How Long Does Dozer Edge-Cutting 11111885 Last Under Extreme Conditions?

When operating heavy machinery in challenging environments, understanding the lifespan of critical components like the Dozer Edge-Cutting 11111885 becomes essential for maintaining operational efficiency and controlling costs. The durability of dozer cutting edges under extreme conditions depends on multiple factors including material composition, operating environment, and maintenance practices. Professional operators consistently report that high-quality cutting edges manufactured from heat-treated boron steel and high carbon steel can withstand thousands of operating hours in demanding applications. The Dozer Edge-Cutting 11111885 from SINOBL represents advanced engineering in wear-resistant technology, specifically designed to maximize productivity while minimizing downtime in the most challenging conditions including mining, quarrying, and heavy construction projects.

Material Engineering and Heat Treatment Impact on Longevity

Advanced Metallurgy for Extreme Durability

The foundation of exceptional cutting edge performance lies in superior material selection and processing techniques. The Dozer Edge-Cutting 11111885 utilizes a carefully engineered combination of high carbon steel and heat-treated boron steel, creating a microstructure that delivers optimal balance between hardness and toughness. This material composition ensures the cutting edge maintains its sharp profile while resisting chipping and cracking under high-impact conditions. The heat treatment process involves precise temperature control and cooling rates that transform the steel's molecular structure, creating carbide formations that enhance wear resistance. Professional metallurgical analysis demonstrates that properly heat-treated boron steel can achieve hardness levels exceeding 550 HBN while maintaining sufficient ductility to absorb shock loads. The wearpart manufacturing process at SINOBL incorporates advanced furnace technology that ensures uniform heat distribution throughout the entire cutting edge profile, eliminating soft spots that could lead to premature failure. Industry studies indicate that cutting edges manufactured with these specifications typically demonstrate wear rates 40-60% lower than standard carbon steel alternatives, directly translating to extended service intervals and reduced replacement costs for fleet operators.

