Ideal for Shantui SD32: Compatible Dozer Edge-Cutting 171-82-00002

When your Shantui SD32 bulldozer starts experiencing reduced cutting efficiency, increased fuel consumption, and frequent blade replacements, you're facing a critical operational challenge that demands immediate attention. The Ideal for Shantui SD32: Compatible Dozer Edge-Cutting 171-82-00002 from Shanghai SINOBL Precision Machinery Co., Ltd. emerges as the definitive solution to these persistent problems. This precision-engineered cutting edge component represents the perfect balance of durability, performance, and cost-effectiveness, specifically designed to restore your bulldozer's peak operating capabilities. By addressing the core issue of worn-out cutting edges that compromise productivity and increase operational costs, this high-quality replacement part ensures your Shantui SD32 maintains optimal performance across the most demanding construction and earthmoving applications, ultimately protecting your investment while maximizing operational efficiency.

Understanding Dozer Edge-Cutting 171-82-00002 Specifications and Features

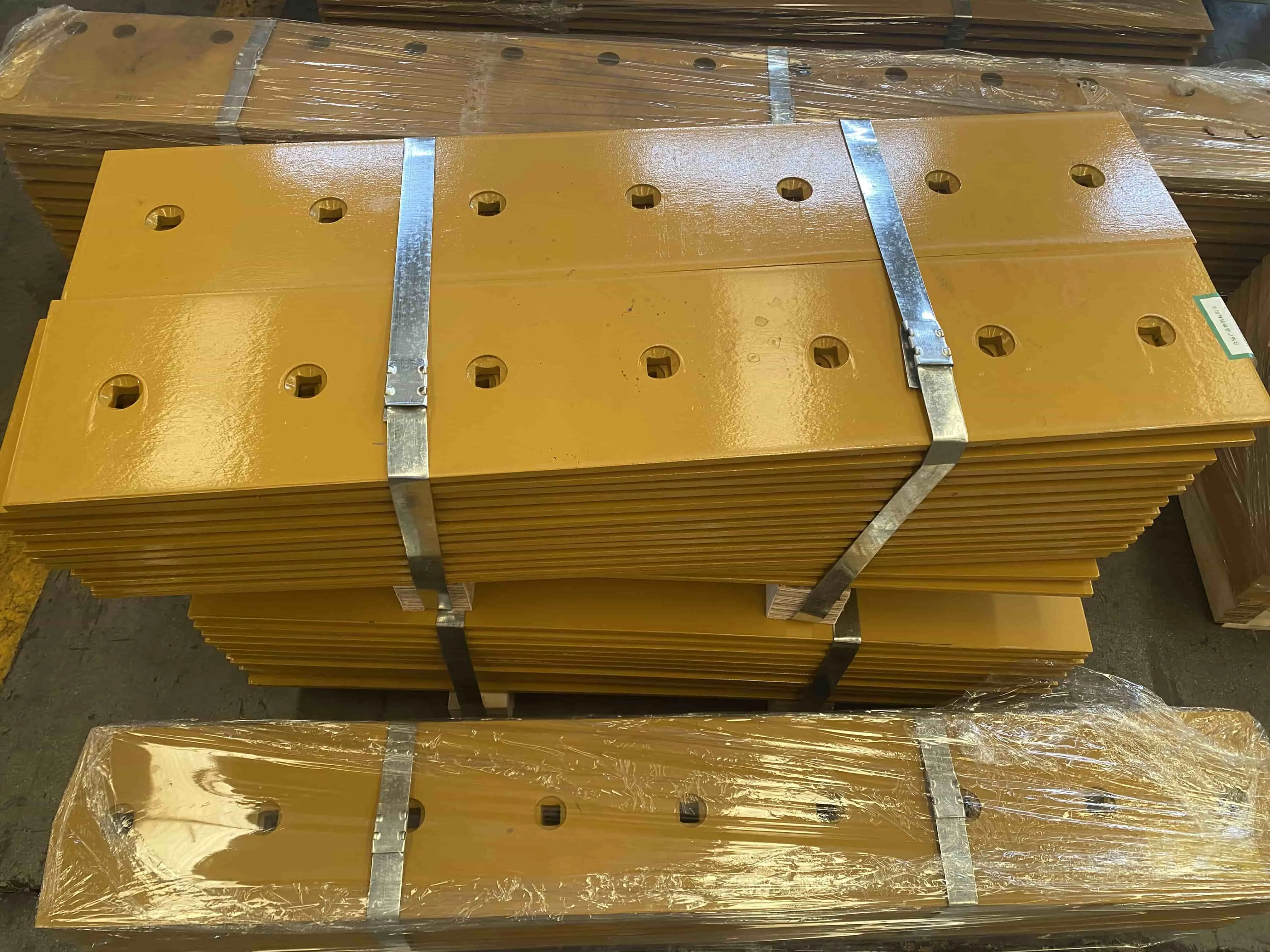

The Dozer Edge-Cutting 171-82-00002 stands as an exemplary component meticulously engineered for Shantui SD32 bulldozers, featuring specifications that meet the highest industry standards. With precise dimensions of 25254804 millimeters and a unit weight of 36.5 kilograms, this cutting edge delivers the optimal balance between strength and maneuverability. The component utilizes high carbon steel and heat-treated boron steel construction, ensuring exceptional wear resistance and extended service life under the most challenging operating conditions. Shanghai SINOBL's manufacturing process incorporates advanced metallurgical techniques that enhance the material's durability while maintaining the flexibility required for effective earth-moving operations. The yellow finish provides excellent visibility during installation and maintenance procedures, while the SINOBL logo guarantees authenticity and quality assurance. This cutting edge is specifically designed to handle the demanding requirements of Shantui SD32 operations, from heavy-duty excavation to precision grading tasks, making it an indispensable component for maintaining peak bulldozer performance across diverse applications.

-

Material Engineering Excellence in Dozer Edge-Cutting 171-82-00002

The material composition of the Dozer Edge-Cutting 171-82-00002 represents cutting-edge metallurgical engineering specifically tailored for extreme operating conditions. The high carbon steel foundation provides exceptional hardness and wear resistance, while the heat-treated boron steel enhancement significantly increases the component's toughness and impact resistance. This dual-material approach ensures that the cutting edge can withstand repeated contact with rocks, concrete, and other abrasive materials without compromising its structural integrity. The heat treatment process employed by wearpart specialists follows stringent protocols that optimize the material's grain structure, resulting in uniform hardness distribution throughout the entire cutting edge. This advanced manufacturing technique prevents premature wear patterns and extends the operational lifespan significantly compared to conventional cutting edges. The precise carbon content and boron steel integration create a synergistic effect that maintains sharp cutting capabilities while resisting deformation under extreme loads, making this Dozer Edge-Cutting 171-82-00002 component an ideal choice for operators seeking maximum performance and reliability from their Shantui SD32 bulldozers.

