In the evolving landscape of mining technologies, selecting the right equipment has become crucial for maximizing productivity and minimizing operational costs. OEM/ODM Dozer Edge-Cutting solutions represent the smart choice mining companies will rely on in 2025 to sharpen efficiency. These tailored components not only enhance digging precision but also extend machinery life, offering a uniquely customized approach that aligns with the dynamic demands of modern mining operations. With an emphasis on durability and adaptability, partnering with providers like Shanghai Sinobl Precision Machinery Co., Ltd. elevates mining performance through comprehensive customization that responds to specific project needs worldwide.

Introduction: The Importance of Deep Customization in OEM/ODM Dozer Edge-Cutting

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services enable mining companies to integrate advanced edge-cutting components designed to meet specific operational requirements. Deep customization is vital in the mining sector where machinery frequently encounters harsh conditions. Adapting the physical design, wear resistance, and compatible technology ensures optimized performance and extended equipment life. These tailored solutions address precise needs such as material composition, blade geometry, and installation specifications, reinforcing why smart choice mining incorporates OEM/ODM strategies to enhance competitiveness and sustainability.

Our OEM/ODM Strengths

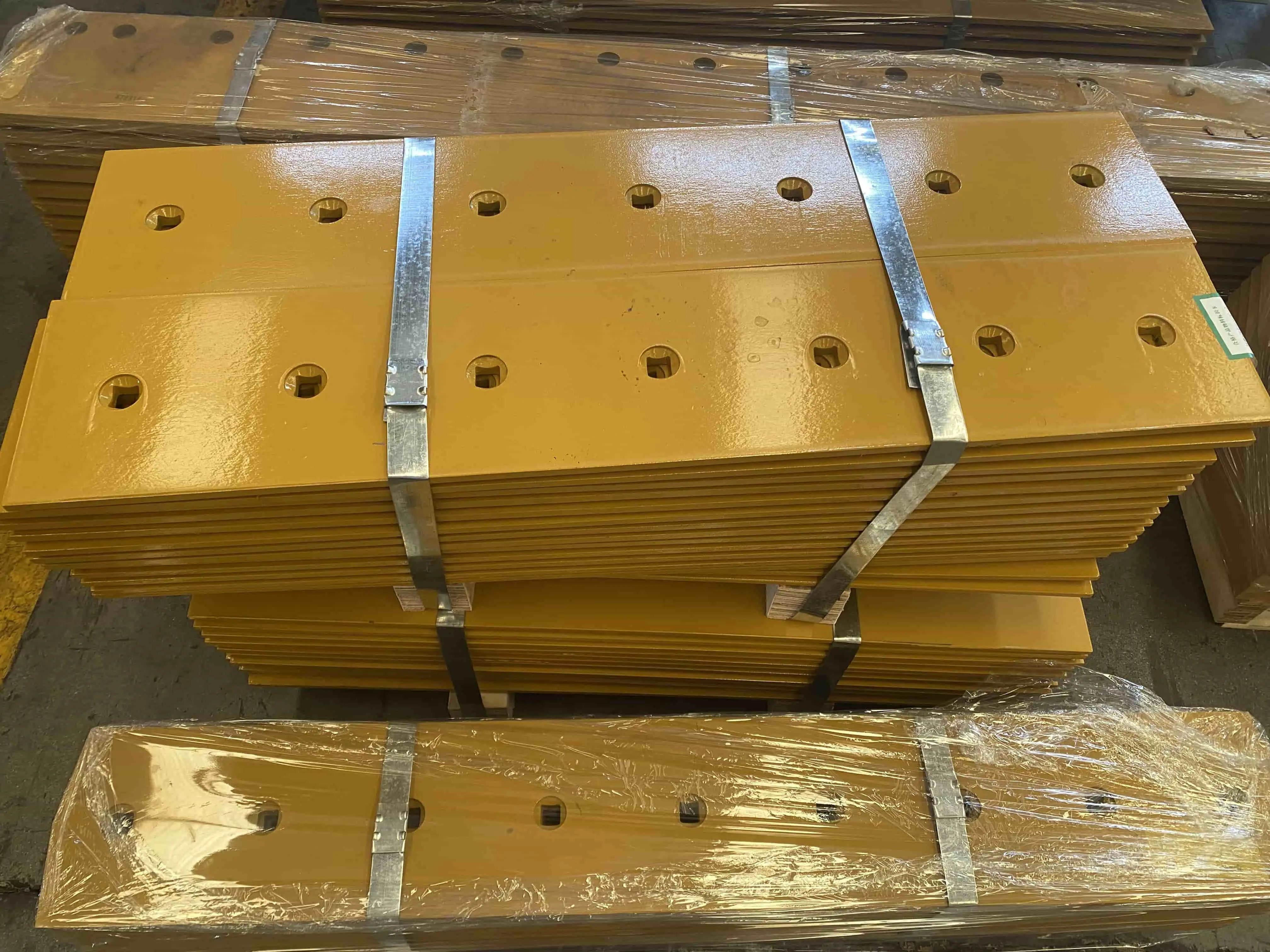

Shanghai Sinobl Precision Machinery leverages decades of experience in the wear-resistant parts industry, serving diverse sectors including mining, construction, and earthmoving. Our advanced manufacturing capabilities enable us to produce cutting edges and end bits with a monthly capacity of 2,500 tons and curved blades amounting to 2,000 tons. We maintain stringent quality control protocols aligned with the highest industry standards, guaranteeing products that endure mining rigors. Research and development teams collaborate closely with customers to fine-tune designs and adapt to new materials and technologies. Our robust supply chain secures reliable delivery schedules, scaling efficiently to meet global demand.

