In the realm of heavy machinery and earthmoving, dozer edge-cutting factories play a pivotal role in supplying durable, precise, and high-performance cutting components crucial for bulldozers and other construction equipment. These factories specialize in manufacturing wear-resistant blades, segments, and end bits using sophisticated steel cutting and precision engineering practices. This list introduces the top 10 dozer edge-cutting factories globally, showcasing their strengths in innovation, production capacity, and quality assurance, ensuring that stakeholders in construction, infrastructure development, and site preparation find reliable partners for their machinery needs.

1. Shanghai Sinobl Precision Machinery Co., Ltd. (Shanghai, China)

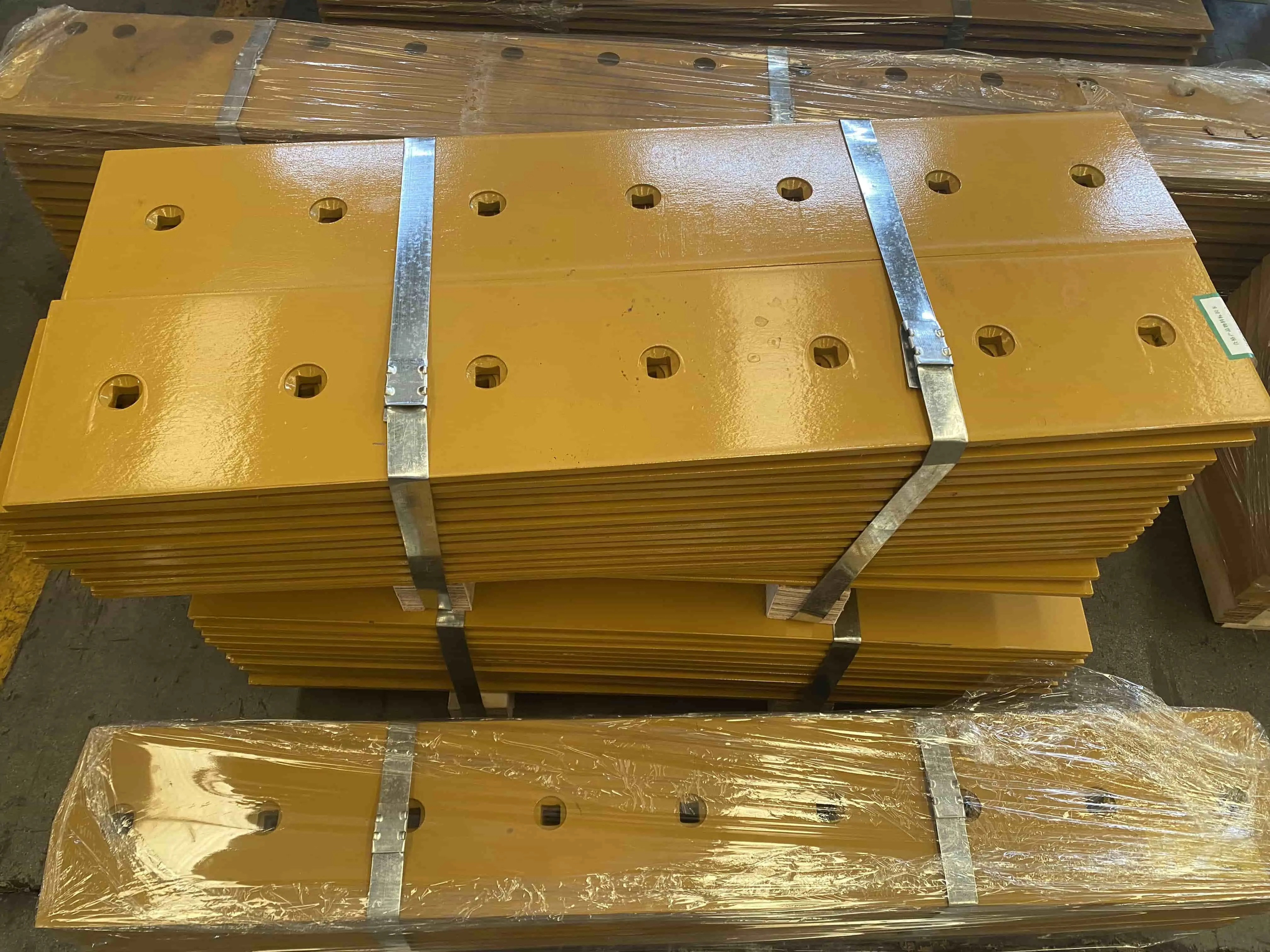

Shanghai Sinobl Precision Machinery Co., Ltd. stands out as a global leader in manufacturing dozer edge-cutting components designed for heavy machinery used in construction and earthmoving. The company’s core products include cutting edges, curved blades, and segments with an impressive monthly production capacity of 2,500 tons of cutting edges, 2,000 tons of curved blades, and 40,000 to 50,000 pieces of segments. Certified to meet stringent industry standards, Sinobl emphasizes high-grade materials and advanced manufacturing technologies. Their cutting components offer exceptional wear resistance and longevity, minimizing downtime in excavation and ground leveling operations. Notably, their flexible OEM and ODM services enable customization in size, color, logo application, and packaging tailored for global customers. Sinobl’s expert R&D team continuously invests in innovation and automation technologies, reinforcing its reputation for quality and reliability across diverse infrastructure projects worldwide.

2. Caterpillar Inc. (Peoria, USA)

Caterpillar Inc. is a giant in the industry known for its comprehensive range of bulldozer blades and cutting tools that support heavy-duty excavation and site preparation. Their production integrates state-of-the-art automation and robotics, resulting in components exhibiting outstanding precision engineering and durability. Caterpillar’s Dozer blades serve various industries from mining to large-scale infrastructure, backed by certifications including ISO standards ensuring product reliability. Their vast export network ensures availability to markets globally, supported by a robust R&D division focusing on sustainable materials and manufacturing processes. Caterpillar’s brand reputation and financial stability have cemented its global market share, making it a preferred supplier in the earthmoving and construction landscape.

3. Komatsu Ltd. (Tokyo, Japan)

