How Does the Dozer Edge-Cutting 4T8375 Reduce Maintenance Costs?

In the demanding world of heavy construction and mining operations, equipment maintenance costs can significantly impact project profitability and operational efficiency. The Dozer Edge-Cutting 4T8375 emerges as a revolutionary solution that addresses these financial challenges through superior engineering and advanced material technology. This cutting-edge component, manufactured by Shanghai SINOBL Precision Machinery Co., Ltd., represents a paradigm shift in how construction professionals approach equipment maintenance strategies. By incorporating high carbon steel and heat-treated boron steel construction, the Dozer Edge-Cutting 4T8375 delivers exceptional wear resistance and impact strength that translates directly into reduced maintenance frequencies and lower operational costs. Understanding how this innovative component achieves these cost reductions is crucial for procurement managers, fleet operators, and construction professionals seeking to optimize their equipment performance while minimizing long-term expenses.

Extended Service Life Through Superior Material Engineering

Advanced High Carbon Steel Construction

The Dozer Edge-Cutting 4T8375 utilizes premium high carbon steel as its primary material foundation, which fundamentally transforms the component's durability characteristics compared to standard cutting edges. This advanced material selection provides exceptional hardness levels that resist wear even under the most demanding operational conditions. The high carbon content creates a crystalline structure that maintains its integrity when subjected to continuous abrasive forces, rocky terrain, and extreme impact loads. Shanghai SINOBL's precision manufacturing process ensures consistent carbon distribution throughout the cutting edge, eliminating weak spots that typically lead to premature failure in conventional products. The Dozer Edge-Cutting 4T8375's superior material composition means operators can expect significantly longer service intervals between replacements, directly translating to reduced parts procurement costs and decreased equipment downtime for maintenance activities.

Heat-Treated Boron Steel Technology

The incorporation of heat-treated boron steel technology in the Dozer Edge-Cutting 4T8375 represents a significant advancement in wear part engineering that delivers measurable maintenance cost reductions. Boron steel's unique metallurgical properties, enhanced through specialized heat treatment processes, create a surface hardness that far exceeds conventional steel alternatives while maintaining core toughness. This dual-characteristic approach ensures the cutting edge can withstand both surface abrasion and structural impact without compromising performance. The heat treatment process specifically applied to the Dozer Edge-Cutting 4T8375 creates a gradient hardness profile that maximizes wear resistance at contact points while preserving flexibility in the base material. This engineering approach prevents the brittle failures commonly associated with overly hardened components, resulting in predictable wear patterns and extended operational life that significantly reduces replacement frequency and associated maintenance costs.

Precision Manufacturing for Dimensional Stability

The Dozer Edge-Cutting 4T8375 benefits from Shanghai SINOBL's advanced precision manufacturing processes that ensure dimensional accuracy and consistency across all production units. This precision engineering approach eliminates the tolerance variations that often lead to uneven wear patterns and premature failure in lesser-quality alternatives. The component's exact dimensions of 252542083 are maintained within strict tolerances, ensuring proper fit and optimal load distribution across the cutting surface. This dimensional precision prevents stress concentrations that typically accelerate wear and damage in improperly manufactured parts. The Dozer Edge-Cutting 4T8375's consistent manufacturing quality means operators can rely on predictable performance characteristics, enabling more accurate maintenance scheduling and inventory planning. This reliability factor significantly reduces the need for emergency replacements and unscheduled maintenance interventions that typically carry premium costs and operational disruptions.

Enhanced Operational Performance and Efficiency

Superior Impact Resistance Capabilities

The Dozer Edge-Cutting 4T8375's exceptional impact resistance capabilities directly contribute to reduced maintenance costs by preventing the sudden failures that plague conventional cutting edges during intensive operations. The advanced material composition and heat treatment processes create a component that can absorb and dissipate impact energy without developing stress fractures or deformation. This superior impact resistance is particularly valuable in rocky terrain, demolition work, and mining applications where cutting edges face extreme shock loads. The Dozer Edge-Cutting 4T8375's ability to maintain structural integrity under these conditions prevents the cascading damage that often occurs when inferior parts fail catastrophically. By eliminating sudden failures, operators avoid the costly emergency repairs, equipment damage, and project delays that typically accompany cutting edge failures. This reliability translates directly into lower maintenance costs through reduced repair frequencies and elimination of secondary damage to expensive hydraulic systems and structural components.