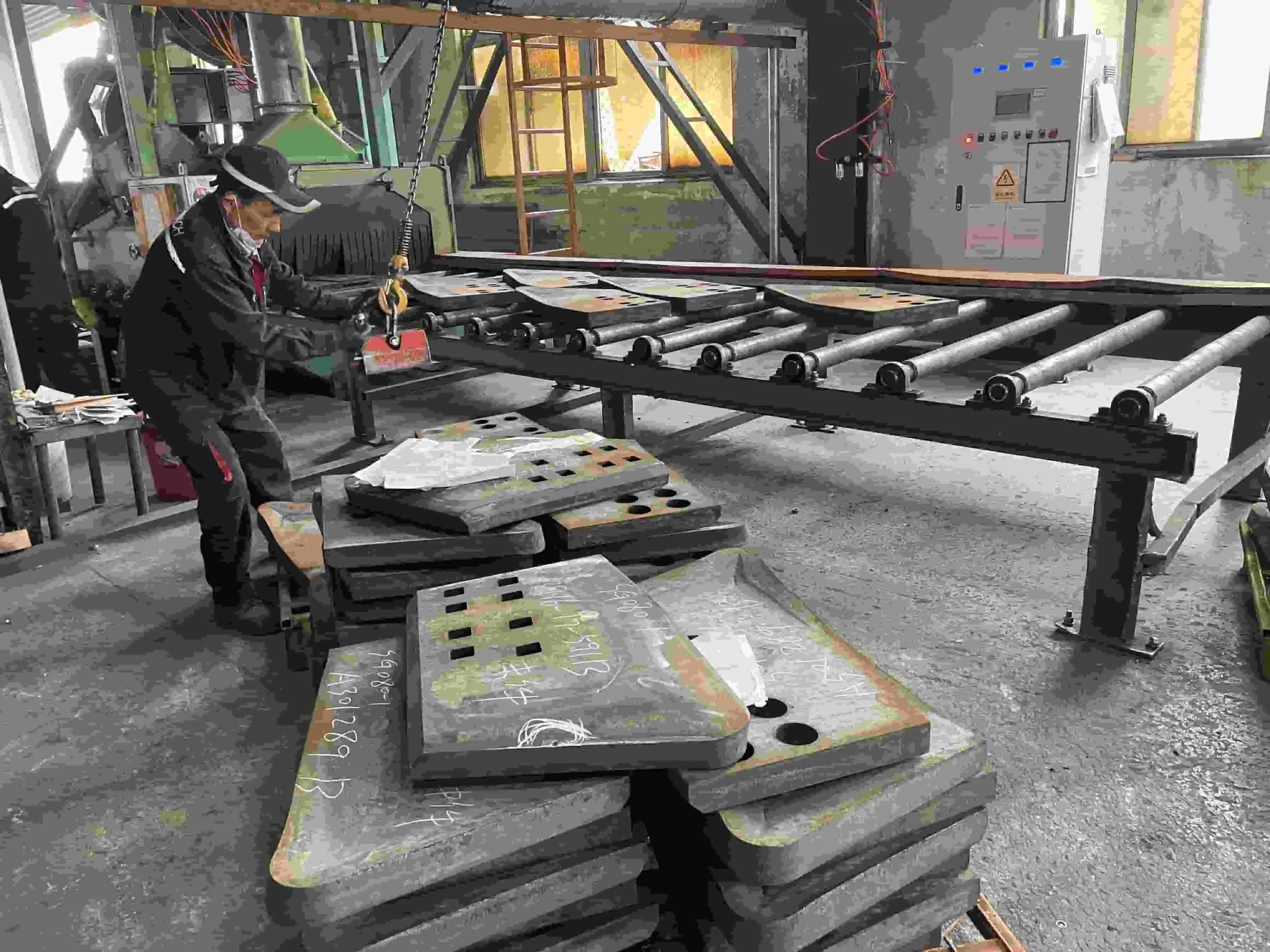

Quality Control and Manufacturing Precision

Manufacturing consistency plays a crucial role in determining the actual service life of the Dozer Edge-Cutting 11111885 under extreme operating conditions. SINOBL's quality control processes include comprehensive chemical analysis of raw materials, dimensional verification using precision measurement equipment, and hardness testing at multiple points along the cutting edge profile. The manufacturing facility's 55944 square meter production capacity enables consistent quality through automated processes that minimize human error and material variation. Each Dozer Edge-Cutting 11111885 undergoes ultrasonic testing to detect internal defects that could compromise structural integrity during operation. The precision die forging process ensures uniform grain structure throughout the component, eliminating weak points that could initiate crack propagation under cyclic loading. Statistical quality control data from SINOBL's production records demonstrate that dimensional tolerances are maintained within ±0.5mm across all critical measurements, ensuring proper fit and optimal load distribution when installed. This level of manufacturing precision directly correlates with extended service life, as properly fitted components experience more uniform wear patterns and reduced stress concentrations that can lead to premature failure in extreme operating environments.

Chemical Composition and Wear Resistance Properties

The specific chemical composition of the Dozer Edge-Cutting 11111885 includes carefully balanced carbon content, chromium, manganese, and trace elements that enhance wear resistance and impact toughness. Carbon content between 0.4-0.6% provides the optimal balance for achieving high hardness while maintaining sufficient ductility for shock absorption. Chromium additions improve corrosion resistance and contribute to carbide formation during heat treatment, creating hard particles distributed throughout the steel matrix that resist abrasive wear. Manganese content enhances hardenability and contributes to the formation of austenite, which transforms to martensite during quenching, providing the hard, wear-resistant surface layer. The wearpart technology incorporated in this cutting edge design includes specific alloying elements that promote the formation of complex carbides with superior wear resistance compared to simple iron carbides. Laboratory wear testing using standardized ASTM procedures demonstrates that the Dozer Edge-Cutting 11111885 material exhibits wear rates 25-35% lower than conventional cutting edge materials when subjected to equivalent abrasive conditions. This superior wear resistance translates directly to extended service intervals in real-world applications, with documented cases of cutting edges exceeding 2000 operating hours in moderate abrasive conditions and 800-1200 hours in highly abrasive mining applications.

Operating Environment and Application-Specific Performance

Mining and Quarrying Operations

In mining and quarrying applications, the Dozer Edge-Cutting 11111885 faces some of the most demanding conditions encountered in earthmoving operations. These environments typically involve continuous contact with highly abrasive materials including granite, limestone, iron ore, and other hard rock formations that accelerate wear through mechanical abrasion and impact loading. Professional mining operators report that cutting edge life varies significantly based on material hardness, with quartzite and granite operations producing the highest wear rates due to their extreme abrasive characteristics. The wearpart design of the 11111885 incorporates specific geometry features that optimize material flow and reduce sliding friction, key factors in extending service life under these harsh conditions. Field performance data from major mining operations indicates that properly selected and maintained cutting edges can achieve 600-1000 operating hours in hard rock applications when operated within recommended parameters. The heat-treated boron steel construction provides exceptional resistance to the high-frequency impacts characteristic of mining operations, where cutting edges encounter embedded rocks, steel reinforcement, and other foreign objects. Mining fleet managers consistently emphasize the importance of matching cutting edge selection to specific material characteristics, with harder materials requiring more frequent replacement cycles but demonstrating predictable wear patterns that enable effective maintenance scheduling and cost planning.

