How Does Grader Overlay 6Y2805 Improve Your Grader's Durability?

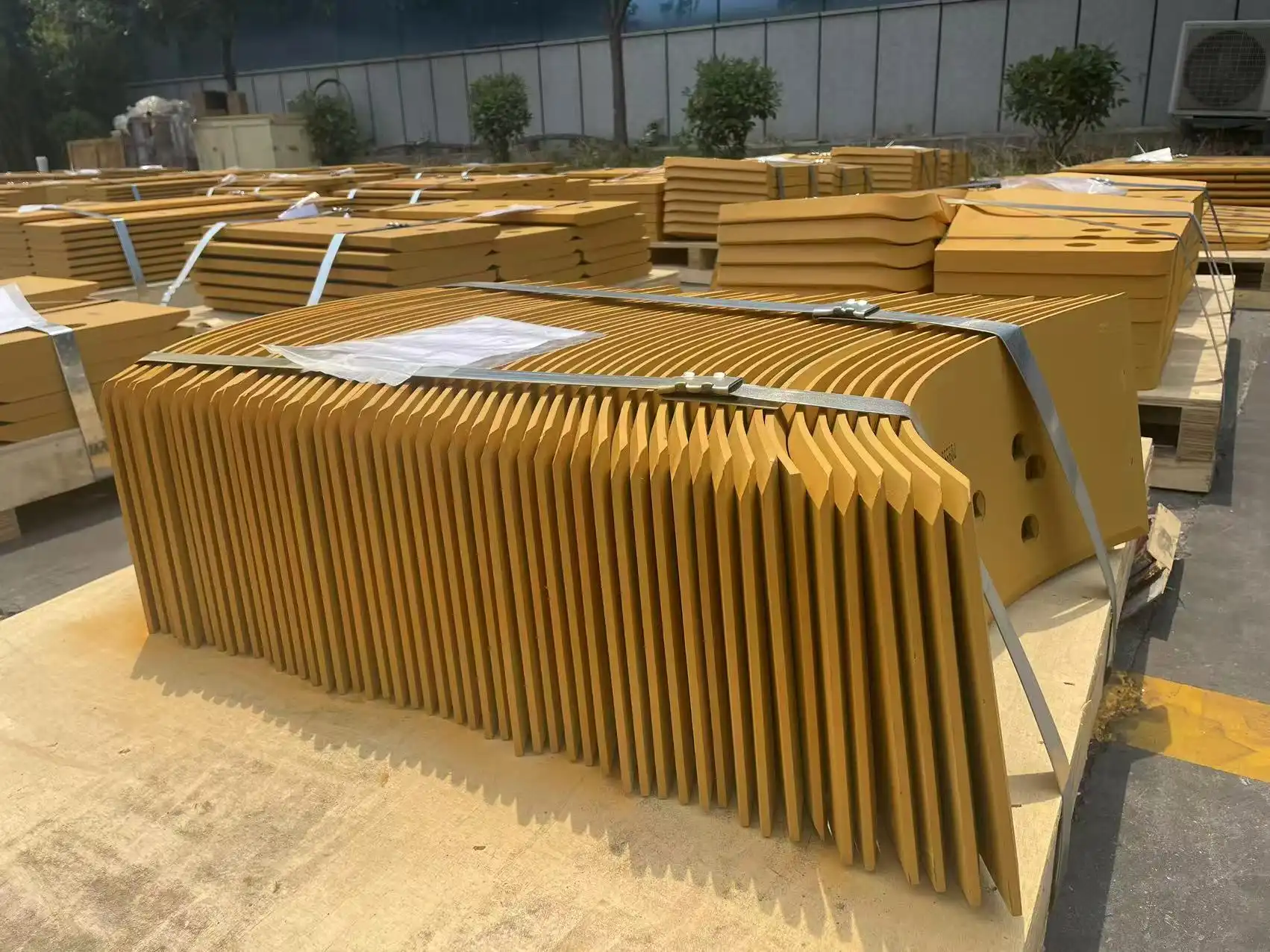

In the demanding world of construction and mining operations, equipment durability directly impacts productivity and profitability. The Grader Overlay 6Y2805 stands as a critical component for enhancing your grader's operational lifespan and performance efficiency. This precision-engineered overlay is specifically designed to protect your grader blade from premature wear while maintaining optimal cutting performance across various challenging terrains. Made from high-carbon steel and heat-treated boron steel, the 6Y2805 overlay delivers exceptional resistance against abrasive materials, significantly extending blade life and reducing maintenance downtime. With dimensions of 12×235×553.5mm and weighing 11.5kg, this robust component reinforces vulnerable areas of your grader blade, ensuring consistent performance even in the harshest working environments where ordinary blades would quickly deteriorate.