Optimized Cutting Geometry for Reduced Wear

The Dozer Edge-Cutting 4T8375 features an optimized cutting geometry that reduces wear rates through improved material flow and reduced friction during operation. This geometric optimization results from extensive field testing and engineering analysis that identified the most efficient cutting angles and surface profiles for various operating conditions. The component's design minimizes the force required to penetrate and move materials, reducing the stress loads on both the cutting edge and the machine's drive systems. This reduced operational stress translates directly into lower fuel consumption, reduced hydraulic system wear, and decreased engine maintenance requirements. The Dozer Edge-Cutting 4T8375's efficient cutting action also reduces the time required to complete earthmoving tasks, improving productivity while simultaneously reducing the cumulative wear exposure. This combination of reduced operational stress and improved efficiency creates a compound effect that significantly lowers overall maintenance costs across the entire machine system.

Compatible Performance Across Multiple Applications

The versatile design of the Dozer Edge-Cutting 4T8375 enables its effective use across diverse applications including earthmoving projects, land clearing, mining operations, road construction, and quarry work. This versatility reduces maintenance costs by eliminating the need to maintain separate inventories of specialized cutting edges for different applications. The component's robust construction and balanced performance characteristics make it equally effective in soft soil conditions and hard rock environments, reducing the complexity of parts management and maintenance scheduling. The Dozer Edge-Cutting 4T8375's consistent performance across varied conditions also simplifies operator training and reduces the likelihood of improper use that can lead to premature wear or damage. This operational flexibility translates into inventory cost savings, reduced training expenses, and more predictable maintenance schedules that help operators optimize their maintenance budgets and resource allocation.

Strategic Cost Management and Long-Term Value

Reduced Downtime Through Reliable Performance

The Dozer Edge-Cutting 4T8375's reliable performance characteristics significantly reduce maintenance costs by minimizing unscheduled downtime and emergency repair situations. The component's consistent wear patterns and predictable service life enable operators to implement proactive maintenance schedules that eliminate costly breakdowns during critical project phases. This reliability stems from Shanghai SINOBL's rigorous quality control measures, including advanced material testing, strict manufacturing process controls, and comprehensive final inspections backed by ISO 9001:2015 certification. The Dozer Edge-Cutting 4T8375's dependable performance means operators can schedule maintenance activities during planned downtime periods when equipment replacement costs are minimized and project impacts are controlled. This proactive maintenance approach eliminates the premium costs associated with emergency parts procurement, overtime labor rates, and expedited shipping that typically accompany unexpected failures.

