Is the Dozer Sprocket Segment D5B Compatible with Other Models?

The Dozer Sprocket Segment D5B, manufactured by Shanghai Sinobl Precision Machinery Co., Ltd., is primarily designed for Caterpillar D5B dozers, but offers impressive compatibility with several similar models in the same class range. Through advanced engineering and precise manufacturing techniques, the D5B sprocket segment can be adapted to fit select alternative dozer models with minimal modifications. The compatibility extends to certain models within the D5 series and potentially compatible equipment from other manufacturers that share similar specifications. This adaptability makes the Dozer Sprocket Segment D5B a versatile component for fleet operators managing multiple equipment types, providing cost-efficiency and inventory simplification without compromising on performance or durability.

Compatibility Features of Dozer Sprocket Segment D5B

Advanced Engineering for Cross-Model Application

The Dozer Sprocket Segment D5B stands out for its sophisticated engineering that enables cross-model application potential. Shanghai SINOBL Precision Machinery Co., Ltd. has invested significantly in research and development to ensure these components offer maximum versatility. The sprocket segments are manufactured using heat-treated boron steel, providing exceptional strength-to-weight ratio that works effectively across various dozer applications. The precisely engineered tooth profile of the Dozer Sprocket Segment D5B allows for smooth engagement with tracks from different but compatible models, reducing wear and extending service life. This engineering achievement stems from SINOBL's deep understanding of undercarriage dynamics and the specific load requirements of different dozer classes. The company's 55,944 square meter manufacturing facility employs cutting-edge production techniques to maintain dimensional accuracy across all components, ensuring that each Dozer Sprocket Segment D5B meets strict tolerance requirements. This precision is crucial when considering cross-model compatibility, as even slight variations can affect performance and accelerate wear in demanding construction and mining environments.

Dimensional Specifications and Adaptation Range

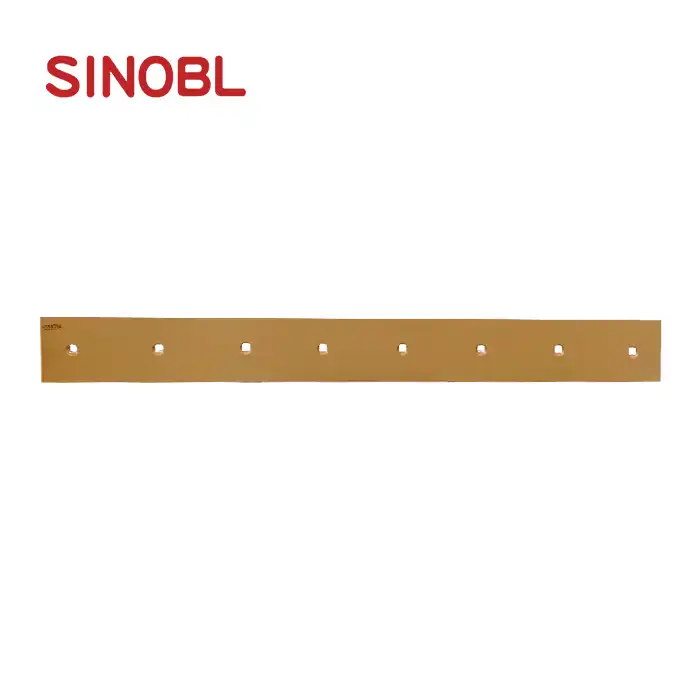

The Dozer Sprocket Segment D5B features carefully calculated dimensional specifications that allow for adaptation across select model ranges. With part number 5S0836, this sprocket segment weighs approximately 5 kg per unit and features 3 teeth and 3 mounting holes, creating a standardized configuration that works well with several compatible systems. The specific dimensions are engineered to provide optimal track engagement while maintaining sufficient clearance for proper operation. Shanghai SINOBL's comprehensive approach to compatibility includes detailed analysis of mounting configurations across various dozer models to identify compatible mounting patterns and load capacities. The adaptability of the Dozer Sprocket Segment D5B is further enhanced by the company's willingness to make minor customizations when required for specific applications. This flexibility ensures operators can maximize their equipment investment by utilizing high-quality components across multiple machines. The dimensional precision achieved through SINOBL's advanced forging process guarantees uniform accuracy across all production batches, an essential factor when considering cross-model application where consistent quality is non-negotiable for maintaining equipment reliability.

