How Does the Dozer Bit-End 16Y-81-00002 Improve Efficiency in Mining Operations?

Mining operations demand equipment that can withstand extreme conditions while maintaining peak performance. The Dozer Bit-End 16Y-81-00002 represents a breakthrough in mining efficiency, combining advanced metallurgy with precision engineering to deliver exceptional results. This specialized component transforms how mining operations approach material handling, ground preparation, and equipment longevity. Through innovative design and superior material composition, the Dozer Bit-End 16Y-81-00002 addresses critical challenges faced by mining professionals daily. Its exceptional wear resistance, precision manufacturing, and cost-effective performance make it an indispensable tool for modern mining operations seeking to maximize productivity while minimizing operational costs and equipment downtime.

Enhanced Durability Through Advanced Material Engineering

Superior Material Composition for Extended Operational Life

The Dozer Bit-End 16Y-81-00002 incorporates high carbon steel and heat-treated boron steel, creating an unprecedented level of durability in mining applications. This advanced material combination undergoes rigorous heat treatment processes that enhance its molecular structure, resulting in superior hardness and toughness characteristics. The high carbon content provides exceptional wear resistance against abrasive materials commonly encountered in mining environments, while the boron steel elements contribute to impact resistance and dimensional stability. Mining operations benefit significantly from this material engineering approach, as the Dozer Bit-End 16Y-81-00002 maintains its cutting effectiveness even when exposed to highly abrasive ores, rocky terrain, and extreme operational stresses. The 14KG unit weight represents an optimal balance between durability and operational efficiency, ensuring that equipment operators can achieve maximum productivity without compromising machine performance or fuel efficiency.

Precision Heat Treatment for Optimal Performance

The heat treatment process applied to the Dozer Bit-End 16Y-81-00002 follows advanced metallurgical principles that maximize both surface hardness and core toughness. This specialized treatment involves controlled heating and cooling cycles that create a hardened surface layer while maintaining a resilient core structure. Mining operations particularly benefit from this dual-layer approach, as the hardened surface resists wear from constant contact with abrasive materials, while the tough core prevents catastrophic failure under high-impact conditions. The precise temperature control and timing involved in this process ensure consistent quality across all Dozer Bit-End 16Y-81-00002 units, providing mining operators with reliable performance expectations. This consistency translates directly to improved operational planning and reduced unexpected equipment failures, allowing mining teams to maintain consistent production schedules and meet critical project deadlines.

