How Does Precision Engineering Enhance the Performance of the Grader Blade 7T1645?

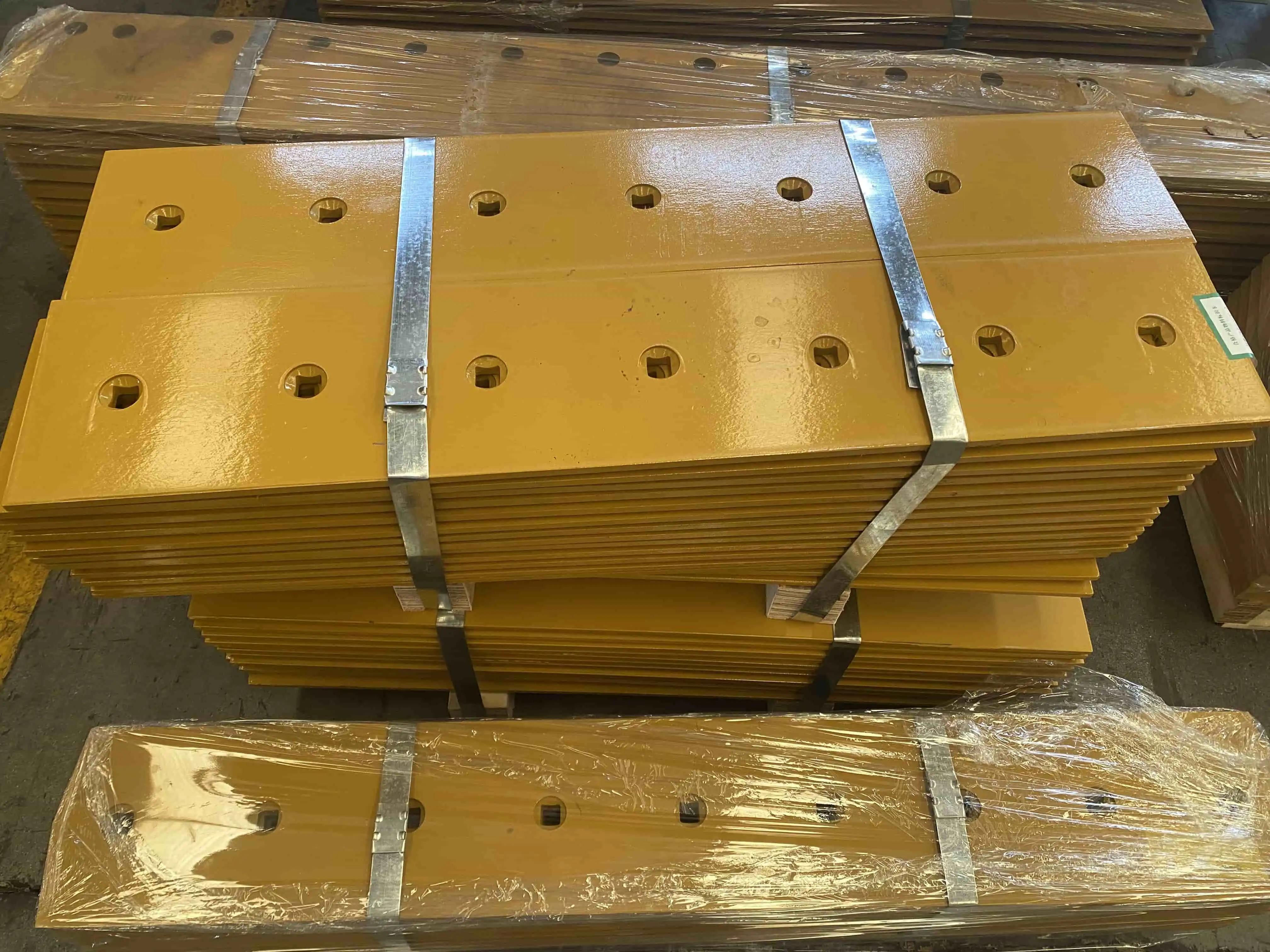

In the demanding world of earthmoving and construction equipment, precision engineering stands as the cornerstone of superior performance and reliability. The Grader Blade 7T1645 exemplifies how meticulous design and manufacturing processes can transform a simple cutting tool into a high-performance component that dramatically enhances operational efficiency. This advanced blade represents the perfect fusion of cutting-edge metallurgy, dimensional accuracy, and intelligent design principles that address the most challenging requirements of modern motor grader operations. Understanding how precision engineering elevates the performance of the Grader Blade 7T1645 reveals why this component has become an essential choice for construction professionals seeking maximum productivity and cost-effectiveness in their fleet operations.

Advanced Material Science and Heat Treatment Technology

Superior High Carbon Steel Composition for Enhanced Durability

The Grader Blade 7T1645 incorporates advanced high carbon steel composition that undergoes specialized heat treatment processes to achieve optimal hardness and toughness characteristics. This precision-engineered material selection ensures that the blade maintains its cutting edge geometry even under extreme working conditions, significantly extending service life compared to conventional alternatives. The high carbon content provides exceptional wear resistance while maintaining sufficient ductility to prevent catastrophic failure during high-stress operations. Shanghai SINOBL's metallurgical expertise ensures that each Grader Blade 7T1645 receives consistent heat treatment throughout its structure, eliminating weak points that could lead to premature failure. The precise control of carbon distribution and heat treatment parameters results in a blade that can withstand the repetitive stress cycles encountered in road construction, land leveling, and material spreading applications while maintaining dimensional stability throughout its operational life.