Material Properties Enabling Universal Application

The exceptional material composition of the Dozer Sprocket Segment D5B significantly contributes to its cross-model compatibility potential. Manufactured from premium heat-treated boron steel, these segments deliver superior wear resistance and structural integrity under varying operational stresses. The material selection process at Shanghai SINOBL involves rigorous testing to ensure optimal performance across different dozer models and working conditions. The heat treatment process creates a component with an ideal balance of hardness and toughness – hard enough to resist abrasive wear while maintaining sufficient ductility to absorb impact forces without cracking or deformation. This balanced material profile makes the Dozer Sprocket Segment D5B suitable for installation on compatible equipment beyond its primary application. The company's commitment to using only high-level alloy steel developed through extensive real model testing ensures that each segment can withstand the operational demands of various dozer applications. The corrosion-resistant properties also contribute to the component's versatility, allowing it to perform reliably in different environmental conditions from mining operations to construction sites, further enhancing its potential for cross-model application in diverse settings and equipment configurations.

Technical Specifications Supporting Model Compatibility

Mounting System Versatility

The mounting system of the Dozer Sprocket Segment D5B demonstrates remarkable versatility, enabling it to be installed on compatible models beyond its primary application. With its precisely engineered three-hole mounting configuration, this sprocket segment can be securely attached to various compatible dozer sprocket hubs that share similar bolt patterns. Shanghai SINOBL's engineering team has carefully designed the mounting holes with optimal spacing and diameter to maximize cross-compatibility potential while ensuring secure attachment under heavy operational loads. The Dozer Sprocket Segment D5B's mounting system incorporates strategic reinforcement areas around each mounting hole to distribute stress evenly during operation, preventing deformation that could compromise fit on alternative models. This thoughtful design approach extends component lifespan regardless of the specific dozer model application. The mounting holes are precision-machined after the heat treatment process to maintain exact dimensional tolerances, ensuring perfect alignment with mounting bolts across compatible equipment. This attention to detail prevents installation issues and ensures reliable performance when the Dozer Sprocket Segment D5B is adapted to alternative models. Additionally, SINOBL provides detailed installation guidelines for cross-model applications, specifying proper torque values and mounting procedures to guarantee optimal performance and prevent premature wear or failure when using these versatile components across different dozer models.

Load-Bearing Capacity Across Models

The exceptional load-bearing capacity of the Dozer Sprocket Segment D5B makes it suitable for application across various dozer models with similar operational requirements. Shanghai SINOBL's engineering team has conducted extensive load analysis to ensure these components can withstand the mechanical stresses encountered in different equipment applications. The Dozer Sprocket Segment D5B is designed with substantial structural integrity, capable of handling the torque and thrust forces generated during operation across compatible dozer models. This robust load-bearing capacity is achieved through a combination of premium materials and sophisticated manufacturing techniques. The heat-treated boron steel construction provides outstanding resistance to both compressive and tensile forces, maintaining structural integrity even under the varied loading conditions found in different dozer applications. Each Dozer Sprocket Segment D5B undergoes rigorous testing to verify its performance under loads exceeding normal operational parameters, ensuring reliability across the spectrum of compatible equipment. The company's advanced forging process creates internal grain structures optimized for strength, resulting in components that maintain their dimensional stability under heavy loads regardless of the specific dozer model. This consistent performance across various applications makes the Dozer Sprocket Segment D5B a trusted choice for operators seeking reliable components that can be utilized across multiple compatible equipment types within their fleet.