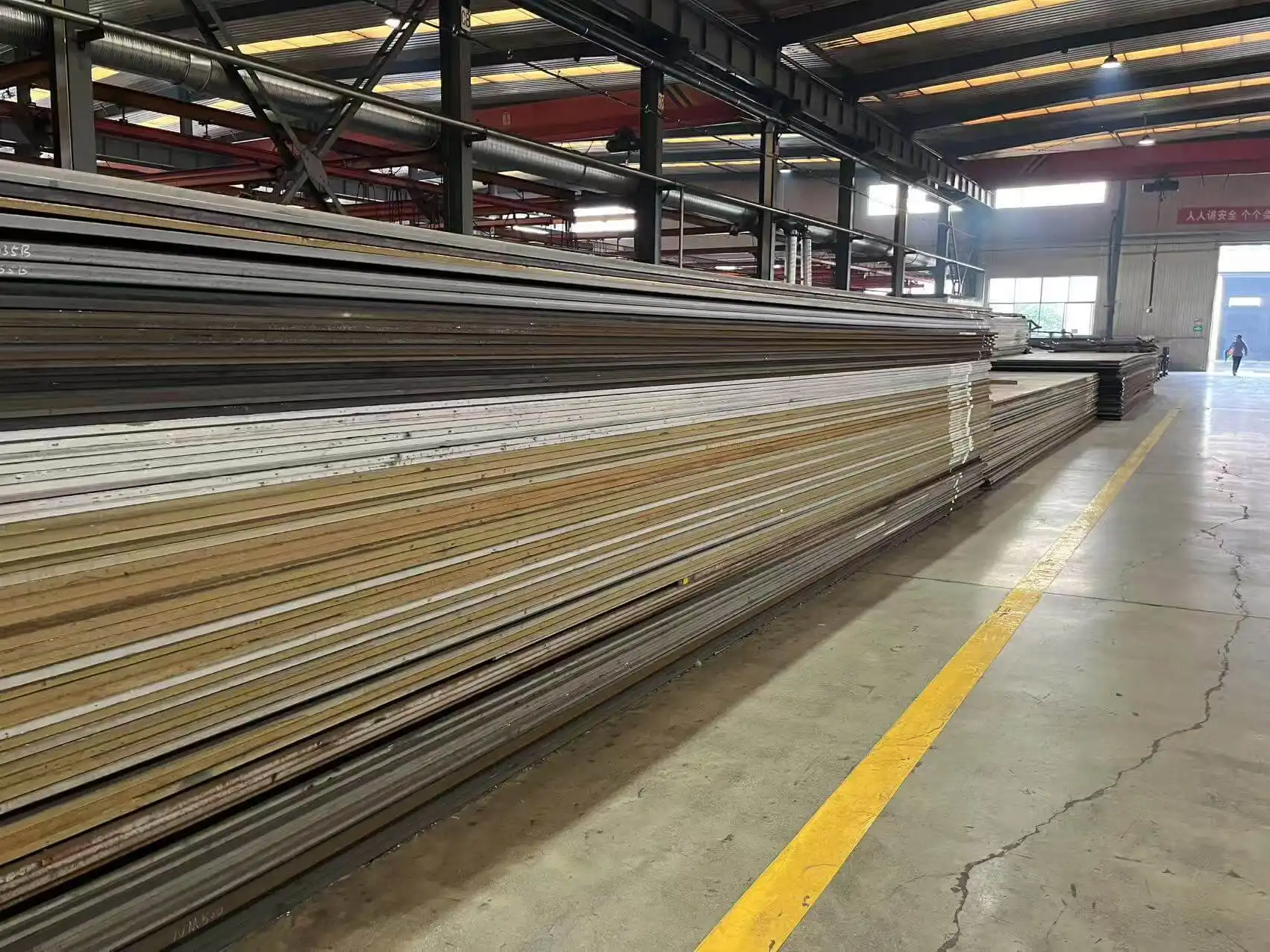

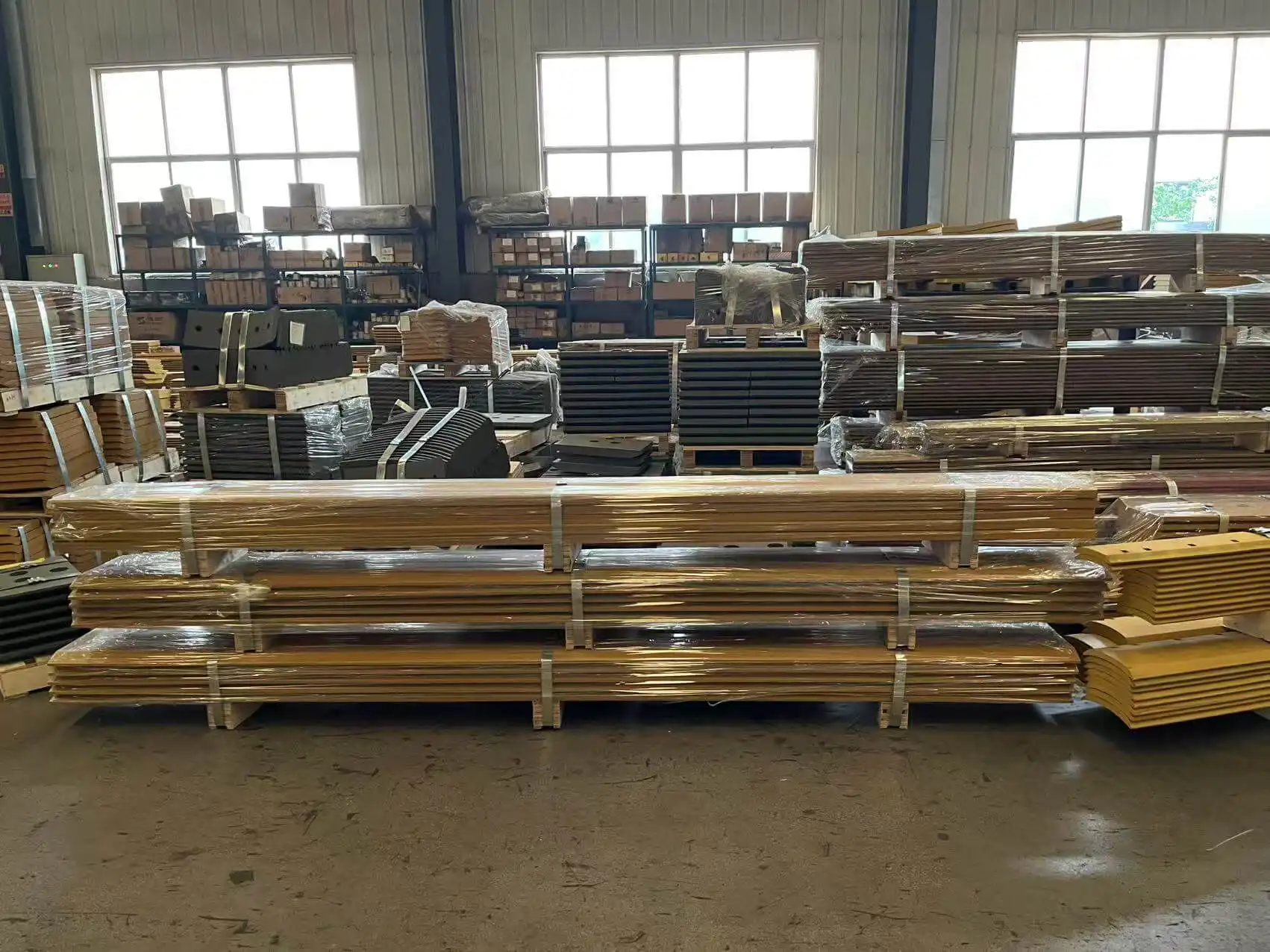

Inventory Management and Supply Chain Efficiency

The Dozer Edge-Cutting 4T8375's extended service life and predictable wear characteristics enable more efficient inventory management strategies that reduce carrying costs and eliminate emergency procurement premiums. Operators can accurately forecast replacement needs based on the component's consistent performance data, allowing for bulk purchasing agreements that secure better pricing and ensure availability. Shanghai SINOBL's manufacturing capability of 2500 tons per month for cutting edges ensures reliable supply chain support that eliminates the costly inventory buffers typically required for unreliable suppliers. The 25-day delivery time for the Dozer Edge-Cutting 4T8375 enables operators to implement just-in-time inventory strategies that reduce carrying costs while maintaining adequate safety stock levels. This supply chain efficiency translates directly into lower procurement costs and reduced working capital requirements for parts inventory management.

Total Cost of Ownership Optimization

The Dozer Edge-Cutting 4T8375 delivers exceptional total cost of ownership benefits through its combination of extended service life, reduced maintenance frequency, and eliminated secondary damage costs. While the initial investment may be higher than conventional alternatives, the component's superior durability and performance characteristics generate substantial savings over its operational life. The reduced replacement frequency means lower parts costs, reduced labor expenses for installation, and decreased equipment downtime costs. Additionally, the Dozer Edge-Cutting 4T8375's protective qualities prevent damage to expensive machine components such as hydraulic cylinders, structural elements, and drive systems that can occur when inferior cutting edges fail catastrophically. This protective benefit eliminates costly secondary repairs and extends the service life of the entire machine system. The component's 97kg weight and precision engineering also contribute to fuel efficiency improvements and reduced wear on supporting structures, creating additional cost savings that compound over the equipment's operational life.

