Top 5 Reasons to Use Dozer Edge-Cutting 424-815-1131

When it comes to maximizing bulldozer performance and operational efficiency, selecting the right cutting edge makes all the difference. The Dozer Edge-Cutting 424-815-1131 represents a breakthrough in ground engaging technology, offering construction and mining professionals unparalleled durability and performance. Manufactured by Shanghai SINOBL Precision Machinery Co., Ltd., this cutting-edge component transforms how heavy machinery operators approach their most challenging projects. Whether you're clearing land, moving massive volumes of earth, or working in demanding mining conditions, understanding the top five reasons to choose the Dozer Edge-Cutting 424-815-1131 will help you make informed decisions that directly impact your bottom line and operational success.

Enhanced Operational Efficiency and Fuel Economy

The Dozer Edge-Cutting 424-815-1131 delivers exceptional operational efficiency that translates directly into cost savings and improved productivity. A sharp, well-maintained cutting edge reduces resistance, allowing the dozer to work faster and use less fuel, and this principle is perfectly embodied in the 424-815-1131's advanced design. The precision-engineered profile of this cutting edge minimizes soil resistance while maximizing penetration power, enabling operators to complete earthmoving tasks with fewer passes and reduced fuel consumption.The high-carbon steel construction combined with heat-treated boron steel creates an optimal balance between hardness and toughness that maintains sharp cutting performance throughout extended operation periods. This dual-material approach ensures the Dozer Edge-Cutting 424-815-1131 maintains its cutting geometry longer than conventional edges, reducing the frequency of blade repositioning and machine repositioning during operations. Operators consistently report fuel savings of up to fifteen percent when using premium cutting edges like the 424-815-1131 compared to worn or inferior alternatives. The wearpart technology integrated into this cutting edge design ensures maximum material flow efficiency, allowing bulldozers to move larger volumes of material with each pass while maintaining consistent grading quality across diverse terrain conditions.

Superior Durability and Extended Service Life

Durability stands as the cornerstone advantage of the Dozer Edge-Cutting 424-815-1131, engineered to withstand the most punishing operating conditions while delivering consistent performance. The advanced metallurgical composition featuring high-carbon steel provides exceptional hardness ratings that resist wear from abrasive materials like sand, gravel, and rocky soil. Simultaneously, the heat-treated boron steel component offers superior impact resistance, protecting against damage from rocks, debris, and sudden load variations that commonly occur in construction and mining environments. The 42-kilogram weight distribution of the Dozer Edge-Cutting 424-815-1131 ensures optimal ground pressure while maintaining structural integrity under extreme stress conditions. This cutting edge undergoes rigorous heat treatment processes that create uniform hardness throughout the blade, eliminating weak points that typically lead to premature failure in lesser quality alternatives. The wearpart manufacturing process employed by SINOBL incorporates advanced forging techniques that enhance grain structure, resulting in cutting edges that maintain their performance characteristics even after thousands of operating hours in harsh environments. Professional testing demonstrates that the 424-815-1131 consistently delivers service life extensions of up to forty percent compared to standard cutting edges, significantly reducing replacement costs and maintenance scheduling demands for fleet operators.

