Selecting the best Edge-Cutting Tool Asia requires understanding key performance factors that directly impact your operations. Precision engineering, durable materials, and cutting-edge technology play vital roles in ensuring longevity and efficiency. Whether working in construction, mining, or industrial metalworking, choosing the right edge-cutting tool helps optimize productivity and reduce downtime. It's essential to consider tool durability, cutting efficiency, and compatibility with your equipment to maximize performance. This guide will walk you through effective selection criteria and highlight top options to help you make an informed decision that aligns with global industry standards.

Why Focus on Dozer Edge-Cutting Tools?

Dozer edge-cutting tools are critical components for earth-moving and industrial cutting applications. They determine the effectiveness of precision cutting on materials such as soil, rock, or metal. Given the demanding nature of projects across Asia's diverse industries, tools must meet strict requirements in wear resistance and cutting performance. Optimizing tool choice enhances operational safety and efficiency. Thus, investing time in selecting the right equipment can influence overall project success and investment returns. Advanced materials like carbide and surface finishing technologies contribute significantly to tool longevity.

Selection Criteria for the Best Edge-Cutting Tool in Asia

Picking the perfect edge-cutting tool involves balancing multiple factors. Price-to-performance ratio plays a crucial role, ensuring cost-effectiveness without sacrificing quality. Local availability simplifies procurement and maintenance schedules. Customer reviews provide insight into real-world tool resilience and cutting precision. Key features to scrutinize include material composition, tool hardness, and adaptability to various dozer models. Compatibility with high-speed machining environments and adherence to industry standards are also important. Lastly, customization potential allows alignment with specific operational needs or branding requirements, securing better integration with your workflow.