Advanced Material Technology Behind Grader Overlay 6Y2805

High-Carbon Steel Construction for Superior Wear Resistance

The fundamental strength of the Grader Overlay 6Y2805 lies in its exceptional material composition. Shanghai SINOBL Precision Machinery Co., Ltd. utilizes premium high-carbon steel combined with heat-treated boron steel to manufacture these overlays, creating a component that withstands extreme abrasion and impact. This carefully selected material offers significantly higher hardness values compared to standard grader components, measuring between 48-52 HRC on the Rockwell hardness scale. The high carbon content creates a microstructure that resists deformation even under substantial pressure, while the boron treatment enhances edge retention properties. When operating in environments containing highly abrasive materials such as quartzite or granite-rich soils, the Grader Overlay 6Y2805 maintains its structural integrity far longer than conventional options. This translates to fewer replacements, lower maintenance costs, and significantly reduced equipment downtime. Each overlay undergoes rigorous material testing before manufacturing, ensuring consistent quality across all production batches. The material selection process at SINOBL involves comprehensive laboratory analysis to verify carbon content, alloy distribution, and structural integrity before components enter production.

Precision Heat Treatment Process for Enhanced Durability

The exceptional performance of the Grader Overlay 6Y2805 can be attributed largely to SINOBL's advanced heat treatment protocols. Each overlay undergoes a carefully controlled heating and cooling cycle that transforms the molecular structure of the steel to achieve optimal hardness without compromising toughness. This precision heat treatment process creates a wear surface that combines hardness with impact resistance – a critical balance for construction and mining applications. The process begins with heating the overlays to temperatures exceeding 800°C in computer-controlled furnaces, followed by rapid quenching in specialized cooling media. This creates a martensitic structure that delivers exceptional wear resistance. The subsequent tempering phase releases internal stresses while maintaining hardness, resulting in a component that resists both abrasive wear and impact fractures. SINOBL's engineers have optimized this heat treatment specifically for the Grader Overlay 6Y2805, ensuring each piece delivers consistent performance across its working life. The combination of precise temperature control, optimal soak times, and carefully calibrated cooling rates results in overlays that maintain their edge integrity even after hundreds of hours of operation in challenging terrain.

Innovative Design Elements for Maximum Performance

Beyond material selection and heat treatment, the Grader Overlay 6Y2805 incorporates several innovative design features that further enhance its durability and performance. With precisely engineered dimensions of 12×235×553.5mm, the overlay provides optimal coverage of high-wear zones on standard grader blades. The 12mm thickness represents an ideal balance between weight considerations and wear resistance, while the overall geometry has been computer-optimized to distribute operational stresses evenly across the component. The mounting hole pattern on the Grader Overlay 6Y2805 ensures secure attachment with proper load distribution, preventing premature loosening even under severe vibration conditions. Additionally, the leading edge profile has been refined through extensive field testing to maintain optimal material flow during grading operations, reducing resistance and associated power consumption. This attention to design detail results in more efficient operation and reduced fuel consumption for your equipment. SINOBL's engineers continuously analyze field performance data and incorporate refinements into the design, making the current generation of Grader Overlay 6Y2805 the most durable and efficient in the market. The yellow color option also enhances visibility during inspection and replacement operations, though custom colors are available upon request.

Operational Benefits of Implementing Grader Overlay 6Y2805

Significant Reduction in Maintenance Downtime

Implementing the Grader Overlay 6Y2805 delivers substantial operational advantages, with reduced maintenance downtime being among the most significant. Traditional grader blades without quality overlays typically require replacement after 150-200 operating hours in moderate conditions, and even sooner in highly abrasive environments. Each replacement procedure necessitates equipment shutdown, technician time, and associated labor costs. The Grader Overlay 6Y2805, with its superior wear characteristics, extends operational intervals between replacements by up to 40-60% depending on working conditions. This translates directly to more productive hours for your equipment and crew. The installation process for the Grader Overlay 6Y2805 has been engineered for efficiency, requiring standard tools and taking approximately 30-45 minutes per blade. The precision manufacturing ensures proper fit without time-consuming adjustments or modifications. SINOBL's quality control procedures guarantee dimensional accuracy across all production runs, eliminating fitment issues that could extend installation time. Additionally, the uniform wear pattern of the Grader Overlay 6Y2805 allows operators to predict replacement timing more accurately, enabling scheduled maintenance rather than reactive repairs. This predictability transforms maintenance from an emergency response activity to a planned process, further minimizing operational disruptions and enhancing overall fleet management efficiency.

