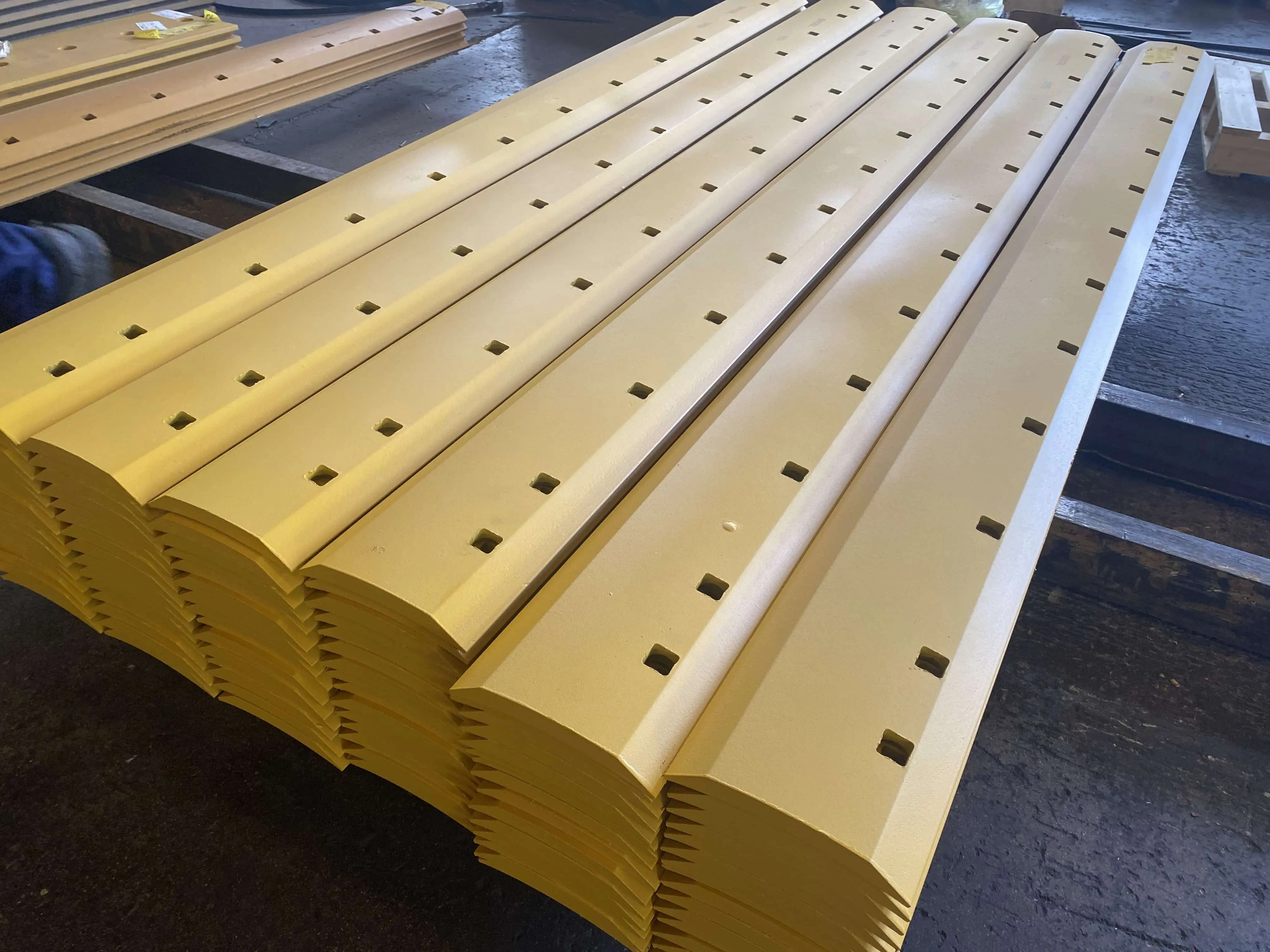

Ideal for Land Clearing: Robust 040100050 Grader Blades

When faced with challenging land clearing projects, construction professionals often struggle with inefficient equipment that breaks down under pressure, leading to costly delays and compromised project timelines. The Dozer Edge-Cutting 040100050 represents a breakthrough solution for these pain points, offering unmatched durability and precision in the most demanding earthmoving applications. This robust grader blade delivers exceptional performance in land clearing operations, ensuring your projects stay on schedule while maintaining the highest quality standards throughout every phase of construction work.