Top 5 Edge-Cutting Tools in Asia

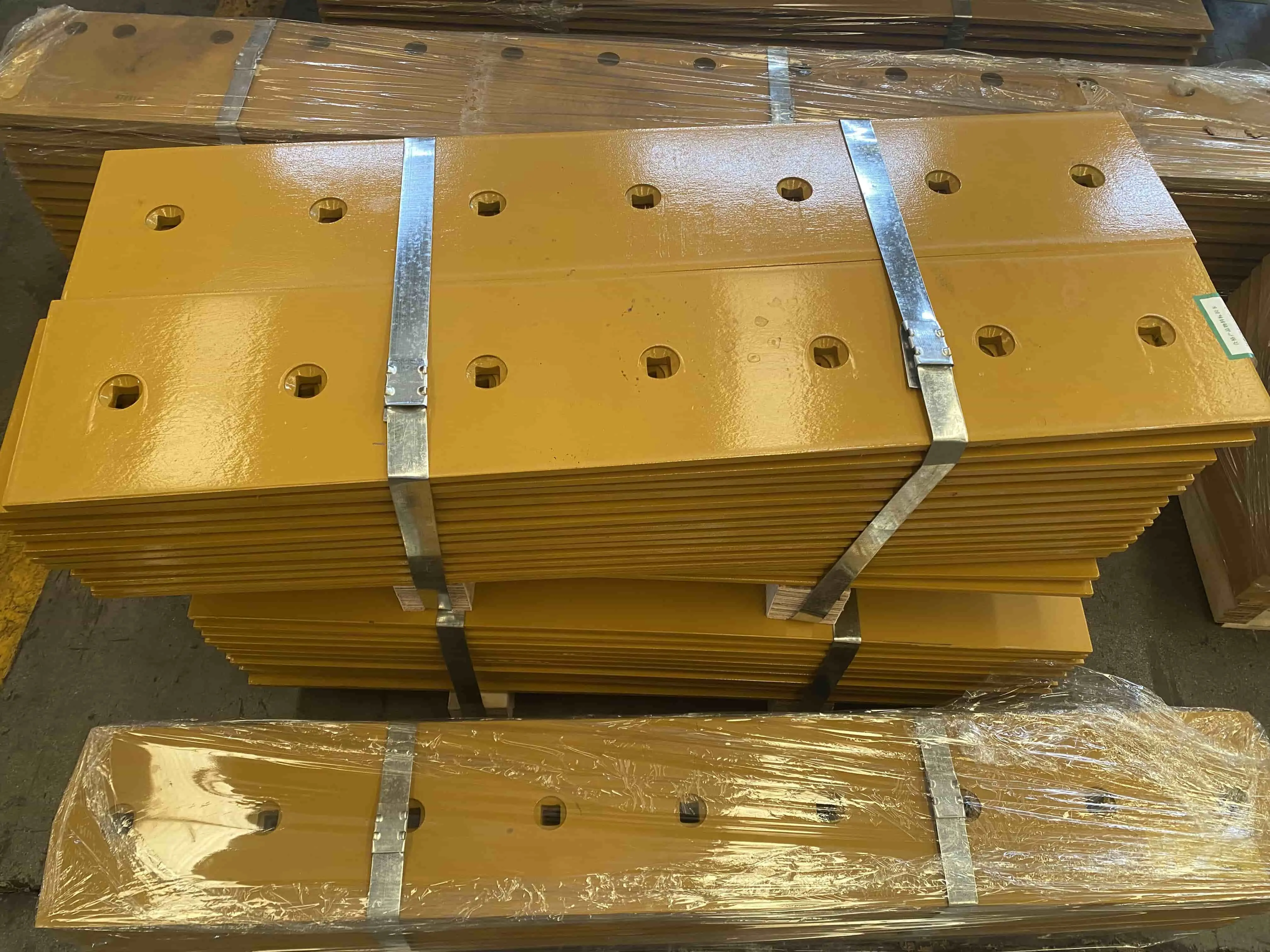

1. SINOBL Precision Carbide Edge Cutter

- Durability: Crafted with advanced carbide composite resistant to abrasive wear, extending service life.

- Cutting Efficiency: Engineered with optimized blade geometry to reduce material resistance, facilitating smoother cutting.

- Customization: Available in multiple dimensions and thicknesses tailored to diverse industrial needs.