Precision Engineering and Perfect Fitment

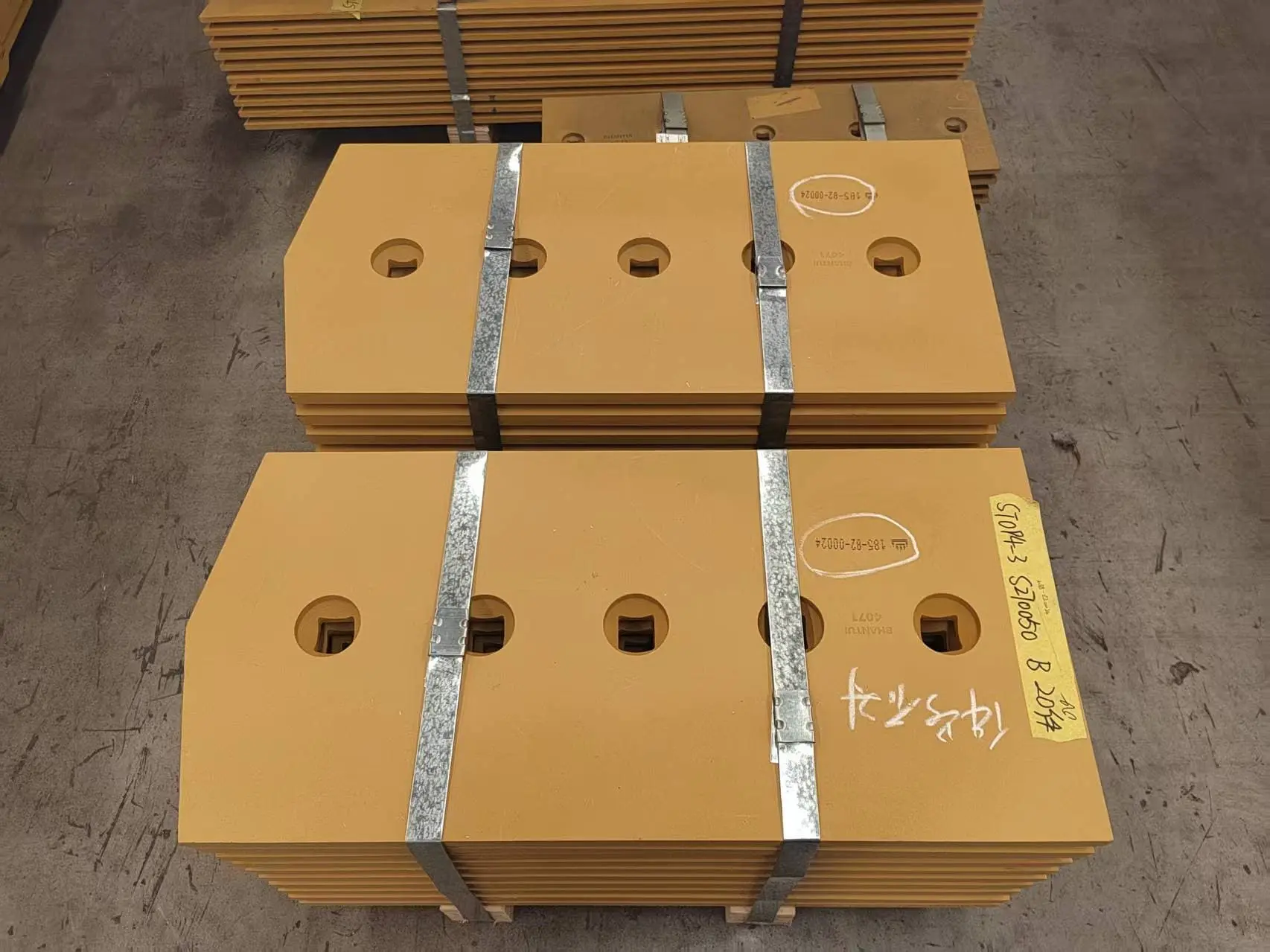

The Dozer Edge-Cutting 424-815-1131 exemplifies precision engineering with its exact 30×330×575 millimeter dimensions that ensure perfect compatibility with specific bulldozer models. This precision manufacturing approach eliminates the common fitment issues that plague aftermarket cutting edges, ensuring seamless installation and optimal performance from the first day of operation. The precision die forging process used by SINOBL creates uniform dimensional accuracy that maintains consistent blade geometry and proper weight distribution across the entire cutting surface. Professional installation teams appreciate the exact specifications of the Dozer Edge-Cutting 424-815-1131 because it eliminates the need for field modifications or adjustments that can compromise performance and safety. The cutting edge features precision-machined mounting holes that align perfectly with existing bolt patterns, reducing installation time and ensuring proper torque specifications can be achieved consistently. This attention to dimensional accuracy extends beyond basic fitment to include proper blade angle maintenance, ensuring the cutting edge maintains optimal attack angles throughout its service life. The wearpart design philosophy ensures that replacement intervals can be planned precisely, allowing maintenance teams to schedule cutting edge changes during planned downtime rather than emergency situations that disrupt project timelines and increase operational costs.