Advanced Engineering Behind Dozer Edge-Cutting 040100050 Performance

-

Superior Material Composition for Extreme Durability

The foundation of exceptional land clearing performance lies in the advanced metallurgy of the Dozer Edge-Cutting 040100050. Manufactured from premium high carbon steel and heat-treated boron steel, this grader blade undergoes rigorous thermal treatment processes that create an optimal balance between hardness and toughness. The wearpart technology employed by Shanghai SINOBL ensures that each blade maintains its cutting edge geometry even under the most abrasive conditions encountered in land clearing operations. The sophisticated material engineering process begins with carefully selected raw steel that meets stringent chemical composition requirements. Through controlled heating and cooling cycles, the molecular structure of the steel is refined to achieve maximum wear resistance while preserving the flexibility needed to withstand impact loads. This dual-phase heat treatment creates a hard working surface that resists abrasive wear while maintaining a tough core that prevents catastrophic failure under shock loading conditions commonly encountered during land clearing activities.

-

Precision Manufacturing Standards and Quality Control

Every Dozer Edge-Cutting 040100050 grader blade is manufactured under ISO 9001:2015 certified quality management systems that ensure consistent performance across every production run. The precision die forging process employed by wearpart specialists creates uniform dimensional accuracy that guarantees proper fit and optimal performance in various equipment configurations. Advanced metallurgical testing procedures verify the mechanical properties of each batch, ensuring that customers receive products that meet or exceed original equipment manufacturer specifications. The multi-stage inspection process includes dimensional verification, hardness testing, and visual inspection to identify any potential defects before products leave the manufacturing facility. This comprehensive quality control approach has resulted in Shanghai SINOBL's reputation as a leading supplier of reliable earthmoving components, with over 3,000 tons of inventory maintained to ensure rapid delivery to customers worldwide.

Optimized Design Features for Land Clearing Applications

-

Geometric Precision for Maximum Cutting Efficiency

The cutting edge geometry of the Dozer Edge-Cutting 040100050 has been optimized through extensive field testing and computer-aided design analysis to provide superior soil penetration and material flow characteristics. The carefully engineered profile reduces cutting forces while maintaining aggressive material removal capabilities, resulting in improved fuel efficiency and reduced operator fatigue during extended land clearing operations. The blade's dimensions of 19203.21982(3/4") provide optimal coverage for most grading applications while maintaining structural integrity under heavy loading conditions. This size configuration represents the ideal balance between productivity and maneuverability, allowing operators to clear significant areas efficiently while maintaining precise control over the grading process. The wearpart design philosophy emphasizes practical functionality over theoretical perfection, resulting in a product that delivers consistent results in real-world applications.

-

Enhanced Durability Through Advanced Heat Treatment

The heat treatment process applied to each Dozer Edge-Cutting 040100050 creates a hardened wear surface that significantly extends service life compared to conventional carbon steel alternatives. The boron steel composition enables deeper hardness penetration during heat treatment, creating a wear-resistant zone that maintains its properties throughout the blade's service life. This advanced metallurgical treatment ensures that the cutting edge remains sharp and effective even after extended use in abrasive soil conditions. The thermal processing parameters are carefully controlled to achieve optimal hardness gradients that provide maximum wear resistance at the cutting edge while maintaining toughness in the blade body. This graduated hardness profile prevents premature wear while avoiding brittleness that could lead to chipping or cracking under impact loading. The result is a grader blade that maintains its cutting performance throughout its extended service life, reducing replacement frequency and total cost of ownership.

Comprehensive Application Versatility and Performance Benefits

-

Multi-Environment Adaptability and Operational Excellence

The robust construction of the Dozer Edge-Cutting 040100050 makes it exceptionally well-suited for diverse land clearing applications, from forest clearing operations to urban development projects. The blade's ability to handle varying soil conditions, from soft loam to rocky terrain, demonstrates its versatility in addressing the complex challenges encountered in modern earthmoving operations. The wearpart technology ensures consistent performance regardless of environmental conditions or application requirements. Construction professionals rely on the Dozer Edge-Cutting 040100050 for projects ranging from highway construction to mining operations, where reliability and performance are critical to project success. The blade's proven track record in demanding applications has established its reputation as a preferred choice among equipment operators who require dependable performance in challenging conditions. The unit weight of 55.3KG provides optimal balance between cutting authority and equipment compatibility across various machine configurations.

