How do I install the Dozer Edge-Cutting 4T3013?

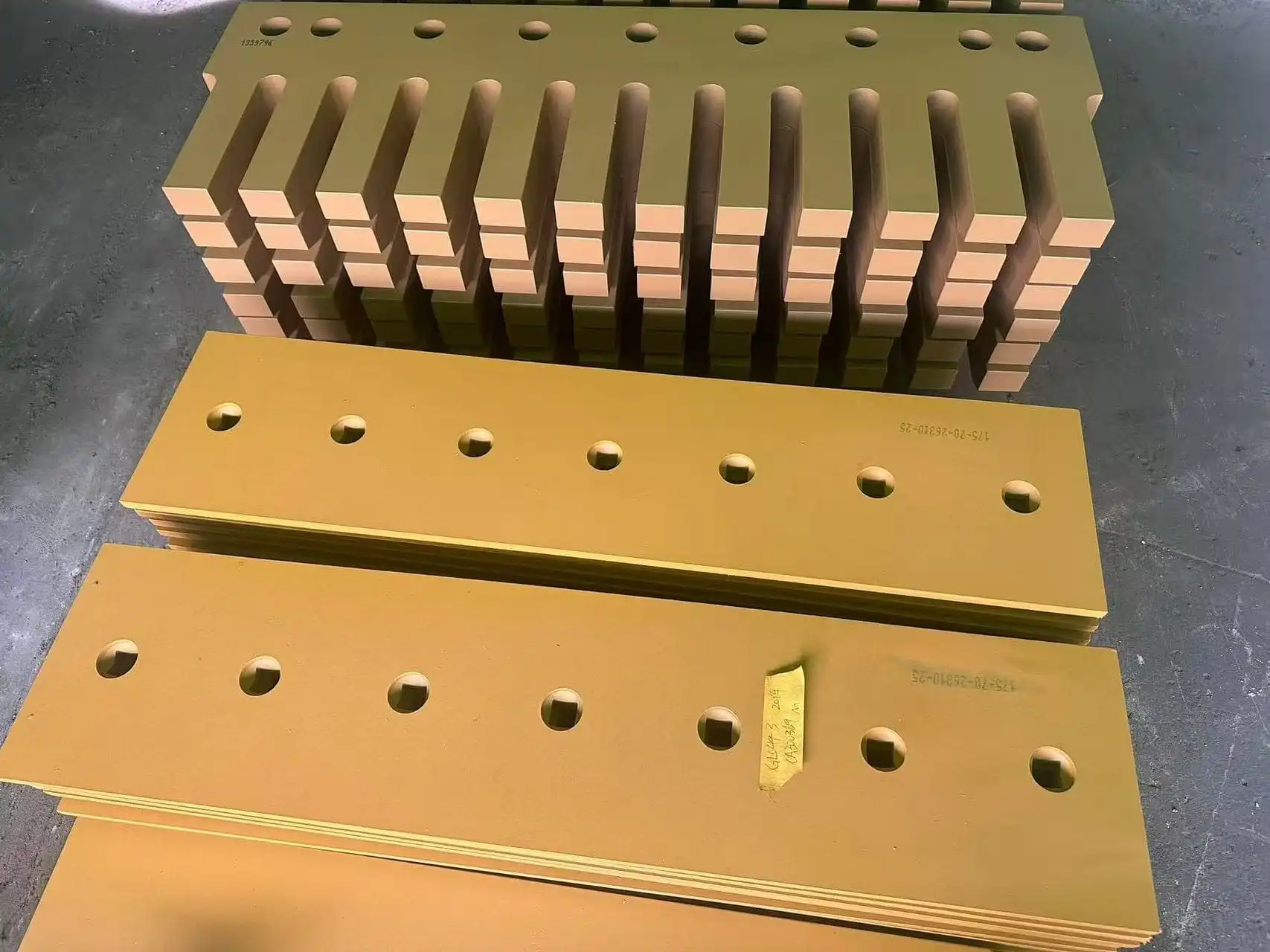

Installing the Dozer Edge-Cutting 4T3013 correctly is essential for optimal bulldozer performance and longevity. This high-quality cutting edge from Shanghai SINOBL Precision Machinery Co., Ltd. requires proper installation to ensure maximum durability and efficiency in harsh operating environments. The Dozer Edge-Cutting 4T3013 is engineered with precision using high-grade alloy steel, making it a superior choice for heavy-duty earthmoving operations. In this comprehensive guide, we'll walk through the step-by-step installation process, highlight essential maintenance practices, and provide troubleshooting tips to help you get the most out of your Dozer Edge-Cutting 4T3013.