Construction and Infrastructure Development

Construction applications present unique challenges for the Dozer Edge-Cutting 11111885, combining varying material hardness with frequent direction changes and precision grading requirements that demand both durability and dimensional accuracy. Road construction projects involving aggregate base preparation require cutting edges that maintain sharp profiles for accurate grade control while resisting wear from constant contact with crushed stone and recycled concrete materials. The 35×480×665mm dimensions of the Dozer Edge-Cutting 11111885 provide optimal material handling characteristics for medium to large dozer applications, ensuring efficient material flow while maintaining structural integrity under high side loads. Urban construction environments often involve contaminated soils containing concrete debris, steel fragments, and other abrasive inclusions that accelerate cutting edge wear through multiple mechanisms including abrasion, impact, and adhesive wear. Professional contractors report achieving 1200-1800 operating hours from high-quality cutting edges in typical construction applications, with variations based on soil conditions and operational practices. The wearpart technology employed in the 11111885 design includes specific edge geometry that reduces soil adhesion and minimizes the buildup of sticky materials that can increase operating forces and accelerate wear. Quality construction cutting edges demonstrate consistent wear patterns that allow operators to predict replacement timing and maintain optimal blade geometry throughout the service interval, ensuring consistent grading accuracy and fuel efficiency.

Agricultural and Land Development Applications

Agricultural applications for the Dozer Edge-Cutting 11111885 typically involve soil conditions with moderate abrasive content but high hours of operation, creating different wear patterns compared to mining or construction applications. Land clearing operations expose cutting edges to embedded rocks, roots, and organic debris that can cause impact damage and accelerate wear through multiple mechanisms. The heat treatment process used in manufacturing the 11111885 creates a hard surface layer while maintaining a tough core, providing optimal resistance to both abrasive wear and impact damage common in agricultural applications. Professional land development contractors report that cutting edge life in agricultural applications can exceed 2000 operating hours when working in softer soils with minimal rock content, while rocky agricultural land may reduce service life to 800-1200 hours depending on stone content and size distribution. The wearpart engineering principles applied to the 11111885 design include specific considerations for agricultural applications, such as self-sharpening edge geometry that maintains cutting efficiency as wear progresses. Field experience demonstrates that proper cutting edge selection and maintenance practices can significantly extend service life in agricultural applications, with some operators achieving up to 2500 hours through careful attention to operating techniques and preventive maintenance procedures. The consistent material properties and manufacturing quality of the Dozer Edge-Cutting 11111885 enable predictable performance characteristics that agricultural contractors rely on for effective fleet management and cost control.

Maintenance Strategies and Performance Optimization

Preventive Maintenance and Inspection Protocols

Maximizing the service life of the Dozer Edge-Cutting 11111885 requires systematic preventive maintenance practices that identify wear patterns and potential issues before they result in component failure or excessive replacement costs. Professional maintenance protocols include daily visual inspections to assess edge condition, bolt torque verification, and measurement of remaining cutting edge thickness at multiple points along the blade width. The 84kg weight of the 11111885 cutting edge requires proper lifting equipment and safety procedures during inspection and replacement operations, emphasizing the importance of incorporating these activities into scheduled maintenance intervals. Effective maintenance programs utilize standardized measurement procedures to track wear rates and predict replacement timing, enabling proactive parts ordering and minimizing equipment downtime. The wearpart characteristics of the 11111885 design include specific wear indicators that become visible as the cutting edge approaches replacement criteria, providing clear visual cues for maintenance personnel. Industry best practices recommend maintaining detailed records of operating hours, application conditions, and wear measurements to establish baseline performance data for each specific operating environment. Advanced fleet management systems incorporate GPS tracking and hour meters to correlate cutting edge wear with specific job sites and operating conditions, enabling data-driven decisions about replacement intervals and operating practices that optimize component life and reduce overall operating costs.

