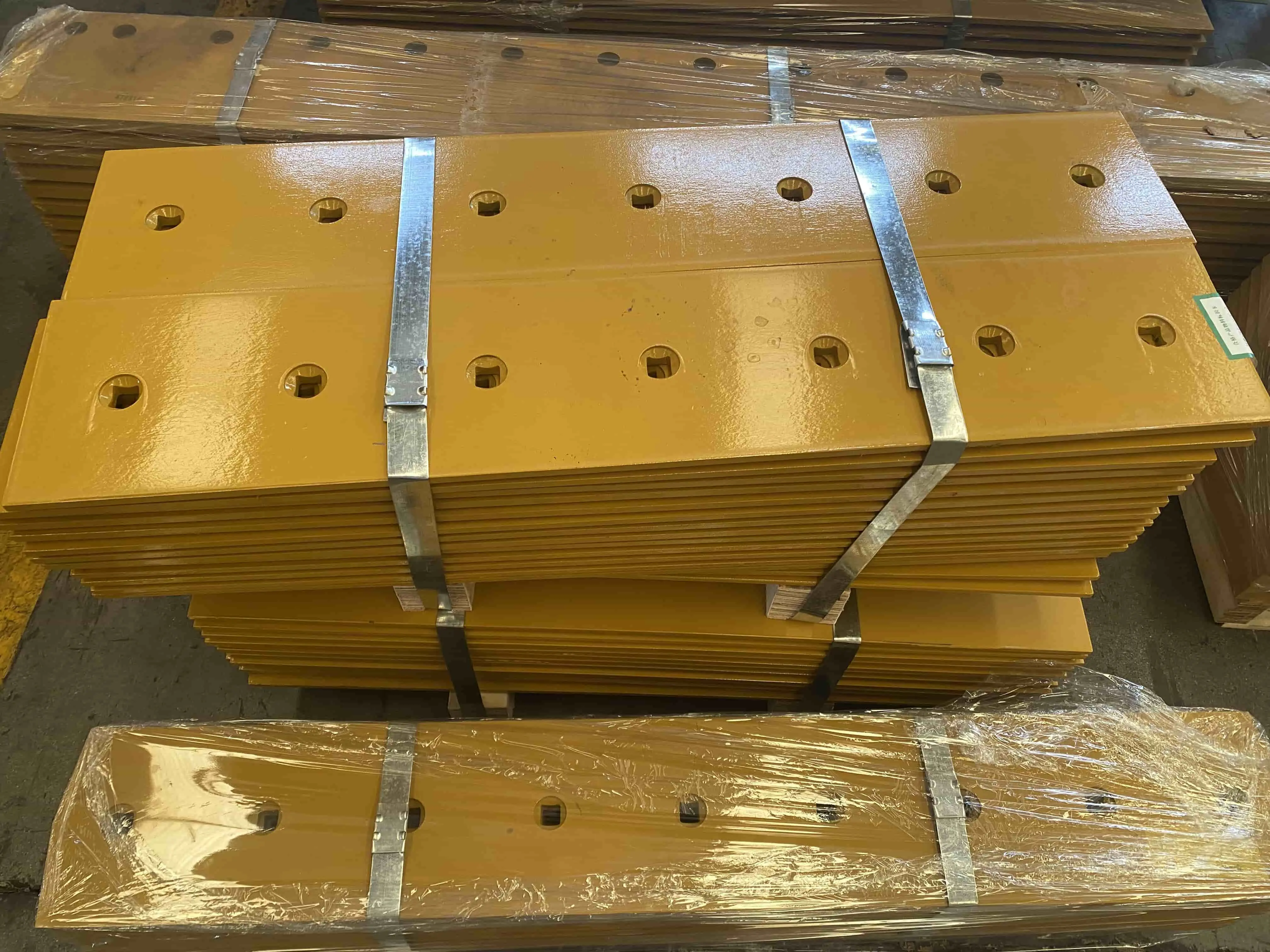

The primary goal of Black Cat Blades is to provide high-quality aftermarket cutting edges with improved performance and longevity, including Dozer Edge-Cutting 140-80-00001. The firm produces cutting edges that often surpass OEM requirements because it places a higher priority on quality than quantity. Its products are designed for users who work in harsh conditions where impact resistance and long wear life are essential. Black Cat serves niche markets requiring specialized configurations not typically offered by mass-production suppliers. Strict quality checks, precise machining, and customized hardening procedures are among the company's technological specialties. Longer wear patterns, better edge retention, and enhanced resilience to impact damage are all characteristics of Black Cat cutting edges. Customers may obtain maximum performance and decreased downtime in specialized or harsh operating circumstances thanks to its engineering methodology, which is focused on application-specific optimization.

Top Uses of Dozer Edge‑Cutting 140‑80‑00001 in Grading and Leveling

The Dozer Edge-Cutting 140-80-00001 stands as a cornerstone component in modern earthmoving operations, specifically engineered for precision grading and leveling applications. This heavy-duty cutting edge transforms bulldozers into versatile grading machines capable of achieving superior surface finishes across construction sites, mining operations, and agricultural projects. Its robust steel construction and optimized geometry enable operators to maintain consistent blade angles while processing various soil conditions. From highway construction to residential development, this cutting edge attachment ensures smooth material flow and exceptional wear resistance. The 140-80-00001 specification delivers reliable performance in demanding environments where precision leveling determines project success.

Leading Manufacturers of Dozer Edge-Cutting Components

Shanghai SINOBL Precision Machinery Co., Ltd.

SINOBL has established itself as a premier manufacturer of ground engaging tools since 2011, operating from a massive 55,944 square meter modern production facility in Shanghai, China. The firm specializes in producing worn parts, end bits, and cutting edges of superior quality for excavators, graders, and bulldozers in various tonnage classes. Strong scalability and operational robustness are shown by its capacity to manufacture cutting edges and end bits at a rate of around 2,500 tons per month. With consistent supply schedules and competitive lead times, SINOBL can meet worldwide aftermarket demand and major