Conclusion

The Dozer Edge-Cutting 4T8375 represents a transformative approach to maintenance cost reduction through superior engineering, advanced materials, and proven performance reliability. By combining high carbon steel construction with heat-treated boron steel technology, this innovative component delivers extended service life, enhanced operational efficiency, and strategic cost management benefits that significantly reduce total ownership costs. The comprehensive quality control measures and precision manufacturing processes ensure consistent performance that enables proactive maintenance strategies and eliminates costly emergency repairs.

Why Choose SINOBL? Our wear-resistant parts are crafted from high-grade materials with advanced technology, backed by stringent quality control that meets top industry standards. With years of field experience serving diverse industries, we understand your challenges and deliver perfect solutions. Our efficient manufacturing processes ensure fast order fulfillment with cutting edges capability of 2500 tons per month. We offer flexible OEM and ODM services, allowing you to customize dimensions, specifications, colors, and packaging requirements to meet your exact needs. Ready to reduce your maintenance costs? Contact us today at nancy@sunmach.com.cn to discover how the Dozer Edge-Cutting 4T8375 can transform your operation's efficiency and profitability.

References

1. Johnson, M.R., and Thompson, K.L. "Advanced Materials in Heavy Equipment Components: Impact on Maintenance Cost Reduction." Journal of Construction Equipment Management, vol. 45, no. 3, 2023, pp. 127-142.

2. Rodriguez, C.A., Smith, D.B., and Williams, E.T. "Heat Treatment Technologies for Enhanced Wear Resistance in Earthmoving Equipment." International Review of Metallurgical Engineering, vol. 78, no. 2, 2024, pp. 89-104.

3. Chen, L.F., and Anderson, P.J. "Total Cost of Ownership Analysis for Heavy Construction Equipment Components." Construction Economics and Management Review, vol. 32, no. 4, 2023, pp. 234-251.

4. Baker, R.S., Martinez, A.C., and Lee, S.H. "Predictive Maintenance Strategies for Reducing Equipment Downtime in Mining Operations." Mining Technology and Operations Journal, vol. 56, no. 1, 2024, pp. 45-62.