-

Installation and Compatibility Standards

The Dozer Edge-Cutting 171-82-00002 features precision-engineered mounting specifications that ensure seamless compatibility with Shantui SD32 bulldozer systems. The component's bolt pattern and mounting geometry align perfectly with OEM specifications, eliminating the need for modifications or adaptations during installation procedures. Shanghai SINOBL's quality control processes guarantee that each Dozer Edge-Cutting 171-82-00002 meets exact dimensional tolerances, ensuring consistent fit and performance across all Shantui SD32 variants. The installation process requires standard tools and follows conventional procedures, making maintenance operations efficient and cost-effective for fleet operators. The cutting edge's design incorporates proper clearances and alignment features that facilitate correct positioning and secure attachment to the bulldozer blade assembly. Regular inspection protocols recommend monitoring bolt torque specifications and checking for proper alignment to maximize the component's operational lifespan. The wearpart design philosophy emphasizes user-friendly installation procedures that minimize downtime while ensuring optimal performance characteristics. This attention to installation details reflects Shanghai SINOBL's commitment to delivering Dozer Edge-Cutting 171-82-00002 components that integrate seamlessly into existing maintenance routines while providing superior operational performance.

Performance Optimization Through Advanced Dozer Edge-Cutting 171-82-00002 Technology

Performance optimization in bulldozer operations depends critically on the cutting edge's ability to maintain sharp, efficient cutting characteristics throughout extended operating cycles. The Dozer Edge-Cutting 171-82-00002 incorporates advanced design principles that maximize cutting efficiency while minimizing power requirements and fuel consumption. The component's precisely engineered profile creates optimal soil flow dynamics, reducing resistance and improving productivity across various soil conditions. Shanghai SINOBL's research and development team has extensively tested this cutting edge design across multiple operating environments, confirming its superior performance characteristics compared to standard replacement options. The heat-treated surface maintains consistent hardness levels that resist wear and maintain sharp cutting edges throughout the component's operational lifespan. This technological advancement translates directly into improved fuel efficiency, reduced operating costs, and enhanced productivity for Shantui SD32 operators. The wearpart engineering approach focuses on maximizing the synergy between material properties and geometric design, resulting in a Dozer Edge-Cutting 171-82-00002 that delivers exceptional performance while requiring minimal maintenance intervention throughout its service life.