-

Cost-Effectiveness and Operational Efficiency

Investment in high-quality Dozer Edge-Cutting 040100050 grader blades delivers significant long-term cost advantages through reduced replacement frequency and improved operational efficiency. The extended service life achieved through advanced materials and manufacturing processes translates to lower per-hour operating costs and reduced equipment downtime for blade changes. This economic advantage becomes particularly significant in high-volume operations where blade replacement costs can substantially impact project profitability. The improved cutting efficiency of the wearpart design also contributes to reduced fuel consumption and faster project completion times. By maintaining sharp cutting edges throughout their service life, these grader blades enable operators to complete land clearing tasks with fewer passes, reducing both time and fuel requirements. The combination of extended durability and enhanced performance makes the Dozer Edge-Cutting 040100050 an excellent investment for operations focused on maximizing productivity while controlling operating costs.

Global Manufacturing Excellence and Supply Chain Reliability

-

Shanghai SINOBL's Manufacturing Capabilities and Infrastructure

Shanghai SINOBL Precision Machinery Co., Ltd. operates from a state-of-the-art 55,944 square meter manufacturing facility that combines advanced production equipment with skilled craftsmanship to produce world-class earthmoving components. The company's production capacity of 2,500 tons per month for cutting edges and end bits ensures reliable supply availability for customers worldwide, while maintaining the quality standards that have established SINOBL as a trusted wearpart supplier in the global marketplace. The manufacturing infrastructure includes advanced forging equipment, precision machining centers, and comprehensive heat treatment facilities that enable complete vertical integration of the production process. This integrated approach ensures quality control at every manufacturing stage while providing the flexibility to customize products according to specific customer requirements. The Dozer Edge-Cutting 040100050 benefits from this comprehensive manufacturing capability, resulting in consistent quality and reliable delivery performance.

-

International Quality Standards and Certifications

The commitment to quality excellence is demonstrated through Shanghai SINOBL's adherence to internationally recognized quality standards, including ISO 9001:2015 certification for quality management systems. The CE certification ensures compliance with European Union safety and environmental regulations, while RoHS certification demonstrates the company's commitment to environmental responsibility through controlled use of hazardous substances in manufacturing processes. These certifications represent more than regulatory compliance; they reflect a fundamental commitment to quality that permeates every aspect of the manufacturing process. The rigorous documentation and process control requirements of these standards ensure that each Dozer Edge-Cutting 040100050 grader blade meets consistent quality specifications regardless of production date or batch. This quality assurance provides customers with confidence in product reliability and performance consistency across multiple orders.

Conclusion

The Dozer Edge-Cutting 040100050 grader blade represents the pinnacle of engineering excellence in land clearing equipment, combining advanced materials science with precision manufacturing to deliver unmatched performance and reliability in demanding earthmoving applications.

Cooperate with Shanghai Sinobl Precision Machinery Co., Ltd.

As a leading China Dozer Edge-Cutting 040100050 factory and China Dozer Edge-Cutting 040100050 supplier, Shanghai SINOBL offers comprehensive solutions for your earthmoving needs. Our position as a premier China Dozer Edge-Cutting 040100050 manufacturer enables us to provide China Dozer Edge-Cutting 040100050 wholesale pricing with Dozer Edge-Cutting 040100050 for sale at competitive Dozer Edge-Cutting 040100050 price points. Experience High Quality Dozer Edge-Cutting 040100050 backed by our expert support. Contact us at nancy@sunmach.com.cn for inquiries and pricing. Click to save this page for future reference when equipment needs arise.

FAQ

Q: What makes the 040100050 grader blade suitable for land clearing operations?

A: The heat-treated boron steel construction and optimized cutting geometry provide superior durability and efficiency in challenging land clearing conditions.

Q: How long does the 040100050 grader blade typically last in heavy-duty applications?

A: With proper maintenance, the blade offers extended service life due to its advanced metallurgy and heat treatment, significantly outperforming standard carbon steel alternatives.

Q: Can the 040100050 grader blade be customized for specific equipment requirements?

A: Yes, Shanghai SINOBL offers comprehensive OEM and ODM services including custom dimensions, branding, and material specifications to meet specific application needs.

Q: What quality certifications does Shanghai SINOBL maintain for the 040100050 grader blade?

A: The company maintains ISO 9001:2015, CE, and RoHS certifications, ensuring compliance with international quality and environmental standards.

References

1. "Heavy Equipment Wear Parts: Materials and Manufacturing Processes" by Industrial Metallurgy Institute, Advanced Materials Research Division

2. "Earthmoving Equipment Performance Optimization" by Construction Equipment Technical Association, Engineering Standards Committee

3. "Heat Treatment of Construction Steel Components" by Materials Science Foundation, Metallurgical Processing Research Group

4. "Quality Management Systems in Heavy Machinery Manufacturing" by International Manufacturing Standards Organization, Quality Assurance Division