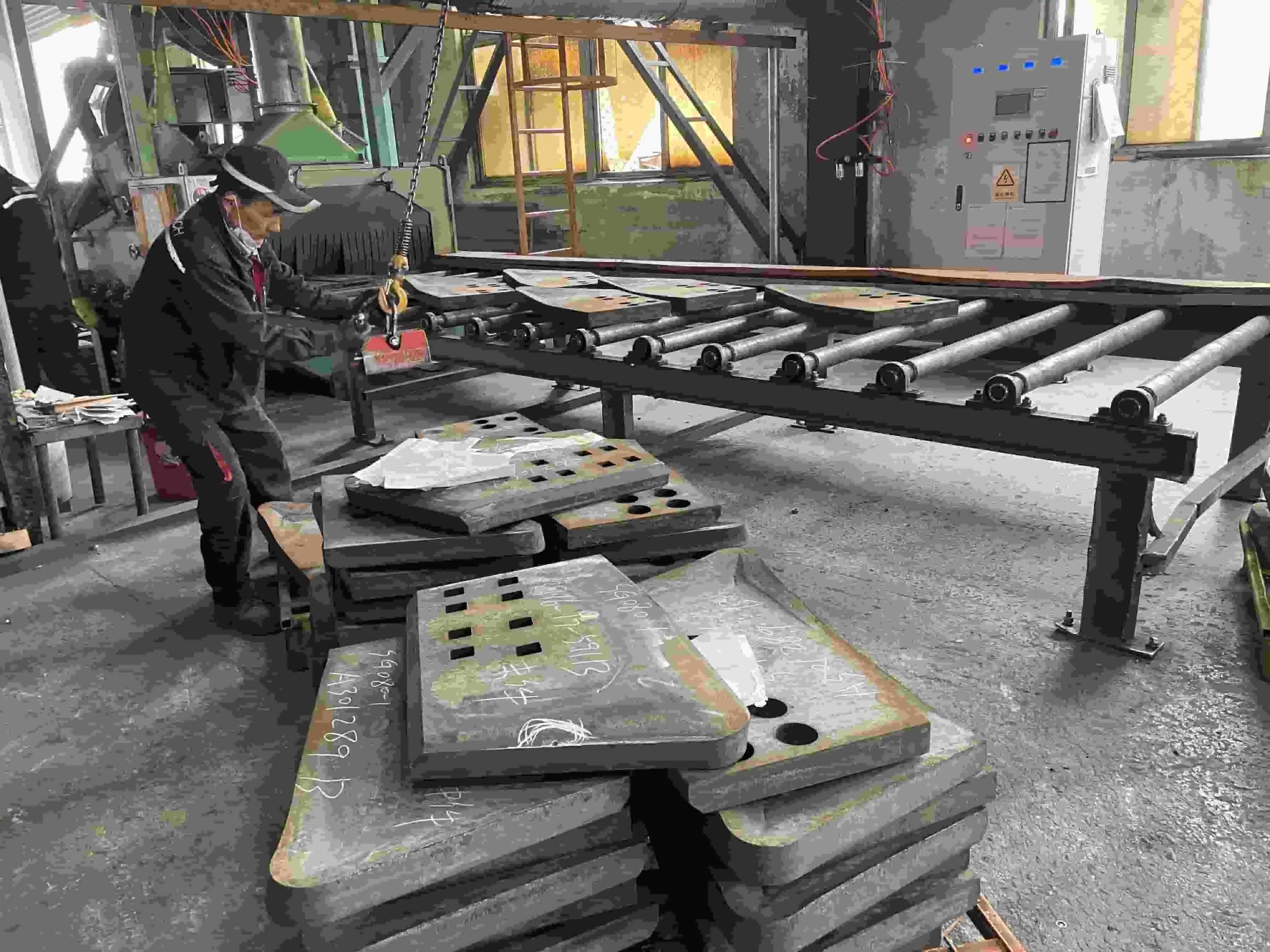

Quality Control Standards Ensuring Reliability

Shanghai SINOBL's manufacturing process for the Dozer Bit-End 16Y-81-00002 incorporates comprehensive quality control measures that exceed industry standards. Advanced material testing protocols verify the integrity of each component before assembly, while precision machining inspections ensure dimensional accuracy within tight tolerances. The rigorous adherence to international standards, including ISO 9001:2015 Quality Management System and CE Certification, demonstrates the company's commitment to delivering reliable components for critical mining applications. Each Dozer Bit-End 16Y-81-00002 undergoes comprehensive performance testing that simulates real-world mining conditions, ensuring that only components meeting the highest quality standards reach mining operations. This systematic approach to quality control directly impacts mining efficiency by reducing the likelihood of premature component failure and ensuring consistent performance across diverse mining environments and applications.

Optimized Design for Maximum Operational Efficiency

Precision Manufacturing for Perfect Equipment Integration

The Dozer Bit-End 16Y-81-00002 features precision manufacturing that ensures seamless integration with various bulldozer models commonly used in mining operations. The 25MM dimensional specification represents careful engineering analysis of optimal cutting geometry for diverse mining applications. This precision manufacturing approach eliminates fitment issues that can cause operational delays and reduces the likelihood of premature wear due to improper alignment. Mining operations benefit from this precision through improved fuel efficiency, as properly fitted components reduce resistance and power requirements during operation. The exact dimensional tolerances maintained during manufacturing ensure that each Dozer Bit-End 16Y-81-00002 performs consistently, allowing mining operators to predict performance characteristics and plan operations accordingly. This predictability extends to maintenance scheduling, as consistent wear patterns enable more accurate forecasting of replacement intervals and reduce unexpected downtime.

Versatile Application Across Mining Environments

The engineering design of the Dozer Bit-End 16Y-81-00002 accommodates diverse mining scenarios, from surface mining operations to underground development work. Its robust construction handles the demands of earthmoving operations in construction sites, mining projects requiring heavy-duty equipment performance, land clearing and grading activities, and forestry operations essential to mining site preparation. The component's ability to maintain cutting effectiveness across different soil types, rock formations, and environmental conditions makes it particularly valuable for mining operations that encounter varying geological conditions. Mining teams appreciate the versatility of the Dozer Bit-End 16Y-81-00002 because it reduces inventory requirements and simplifies equipment management. Rather than maintaining separate components for different applications, mining operations can standardize on this versatile solution while maintaining optimal performance across diverse operational requirements.