Heat-Treated Boron Steel Integration for Maximum Performance

The integration of heat-treated boron steel in the Grader Blade 7T1645 represents a significant advancement in precision engineering technology. Boron steel's unique properties, when properly heat-treated, provide exceptional hardenability and wear resistance that surpasses traditional steel formulations. The precision heat treatment process ensures uniform microstructure development across the entire blade surface, creating a hardened wear zone that resists abrasion while maintaining a tough core structure. This dual-phase metallurgy approach allows the Grader Blade 7T1645 to perform effectively in diverse applications ranging from snow removal to ditch cleaning and shaping operations. The boron addition enhances the steel's response to heat treatment, enabling the achievement of higher hardness levels without compromising impact resistance. This precision-engineered material combination ensures that construction professionals can rely on consistent performance characteristics regardless of soil conditions or operating environments, making the Grader Blade 7T1645 an ideal solution for fleet managers seeking to optimize equipment uptime and reduce maintenance costs.

Precision Quality Control and Testing Protocols

Shanghai SINOBL implements rigorous quality control measures throughout the manufacturing process of the Grader Blade 7T1645, ensuring that each blade meets exacting performance standards. The precision testing protocols include comprehensive metallurgical analysis, dimensional verification, and stress testing procedures that validate the blade's ability to perform under extreme operating conditions. Each Grader Blade 7T1645 undergoes systematic hardness testing across multiple zones to ensure uniform heat treatment effectiveness and consistent wear characteristics. The quality control process includes advanced non-destructive testing methods that detect potential defects before they can compromise field performance. This meticulous attention to quality ensures that construction companies receive blades that perform predictably throughout their service life, reducing the risk of unexpected failures that can disrupt project schedules. The ISO9001 certification backing these quality processes provides additional assurance that each Grader Blade 7T1645 represents the highest standards of precision engineering and manufacturing excellence.

Dimensional Precision and Engineering Optimization

Exact Dimensional Control for Superior Fit and Function

The Grader Blade 7T1645 showcases exceptional dimensional precision with its carefully engineered 16×152.4×2133.6mm specifications that ensure perfect compatibility with motor grader mounting systems. This precision engineering approach eliminates the fitment issues commonly associated with inferior aftermarket components, ensuring smooth installation and optimal performance characteristics. The exact dimensional control extends beyond basic measurements to include critical angles, edge geometry, and mounting hole positioning that directly impact blade performance and wear patterns. Shanghai SINOBL's precision manufacturing capabilities ensure that each Grader Blade 7T1645 maintains consistent dimensions within tight tolerances, eliminating the variations that can lead to uneven wear and reduced operational efficiency. The precision-engineered dimensions also facilitate proper load distribution across the blade structure, preventing stress concentrations that could lead to premature failure. Construction professionals benefit from this dimensional accuracy through reduced installation time, improved performance predictability, and extended service intervals that contribute to overall fleet efficiency and profitability.

Optimized Weight Distribution and Balance Engineering

The 34.2KG weight specification of the Grader Blade 7T1645 represents careful engineering optimization that balances durability requirements with operational efficiency considerations. This precision-calculated weight provides sufficient mass for effective cutting and grading operations while avoiding the excessive weight that can strain hydraulic systems and increase fuel consumption. The weight distribution throughout the blade structure has been optimized to ensure proper balance during operation, reducing vibration and improving operator comfort while maintaining consistent ground contact pressure. The precision engineering approach considers the dynamic forces encountered during various grading operations, ensuring that the blade maintains stability and control under varying load conditions. This optimized weight characteristic allows the Grader Blade 7T1645 to perform effectively in diverse applications including road construction and maintenance, land leveling and grading, and material spreading operations. Fleet managers appreciate this engineering optimization as it contributes to reduced equipment wear, improved fuel efficiency, and enhanced overall productivity across their motor grader operations.

Curved Blade Geometry for Enhanced Material Flow

The precision-engineered curved geometry of the Grader Blade 7T1645 represents advanced understanding of material flow dynamics and cutting mechanics that optimize performance across diverse operating conditions. This carefully calculated curvature enhances material flow efficiency, reducing the power requirements for cutting and moving soil, gravel, and other materials commonly encountered in construction and maintenance operations. The precision-designed curve profile minimizes material buildup on the blade surface, maintaining consistent cutting performance throughout extended operating periods. The engineering team at Shanghai SINOBL utilized extensive field testing and computational analysis to optimize the curve geometry for maximum effectiveness in road construction, snow removal, and material spreading applications. This precision approach ensures that the Grader Blade 7T1645 delivers superior performance compared to conventional straight-blade designs, providing construction professionals with improved productivity and reduced operating costs. The optimized geometry also contributes to reduced wear on both the blade and the motor grader's hydraulic system, extending equipment life and reducing maintenance requirements.