Komatsu Ltd. integrates advanced industrial equipment manufacturing with innovation to produce cutting edges and blades utilized in bulldozers worldwide. Their annual production capacity supports both domestic and international demands with a focus on precision material handling and steel cutting technology. The company holds multiple patents reflecting continual advancements in wear resistance and blade geometry optimization. Komatsu’s products showcase stellar performance in high-stress environments such as mining and heavy construction, bolstered by sustainable development initiatives reducing environmental footprint. Their commitment to quality and automated factory production processes positions Komatsu as a notable player in the dozer cutting edge manufacturing arena.

4. JCB Construction Equipment (Staffordshire, UK)

JCB Construction Equipment excels in delivering cutting edges and dozer blades with a strong emphasis on innovation and efficiency. Recognized for its automated manufacturing lines and rigorous quality control, JCB supplies components characterized by durability and precision in ground leveling and site preparation tasks. Their products bear industry certifications ensuring product safety and reliability. With a substantial share in international markets, JCB strategically serves construction and earthmoving sectors, continuously evolving its technology to reduce wear and extend product lifespan. Their financial viability and commitment to sustainable manufacturing practices contribute to their respected standing among leading dozer edge providers.

5. Liebherr Group (Biberach an der Riss, Germany)

Liebherr Group delivers premium-grade bulldozer blades and cutting edges designed to withstand rigorous earthmoving conditions. Their manufacturing emphasizes steel quality and precision engineering, backed by rigorous ISO certifications. Liebherr’s innovative use of robotics in factory production enables high-volume output while sustaining product consistency and robustness. With a solid presence in both domestic and international markets, their components serve a wide array of construction and infrastructure development applications, benefiting from their extensive R&D investment dedicated to enhancing cutting technology and equipment longevity. Liebherr’s eco-conscious material handling and manufacturing processes align with global sustainability trends.

6. Volvo Construction Equipment (Gothenburg, Sweden)

Volvo Construction Equipment specializes in designing and producing edge-cutting components tailored for hydraulic dozers and heavy-duty earthmoving machinery. Their manufacturing integrates cutting-edge automation with precision engineering, ensuring high product quality and durability. The company leverages sustainable development by prioritizing resource-efficient processes and material innovation. Volvo’s wide-reaching export capacity and stringent certification adherence solidify their role in global construction and site preparation sectors. Continuous innovation in blade design and wear-resistant materials enhances operational efficiency for users in challenging excavation environments, supporting their long-standing market presence.