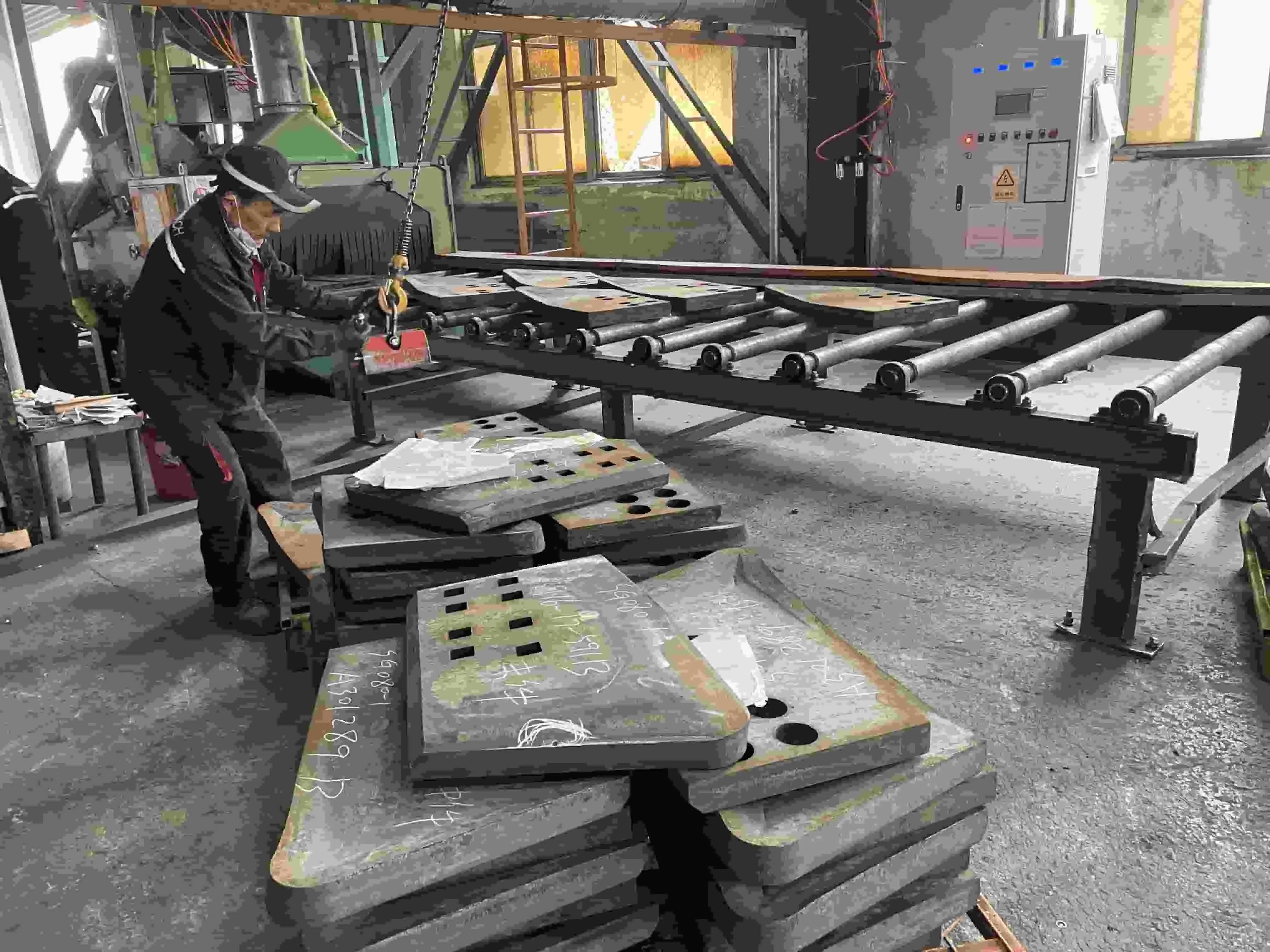

- Manufacturing Technology: Utilizes CNC machining ensuring tight tolerances and surface finishing excellence.

- Performance: Ideal for high-speed machining on metal and soil substrates, consistently maintaining edge sharpness.

- Customer Trust: Positive feedback highlights long-lasting reliability and reduced downtime.

The SINOBL Precision Carbide Edge Cutter stands out for its robust construction using high-grade materials and cutting-edge manufacturing processes. Its superior durability reduces frequent replacements, making it cost-effective for large-scale projects. The tool’s surface finishing enhances cutting efficiency and minimizes friction, contributing to clean cuts even in demanding terrains. Backed by extensive field experience, it adapts well across various earthmoving and industrial applications.

2. Astec Industrial Abrasive Edge Cutter

- Material Technology: Combines abrasive tool technology with micro-alloyed steel for enhanced wear resistance.

- Design Advantage: Serrated edge design that improves grip on material, minimizing slippage during operation.

- Local Support: Established distributor networks facilitate quick supply and technical assistance across Asia.

- Performance Optimization: Suitable for heavy-duty cutting tasks with stable edge retention under high stress.

- Adaptability: Compatible with multiple dozer brands requiring minimal modifications.

- Environmental Compliance: Meets regional eco-standards ensuring safer disposal and recycling.

Astec’s abrasive edge cutter excels in industrial cutting environments where tool durability under abrasive conditions is paramount. Its innovative design offers enhanced cutting stability, essential for maintaining production rhythm in heavy applications. Strong regional presence guarantees easy access to replacement parts and expertise. Additionally, its environmentally conscious manufacturing aligns with evolving regulations in Asian nations, further validating its suitability.

3. Kamura Carbide-Tipped Dozer Blade

- Cutting-Edge Technology: Carbide-tipped edges ensure superior hardness and abrasion resistance.

- Precision Engineering: CNC machining ensures accurate dimension control and flawless surface finishing.

- Tool Manufacturing Expertise: Long-standing industry experience yields reliable and innovative designs.

- Operational Efficiency: Minimizes energy consumption due to smooth and consistent cutting.

- Customization: Options for color coding and logo placement for easy identification.

- After-Sales Service: Comprehensive support including spare parts and technical consultation.

Kamura’s carbide-tipped blade incorporates the best of tool innovation and manufacturing solutions. Known for outstanding tool durability, its cutting edges maintain sharpness even under continuous high-speed machining. The brand’s commitment to performance optimization reflects in its product's ability to handle diverse material hardness with minimal wear. Its adaptability to particular job specifications through OEM & ODM options provides strategic advantages.

4. Triton High-Speed Milling Cutter Edge

- High-Speed Machining: Designed specifically for rapid operation environments, maintaining precision.

- Abrasive Resistance: Advanced materials resist microfractures during intense cutting.

- Manufacturing Solutions: Produced through automated CNC lines guaranteeing consistent quality.

- Industrial Cutting Applications: Versatile across multiple sectors including mining and construction.

- Tool Innovation: Incorporates micro-textured surfaces to reduce friction and heat buildup.

- Customer Feedback: Widely praised for consistent lifecycle performance and reliability.

Triton’s milling cutter edge suits projects where speed and precision are imperative. Utilizing advanced abrasive tools and surface finishing technology, the product minimizes wear and thermal strain during operations. This translates to longer tooling cycles, reduced maintenance, and significant cost savings. Its broad industrial compatibility supports users globally, addressing a range of cutting challenges with innovative solutions.

5. Orion Custom Tooling Edge Solutions

- Customization: Tailored dimensions, colors, and packaging to meet client-specific needs.