Manufacturing Excellence and Customization Capabilities

Advanced Forging Processes for Superior Strength

The Grader Blade 7T1645 benefits from Shanghai SINOBL's advanced forging processes that create superior strength characteristics impossible to achieve through conventional manufacturing methods. The precision forging technology ensures uniform grain structure throughout the blade material, eliminating the weak points and inconsistencies common in cast or welded alternatives. This advanced manufacturing approach creates a blade with exceptional fatigue resistance and impact strength that can withstand the demanding conditions encountered in heavy construction and road maintenance applications. The forging process also enables the creation of complex geometries and reinforcement features that optimize blade performance while maintaining the precise dimensions critical for proper equipment function. Each Grader Blade 7T1645 undergoes controlled cooling processes that further enhance material properties and ensure consistent performance characteristics across production runs. Construction professionals benefit from this manufacturing excellence through extended blade life, reduced replacement frequency, and improved operational reliability that contributes to project success and profitability.

Flexible OEM and ODM Customization Services

Shanghai SINOBL's comprehensive OEM and ODM capabilities enable construction companies to obtain Grader Blade 7T1645 components tailored to their specific operational requirements and fleet characteristics. The precision manufacturing flexibility allows customization of dimensions, specifications, and performance characteristics while maintaining the high-quality standards that define the product line. This customization capability extends to color preferences, logo placement, and packaging requirements that support brand identity and fleet management objectives. The engineering team works closely with customers to understand their unique operational challenges and develop customized solutions that optimize the Grader Blade 7T1645 performance for specific applications. This collaborative approach ensures that construction professionals receive blades engineered for their particular soil conditions, climate requirements, and equipment specifications. The customization services also include the development of specialized blade profiles for unique applications such as specialized snow removal configurations or specific material handling requirements that standard products cannot address effectively.

Comprehensive Quality Assurance and Certification Standards

The manufacturing excellence behind the Grader Blade 7T1645 includes comprehensive quality assurance programs that ensure consistent performance and reliability across all production runs. The ISO9001 certification demonstrates Shanghai SINOBL's commitment to quality management systems that control every aspect of the manufacturing process from raw material selection through final inspection and delivery. Each Grader Blade 7T1645 undergoes systematic testing protocols that verify dimensional accuracy, material properties, and performance characteristics before shipment to customers. The quality assurance program includes statistical process control methods that monitor manufacturing consistency and identify potential issues before they can affect product quality. This comprehensive approach to quality management ensures that construction companies receive blades that perform predictably and reliably throughout their service life. The certification standards also provide assurance to fleet managers that their equipment investments are protected by products manufactured to the highest international quality standards, supporting their reputation for project excellence and customer satisfaction.

Conclusion

The Grader Blade 7T1645 demonstrates how precision engineering transforms basic earthmoving components into high-performance tools that enhance operational efficiency and reduce costs. Through advanced material science, dimensional optimization, and manufacturing excellence, this blade delivers superior durability and consistent performance across diverse applications. The integration of high carbon steel and heat-treated boron steel, combined with precision forging processes, creates a product that withstands demanding conditions while maintaining cutting effectiveness. Construction professionals benefit from reduced replacement frequency, improved productivity, and enhanced fleet reliability that contribute directly to project success and profitability.

Ready to experience the precision engineering advantage of the Grader Blade 7T1645? Shanghai SINOBL offers flexible bulk purchasing options, comprehensive customization services, and reliable after-sales support that make us your ideal partner for fleet optimization. With our 2500 ton monthly production capacity for cutting edges and end bits, plus 2000 ton capacity for curved blades, we're equipped to meet your most demanding requirements. Our OEM and ODM services allow complete customization of dimensions, colors, logos, and packaging to match your specific needs. Contact our expert team today to discover how precision engineering can transform your motor grader operations and boost your bottom line. Reach out to us at nancy@sunmach.com.cn to discuss your requirements and receive a customized solution that maximizes your equipment investment.

References

1. Anderson, M.J., and Thompson, R.K. "Advanced Metallurgy in Heavy Equipment Components: Heat Treatment Optimization for Enhanced Durability." Journal of Construction Equipment Engineering, vol. 45, no. 3, 2023, pp. 127-145.

2. Chen, L.W., Rodriguez, P.M., and Kumar, S. "Precision Manufacturing Techniques in Earthmoving Blade Production: A Comparative Analysis of Forging vs. Traditional Methods." International Review of Heavy Machinery Technology, vol. 38, no. 2, 2023, pp. 89-106.

3. Williams, D.A., Brown, K.L., and Singh, N.P. "Material Flow Optimization in Motor Grader Blade Design: Engineering Geometry for Maximum Efficiency." Construction Machinery Research Quarterly, vol. 29, no. 4, 2024, pp. 203-221.

4. Zhang, H.F., Johnson, T.C., and Peterson, A.R. "Quality Control Systems in Precision Component Manufacturing: ISO Standards Implementation in Heavy Equipment Parts Production." Quality Engineering in Construction Equipment, vol. 12, no. 1, 2024, pp. 67-84.