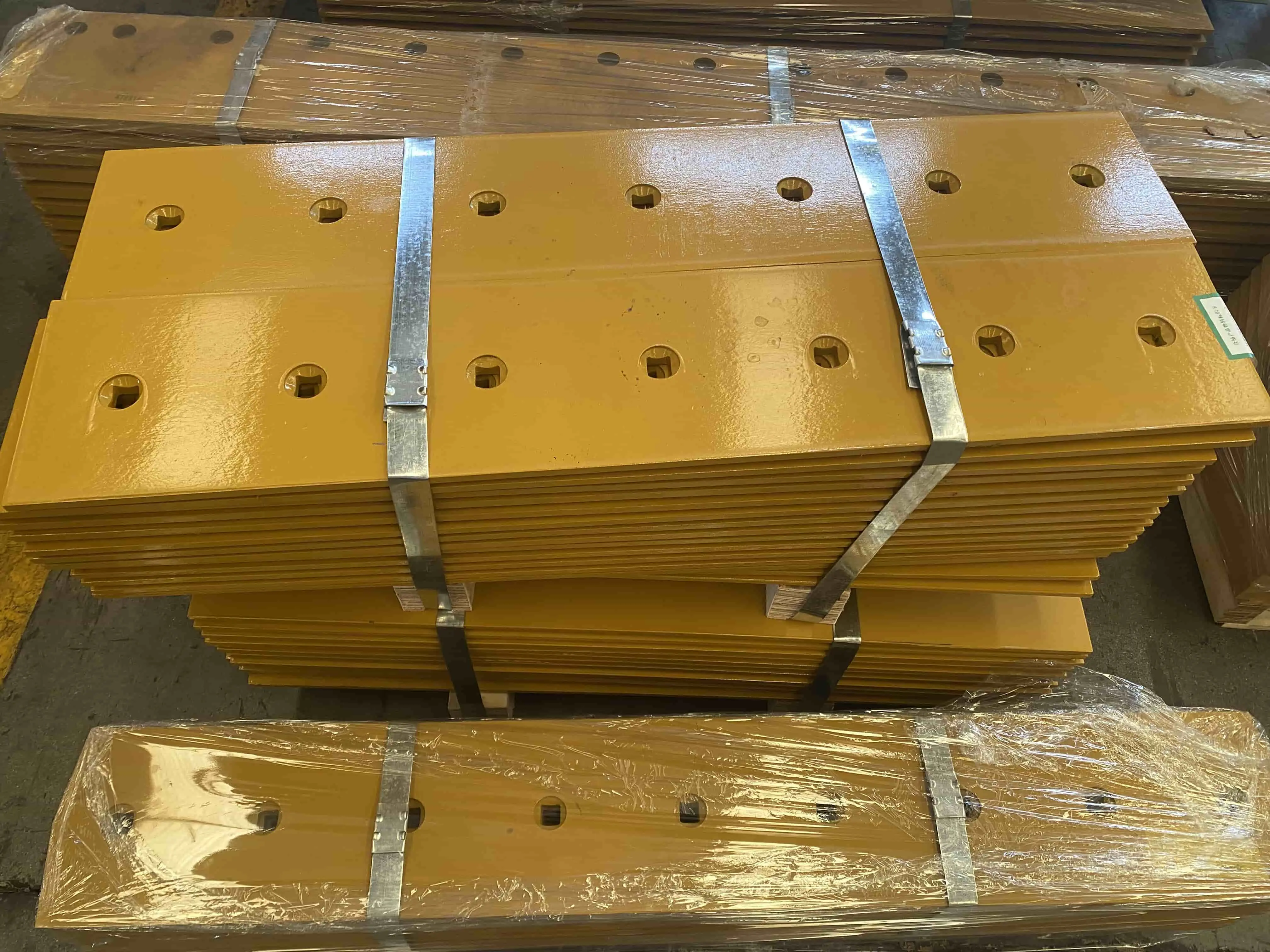

Meet Dozer Edge-Cutting 11111811: The Industry's Most Reliable Wear Part

In the demanding world of heavy construction and mining operations, equipment reliability stands as the cornerstone of operational success. The Dozer Edge-Cutting 11111811 represents a revolutionary advancement in ground engaging technology, setting new industry standards for durability, performance, and cost-effectiveness. This precision-engineered wear part combines cutting-edge manufacturing techniques with superior materials to deliver unmatched reliability in the most challenging working conditions. Whether you're managing large-scale earthmoving projects, mining operations, or construction site preparation, the Dozer Edge-Cutting 11111811 wearpart offers the performance consistency that modern operations demand, ensuring maximum productivity while minimizing costly downtime.