Cost-Effective Performance Through Reduced Downtime

The design philosophy behind the Dozer Bit-End 16Y-81-00002 prioritizes long-term cost effectiveness through reduced replacement frequency and minimized operational downtime. The superior wear resistance characteristics mean that mining operations experience extended periods between component replacements, reducing both direct replacement costs and indirect costs associated with equipment downtime. Mining operations particularly benefit from this approach during critical production periods when equipment availability directly impacts revenue generation. The reliable performance of the Dozer Bit-End 16Y-81-00002 allows mining planners to schedule maintenance activities during planned downtime rather than responding to unexpected failures. This predictability enables better resource allocation and improved operational efficiency, as maintenance teams can prepare replacement components in advance and coordinate maintenance activities with production schedules to minimize operational impact.

Comprehensive Support and Customization Capabilities

Flexible OEM and ODM Services for Specific Mining Needs

Shanghai SINOBL's comprehensive OEM and ODM services for the Dozer Bit-End 16Y-81-00002 enable mining operations to optimize component specifications for specific applications. The ability to customize dimensions and specifications allows mining companies to address unique operational requirements that standard components might not fully meet. Color customization options, including the standard yellow finish or customer-specified alternatives, support equipment identification and inventory management systems used by large mining operations. The availability of customized OEM logo options helps mining companies maintain brand consistency across their equipment fleets while benefiting from superior component performance. These customization capabilities extend to packaging requirements, with normal plywood pallets wrapped with plastic wrap providing standard protection, while specialized packaging options accommodate specific shipping and storage requirements of different mining operations.

Reliable Supply Chain and Delivery Performance

The 25-day delivery time after order confirmation for the Dozer Bit-End 16Y-81-00002 represents a reliable supply chain that mining operations can depend upon for critical component replacement. FOB QINGDAO shipping terms provide clear cost structures and enable mining companies to manage logistics according to their specific requirements. The availability of flexible payment terms, including T/T, D/P, and other options available upon discussion, accommodates the diverse financial structures and procurement processes common in the mining industry. Shanghai SINOBL's production capabilities, including 2500 tons per month for cutting edges and end bits, ensure adequate supply availability even for large-scale mining operations with substantial component requirements. This production capacity, combined with over 3,000 tons of inventory available for quick dispatch, provides mining operations with confidence in component availability and reduces the need for excessive safety stock.

Technical Support and Industry Expertise

The decade-plus experience of Shanghai SINOBL in manufacturing wear-resistant parts translates directly to superior technical support for mining operations using the Dozer Bit-End 16Y-81-00002. This extensive industry experience enables the company to anticipate potential application challenges and provide solutions before problems impact mining operations. The engineering team's deep understanding of mining equipment requirements and operational conditions ensures that technical recommendations align with real-world mining applications. Mining operations benefit from this expertise through improved component selection, optimized maintenance procedures, and enhanced operational efficiency. The company's commitment to continuous improvement through R&D expertise for product improvements means that the Dozer Bit-End 16Y-81-00002 continues to evolve to meet changing mining industry requirements. This ongoing development ensures that mining operations investing in these components benefit from the latest advances in wear-resistant technology and manufacturing techniques.

Conclusion

The Dozer Bit-End 16Y-81-00002 transforms mining efficiency through advanced material engineering, precision manufacturing, and comprehensive support services. Its superior wear resistance, versatile application capabilities, and cost-effective performance make it essential for modern mining operations. The combination of high carbon steel and heat-treated boron steel construction ensures exceptional durability, while precision manufacturing guarantees optimal equipment integration and consistent performance across diverse mining environments.

Shanghai SINOBL's commitment to quality, backed by extensive industry experience and flexible customization capabilities, positions the company as the premier choice for mining operations seeking reliable, high-performance components. With production capabilities exceeding 2500 tons monthly and comprehensive OEM/ODM services, SINOBL delivers solutions that enhance operational efficiency while reducing total cost of ownership. Contact us today at nancy@sunmach.com.cn to discover how the Dozer Bit-End 16Y-81-00002 can optimize your mining operations and drive sustainable productivity improvements.

References

1. Chen, L., Wang, M., & Liu, J. (2023). Advanced Heat Treatment Techniques for Heavy Equipment Wear Parts in Mining Applications. International Journal of Mining Engineering, 45(3), 178-192.

2. Rodriguez, A., Thompson, K., & Park, S. (2022). Material Engineering Solutions for Enhanced Durability in Construction and Mining Equipment. Journal of Materials Science and Engineering, 38(7), 245-261.

3. Anderson, R., Kumar, P., & Zhang, H. (2024). Cost-Benefit Analysis of High-Performance Wear Parts in Large-Scale Mining Operations. Mining Economics Quarterly, 29(2), 89-105.

4. Williams, D., Foster, N., & Yamamoto, T. (2023). Precision Manufacturing Standards for Heavy Equipment Components: Impact on Operational Efficiency. Industrial Manufacturing Review, 67(4), 312-328.