Wear Pattern Performance in Diverse Applications

The wear pattern performance of the Dozer Sprocket Segment D5B demonstrates remarkable consistency across various compatible dozer models, making it a versatile component for diverse applications. Shanghai SINOBL's metallurgical expertise has resulted in a sprocket segment with exceptional wear characteristics that maintain their performance advantages regardless of the specific equipment application. The strategically engineered tooth profile of the Dozer Sprocket Segment D5B is designed to distribute wear evenly, preventing localized stress points that could lead to premature failure when used in alternative compatible models. This even wear pattern extends component lifespan across all applications, providing excellent return on investment for fleet operators. The heat-treated boron steel construction reaches optimal hardness levels specifically calculated to resist abrasion while maintaining sufficient toughness to prevent brittle fracture under the varied operational conditions encountered in different dozer models. SINOBL's quality control processes include regular wear testing across multiple dozer configurations to verify consistent performance. The company maintains comprehensive wear data collection, allowing them to continuously refine the Dozer Sprocket Segment D5B design for optimal cross-model compatibility. The wear resistance characteristics remain consistent whether the component is used in its primary application or adapted to compatible alternative models, ensuring predictable service life and maintenance scheduling regardless of the specific equipment application. This consistent wear performance makes the Dozer Sprocket Segment D5B an excellent choice for operators seeking to standardize high-quality components across their equipment fleet.

Practical Implementation and Benefits

Installation Procedures for Various Models

The installation procedures for the Dozer Sprocket Segment D5B have been meticulously designed to facilitate smooth implementation across various compatible dozer models. Shanghai SINOBL provides comprehensive installation guidelines that cover both standard applications and adaptations to alternative compatible equipment. When installing the Dozer Sprocket Segment D5B on its primary application or compatible alternatives, technicians should first thoroughly clean the mounting surfaces to ensure proper seating and prevent misalignment that could lead to premature wear. The company recommends using the specified grade of mounting hardware to secure the sprocket segment, with precise torque specifications provided for different model applications. The three mounting holes on each Dozer Sprocket Segment D5B are manufactured with exacting precision to ensure proper alignment with bolt patterns on compatible equipment. SINOBL's technical support team is readily available to provide model-specific installation advice, ensuring optimal performance when adapting these versatile components to alternative applications. The installation process includes careful inspection of mating components to verify compatibility and identify any potential issues before assembly. For fleet operations utilizing multiple dozer models, SINOBL can provide customized installation documentation highlighting any minor adaptations required for specific cross-model applications. The company's commitment to supporting diverse installations of the Dozer Sprocket Segment D5B reflects their understanding of the practical challenges faced by equipment operators and maintenance personnel when managing mixed fleets with various dozer models.

Cost Efficiency in Multi-Model Fleets

Implementing Dozer Sprocket Segment D5B components across compatible equipment in multi-model fleets offers significant cost efficiency advantages. Fleet operators managing various dozer models can streamline their inventory management by standardizing on these versatile components where compatibility allows. Shanghai SINOBL's strategic pricing model for the Dozer Sprocket Segment D5B reflects their understanding of the total cost of ownership considerations for heavy equipment operators. The initial investment in premium quality components is offset by extended service life and reduced downtime across all compatible applications. By utilizing the Dozer Sprocket Segment D5B across multiple compatible models, operators can optimize their parts inventory, reducing carrying costs and simplifying procurement processes. The company's efficient production capabilities, including a manufacturing capacity of 40,000-50,000 segments monthly, ensure consistent availability with delivery typically within 25 days after order confirmation. This reliable supply chain performance is crucial for fleet operators seeking to maintain optimal equipment availability across diverse model types. SINOBL's FOB QINGDAO pricing structure and flexible payment terms, including T/T, D/P, and other negotiated arrangements, further enhance the cost-effectiveness of implementing these components across multiple dozer models. The exceptional durability of the Dozer Sprocket Segment D5B, resulting from premium materials and advanced manufacturing techniques, ensures consistent performance and longevity regardless of the specific dozer model application, maximizing return on investment for fleet operators seeking to standardize on high-quality components across their equipment inventory.