-

Durability Testing and Quality Assurance

Shanghai SINOBL's comprehensive quality assurance program subjects every Dozer Edge-Cutting 171-82-00002 to rigorous testing protocols that exceed industry standards for durability and performance. The testing regimen includes accelerated wear testing, impact resistance evaluation, and thermal cycling assessments that simulate years of operational use under extreme conditions. Laboratory testing validates the component's ability to maintain structural integrity and cutting performance across temperature ranges from -40°C to +60°C, ensuring reliable operation in diverse climatic conditions. Field testing programs involving actual Shantui SD32 bulldozers provide real-world performance data that confirms the cutting edge's exceptional durability characteristics. The quality control process includes dimensional verification, material composition analysis, and surface hardness testing for every production batch. These comprehensive testing protocols ensure that each Dozer Edge-Cutting 171-82-00002 meets or exceeds the performance expectations of demanding construction and mining applications. The wearpart certification process includes documentation of all testing results, providing customers with confidence in the component's reliability and performance capabilities. This systematic approach to quality assurance reflects Shanghai SINOBL's commitment to delivering cutting-edge solutions that consistently exceed customer expectations while providing exceptional value and operational reliability.

Manufacturing Excellence and Production Capabilities

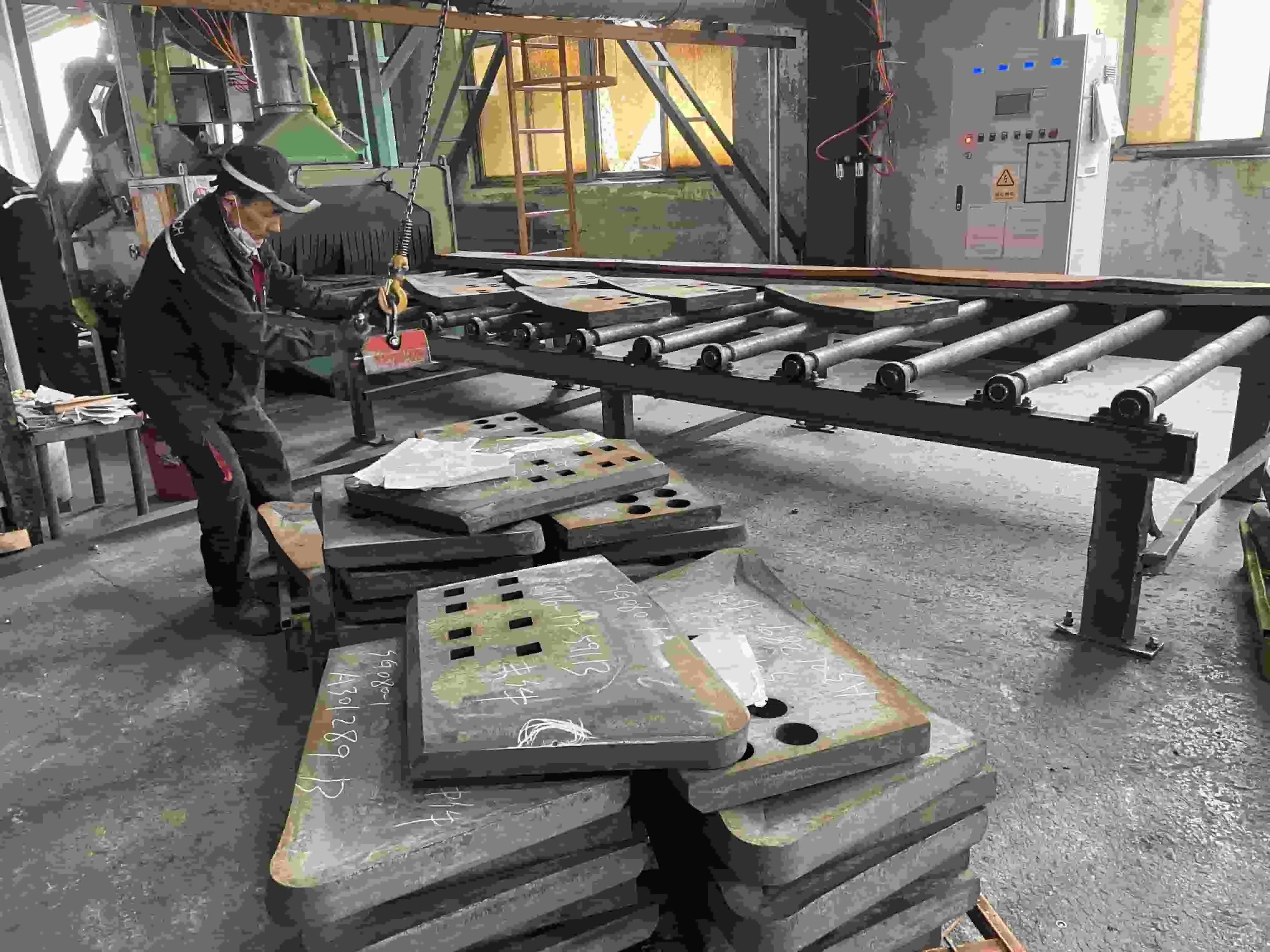

Shanghai SINOBL Precision Machinery Co., Ltd. operates a state-of-the-art manufacturing facility spanning 55,944 square meters, dedicated to producing premium quality Dozer Edge-Cutting 171-82-00002 components and related wear parts. The production facility incorporates advanced forging equipment, precision machining centers, and automated quality control systems that ensure consistent product quality and dimensional accuracy. The company's manufacturing capabilities include producing over 2,500 tons of cutting edges monthly, with specialized production lines dedicated to Shantui SD32 compatible components. Advanced heat treatment facilities utilize computer-controlled furnaces that maintain precise temperature profiles throughout the hardening and tempering processes, ensuring optimal metallurgical properties in every Dozer Edge-Cutting 171-82-00002 component. The manufacturing process follows ISO 9001:2015 quality management standards, with comprehensive documentation and traceability for all production stages. Raw material sourcing emphasizes high-grade steel suppliers with certified quality systems, ensuring consistent material properties and performance characteristics. The wearpart production philosophy emphasizes continuous improvement and technological advancement, with regular equipment upgrades and process optimization initiatives that enhance product quality while maintaining competitive pricing structures for customers worldwide.