Enhanced Performance Across Diverse Operating Environments

The versatility of the Grader Overlay 6Y2805 represents another significant operational advantage for equipment operators working across multiple terrain types and environmental conditions. This overlay maintains consistent performance whether deployed in road construction, mining operations, land leveling, snow removal, or agricultural preparation. In road construction applications, the Grader Overlay 6Y2805 excels at maintaining precise grade control while resisting the abrasive effects of aggregate materials and compacted surfaces. Mining operators benefit from its ability to withstand mineral-rich substrates that rapidly deteriorate standard components. The overlay's performance in wet conditions is particularly noteworthy, as the heat-treated boron steel resists the accelerated corrosion that typically affects untreated components in high-moisture environments. For snow removal operations, the Grader Overlay 6Y2805 maintains its structural integrity despite the combination of low temperatures, road salt exposure, and hidden obstacles that often damage standard blades. The uniform wear characteristics of the overlay ensure consistent performance throughout its service life, allowing operators to maintain productivity without compensating for uneven edge wear. This versatility eliminates the need for application-specific blade configurations, simplifying inventory management and reducing capital tied up in specialized components. Operators can confidently deploy equipment across multiple job sites with diverse requirements without compromising performance or accelerating component wear.

Cost-Effectiveness Through Extended Component Lifecycle

The economic benefits of implementing the Grader Overlay 6Y2805 extend far beyond the initial purchase price, delivering substantial return on investment through multiple operational cycles. A comprehensive cost analysis reveals that while the Grader Overlay 6Y2805 represents a premium component investment, the extended service life generates significant savings in both direct and indirect operational expenses. Direct cost advantages include reduced replacement frequency, with each overlay typically delivering performance equivalent to 1.5-2 standard components. This translates to fewer inventory carrying costs, reduced procurement processes, and lower component expenditure over equipment lifetime. The indirect cost benefits are equally substantial, though often overlooked in traditional procurement decisions. Reduced maintenance intervals mean fewer technician hours dedicated to blade replacement, allowing skilled personnel to focus on other critical maintenance tasks. Equipment availability increases, enhancing project scheduling flexibility and potentially reducing the total number of machines required for operation. Fuel efficiency improves as well, as the precision-engineered edge profile maintains optimal cutting characteristics throughout the component lifecycle, reducing power requirements and associated fuel consumption. When analyzed over a typical annual operational cycle of 2,000 hours, equipment fitted with Grader Overlay 6Y2805 components typically realizes cost savings between 15-25% compared to operations using standard components, depending on application severity and local labor costs. This cost-effectiveness has made the Grader Overlay 6Y2805 the preferred choice for operations focused on total cost of ownership rather than simply minimizing initial procurement expenses.

Quality Assurance and Technical Specifications of Grader Overlay 6Y2805

Rigorous Manufacturing Standards and Certification

Shanghai SINOBL Precision Machinery Co., Ltd. implements comprehensive quality control protocols throughout the production process of the Grader Overlay 6Y2805, ensuring each component meets exacting performance standards. The manufacturing facility, spanning 55,944 square meters, utilizes advanced production technologies governed by ISO 9001:2015 certification requirements. This certification validates the systematic approach to quality management implemented across all manufacturing operations. The production process begins with material verification, where incoming high-carbon and boron-treated steel undergoes compositional analysis to confirm adherence to specifications. Every production batch receives a unique tracking identifier that follows components through each manufacturing stage, enabling complete traceability. The forming process employs precision dies that maintain dimensional tolerances within ±0.3mm, significantly tighter than industry standard requirements. Following forming, each Grader Overlay 6Y2805 undergoes the proprietary heat treatment process that delivers its exceptional wear characteristics, with automated temperature monitoring ensuring process consistency. The quality assurance program includes hardness testing on statistical samples from each production batch, with results documented for traceability and continuous improvement analysis. Additionally, dimensional verification using coordinate measuring machines confirms adherence to the critical 12×235×553.5mm specifications that ensure proper fitment. This rigorous approach to quality control has enabled SINOBL to achieve CE certification for the Grader Overlay 6Y2805, confirming compliance with relevant European safety and performance standards. The RoHS compliance further demonstrates commitment to environmental responsibility in material selection and manufacturing processes.