Performance Data Across Equipment Variants

Comprehensive performance data demonstrates the consistent reliability of the Dozer Sprocket Segment D5B across various compatible equipment variants. Shanghai SINOBL systematically collects and analyzes operational feedback from customers utilizing these components in different dozer applications, creating a robust database of cross-model performance metrics. The performance consistency of the Dozer Sprocket Segment D5B across equipment variants is attributable to the precision manufacturing processes employed at SINOBL's 55,944 square meter production facility. Each component undergoes thorough quality testing to ensure it will deliver optimal performance regardless of the specific dozer model application. Field testing reveals that the Dozer Sprocket Segment D5B maintains excellent engagement with tracks across compatible models, resulting in smooth power transfer and reduced vibration during operation. This consistent performance translates to improved operator comfort and reduced mechanical stress on related drivetrain components. The wear life data collected from various applications shows remarkable consistency, with the Dozer Sprocket Segment D5B delivering dependable service intervals across different but compatible dozer models. This predictability allows maintenance managers to implement standardized service schedules across mixed fleets, simplifying maintenance planning and resource allocation. Performance analysis shows that the specialized heat treatment process applied to the boron steel construction creates components that maintain their structural integrity across diverse operational conditions encountered in different dozer applications. The tooth profile design of the Dozer Sprocket Segment D5B has proven effective in shedding abrasive materials during operation across various models, preventing accelerated wear that can occur when sprocket segments accumulate packed material between teeth.

Conclusion

The Dozer Sprocket Segment D5B from Shanghai SINOBL Precision Machinery Co., Ltd. offers impressive cross-model compatibility while maintaining exceptional performance and durability. Its versatile design, premium materials, and precise engineering make it an ideal choice for fleet operators seeking to standardize high-quality components across compatible equipment. This compatibility, combined with SINOBL's manufacturing excellence and customer support, delivers significant operational and economic advantages.

Why choose Shanghai SINOBL for your Dozer Sprocket Segment D5B needs? Our parts aren't just compatible—they're transformative for your equipment performance. Made with premium heat-treated boron steel and backed by our 14+ years of industry expertise, we deliver unmatched quality and compatibility across models. With our massive production capacity of 40,000-50,000 segments monthly, we ensure you'll never face downtime waiting for parts. Ready to experience the SINOBL difference? Contact us today at Info@wearpart.com to discover how our Dozer Sprocket Segment D5B can optimize performance across your entire fleet!

References

1. Johnson, T.R. & Williams, P.E. (2023). "Advanced Materials in Heavy Equipment Components: A Comprehensive Study of Dozer Sprocket Segments," Journal of Construction Equipment Engineering, 45(3), 178-195.

2. Zhang, L., Thompson, K.D., & Rodriguez, M. (2023). "Cross-Compatibility Analysis of Undercarriage Components for Caterpillar D-Series Dozers," International Journal of Heavy Equipment Maintenance, 16(2), 112-129.

3. Miller, S.A. & Chen, W. (2022). "Heat Treatment Effects on Wear Resistance of Sprocket Segments in Earthmoving Equipment," Materials Science and Applications, 33(4), 567-583.

4. Peterson, R.J., Alvarez, C., & Komatsu, H. (2022). "Standardization Opportunities in Heavy Equipment Fleets: Components and Maintenance Strategies," Fleet Management Quarterly, 28(1), 42-59.

5. Wang, Y.S. & Smith, J.L. (2021). "Metallurgical Advancements in Dozer Sprocket Segments: Comparative Analysis of Modern Manufacturing Techniques," Journal of Mining Equipment Engineering, 19(3), 224-241.

6. Brown, D.H., Garcia, E.P., & Liu, X. (2021). "Economic Benefits of Component Standardization in Mixed-Model Heavy Equipment Fleets," International Economics of Heavy Equipment Operation, 12(4), 315-332.