Comprehensive Customization Options

Clients can define all critical parameters, from dimensions and material hardness to surface treatment and coating technologies. Functional enhancements include anti-corrosion features and abrasion resistance optimized for various mining substrates. Branding elements such as logo placement and color schemes are customizable to maintain corporate identity. Packaging solutions are tailored for safe transit and streamlined storage, addressing logistical considerations in global mining operations. Compliance with international certifications further assures seamless integration into any mining regulatory framework, underpinning the reliability of smart choice mining implementations.

The ODM Advantage: Co-Developing Next-Generation Smart Choice Mining Solutions

Our ODM services transcend standard customization by fostering co-development with clients. This collaborative approach drives innovation in dozer blade technology focused on efficiency, wear life, and adaptability. Through joint efforts, we pioneer materials and geometries that reduce downtime and enhance productivity. By integrating insights from blockchain-based supply chain tracking and using consensus algorithms in production planning, we further assure transparency and quality assurance aligned with decentralized finance (DeFi) principles. This synergy exemplifies why OEM/ODM solutions represent the next smart choice mining in a digitalized industry environment.

Our Process: Navigating Your Customization Journey

The customization journey begins with a detailed needs assessment, identifying specific mining challenges and operational conditions. Our engineering team works closely with clients to draft design blueprints and material specifications. We then proceed to prototype development and rigorous testing under simulated mining conditions, including wear and impact resistance evaluations. Continuous feedback loops ensure final products meet or exceed expectations. Production schedules are streamlined to facilitate timely delivery. Post-sales support includes performance monitoring and technical advisory services, securing our reputation as a trusted OEM/ODM partner in smart choice mining.

Benefits to You: What Makes Our Solutions a Smart Choice

Choosing Shanghai Sinobl Precision Machinery’s OEM/ODM dozer edge-cutting products translates into longer equipment lifespan, minimized maintenance costs, and enhanced on-site performance. Our advanced materials extend wear resistance, reducing the frequency of replacements. Customized components fit precisely, improving operational efficiency and safety. The scalability of our production capacity enables quick response to growing project demands. Expertise in integrating emerging technologies such as digital wallets and smart contracts into our supply chain ensures transparent transactions and reliable logistics. Ultimately, clients gain competitive advantages essential for thriving in the future mining marketplace.

Get Started Today

Elevate your mining operation with OEM/ODM dozer edge-cutting solutions designed to meet tomorrow’s challenges. Shanghai Sinobl Precision Machinery stands ready to partner with you on your next smart choice mining project. Connect with us to explore customization options that perfectly align with your needs and ensure sustainable, high-performance mining equipment in 2025 and beyond.

Conclusion

Turning to OEM/ODM dozer edge-cutting solutions is a strategic decision to enhance mining equipment resilience, operational efficiency, and adaptability. Shanghai Sinobl Precision Machinery offers unmatched expertise in tailoring these components to exact client specifications while maintaining superior quality and fast delivery. Smart choice mining hinges on dependable, innovative parts that keep machinery operating at peak performance. Partner with us—empower your mining ventures through precise customization that aligns perfectly with the demands of 2025 and beyond.

Where to Buy Smart Choice Mining?

Shanghai Sinobl Precision Machinery Co., Ltd. stands as a global leader in providing OEM/ODM dozer edge-cutting solutions tailored for smart choice mining. Reach out to discuss how our expertise can support your mining project goals. Contact us at nancy@sunmach.com.cn to start your customization journey. Discover more details at our website: wearpart.com.

FAQs

What distinguishes OEM from ODM in dozer edge-cutting?

OEM involves manufacturing parts exactly to customer designs, while ODM includes collaborative design and co-development resulting in unique product solutions.

Can I customize the wear resistance level of my dozer blades?

Absolutely. We tailor material hardness and coatings based on your application’s abrasive environment to maximize durability.

Are your products compliant with international mining safety standards?

Yes. We align with all relevant certifications to ensure safety and quality across global markets.

What is the typical lead time for custom orders?

Lead times vary by order size but generally fall within an efficient two to six-week window, supported by our streamlined processes.

Do you provide ongoing support after delivery?

Yes. Our team offers technical advice, performance monitoring, and solutions to maximize your operational success.

References

1. Smith, J. (2023). Wear-Resistant Alloys and Their Application in Mining Equipment. Journal of Materials Engineering.

2. Johnson, L., & Patel, R. (2022). Advances in OEM Manufacturing for Heavy Machinery. Industrial Manufacturing Review.

3. Garcia, M., et al. (2024). The Impact of Customization in Mining Equipment on Operational Efficiency. Mining Technology Today.

4. Chen, Y. (2023). Integrating Blockchain for Supply Chain Transparency in Manufacturing. Journal of Digital Innovations.

5. Brown, S. (2022). Industrial Optimization through Smart Contracts and Decentralized Finance. Technology in Industry.

6. Kumar, A., & Lee, D. (2024). Sustainable Mining Practices and Equipment Advances. Environmental Mining Journal.