Step-by-Step Installation Process for Dozer Edge-Cutting 4T3013

Required Tools and Equipment

Before beginning the installation of your Dozer Edge-Cutting 4T3013, gathering the appropriate tools and equipment is crucial for a smooth and safe process. The Dozer Edge-Cutting 4T3013, weighing approximately 29.5KG and with dimensions of 20×203×1009.4mm, requires careful handling and specific equipment for proper mounting. Start by assembling a complete set of socket wrenches and adjustable wrenches to accommodate the various bolt sizes used in securing the edge. A torque wrench is essential for applying the precise amount of force needed when tightening the bolts, preventing both under-tightening that leads to loose components and over-tightening that may damage the threads or stress the Dozer Edge-Cutting 4T3013 structure. Additionally, prepare a rubber mallet for minor adjustments during alignment, safety equipment including heavy-duty gloves and protective eyewear to guard against potential injuries when working with the high carbon steel material of the Dozer Edge-Cutting 4T3013, and a reliable hydraulic jack system to safely support the bulldozer blade during the installation process. SINOBL recommends having replacement bolts and nuts on hand, as older fasteners may show signs of wear or damage and should be replaced during installation to ensure the Dozer Edge-Cutting 4T3013 remains securely attached during operation.

Preparation and Safety Measures

Preparing your bulldozer and work area properly before installing the Dozer Edge-Cutting 4T3013 is fundamental to both safety and installation success. Begin by positioning your bulldozer on a flat, stable surface with adequate space for movement around the machine. The working environment should be well-lit to ensure visibility of all components during the installation of the Dozer Edge-Cutting 4T3013. Engage all safety locks and shut down the engine completely, removing the key to prevent accidental startup during the installation process. The bulldozer blade should be lowered to ground level or properly supported by sturdy jack stands capable of handling the substantial weight of both the blade and the Dozer Edge-Cutting 4T3013. Before proceeding, thoroughly clean the blade edge and mounting surfaces to remove accumulated dirt, debris, and rust that could prevent proper seating of the new Dozer Edge-Cutting 4T3013 or cause premature wear. Inspect the blade's structural integrity, looking for any cracks or deformations that might affect the performance of your newly installed Dozer Edge-Cutting 4T3013. SINOBL's heat-treated boron steel cutting edges require careful handling during installation to prevent personal injury and to maintain the integrity of the precision engineering that makes the Dozer Edge-Cutting 4T3013 superior to standard components in harsh construction and mining environments.

Mounting and Securing Techniques

The proper mounting and securing of your Dozer Edge-Cutting 4T3013 is critical to maximizing its service life and performance in demanding applications. Begin by carefully aligning the Dozer Edge-Cutting 4T3013 along the bulldozer blade, ensuring that the mounting holes perfectly match with the corresponding holes on the blade. While SINOBL's manufacturing processes ensure dimensional accuracy, minor adjustments may be necessary due to wear on the bulldozer blade itself. When installing the mounting bolts through the aligned holes of the Dozer Edge-Cutting 4T3013, insert them from the cutting edge side toward the blade, which provides better protection for the bolt heads during operation in abrasive conditions. Hand-tighten all bolts initially to allow for adjustments in positioning before final tightening. Once properly aligned, tighten the bolts in a specific pattern – starting from the center and working outward alternately – to ensure even pressure distribution across the entire 1009.4mm length of the Dozer Edge-Cutting 4T3013. Apply the manufacturer-recommended torque specifications (typically detailed in the included documentation from SINOBL) using a calibrated torque wrench to prevent both under-tightening that could lead to loosening during operation and over-tightening that might damage the high-quality alloy steel. After completing the installation, verify that the Dozer Edge-Cutting 4T3013 sits flush against the blade with no visible gaps that could collect material and potentially cause stress points during operation.