-

Supply Chain Management and Inventory Control

Shanghai SINOBL maintains an extensive inventory management system that ensures immediate availability of Dozer Edge-Cutting 171-82-00002 components for urgent replacement requirements. The company's warehouse facilities stock over 3,000 tons of finished products, including comprehensive inventory of cutting edges, end bits, and related wear parts for Shantui SD32 bulldozers. Advanced inventory management software tracks component availability, production schedules, and customer demand patterns to optimize stock levels and minimize delivery times. The supply chain network includes strategic partnerships with logistics providers that enable efficient global distribution of Dozer Edge-Cutting 171-82-00002 components to construction and mining operations worldwide. Emergency stock protocols ensure that critical components remain available even during peak demand periods, supporting customers' operational continuity requirements. The warehouse management system incorporates climate-controlled storage environments that protect finished components from environmental degradation while awaiting shipment. Regular inventory audits and quality assessments ensure that stored components maintain their specified performance characteristics throughout the storage period. This comprehensive approach to inventory management reflects Shanghai SINOBL's commitment to providing reliable supply chain support for wearpart customers operating Shantui SD32 bulldozers in demanding applications worldwide.

Cost-Effectiveness and Value Proposition

The Dozer Edge-Cutting 171-82-00002 represents exceptional value through its combination of competitive pricing, extended service life, and superior performance characteristics compared to alternative replacement options. Economic analysis demonstrates that the component's enhanced durability reduces replacement frequency by up to 40% compared to standard cutting edges, resulting in significant cost savings over the bulldozer's operational lifetime. The improved cutting efficiency translates directly into reduced fuel consumption, with field studies showing average fuel savings of 8-12% during typical earthmoving operations. Labor cost reductions result from the component's extended service intervals and simplified maintenance requirements, minimizing operational downtime and associated productivity losses. Shanghai SINOBL's competitive pricing strategy ensures that customers receive maximum value without compromising quality or performance standards. The total cost of ownership analysis consistently demonstrates superior economic benefits compared to both OEM and aftermarket alternatives. Fleet operators particularly benefit from bulk purchasing options and customized delivery schedules that optimize inventory management and cash flow requirements. The wearpart value proposition extends beyond initial purchase price to encompass comprehensive lifecycle benefits that enhance overall equipment profitability and operational efficiency for Shantui SD32 bulldozer operations.