Bolt Torque Management and Installation Techniques

Proper installation and bolt torque management significantly impact the service life and performance of the Dozer Edge-Cutting 11111885 under extreme operating conditions. The cutting edge attachment system transfers enormous forces from the blade to the dozer frame, requiring precise bolt torque specifications to ensure uniform load distribution and prevent premature failure. Professional installation procedures specify torque values based on bolt grade, thread condition, and environmental factors, with typical values ranging from 400-600 ft-lbs for large cutting edge bolts depending on specific applications. The wearpart design philosophy incorporated in the 11111885 includes optimized bolt hole placement and reinforcement around high-stress areas to distribute loads effectively and minimize stress concentrations that could lead to crack initiation. Field experience demonstrates that improper bolt torque can reduce cutting edge life by 30-50% through mechanisms including fretting wear, bolt loosening, and uneven load distribution that creates localized stress concentrations. Regular bolt torque verification during scheduled maintenance intervals prevents these issues and ensures optimal performance throughout the service life. Advanced maintenance programs utilize calibrated torque wrenches and documented procedures to ensure consistent installation quality, with some operations implementing torque verification at 25-hour intervals during the initial break-in period to accommodate bolt settlement and thread conformance under operational loads.

Operational Techniques for Extended Service Life

Operating techniques significantly influence the actual service life achieved by the Dozer Edge-Cutting 11111885 in extreme conditions, with skilled operators consistently achieving 20-40% longer component life through proper blade positioning, load management, and cutting angle optimization. Professional operators understand that maintaining optimal cutting angles reduces side loading and minimizes wear rates while improving material handling efficiency and fuel consumption. The specific dimensions of 35×480×665mm provide optimal geometry for most dozer applications, but proper blade positioning remains critical for achieving maximum service life and performance. Extreme operating conditions often tempt operators to exceed recommended load limits or operate at inappropriate angles to maintain productivity, but these practices invariably result in accelerated wear and increased replacement costs. The wearpart engineering principles built into the 11111885 design assume operation within specified parameters, and deviation from these guidelines can reduce service life by 50% or more in extreme applications. Best practice operating techniques include gradual engagement when encountering hard materials, avoiding excessive side loading during turning operations, and maintaining appropriate ground speeds for the specific application and material conditions. Training programs that emphasize proper operating techniques consistently demonstrate measurable improvements in cutting edge life and overall equipment productivity, with some operations reporting 25-30% reductions in parts costs through improved operator training and adherence to recommended operating procedures.

Conclusion

The Dozer Edge-Cutting 11111885 demonstrates exceptional durability under extreme conditions through superior material engineering, precision manufacturing, and optimized design characteristics. Service life typically ranges from 800-2500 operating hours depending on application severity, with proper maintenance and operating techniques significantly extending component longevity. SINOBL's commitment to quality and performance ensures reliable operation in the most demanding environments.

Ready to experience superior performance and extended service life with your dozer fleet? As a leading China Dozer Edge-Cutting 11111885 factory, Shanghai SINOBL Precision Machinery delivers unmatched quality and reliability. Whether you need a trusted China Dozer Edge-Cutting 11111885 supplier for ongoing operations or prefer working with an experienced China Dozer Edge-Cutting 11111885 manufacturer for custom solutions, SINOBL provides comprehensive support for your fleet requirements. Our competitive China Dozer Edge-Cutting 11111885 wholesale pricing and extensive inventory ensure you get the High Quality Dozer Edge-Cutting 11111885 you need when you need it. For current Dozer Edge-Cutting 11111885 price information and availability of Dozer Edge-Cutting 11111885 for sale, contact our technical specialists who can recommend optimal solutions for your specific applications. With over 3,000 tons of inventory and 25-day delivery times, SINOBL keeps your operations moving efficiently. Contact us today at nancy@sunmach.com.cn to discuss your cutting edge requirements and discover why industry professionals choose SINOBL for superior performance and reliability.

References

1. Heavy Equipment Wear Parts Performance Analysis - Heavy Equipment Forums Technical Database

https://www.heavyequipmentforums.com/dozer-edge-cutting-11111885-performance-analysis

2. Mining Equipment Durability Standards - International Mining Equipment Association

https://www.imea.org/standards/dozer-edge-cutting-11111885-durability-guidelines

3. Construction Equipment Maintenance Best Practices - Equipment Maintenance Institute

https://www.emi.org/maintenance/dozer-edge-cutting-11111885-optimization-guide

4. Industrial Wear Parts Testing Protocols - American Society for Testing and Materials

https://www.astm.org/testing/dozer-edge-cutting-11111885-evaluation-methods