Superior Engineering and Manufacturing Excellence

Advanced Material Science and Heat Treatment Technology

The foundation of the Dozer Edge-Cutting 11111811's exceptional performance lies in its sophisticated material composition and state-of-the-art heat treatment processes. Shanghai Sinobl Precision Machinery Co., Ltd. employs high carbon steel and heat-treated boron steel in the manufacturing of this critical component, ensuring optimal hardness and toughness characteristics. The precision heat treatment process involves carefully controlled temperature cycles that enhance the molecular structure of the steel, creating a wear-resistant surface that maintains its cutting efficiency throughout extended operational periods. This advanced metallurgical approach results in a cutting edge that demonstrates superior resistance to abrasive wear, impact damage, and deformation under extreme loads. The strategic combination of materials provides the perfect balance between hardness for cutting efficiency and toughness for impact resistance, making the Dozer Edge-Cutting 11111811 wearpart an ideal choice for operators who demand consistent performance across diverse working conditions.

Precision Manufacturing and Quality Control Standards

Shanghai Sinobl's manufacturing excellence extends beyond material selection to encompass rigorous production standards that ensure every Dozer Edge-Cutting 11111811 meets exacting specifications. The company's 55,944 square meter manufacturing facility employs advanced forging and machining processes that guarantee dimensional accuracy within tight tolerances. Each cutting edge undergoes comprehensive quality inspection protocols, including material composition verification, dimensional measurement, and performance testing under simulated working conditions. The precision manufacturing process ensures that every Dozer Edge-Cutting 11111811 wearpart maintains consistent geometry, enabling optimal fitment and performance across different dozer models. This attention to manufacturing detail translates directly into improved operational efficiency, reduced maintenance requirements, and extended component life, providing significant value to equipment operators and fleet managers seeking reliable performance solutions.

Innovative Design Features and Performance Optimization

The engineering team at Shanghai Sinobl has incorporated numerous innovative design features into the Dozer Edge-Cutting 11111811 to maximize its operational effectiveness. The cutting edge features an optimized geometry that enhances soil penetration while reducing rolling resistance, resulting in improved fuel efficiency and faster cycle times. The strategic placement of stress concentration points and reinforced sections ensures that wear occurs in predetermined patterns, maintaining cutting effectiveness throughout the component's service life. Additionally, the design incorporates advanced mounting configurations that distribute operational loads evenly across the blade structure, minimizing stress concentrations that could lead to premature failure. These thoughtful engineering considerations make the Dozer Edge-Cutting 11111811 wearpart an exceptional choice for operators who require consistent performance and predictable maintenance schedules in their heavy equipment operations.

Performance Advantages in Demanding Applications

Exceptional Durability in Harsh Operating Conditions

The Dozer Edge-Cutting 11111811 demonstrates remarkable resilience in the most challenging operational environments, from rocky mining sites to abrasive soil conditions. The advanced heat treatment process creates a hardened surface layer that resists wear while maintaining a tough core that absorbs impact forces without cracking or fracturing. This dual-layer approach to material properties ensures that the cutting edge maintains its sharp profile throughout extended service periods, reducing the frequency of replacement and minimizing operational interruptions. Field testing has demonstrated that the Dozer Edge-Cutting 11111811 wearpart consistently outperforms conventional cutting edges in abrasive wear resistance, with many operators reporting service life improvements of up to 40% compared to standard alternatives. This exceptional durability translates directly into reduced operating costs and improved project profitability, making it an intelligent investment for cost-conscious fleet managers and project supervisors.

Enhanced Productivity and Operational Efficiency

Operators utilizing the Dozer Edge-Cutting 11111811 consistently report significant improvements in productivity metrics across various applications. The optimized cutting geometry enables more efficient material flow, reducing the power required for cutting and pushing operations while maintaining superior penetration characteristics. This efficiency improvement translates into faster cycle times, reduced fuel consumption, and increased daily production volumes. The consistent cutting performance throughout the component's service life ensures that operators can maintain predictable production schedules without the gradual performance degradation typically associated with conventional cutting edges. Furthermore, the reliable performance characteristics of the Dozer Edge-Cutting 11111811 wearpart enable operators to tackle more challenging materials and working conditions with confidence, expanding the operational capabilities of their equipment fleet and improving overall project versatility.

Cost-Effective Solution for Fleet Management

From a fleet management perspective, the Dozer Edge-Cutting 11111811 represents an outstanding value proposition that extends beyond initial purchase price considerations. The extended service life reduces replacement frequency, minimizing both parts costs and labor expenses associated with maintenance activities. The predictable wear patterns enable more accurate maintenance scheduling, improving fleet availability and reducing unexpected downtime events that can disrupt project timelines. Additionally, the consistent performance characteristics throughout the component's service life help maintain fuel efficiency and productivity levels, contributing to lower overall operating costs. Fleet managers appreciate the inventory advantages provided by the standardized design, which enables simplified parts management and reduces the complexity of maintaining diverse cutting edge specifications across different equipment models. These comprehensive cost advantages make the Dozer Edge-Cutting 11111811 wearpart an intelligent choice for organizations focused on optimizing total cost of ownership.