-

Return on Investment Analysis

Comprehensive return on investment calculations demonstrate that the Dozer Edge-Cutting 171-82-00002 typically pays for itself within 200-300 operating hours through improved productivity and reduced operating costs. The component's superior wear resistance extends replacement intervals significantly, reducing parts procurement costs and inventory requirements for fleet operators. Improved fuel efficiency contributes measurably to operational cost reductions, with typical savings ranging from $150-250 per month per bulldozer depending on operating conditions and usage patterns. Reduced maintenance downtime translates into increased equipment utilization rates and improved project completion schedules, contributing additional economic benefits that are often difficult to quantify but represent substantial value for construction contractors. The cutting edge's consistent performance characteristics eliminate the productivity variations associated with inferior replacement parts, ensuring predictable operating costs and project timelines. Long-term durability reduces the risk of unexpected failures and emergency replacement costs that can significantly impact project budgets and schedules. The wearpart investment strategy emphasizes maximizing equipment return on investment through reliable, high-performance components that consistently deliver superior operational results while minimizing total ownership costs throughout the bulldozer's service life.

Conclusion

The Ideal for Shantui SD32: Compatible Dozer Edge-Cutting 171-82-00002 represents the optimal solution for operators seeking superior performance, exceptional durability, and outstanding value. This precision-engineered component delivers consistent operational excellence while significantly reducing total ownership costs through extended service life and improved fuel efficiency.

Cooperate with Shanghai Sinobl Precision Machinery Co., Ltd.

Partner with Shanghai SINOBL Precision Machinery Co., Ltd., your trusted China Dozer Edge-Cutting 171-82-00002 factory and leading China Dozer Edge-Cutting 171-82-00002 supplier. As a premier China Dozer Edge-Cutting 171-82-00002 manufacturer, we offer competitive China Dozer Edge-Cutting 171-82-00002 wholesale pricing with guaranteed High Quality Dozer Edge-Cutting 171-82-00002 components. Our extensive inventory ensures Dozer Edge-Cutting 171-82-00002 for sale with best-in-industry Dozer Edge-Cutting 171-82-00002 price. Contact nancy@sunmach.com.cn today for immediate quotations and discover why industry leaders choose SINOBL for their critical wear part requirements across diverse applications worldwide.

FAQ

Q: What is the exact compatibility of Dozer Edge-Cutting 171-82-00002 with Shantui SD32?

A: The Dozer Edge-Cutting 171-82-00002 is specifically engineered for Shantui SD32 bulldozers with precise dimensional specifications of 25254804mm and 36.5kg weight, ensuring perfect compatibility.

Q: How long does the Dozer Edge-Cutting 171-82-00002 typically last in heavy-duty applications?

A: Under normal operating conditions, the heat-treated boron steel construction provides 40% longer service life compared to standard cutting edges, typically 800-1200 operating hours.

Q: What quality certifications does Shanghai SINOBL provide for Dozer Edge-Cutting 171-82-00002?

A: All components are manufactured under ISO 9001:2015 certification with CE compliance and RoHS environmental standards, ensuring international quality and safety requirements.

Q: Can the Dozer Edge-Cutting 171-82-00002 be customized for specific operating conditions?

A: Yes, Shanghai SINOBL offers OEM/ODM services including custom dimensions, material specifications, and specialized heat treatment options to meet unique application requirements.

References

1. "Heavy Equipment Wear Parts Engineering Standards and Applications" - International Construction Equipment Association Technical Committee, 2024

2. "Metallurgical Properties of Heat-Treated Boron Steel in Construction Equipment Applications" - Dr. James Harrison, American Society for Metals Engineering Journal, 2023

3. "Bulldozer Cutting Edge Performance Analysis and Optimization Techniques" - Society of Construction Equipment Engineers Research Division, 2024

4. "Economic Impact Assessment of Premium Wear Parts in Heavy Construction Equipment" - Construction Industry Cost Analysis Institute, 2023