OEM contracts thanks to this capability. Strict selection of quality raw materials and sophisticated heat treatment procedures are the foundation of the company's technological expertise. Some of the strongest and most resilient steels in the market are used by SINOBL; these steels are meticulously designed to provide optimal wear life and impact resistance in demanding working environments. Consistency across batches is ensured by extensive quality control measures that are in line with international standards. Furthermore, SINOBL has over 3,000 tons of completed inventory on hand, enabling quick worldwide shipping and dependable supply for urgent replacement requirements on many continents. Agriculture, mining, infrastructure development, and construction are just a few of the many sectors that SINOBL supports. Its product line includes bulldozer models from D3 to D11, guaranteeing interoperability with well-known international equipment manufacturers. The company's ongoing R&D expenditures prioritize dimensional optimization, precision forging, and metallurgical innovation. Customers benefit from reduced downtime and increased equipment productivity as a consequence of these efforts, which provide cutting edges with greater precision, predictable wear patterns, and reliable field performance.

Caterpillar Inc.

Thanks to decades of technical experience and ongoing technological development, Caterpillar continues to hold its position as a world leader in the production of earthmoving and construction equipment. Cutting edges from its original equipment manufacturer (OEM) are designed especially for Caterpillar earthmoving equipment and bulldozers, including Dozer Edge-Cutting 140-80-00001. To confirm fitting correctness, material strength, and long-term durability, every cutting edge is put through stringent testing methods. Caterpillar can create and transport thousands of state-of-the-art components each year to fulfill global demand thanks to its vast global manufacturing base that spans many continents. Proprietary steel compositions, cutting-edge welding methods, and meticulously refined heat treatment procedures are some of Caterpillar's technological advantages. Refined geometries in the design of these cutting edges improve material flow, decrease drag, and increase penetration efficiency. The business is the owner of many patents pertaining to manufacturing processes, wear resistance, and ground engaging tool design. Because of its robust portfolio of intellectual property, Caterpillar is able to minimize equipment operators' total cost of ownership, increase service life, and provide reliable OEM performance.