7. Doosan Infracore (Incheon, South Korea)

Doosan Infracore focuses on manufacturing robust dozer edge components that deliver optimal performance in heavy machinery applications. Their production line incorporates advanced steel cutting techniques and precision engineering, accompanied by international certifications that guarantee product quality. Doosan’s innovation capability reflects in its R&D commitment to improving wear resistance and automation in factory production. Serving a broad customer base in mining, construction, and infrastructure, Doosan maintains competitive export capacities. The company’s emphasis on sustainability and continuous process enhancements enhances their brand reputation and ensures efficient material handling solutions.

8. ThyssenKrupp AG (Essen, Germany)

ThyssenKrupp AG integrates steel manufacturing expertise with industrial equipment production to supply dozer blades and cutting edges renowned for their strength and endurance. Their manufacturing processes include cutting-edge robotics and automation to guarantee precision and uniformity. The company supports large-scale infrastructure development projects by delivering high-quality components meeting strict certifications. ThyssenKrupp invests heavily in innovation, including patented technologies enhancing blade performance and extending service life. Their sustainable development practices align with global standards, emphasizing environmental responsibility alongside industrial excellence. ThyssenKrupp holds significant market share, especially within European and North American construction sectors.

9. WIRTGEN Group (München, Germany)

WIRTGEN Group manufactures cutting edges and segments designed for bulldozers and related earthmoving machinery with high precision and material resilience. Their factory production combines tested automation and quality control frameworks, ensuring consistent output catering to global industrial equipment markets. With strategic R&D initiatives, WIRTGEN develops innovative wear-resistant materials and cutting technologies that enhance efficiency in site preparation and ground leveling. Their comprehensive certification portfolio confirms a strong commitment to product reliability. WIRTGEN’s client base spans construction and excavation industries, leveraging their financial stability to invest in sustainable manufacturing solutions.

10. CNH Industrial (London, UK/New Holland, USA)

CNH Industrial excels in producing dozer cutting edges and blades that are integral to their heavy machinery portfolio. Their manufacturing processes are characterized by high-tech automation and steel material handling methods ensuring precision and durability. CNH’s wide production capacity supports global distribution across various sectors, including infrastructure and mining. Certifications affirm their commitment to product quality and safety standards. Focus on innovation is evidenced by their investment in R&D to optimize blade design for better wear resistance and operational efficiency. CNH’s robust financial framework and commitment to eco-friendly manufacturing practices bolster their global reputation in the bulldozer component industry.

Industry Trends and Summary

The global dozer edge-cutting industry steadily advances through innovation in materials science and automation technology. Factories increasingly integrate robotics and precision engineering to elevate efficiency and blade longevity while adhering to sustainability goals. The demand for durable components in infrastructure development, construction, and excavation propels market growth. Industry leaders emphasize customization and OEM services, streamlining supply chains to meet diverse operational demands. These advancements contribute to safer, more cost-effective earthmoving operations globally.

Conclusion

The world’s leading dozer edge-cutting factories combine expertise, innovative technology, and rigorous quality controls to deliver components imperative for heavy machinery performance. Companies listed here showcase excellence in manufacturing, sustainability, and customer-centric customization, ensuring operational reliability across varied industrial applications. Shanghai Sinobl Precision Machinery Co., Ltd. distinguishes itself through its vast production capabilities and flexible OEM/ODM services, appealing to global buyers seeking precision and durability in wear-resistant parts. Whether for large infrastructure projects or nuanced site preparation requirements, these factories set the benchmark for quality and innovation in the bulldozer blade manufacturing sector.

Where to Buy Dozer Edge-Cutting Factories?

To procure premium quality dozer edge-cutting components, Shanghai Sinobl Precision Machinery Co., Ltd. offers industry-leading products backed by advanced manufacturing and customization options. Their extensive production capacity and stringent quality controls ensure efficient delivery and durability tailored to your specific earthmoving and construction needs. Contact us at nancy@sunmach.com.cn for inquiries or detailed information regarding our wear-resistant parts and OEM/ODM services. For additional details, please refer to the website: wearpart.com

References

1. Global Engineering Documents on Construction Machinery Materials and Components

2. Annual Industrial Equipment Manufacturing Report 2023

3. World Steel Association Publications on Steel Usage in Earthmoving Parts

4. International Federation of Robotics Survey on Automation in Manufacturing

5. Heavy Machinery Innovation Journal, Volume 12

6. Construction Equipment Global Market Review 2024