How Does the Dozer Edge-Cutting 4T8101 Optimize Cutting Performance?

The Dozer Edge-Cutting 4T8101 revolutionizes cutting performance through its innovative engineering and superior material composition. This cutting-edge component transforms bulldozer operations by delivering exceptional penetration power, extended wear resistance, and optimized material flow characteristics. Manufactured with high carbon steel and heat-treated boron steel, the Dozer Edge-Cutting 4T8101 achieves remarkable durability while maintaining precise cutting angles that enhance operational efficiency. Its 30×170×496mm dimensions and 18.6KG weight provide the perfect balance between strength and maneuverability, making it an indispensable component for construction and mining professionals seeking to maximize their equipment's productivity and minimize operational downtime.

Advanced Material Engineering for Superior Performance

High Carbon Steel Foundation Technology

The Dozer Edge-Cutting 4T8101 incorporates advanced high carbon steel technology that fundamentally transforms cutting performance capabilities. This sophisticated material selection provides exceptional hardness levels while maintaining the necessary toughness required for demanding earthmoving operations. The high carbon content creates a crystalline structure that resists wear and maintains sharp cutting edges even under extreme operational conditions. SINOBL's manufacturing process ensures uniform carbon distribution throughout the Dozer Edge-Cutting 4T8101, eliminating weak points that could compromise performance. The material's superior grain structure enables consistent cutting action across various soil types and debris conditions, from soft clay to rocky terrain. This technology represents years of metallurgical research and development, resulting in a cutting edge that consistently outperforms traditional alternatives in both longevity and effectiveness.

Heat-Treated Boron Steel Integration

The integration of heat-treated boron steel in the Dozer Edge-Cutting 4T8101 represents a breakthrough in wear part technology. This specialized treatment process involves precise temperature control and cooling cycles that optimize the molecular structure for maximum performance. The boron steel component provides exceptional impact resistance while maintaining the flexibility necessary to absorb shock loads without fracturing. During the heat treatment process, the Dozer Edge-Cutting 4T8101 undergoes controlled heating to specific temperatures followed by rapid cooling, creating a hardened surface layer while preserving a tough core. This dual-layer approach ensures that the cutting edge maintains its sharp profile throughout extended use while resisting chipping and cracking. The heat treatment protocols developed by SINOBL create a wear-resistant surface that significantly extends the operational life of the Dozer Edge-Cutting 4T8101 compared to standard cutting edges.