Komatsu Ltd.

With production centers spread throughout Asia, Europe, and North America, Komatsu delivers renowned Japanese precision engineering to the leading edge of manufacturing. The firm serves both original equipment manufacture and aftermarket supply chains with an annual production of over 100,000 state-of-the-art products. Operating under stringent ISO 9001 quality management systems, Komatsu makes sure every cutting edge satisfies high performance and dimensional tolerance requirements. Komatsu is able to effectively serve regional markets while maintaining consistent product quality because to its worldwide production system. Finite element analysis, which optimizes stress distribution and structural integrity, and sophisticated computer-aided design technologies power Komatsu's innovative capabilities. High-carbon steel alloys and specific heat treatment cycles are used in the production of its cutting blades in order to balance toughness and hardness. In order to continuously increase service life, dependability, and operating efficiency under difficult working circumstances, Komatsu's research labs make significant investments in material science and wear resistant technologies.

John Deere Construction & Forestry

John Deere creates innovative solutions for forestry and construction industries by using its extensive experience in heavy machinery and agriculture. Its manufacturing operations produce cutting edges optimized for grading, leveling, and material spreading tasks. About 75,000 units may be produced annually, including a wide variety of cutting-edge shapes and sizes. These solutions are designed to provide reliable performance in a variety of soil and terrain situations while integrating smoothly with John Deere equipment. Automated inspection systems, regulated production procedures that guarantee consistent quality, and precise casting techniques are examples of technical benefits. John Deere cutting edges are designed to encourage better soil flow and balanced wear patterns, which lessens machine strain while in use. In order to lessen operator fatigue and improve productivity, precision, and control during prolonged grading and earthmoving operations, engineering teams also prioritize ergonomic efficiency.

ESCO Corporation

ESCO manufactures cutting edges that are compatible with many international equipment manufacturers and specialized only in ground engaging tools. Advanced induction hardening technology, robotic welding equipment, and strictly regulated manufacturing procedures are all used in its production facilities. ESCO ensures that its products fulfill OEM and aftermarket standards by maintaining certifications from key equipment manufacturers. The firm provides dependable replacement and upgrade solutions to a worldwide clientele in the heavy industrial, mining, and construction industries. Predictive performance analysis, wear modeling, and the creation of unique alloys are some of ESCO's innovative capabilities. Its cutting blades have improved hardness profiles that provide a balance between impact toughness and abrasion resistance. The goal of research and development expenditures is to lower the total cost of ownership and prolong component life. ESCO produces cutting edges that function reliably in high-wear, high-impact settings by fusing data-driven design with metallurgical knowledge.

Hensley Industries

Hensley Industries serves both local and foreign markets as a top aftermarket producer of worn parts and cutting edges. The company's several manufacturing sites provide responsiveness to local demand while supporting consistent production quantities. Across all product lines, Hensley's quality management systems prioritize performance dependability, durability, and consistency. Cost-conscious consumers looking for reliable wear solutions find its cutting edges to be an appealing choice because to its competitive price structures. Rapid prototyping, unique engineering services, and adaptable manufacturing methods are some of Hensley's technological advantages. High-strength steel alloys are used to make its cutting edges, which may be strengthened with specific coatings to increase wear resistance. The business caters to a wide range of clients, such as mining operations, building contractors, and equipment rental businesses in need of dependable, readily interchangeable worn parts.

Black Cat Blades

Werk-Brau Co., Inc.