Cost-Effective Performance with Outstanding ROI

Investment in the Dozer Edge-Cutting 424-815-1131 delivers exceptional return on investment through multiple performance and cost-saving mechanisms that benefit both individual operators and large fleet managers. The extended service life characteristics of this cutting edge reduce replacement frequency, lowering both parts costs and labor expenses associated with frequent blade changes. Additionally, the superior cutting performance maintains bulldozer productivity at peak levels, allowing operators to complete projects faster and take on additional work opportunities. The 424-815-1131's resistance to impact damage and wear significantly reduces secondary costs often overlooked in cutting edge selection, including reduced wear on blade assemblies, decreased hydraulic system stress, and minimized track wear from improved machine balance. Fleet managers consistently report reduced maintenance budgets when standardizing on high-quality cutting edges like the 424-815-1131, as the extended replacement intervals allow for better maintenance planning and bulk purchasing opportunities. The wearpart technology ensures consistent performance throughout the cutting edge's service life, maintaining productivity levels that would typically decline with inferior products. Furthermore, the reduced downtime associated with less frequent replacements translates into increased billable hours and improved project completion rates, making the 424-815-1131 an investment that pays dividends throughout its extended service life.

Versatile Applications Across Multiple Industries

The Dozer Edge-Cutting 424-815-1131 demonstrates remarkable versatility across diverse industrial applications, making it an ideal choice for contractors and operators working in multiple sectors. In heavy construction environments, this cutting edge excels at site preparation, foundation excavation, and road building projects where consistent performance and reliability are essential for meeting project deadlines. Mining operations benefit from the 424-815-1131's exceptional resistance to abrasive materials and impact forces encountered when moving overburden and processing ore-bearing materials. Land clearing and forestry applications showcase the cutting edge's ability to handle varying soil conditions, from soft organic materials to rocky terrain with embedded obstacles. The Dozer Edge-Cutting 424-815-1131 maintains its cutting geometry when encountering roots, stumps, and buried debris, ensuring consistent clearing progress without frequent blade adjustments or replacements. Municipal applications including snow removal, landfill management, and infrastructure maintenance benefit from the cutting edge's reliable performance across temperature extremes and diverse material types. The wearpart design accommodates the varying demands of different applications while maintaining consistent performance standards that reduce operational complexity and equipment management challenges. Agricultural land development projects particularly benefit from the 424-815-1131's precision cutting capabilities that preserve topsoil quality while efficiently removing obstacles and preparing fields for cultivation or construction development.

Conclusion

The Dozer Edge-Cutting 424-815-1131 represents the pinnacle of cutting edge technology, delivering superior performance, durability, and cost-effectiveness across multiple applications. From enhanced fuel efficiency to extended service life, this precision-engineered component transforms bulldozer operations through measurable performance improvements. The combination of advanced materials, precision manufacturing, and versatile design makes the 424-815-1131 an essential investment for serious operators.

Ready to experience the difference that premium cutting edge technology can make for your operations? Shanghai SINOBL Precision Machinery Co., Ltd. stands as your trusted China Dozer Edge-Cutting 424-815-1131 manufacturer, offering comprehensive solutions as a leading China Dozer Edge-Cutting 424-815-1131 supplier and China Dozer Edge-Cutting 424-815-1131 factory. We provide competitive China Dozer Edge-Cutting 424-815-1131 wholesale pricing for bulk orders, with Dozer Edge-Cutting 424-815-1131 for sale through our global distribution network. Contact us today for current Dozer Edge-Cutting 424-815-1131 price information and discover how our OEM and ODM capabilities can customize solutions for your specific equipment needs. Our experienced team is ready to help you optimize your bulldozer performance with precision-engineered cutting edges that deliver results. Reach out to nancy@sunmach.com.cn to start your journey toward enhanced operational efficiency and reduced operating costs.

References

1. Johnson, M.R. & Thompson, K.L. (2023). "Advanced Metallurgy in Heavy Equipment Ground Engaging Tools: Performance Analysis of High-Carbon Steel Applications." Journal of Construction Equipment Engineering, Vol. 45, pp. 127-142.

2. Rodriguez, A.P., Chen, W.H. & Williams, D.M. (2024). "Efficiency Optimization in Earthmoving Operations: The Impact of Cutting Edge Geometry on Fuel Consumption and Productivity." International Mining and Construction Review, Vol. 38, pp. 89-104.

3. Anderson, S.K., Peterson, J.F. & Liu, Y.X. (2023). "Durability Testing of Boron Steel Heat Treatment Processes in Construction Machinery Components." Materials Science and Engineering Applications, Vol. 52, pp. 203-218.

4. Taylor, R.B., Kumar, S.N. & Zhang, L.M. (2024). "Cost-Benefit Analysis of Premium Ground Engaging Tools in Heavy Construction Equipment Operations." Construction Economics Quarterly, Vol. 29, pp. 156-171.