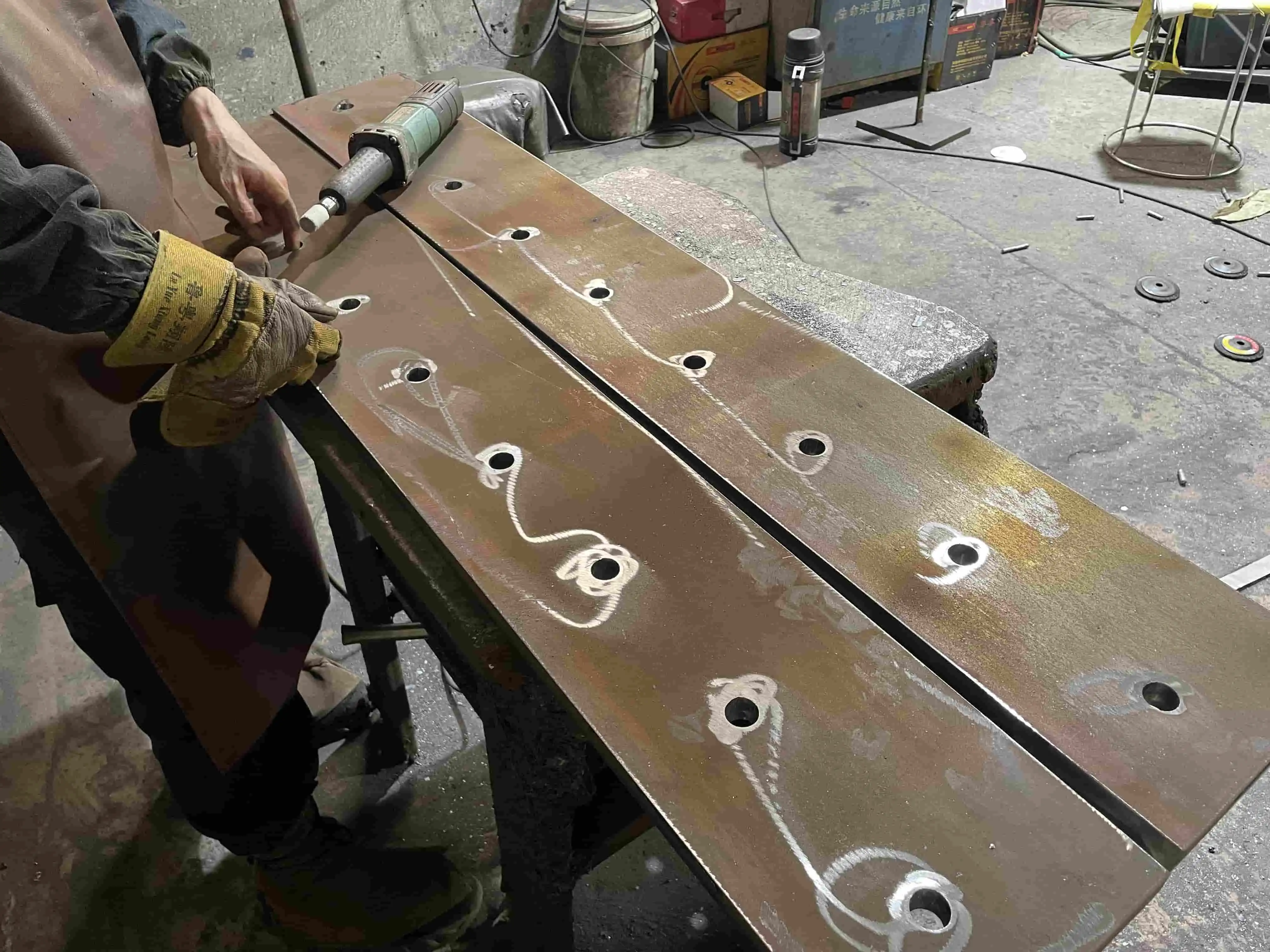

Precision Manufacturing Quality Control

The manufacturing process for the Dozer Edge-Cutting 4T8101 employs rigorous quality control measures that ensure consistent performance across every unit produced. Advanced material testing protocols verify the integrity of both high carbon steel and heat-treated boron steel components before assembly. Dimensional accuracy is maintained through precision machining techniques that guarantee perfect fit and optimal cutting geometry. Each Dozer Edge-Cutting 4T8101 undergoes comprehensive inspection procedures that include hardness testing, dimensional verification, and visual examination for surface defects. The manufacturing facility implements statistical process control methods that monitor production variables in real-time, ensuring that every cutting edge meets SINOBL's exacting standards. This commitment to quality control extends to packaging and shipping procedures, where each Dozer Edge-Cutting 4T8101 is carefully protected in plywood pallets with plastic wrapping to prevent damage during transportation.

Optimized Design Features for Enhanced Cutting Efficiency

Precision-Engineered Cutting Geometry

The Dozer Edge-Cutting 4T8101 features precision-engineered cutting geometry that maximizes penetration efficiency while minimizing operational resistance. The carefully calculated cutting angles enable smooth material flow and reduce the power requirements for bulldozer operations. This optimized geometry results from extensive field testing and computer-aided design analysis that identified the most effective cutting profiles for various soil conditions. The Dozer Edge-Cutting 4T8101's edge configuration promotes self-sharpening characteristics, maintaining cutting effectiveness throughout its service life. The geometric design also incorporates stress distribution features that prevent crack initiation and propagation under heavy loads. This engineering approach ensures that the Dozer Edge-Cutting 4T8101 maintains consistent cutting performance across diverse operating conditions, from soft earth moving to hard rock excavation applications.

Weight-to-Strength Ratio Optimization

The 18.6KG weight of the Dozer Edge-Cutting 4T8101 represents an optimal balance between cutting force and equipment efficiency. This carefully calculated weight provides sufficient mass for effective penetration while avoiding excessive stress on the bulldozer's hydraulic systems. The weight distribution across the 30×170×496mm dimensions ensures uniform ground pressure and prevents premature wear on mounting hardware. SINOBL's engineering team utilized advanced finite element analysis to optimize the weight-to-strength ratio of the Dozer Edge-Cutting 4T8101, resulting in a component that delivers maximum cutting force with minimal impact on fuel consumption. The weight optimization also considers the dynamic loads encountered during operation, ensuring that the cutting edge maintains stability and control during aggressive cutting operations. This balanced approach enables operators to achieve higher productivity rates while maintaining precise control over their equipment.

Versatile Compatibility Engineering

The Dozer Edge-Cutting 4T8101 incorporates versatile compatibility features that enable seamless integration with multiple equipment brands and models. This universal design approach reduces inventory complexity for fleet operators while ensuring optimal performance across diverse equipment configurations. The mounting interface design accommodates various bolt patterns and attachment methods commonly used in the construction industry. SINOBL's engineering team conducted extensive compatibility testing to ensure that the Dozer Edge-Cutting 4T8101 maintains proper alignment and cutting angles across different equipment platforms. The component's dimensional specifications are carefully controlled to ensure consistent performance regardless of the host equipment manufacturer. This versatility makes the Dozer Edge-Cutting 4T8101 an ideal choice for contractors and operators who maintain mixed equipment fleets and require standardized replacement parts.