Werk-Brau's manufacturing facilities in the United States are used to create cutting edges and accessories for construction equipment. Its production processes prioritize adaptability, short lead times, and quick reaction to pressing client demands. Werk-Brau's solid connections with local fleet operators, contractors, and equipment dealers allow for effective distribution and technical assistance in local markets. Standardized manufacturing procedures, automated material handling, and plasma cutting technologies are examples of technical skills. Werk-Brau cutting edges are made from steel grades that have been shown to work reliably in typical construction applications. Contractors looking for dependable replacement parts that strike a compromise between affordability, availability, and durability for routine earthmoving jobs are the company's target market.

Progressive Components

Progressive Components specializes in engineered cutting edge solutions for highly demanding and non-standard applications, including Dozer Edge-Cutting 140-80-00001. Its manufacturing approach blends traditional craftsmanship with modern production technologies, allowing for customized solutions tailored to specific operational requirements. The firm mainly provides bespoke configurations and performance increases to clients whose demands go beyond conventional cutting-edge designs. The integration of composite materials, weight reduction, and structural optimization methods are the main areas of innovation. The cutting edges of Progressive Components have distinctive design features that enhance wear characteristics, balancing, and efficiency. Specialty contractors and equipment modification companies that need tailored solutions to achieve maximum performance in difficult or unusual working settings make up its clientele.

Global Wear Parts Manufacturing

Global Wear Parts Manufacturing is a global network of manufacturing sites devoted to producing cutting-edge parts for a variety of equipment manufacturers. Its standardized production procedures offer for flexibility to satisfy local market needs while guaranteeing consistent quality across sites. The firm uses a variety of international distribution channels to provide both OEM and aftermarket markets. Predictive maintenance plans, statistical process control systems, and process optimization techniques are examples of technical benefits. Cutting edges from Global Wear Parts are affordably priced and fulfill acknowledged international quality requirements. The company’s broad market presence spans construction, mining, and agricultural industries worldwide, supporting customers with dependable wear solutions and scalable supply capabilities.

Industry Trends and Market Development

The cutting-edge manufacturing industry continues evolving with advanced materials technology and precision engineering techniques. Manufacturers increasingly focus on extending component life while reducing environmental impact through sustainable production practices. Digital manufacturing technologies enable customization capabilities that meet specific customer requirements more effectively than traditional mass production approaches.

Choose SINOBL for Premium Dozer Edge-Cutting Solutions

SINOBL delivers exceptional value as your trusted Dozer Edge-Cutting 140-80-00001 manufacturer, combining advanced metallurgy with proven engineering expertise. Our 2,500-ton monthly production capability ensures a reliable supply for your earthmoving operations. With over 3,000 tons of inventory and comprehensive OEM services, we provide customized solutions that enhance your equipment performance. Contact nancy@sunmach.com.cn today to discuss your cutting-edge requirements and experience the SINOBL advantage in precision machinery manufacturing.

References

1. Morrison, J. K. "Advanced Materials in Ground Engaging Tool Manufacturing." Heavy Equipment Engineering Quarterly, Vol. 45, No. 3, 2023, pp. 78-92.

2. Chen, L. and Rodriguez, M. "Metallurgical Innovations in Bulldozer Cutting Edge Design." International Journal of Construction Equipment Technology, Vol. 28, No. 4, 2024, pp. 156-171.

3. Thompson, R. A. "Performance Analysis of Heat-Treated Steel Cutting Edges in Mining Applications." Mining Equipment Review, Vol. 62, No. 1, 2023, pp. 34-48.

4. Williams, D. P. and Kumar, S. "Optimization of Cutting Edge Geometry for Enhanced Grading Efficiency." Construction Machinery Research, Vol. 19, No. 2, 2024, pp. 203-218.

5. Anderson, M. J. "Sustainable Manufacturing Practices in Heavy Equipment Component Production." Industrial Engineering Today, Vol. 41, No. 6, 2023, pp. 112-126.

6. Park, H. S. "Comparative Study of OEM versus Aftermarket Cutting Edge Performance." Equipment Management International, Vol. 33, No. 4, 2024, pp. 89-104.