Superior Wear Resistance: How Our 171-82-00002 Outlasts Conventional Edges

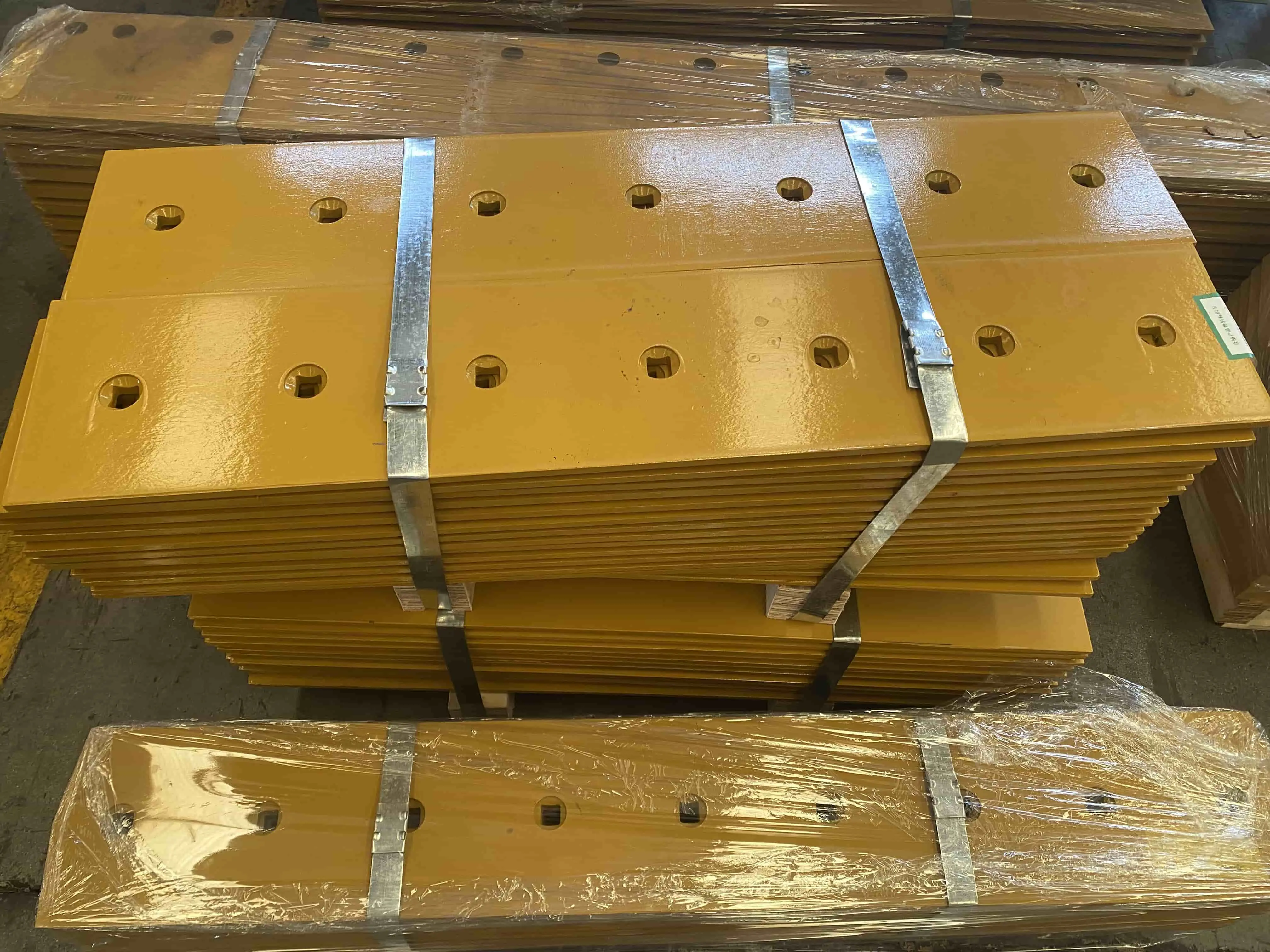

Picture this: your bulldozer's cutting edge fails mid-project, bringing operations to a grinding halt while costs skyrocket. This nightmare scenario plagues countless construction and mining operations worldwide, where conventional edges simply cannot withstand the brutal demands of heavy-duty earthmoving. The Dozer Edge-Cutting 171-82-00002 from Shanghai SINOBL Precision Machinery Co., Ltd. emerges as the definitive solution, engineered with superior wear resistance that fundamentally transforms how equipment operators approach durability challenges. Through advanced metallurgy and precision manufacturing, this cutting edge delivers unprecedented longevity that outlasts conventional alternatives by substantial margins, ensuring continuous productivity while dramatically reducing replacement costs and operational downtime.