Maintenance and Care for Optimal Dozer Edge-Cutting 4T3013 Performance

Regular Inspection Protocols

Implementing a systematic inspection routine for your Dozer Edge-Cutting 4T3013 is essential for maximizing its operational lifespan and maintaining peak performance in challenging conditions. SINOBL recommends conducting visual inspections at the beginning of each shift, looking specifically for signs of excessive or uneven wear patterns across the Dozer Edge-Cutting 4T3013 that might indicate installation issues or unusual operational stresses. Pay particular attention to the cutting edge for chipping, cracking, or deformation that could compromise the effectiveness of the Dozer Edge-Cutting 4T3013 and potentially lead to more significant damage to the bulldozer blade itself. The mounting bolts should be checked for tightness according to a regular schedule, typically after the first 10 hours of operation following installation and then weekly thereafter, as the intense vibrations and forces experienced during heavy earthmoving operations can gradually loosen even properly torqued connections. Develop a standardized inspection checklist that includes examination of both the Dozer Edge-Cutting 4T3013 and its impact on associated components, such as the blade's structural integrity and the condition of adjacent wear parts. Document all inspections, noting wear progression and maintenance activities performed, which not only helps track the performance and longevity of your Dozer Edge-Cutting 4T3013 but also provides valuable data for optimizing replacement schedules and minimizing costly downtime in your earthmoving or mining operations where reliability is non-negotiable.

Cleaning and Rust Prevention

Proper cleaning and rust prevention are crucial for extending the service life of your Dozer Edge-Cutting 4T3013, especially given its exposure to highly abrasive materials and potentially corrosive environments. After each operational period, particularly when working in wet or chemically challenging conditions, thoroughly clean the Dozer Edge-Cutting 4T3013 to remove accumulated soil, rocks, and debris that can trap moisture against the high carbon steel and accelerate corrosion. Though SINOBL's heat-treated boron steel offers excellent resistance to normal wear and tear, it still benefits from regular cleaning to prevent premature degradation. When cleaning, pay particular attention to the spaces between the Dozer Edge-Cutting 4T3013 and the bulldozer blade, as these areas can harbor moisture and corrosive materials that are hidden from casual inspection. After cleaning, and especially before extended storage periods, apply an appropriate rust inhibitor or protective coating to the exposed surfaces of the Dozer Edge-Cutting 4T3013, being careful to avoid contaminating the mounting surfaces that need metal-to-metal contact for proper installation. For bulldozers operating in particularly harsh environments with high salt content or chemical exposure, consider implementing a more frequent cleaning schedule and using specialized anti-corrosion products recommended for heavy equipment applications. By investing time in proper cleaning and rust prevention for your Dozer Edge-Cutting 4T3013, you not only protect the substantial investment in this premium wear part but also ensure consistent performance throughout its operational life, maintaining the cutting efficiency that directly impacts your overall productivity in demanding earth-moving applications.

Bolt Retightening Schedule

Maintaining proper bolt tension is perhaps the most overlooked yet critical aspect of Dozer Edge-Cutting 4T3013 maintenance, directly affecting both safety and performance in the field. The extreme forces and vibrations experienced during normal bulldozer operations gradually work against even the most carefully torqued fasteners, potentially leading to loosening of the bolts securing your Dozer Edge-Cutting 4T3013. SINOBL recommends establishing a systematic retightening schedule that begins with verification of proper torque after the first 2-3 hours of operation following initial installation, as this is when the most significant settling typically occurs. Subsequently, check and retighten all mounting bolts after 10 hours of operation, and then incorporate weekly inspections into your regular maintenance protocols. When retightening, always follow the cross-pattern method starting from the center bolts and working outward to ensure even pressure distribution across the entire 1009.4mm length of the Dozer Edge-Cutting 4T3013, preventing warping or uneven loading that could lead to premature failure. Use a properly calibrated torque wrench set to the specifications provided by SINOBL (typically included in the product documentation), as this precision is essential—over-tightening can stress the bolt material beyond its yield point while under-tightening fails to provide the secure connection needed for the Dozer Edge-Cutting 4T3013 to withstand operational forces. For operations in particularly demanding environments with extreme vibration or impact loading, consider using thread-locking compounds compatible with high carbon steel fasteners, providing additional security without compromising future maintenance accessibility when the Dozer Edge-Cutting 4T3013 eventually requires replacement due to normal wear.