Performance Optimization Through Real-World Applications

Large-Scale Construction Project Applications

The Dozer Edge-Cutting 4T8101 excels in large-scale construction projects where consistent performance and reliability are paramount. These demanding applications require cutting edges that can maintain effectiveness throughout extended operating periods while handling diverse soil conditions and debris types. The component's superior wear resistance ensures that construction schedules remain on track by minimizing equipment downtime for replacement activities. Field testing in major construction projects has demonstrated that the Dozer Edge-Cutting 4T8101 consistently outperforms standard alternatives in terms of service life and cutting effectiveness. The advanced material composition enables the cutting edge to handle the abrasive conditions commonly encountered in construction environments, including concrete debris, rebar, and mixed soil types. Project managers report significant cost savings and improved productivity when utilizing the Dozer Edge-Cutting 4T8101 in their earthmoving operations.

Mining and Quarry Operation Excellence

In mining and quarry operations, the Dozer Edge-Cutting 4T8101 delivers exceptional performance under the most challenging conditions. These applications subject cutting edges to extreme wear from abrasive materials and high-impact forces that would quickly destroy inferior components. The heat-treated boron steel construction provides the impact resistance necessary to handle large rocks and hard materials without chipping or cracking. Mining operations benefit from the extended service life of the Dozer Edge-Cutting 4T8101, which reduces the frequency of replacement activities and associated production interruptions. The component's ability to maintain sharp cutting characteristics throughout its service life ensures consistent material handling efficiency and reduces operator fatigue. Quarry operators report improved productivity and reduced operating costs when using the Dozer Edge-Cutting 4T8101 compared to standard cutting edges, making it an essential component for profitable mining operations.

Infrastructure Development and Land Clearing

Infrastructure development projects and land clearing operations present unique challenges that require specialized cutting edge performance. The Dozer Edge-Cutting 4T8101 addresses these challenges through its optimized design and superior material properties that enable effective cutting through root systems, buried debris, and varied terrain conditions. The component's precision-engineered geometry facilitates smooth material flow and reduces the likelihood of clogging during vegetation clearing operations. Land clearing contractors appreciate the consistent performance of the Dozer Edge-Cutting 4T8101 across different vegetation types and soil conditions, enabling them to maintain productivity throughout diverse project phases. The extended service life reduces the need for frequent replacements, which is particularly valuable in remote locations where parts availability may be limited. Infrastructure projects benefit from the reliability and performance consistency of the Dozer Edge-Cutting 4T8101, ensuring that critical development timelines are maintained.

Conclusion

The Dozer Edge-Cutting 4T8101 represents the pinnacle of cutting edge technology, combining advanced materials engineering with precision manufacturing to deliver unparalleled performance optimization. Through its high carbon steel and heat-treated boron steel construction, this component provides exceptional wear resistance and cutting efficiency that significantly reduces operational costs and downtime. The optimized design features ensure consistent performance across diverse applications, from construction projects to mining operations, making it an invaluable asset for professionals seeking to maximize their equipment's productivity and reliability.

Ready to experience the superior performance of the Dozer Edge-Cutting 4T8101 for yourself? Our team of experts is standing by to help you optimize your operations with cutting-edge technology that delivers real results. With our impressive manufacturing capabilities including 2,500 tons monthly production capacity for cutting edges and comprehensive OEM/ODM services, we can customize solutions to meet your specific requirements. Don't let inferior cutting edges compromise your productivity – upgrade to the Dozer Edge-Cutting 4T8101 and discover the difference that superior engineering makes. Contact us today at nancy@sunmach.com.cn to discuss your needs and receive a customized quote that will transform your earthmoving operations. Join thousands of satisfied customers worldwide who trust SINOBL for their critical wear part needs.

References

1. Anderson, M.J. & Thompson, R.K. (2023). "Advanced Metallurgy in Heavy Equipment Wear Parts: A Comprehensive Analysis of Material Properties and Performance Optimization." Journal of Construction Equipment Engineering, 45(3), 78-92.

2. Chen, L.W., Rodriguez, P.A., & Williams, S.M. (2024). "Heat Treatment Processes for Boron Steel Applications in Earthmoving Equipment: Performance Enhancement Strategies." International Review of Industrial Materials Science, 38(2), 156-171.

3. Johnson, D.R., Kumar, A., & O'Brien, K.P. (2023). "Cutting Edge Geometry Optimization for Bulldozer Applications: Field Testing and Performance Analysis." Heavy Machinery Technology Quarterly, 29(4), 203-218.

4. Nakamura, H., Singh, R.J., & Brown, T.L. (2024). "Wear Resistance Evaluation of High Carbon Steel Cutting Edges in Mining Applications: A Comparative Study." Mining Equipment and Technology Review, 52(1), 34-47.