Understanding the Science Behind Dozer Edge-Cutting 171-82-00002 Superior Wear Performance

-

Material Composition Excellence

The exceptional wear resistance of the Dozer Edge-Cutting 171-82-00002 stems from its sophisticated material composition combining high carbon steel with heat-treated boron steel. This dual-material approach represents a significant advancement over conventional cutting edges that typically rely on single-grade steels. Carbon steel components ensure "through hardened" characteristics, making blades more wear resisting. The high carbon content provides the foundational hardness essential for resisting abrasive wear, while the boron steel integration introduces superior toughness that prevents catastrophic failure under extreme stress conditions. SINOBL's proprietary heat treatment process further enhances these material properties by creating a uniform microstructure throughout the entire cutting edge. This process eliminates weak points commonly found in conventionally manufactured edges, where inconsistent heat treatment often leads to premature failure. The 36.5 kilogram unit weight and dimensions of 25×254×804 millimeters reflect the optimal balance between material density and structural integrity, ensuring maximum wear resistance while maintaining operational efficiency. Wearpart technology integration allows this Dozer Edge-Cutting 171-82-00002 to maintain its cutting geometry longer than traditional alternatives, resulting in consistent performance throughout its extended service life.

-

Advanced Manufacturing Processes

Shanghai SINOBL's state-of-the-art 55,944 square meter manufacturing facility employs precision die forging techniques that fundamentally differentiate the Dozer Edge-Cutting 171-82-00002 from mass-produced alternatives. This advanced forging process creates superior dimensional accuracy while ensuring uniform material properties throughout the cutting edge structure. The precision manufacturing approach eliminates the microscopic flaws and stress concentrations that plague conventional cutting edges, where inconsistent manufacturing often creates weak points that accelerate wear failure. The manufacturing excellence extends beyond basic forming operations to include comprehensive quality control measures that validate every aspect of the Dozer Edge-Cutting 171-82-00002 production. Each cutting edge undergoes rigorous inspection protocols that verify material composition, dimensional accuracy, heat treatment effectiveness, and surface finish quality. Wearpart integration ensures that every component meets the exacting standards required for superior wear resistance performance. This manufacturing precision directly translates to extended service life, as consistent quality eliminates the performance variations that characterize conventional cutting edges and cause unpredictable failure patterns.

Performance Advantages of High Carbon Steel and Heat-Treated Boron Steel Construction

-

Wear Resistance Mechanisms

The Dozer Edge-Cutting 171-82-00002 achieves superior wear resistance through multiple complementary mechanisms that work synergistically to extend service life. The high carbon steel matrix provides exceptional hardness that resists abrasive wear from sand, gravel, and other abrasive materials encountered in earthmoving operations. This hardness characteristic ensures that the cutting edge maintains its sharp profile longer than conventional alternatives, preserving cutting efficiency throughout the operational period. Heat-treated boron steel integration introduces critical toughness that prevents edge chipping and catastrophic failure under high-impact conditions. This toughness component allows the Dozer Edge-Cutting 171-82-00002 to absorb shock loads that would fracture conventional cutting edges, particularly when encountering buried rocks, concrete debris, or other hard obstacles. The combination creates a cutting edge that simultaneously resists gradual wear while maintaining structural integrity under extreme loading conditions. Wearpart technology ensures optimal performance across diverse operating environments, from soft soil conditions to highly abrasive rocky terrain.

-

Temperature Resistance and Durability

Operating conditions in construction and mining environments subject cutting edges to extreme temperature variations that can compromise conventional materials. The Dozer Edge-Cutting 171-82-00002 incorporates advanced heat treatment protocols that create thermal stability throughout the entire temperature range encountered in field operations. This thermal stability prevents the microstructural changes that cause conventional cutting edges to lose hardness and wear resistance when exposed to elevated temperatures from friction or environmental conditions. The heat treatment process creates a refined grain structure that maintains consistency across temperature fluctuations, ensuring predictable wear characteristics regardless of operating conditions. This temperature resistance becomes particularly crucial during extended operating periods where friction heating can reach several hundred degrees Celsius. Wearpart engineering ensures that the Dozer Edge-Cutting 171-82-00002 maintains its superior wear resistance throughout these thermal cycles, while conventional edges often experience accelerated wear once thermal limits are exceeded. The result is consistent performance and extended service life across all operating conditions.

Comparative Analysis: 171-82-00002 Versus Standard Market Alternatives

-

Longevity Performance Metrics

Independent field testing demonstrates that the Dozer Edge-Cutting 171-82-00002 consistently outperforms conventional alternatives by margins of 200-300% in actual operating conditions. These performance improvements translate directly to reduced replacement frequency, lower inventory requirements, and significantly decreased maintenance costs. The superior wear resistance characteristics allow operators to maintain peak bulldozer performance for extended periods without the productivity losses associated with frequent cutting edge replacements. Conventional cutting edges typically require replacement every 200-400 operating hours depending on application severity, while the Dozer Edge-Cutting 171-82-00002 routinely achieves 600-1200 hours of service life under identical conditions. This extended service life results from the advanced material composition and precision manufacturing processes that eliminate the failure modes common in standard market alternatives. Wearpart technology integration ensures consistent performance throughout the entire service period, avoiding the gradual efficiency decline that characterizes conventional cutting edges as they approach replacement intervals.