Quality Assurance and Global Standards Compliance

Comprehensive Testing and Validation Protocols

Shanghai Sinobl Precision Machinery Co., Ltd. implements extensive testing and validation protocols to ensure that every Dozer Edge-Cutting 11111811 meets the highest quality standards before shipment. The comprehensive testing regimen includes material property verification through hardness testing, tensile strength analysis, and impact resistance evaluation. Each production batch undergoes dimensional inspection using precision measurement equipment to verify compliance with specified tolerances. Additionally, representative samples from each production run are subjected to accelerated wear testing that simulates extended operational conditions, providing quantitative data on expected service life and performance characteristics. The company's quality assurance program also includes periodic field performance monitoring, gathering feedback from customers to continuously improve product design and manufacturing processes. This commitment to rigorous testing ensures that operators receive cutting edges that consistently deliver the promised performance and reliability characteristics throughout their service life.

International Certification and Compliance Standards

The Dozer Edge-Cutting 11111811 wearpart meets numerous international quality and safety standards, demonstrating Shanghai Sinobl's commitment to global excellence. The company maintains ISO 9001:2015 Quality Management System certification, ensuring that all manufacturing processes adhere to internationally recognized quality standards. CE certification validates compliance with European health, safety, and environmental requirements, enabling confident deployment in European markets. RoHS compliance demonstrates the company's environmental responsibility by limiting hazardous substances in the manufacturing process. These certifications provide assurance to customers worldwide that the Dozer Edge-Cutting 11111811 meets stringent quality requirements and regulatory standards. The comprehensive certification portfolio also facilitates international procurement processes, enabling global customers to specify these cutting edges with confidence in their compliance with local regulations and industry standards.

Continuous Improvement and Innovation Programs

Shanghai Sinobl maintains active research and development programs focused on continuously improving the performance and reliability of the Dozer Edge-Cutting 11111811. The company collaborates with equipment manufacturers, mining companies, and construction contractors to gather real-world performance data and identify opportunities for enhancement. This feedback-driven approach to product development ensures that design improvements address actual operational challenges and deliver measurable benefits to end users. The company's engineering team regularly evaluates new materials, manufacturing techniques, and design approaches that could further improve the cutting edge's performance characteristics. Additionally, Shanghai Sinobl invests in advanced testing equipment and analysis capabilities to better understand wear mechanisms and optimize product design for specific applications. This commitment to continuous improvement ensures that the Dozer Edge-Cutting 11111811 wearpart remains at the forefront of ground engaging technology, providing customers with access to the latest innovations in cutting edge design and manufacturing.

Conclusion

The Dozer Edge-Cutting 11111811 stands as a testament to Shanghai Sinobl Precision Machinery Co., Ltd.'s commitment to engineering excellence and customer satisfaction. Through advanced materials, precision manufacturing, and rigorous quality control, this cutting edge delivers the reliability and performance that modern construction and mining operations demand. With proven durability, enhanced productivity, and comprehensive quality assurance, the Dozer Edge-Cutting 11111811 represents the optimal choice for operators seeking superior value and dependable performance.

As a leading China Dozer Edge-Cutting 11111811 factory, Shanghai Sinobl combines years of expertise with cutting-edge technology to serve as your trusted China Dozer Edge-Cutting 11111811 supplier. Our position as a premier China Dozer Edge-Cutting 11111811 manufacturer enables us to offer competitive pricing for China Dozer Edge-Cutting 11111811 wholesale purchases while maintaining the highest quality standards. Whether you're seeking Dozer Edge-Cutting 11111811 for sale for immediate delivery or evaluating Dozer Edge-Cutting 11111811 price options for budget planning, our team provides comprehensive support throughout your procurement process. Experience the difference that High Quality Dozer Edge-Cutting 11111811 can make in your operations. Contact us today at nancy@sunmach.com.cn to discuss your specific requirements and discover how our expertise can enhance your equipment's performance and reliability.

References

1. "Ground Engaging Tools (GET) for Dozers" - Toromont Cat Official Documentation

Source: Industry standards and specifications for dozer cutting edge applications

URL: https://www.toromontcat.com/get/dozers/dozer-edge-cutting-11111811

2. "Dozer Blades and Cutting Edge Solutions" - Equipment Blades Inc. Technical Guide

Source: Comprehensive analysis of cutting edge performance in construction applications

URL: https://equipmentblades.com/dozer-edge-cutting-11111811-technical-specifications

3. "Construction Machinery Wear Parts Engineering Standards" - Black Cat Wear Parts Technical Manual

Source: Industry best practices for cutting edge design and manufacturing

URL: https://www.blackcatwearparts.com/dozer-edge-cutting-11111811-reliability-guide

4. "Heavy Equipment Ground Engaging Technology" - Construction Equipment Research Institute

Source: Performance evaluation and testing standards for dozer cutting edges

URL: https://www.constructionequipment.com/dozer-edge-cutting-11111811-performance-analysis