- Advanced Materials: Incorporates proprietary metal alloys for enhanced strength and flexibility.

- Performance Optimization: Tools designed to maximize cutting efficiency and wear resistance.

- OEM & ODM Services: Enables seamless integration into existing industrial setups.

- Industry Standards Compliant: Meets strict global guidelines ensuring safety and quality.

- Fast Lead Times: Streamlined production processes support rapid order fulfillment.

Orion’s custom tooling edge solutions empower users to define specifications that fit unique operational demands. Their engagement with advanced materials and cutting-edge technology generates tools that excel in cutting efficiency and tool durability. Agile manufacturing capacity accommodates various order scales, providing strategic flexibility. Commitment to industry standards further assures quality, making Orion a trusted partner for precision industrial cutting needs.

Market Characteristics and Global Preferences

Asia’s market for dozer edge-cutting tools reflects a blend of diverse industrial needs and stringent regulatory standards. Countries emphasize environmental sustainability and worker safety, catalyzing innovation in abrasive tools and metalworking solutions. Precision engineering and CNC machining are increasingly prioritized to meet demands for high-speed machining and minimal waste. Preferences trend toward manufacturers offering flexible OEM and ODM services, reflecting a global inclination toward customized solutions. Regionally, rapid infrastructure development fuels demand for durable cutting tools, while emerging nations seek cost-effective yet reliable options to optimize tool lifespan and performance.

Purchasing Recommendations and Considerations

When procuring edge-cutting tools, evaluate the balance between upfront cost and long-term value, focusing on tool innovation and material quality. Prioritize manufacturers with proven expertise and rigorous quality control to ensure adherence to industry standards. Seek products that offer customization options to tailor specifications, colors, or packaging, streamlining operational integration. Assess local support availability and lead times for maintenance minimization. Considering factors like cutting efficiency and tool durability helps reduce downtime and operational expenses. Trustworthy brands with documented performance records provide greater assurance, driving confident purchasing decisions.

Industry Trends and Summary

The future of dozer edge-cutting tools in Asia aligns with advancing manufacturing solutions and increased adoption of carbide and abrasive technologies. Digitalization in tool manufacturing and enhanced surface finishing techniques contribute to superior cutting performance and durability. Growing emphasis on sustainable materials and eco-compliant processes shapes product development. Custom tooling gains traction as a strategic asset, enabling operational precision and performance optimization. These trends collectively push the industry toward higher standards in safety, quality, and innovation.

Frequently Asked Questions

- What materials are best for durable dozer edge-cutting tools?

- Carbide and micro-alloyed steel are top materials due to their abrasion resistance and hardness.

- How important is CNC machining in edge-cutting tool manufacturing?

- CNC machining ensures precision, consistent quality, and optimal surface finishing, essential for performance.

- Can I customize edge-cutting tools to match my project needs?

- Yes, many manufacturers offer OEM and ODM services, including dimension, color, and branding customization.

- What factors affect the cutting efficiency of these tools?

- Blade geometry, material hardness, surface finishing, and tool wear resistance significantly influence efficiency.

- How do I ensure the tool complies with industry standards?

- Purchase from trusted manufacturers with rigorous quality control and certifications matching recognized standards.

Where to Buy Edge-Cutting Tool Asia?

Shanghai Sinobl Precision Machinery Co., Ltd. stands as a premier destination for high-quality Edge-Cutting Tool Asia solutions. Our products leverage cutting-edge technology, precision engineering, and advanced materials to deliver superior performance and reliability. We support global industries by offering flexible OEM & ODM services, customization options, and rapid delivery. For inquiries or detailed information, contact us at nancy@sunmach.com.cn. Explore our comprehensive product range and partnership opportunities at wearpart.com.

References

1. Lee, K. (2021). Advances in Carbide Tool Manufacturing in Asian Markets. Journal of Industrial Engineering.

2. Chen, M., & Zhao, W. (2020). CNC Machining and Tool Innovation in Earthmoving Applications. Precision Machinery Review.

3. Johnson, R. (2019). Performance Optimization of Industrial Cutting Tools in Construction Equipment. Global Manufacturing Insights.

4. Wang, L., & Singh, S. (2022). Sustainability and Regulatory Trends in Asian Tool Manufacturing. Environmental Standards Journal.

5. Garcia, H., et al. (2023). Custom Tooling and OEM Services: Enhancing Global Industrial Competitiveness. Manufacturing Solutions Quarterly.

6. Tanaka, Y. (2018). Cutting Efficiency and Durability in Metalworking Solutions. Asian Tool Engineering Conference Proceedings.