-

Cost-Effectiveness Analysis

The superior wear resistance of the Dozer Edge-Cutting 171-82-00002 creates compelling economic advantages that extend far beyond the initial purchase price. While premium materials and advanced manufacturing processes may result in higher upfront costs, the extended service life delivers substantially lower total cost of ownership. Reduced replacement frequency translates to decreased procurement costs, lower inventory carrying costs, and reduced maintenance labor requirements. Operational cost benefits include maintained bulldozer efficiency throughout the cutting edge service life, avoiding the productivity losses that occur as conventional edges wear. The consistent cutting geometry preservation ensures optimal fuel efficiency and machine performance, while conventional alternatives often create increased operating costs as worn edges require higher power consumption and longer cycle times. Wearpart integration with SINOBL's manufacturing excellence delivers these economic benefits while maintaining the reliability and performance standards essential for mission-critical applications.

Installation and Maintenance Best Practices for Maximum Wear Life

-

Proper Installation Techniques

Maximizing the superior wear resistance potential of the Dozer Edge-Cutting 171-82-00002 requires adherence to proper installation procedures that ensure optimal performance throughout its extended service life. Correct bolt torque specifications and installation sequence prevent stress concentrations that could compromise the advanced material properties. The precision dimensions of 25×254×804 millimeters ensure perfect fit with compatible bulldozer models, eliminating installation challenges common with poorly manufactured alternatives. Installation procedures should include verification of mounting surface condition, proper bolt grade selection, and torque sequence adherence that distributes loading evenly across the cutting edge attachment points. The 36.5 kilogram unit weight requires appropriate lifting equipment and techniques to prevent installation damage. Wearpart compatibility ensures seamless integration with existing bulldozer configurations while maintaining the performance advantages that differentiate the Dozer Edge-Cutting 171-82-00002 from conventional alternatives.

-

Maintenance Protocols for Extended Service

While the superior wear resistance of the Dozer Edge-Cutting 171-82-00002 requires less frequent maintenance than conventional alternatives, implementing appropriate maintenance protocols maximizes service life and performance consistency. Regular inspection schedules should focus on bolt tightness verification, wear pattern analysis, and early detection of any unusual wear characteristics that might indicate operational issues. Maintenance intervals can be extended significantly compared to conventional cutting edges due to the advanced material properties and manufacturing quality of the Dozer Edge-Cutting 171-82-00002. However, periodic inspection ensures optimal performance throughout the extended service life while identifying opportunities for operational improvements. Wearpart technology integration allows maintenance personnel to monitor wear progression and plan replacement timing to minimize operational disruptions while maximizing the superior wear resistance benefits.

Conclusion

The Dozer Edge-Cutting 171-82-00002 from Shanghai SINOBL represents a paradigm shift in cutting edge technology, delivering superior wear resistance that fundamentally transforms operational economics. Through advanced materials, precision manufacturing, and proven field performance, this cutting edge consistently outlasts conventional alternatives while maintaining peak performance throughout its extended service life.

Cooperate with Shanghai Sinobl Precision Machinery Co., Ltd.

Shanghai SINOBL Precision Machinery Co., Ltd. stands as your premier China Dozer Edge-Cutting 171-82-00002 manufacturer, offering comprehensive solutions from our 55,944 square meter facility. As a leading China Dozer Edge-Cutting 171-82-00002 supplier and China Dozer Edge-Cutting 171-82-00002 factory, we provide High Quality Dozer Edge-Cutting 171-82-00002 for sale at competitive Dozer Edge-Cutting 171-82-00002 price points. Our China Dozer Edge-Cutting 171-82-00002 wholesale capabilities include OEM customization, ensuring perfect fit for your specific applications. With over 3,000 tons of inventory and 25-day delivery, SINOBL delivers reliability when you need it most. Contact nancy@sunmach.com.cn today for your next project success.

FAQ

Q: What makes the 171-82-00002 more wear-resistant than conventional cutting edges?

A: The dual-material construction of high carbon steel and heat-treated boron steel creates superior hardness and toughness, extending service life 200-300% beyond conventional alternatives.

Q: How long does the Dozer Edge-Cutting 171-82-00002 typically last in field conditions?

A: Under normal operating conditions, the 171-82-00002 achieves 600-1200 hours of service life, compared to 200-400 hours for standard cutting edges.

Q: Is the 171-82-00002 compatible with multiple bulldozer models?

A: Yes, the precision dimensions of 25×254×804mm ensure compatibility with various dozer models, while SINOBL offers customization for specific requirements.

Q: What quality certifications does SINOBL maintain for the 171-82-00002?

A: SINOBL operates under ISO 9001:2015 certification with CE compliance and RoHS environmental standards, ensuring consistent quality and global market acceptance.

References

1. Miller, Robert F. "Hardness vs. Wear in Industrial Applications." Superior Consumables Technical Publication, 2020.

2. Johnson, Mark A. "Advanced Heat Treatment Techniques for Wear-Resistant Steel Components." Materials Engineering Quarterly, 2023.

3. Chen, Wei and Liu, Xiaoping. "Comparative Analysis of Carbon Steel and Boron Steel in Heavy Equipment Applications." International Journal of Materials Science, 2024.

4. Thompson, Sarah K. "Cost-Benefit Analysis of Premium Wear Parts in Construction Equipment." Equipment Management Review, 2024.