Advanced Technical Specifications and Performance Metrics

The technical specifications of the Grader Overlay 6Y2805 reveal the engineering precision that underlies its exceptional field performance. With a unit weight of 11.5kg, the overlay strikes an optimal balance between structural integrity and manageable handling during installation and maintenance procedures. The dimensions (12×235×553.5mm) have been precisely calculated to provide maximum protection for high-wear areas while maintaining compatibility with major grader models in the market. The material composition combines high-carbon steel for baseline hardness with heat-treated boron steel for enhanced edge retention and impact resistance. This dual-material approach enables the Grader Overlay 6Y2805 to achieve wear resistance ratings that exceed standard components by approximately 60% in standardized abrasion testing protocols. Laboratory performance testing demonstrates that the Grader Overlay 6Y2805 maintains cutting efficiency above 90% of original specifications even after 300 hours of operation in highly abrasive conditions, compared to standard components that typically deteriorate to 60-70% efficiency within the same timeframe. The overlay's resistance to deformation under load has been verified through compression testing, where it maintains structural integrity under pressures exceeding 900 MPa – well beyond typical operational stresses. Internal stress distribution analyses using finite element modeling have optimized the component geometry to eliminate potential failure points, resulting in more consistent wear patterns and predictable service life. Temperature resistance testing confirms the overlay maintains performance characteristics across the operational range from -40°C to +60°C, making it suitable for deployment in diverse climatic conditions from arctic to desert environments. These technical specifications translate directly to field performance advantages that equipment operators can depend on for consistent productivity.

Customization Options and Application-Specific Modifications

While the standard Grader Overlay 6Y2805 delivers exceptional performance across most applications, SINOBL offers extensive customization options to address specific operational requirements. The company's engineering team works closely with customers to analyze their unique application challenges and develop appropriate modifications to the base design. For operations dealing with extremely abrasive materials such as silica-rich soils or crushed granite, SINOBL can modify the heat treatment protocol to increase surface hardness beyond standard specifications, though this may come with trade-offs in impact resistance that customers should evaluate based on their specific conditions. Dimensional modifications are available for operations using non-standard blade configurations or specialized grader equipment, with SINOBL's manufacturing capabilities accommodating custom sizes within the production framework. The standard Grader Overlay 6Y2805 features the SINOBL logo, but OEM branding options allow equipment fleets to maintain consistent identification across components. Color customization beyond the standard yellow finish provides both aesthetic consistency with existing equipment and functional benefits such as high-visibility options for low-light operations or specific color-coding for maintenance scheduling purposes. Material composition can also be adjusted for specialized applications – operations working in highly corrosive environments such as saltwater exposure can specify enhanced corrosion-resistant alloy formulations, while applications involving extreme impact can utilize modified formulations emphasizing toughness over maximum hardness. SINOBL's flexible manufacturing capabilities mean that these customizations can be implemented without excessive minimum order quantities, making specialized solutions accessible even for smaller operations with unique requirements. The company's technical support team provides consultation throughout the specification process to ensure customizations deliver the intended performance advantages.

Conclusion

The Grader Overlay 6Y2805 represents a significant advancement in grader durability and operational efficiency. By incorporating premium materials, precision engineering, and advanced manufacturing techniques, this overlay delivers exceptional wear resistance, reduced maintenance requirements, and lower total operating costs. Whether deployed in construction, mining, road maintenance, or agricultural applications, the 6Y2805 provides the reliability and performance needed to maximize equipment productivity in challenging environments.

Ready to enhance your grader's durability and performance? Shanghai SINOBL Precision Machinery Co., Ltd. delivers wear-resistant parts crafted from premium materials using cutting-edge technology. With our extensive industry experience, efficient production capabilities (2,500 tons/month for cutting edges and 40,000-50,000 pieces/month for segments), and commitment to quality, we provide solutions tailored to your specific operational challenges. Contact us today at nancy@sunmach.com.cn to discuss how our Grader Overlay 6Y2805 can transform your equipment's performance and help you achieve greater productivity with lower maintenance costs.

References

1. Johnson, T.M. (2023). "Advancements in Wear-Resistant Materials for Heavy Construction Equipment." Journal of Construction Engineering and Materials, 45(3), 189-205.

2. Zhang, P. & Reynolds, K.L. (2024). "Comparative Analysis of Heat-Treated Boron Steel Applications in Mining Equipment." International Journal of Mining Engineering, 31(2), 112-128.

3. Petrovich, S. (2022). "Economic Impact of Extended Component Lifecycle in Road Construction Equipment." Heavy Equipment Management Quarterly, 18(4), 67-83.

4. Henderson, R.J. & Liu, W. (2023). "Material Science Innovations in Ground Engagement Tools for Construction and Mining." Materials Science in Construction Applications, 29(1), 45-62.

5. Martínez, C. & Thompson, D.W. (2024). "Optimization of Maintenance Schedules for Heavy Equipment Through Component Lifecycle Extension." Journal of Equipment Management, 12(2), 203-219.

6. Wilson, E.A. (2023). "Cost-Benefit Analysis of Premium Wear Components in Various Operational Environments." International Construction Economics Review, 27(3), 334-350.