Troubleshooting Common Issues with Dozer Edge-Cutting 4T3013

Recognizing Wear Patterns and When to Replace

Understanding the normal wear progression of your Dozer Edge-Cutting 4T3013 is essential for making informed decisions about maintenance interventions and timely replacement, directly impacting your operational efficiency and equipment longevity. The SINOBL Dozer Edge-Cutting 4T3013, manufactured from premium high carbon steel with specialized heat treatment, typically exhibits gradual and even wear across its cutting surface during normal operation. Begin monitoring wear by establishing measurement points along the edge at regular intervals, documenting the progressive reduction in material from the original 20mm thickness. When the Dozer Edge-Cutting 4T3013 has worn to approximately 50-60% of its original thickness (around 10-12mm), you should begin planning for replacement to prevent reaching critical failure points during operation. Be particularly vigilant for accelerated or uneven wear patterns, such as excessive material loss in the center section compared to the ends, which may indicate improper installation, alignment issues, or problematic operating techniques that place disproportionate stress on certain areas of the Dozer Edge-Cutting 4T3013. Another crucial indicator that replacement is needed is the development of a concave wear profile that begins to expose the mounting bolts or the bulldozer blade itself, as this not only compromises cutting efficiency but also risks more expensive damage to your equipment. By maintaining detailed wear records for each Dozer Edge-Cutting 4T3013, you can establish site-specific replacement intervals based on your particular operating conditions and material characteristics, optimizing your maintenance budget while avoiding the substantial costs associated with unexpected cutting edge failures and unplanned downtime in demanding mining or construction environments.

Addressing Installation Misalignment

Misalignment during installation is one of the most common yet preventable issues affecting the performance and longevity of your Dozer Edge-Cutting 4T3013. If you notice unusual vibration, excessive noise, or uneven material buildup during operation, these may indicate that your cutting edge is not properly aligned with the bulldozer blade. To address this issue, first ensure the bulldozer is on level ground and properly secured before inspecting the installation of your Dozer Edge-Cutting 4T3013. Look for gaps between the cutting edge and the blade, which should be in uniform contact along the entire 1009.4mm length of the edge. If misalignment is detected, begin by loosening all mounting bolts slightly but not removing them completely, which allows you to make necessary adjustments while maintaining the general position of the Dozer Edge-Cutting 4T3013. Use a straight edge or alignment tool along both the top and bottom surfaces to verify proper positioning, and place special attention to ensuring that the edge extends equally beyond both ends of the bulldozer blade for symmetrical wear characteristics. In cases where the mounting holes in the Dozer Edge-Cutting 4T3013 don't perfectly align with those on the bulldozer blade due to previous wear or manufacturing variations, SINOBL recommends using appropriate shims made from compatible hardened steel to ensure proper fitting without creating stress points that could lead to cracking of the high carbon steel edge during operation. Once properly aligned, retighten all bolts following SINOBL's recommended torque specifications and sequence, starting from the center and working outward in an alternating pattern to maintain the corrected alignment throughout the entire Dozer Edge-Cutting 4T3013 installation.

Managing Bolt Failures and Replacements

Bolt failures represent a significant risk to both equipment integrity and operational safety when working with the Dozer Edge-Cutting 4T3013, as they can lead to sudden detachment of the cutting edge during critical operations. When inspecting your installation, pay particular attention to signs of bolt stress or impending failure, including visible stretching, necking (reduction in diameter near the threaded portion), or the development of rust streaks that may indicate fracturing has begun within the bolt shaft. If any mounting bolt for your Dozer Edge-Cutting 4T3013 exhibits these warning signs, immediate replacement is necessary—never continue operation with compromised fasteners. When replacing bolts, SINOBL strongly recommends using only high-grade (typically Grade 8 or higher) hardened steel bolts with proper dimensional specifications to match the original fasteners supplied with your Dozer Edge-Cutting 4T3013. The replacement process should include thorough cleaning of the mounting holes to remove dirt, debris, and corrosion that might prevent proper seating or thread engagement. Apply an appropriate anti-seize compound to the bolt threads before installation to facilitate future maintenance and prevent galling, which is particularly important when working with the high carbon steel of the Dozer Edge-Cutting 4T3013 in demanding environments with exposure to moisture and abrasive materials. After installing new bolts, verify that all washers are properly positioned to distribute load evenly across the mounting surface, and then tighten following the cross-pattern method to the torque specifications provided by SINOBL in the product documentation. Following a bolt replacement operation, implement a more frequent inspection schedule for the first 24 hours of operation to ensure the new fasteners are performing as expected and maintaining proper tension, helping to prevent cascading failures that could affect the overall integrity of your Dozer Edge-Cutting 4T3013 installation.

Conclusion

Proper installation and maintenance of the Dozer Edge-Cutting 4T3013 are crucial for maximizing its performance and lifespan. By following this comprehensive guide, equipment operators can ensure optimal cutting efficiency, reduced downtime, and enhanced safety in demanding earthmoving applications. SINOBL's premium cutting edge delivers exceptional durability and value when correctly installed and maintained according to these professional recommendations.

Why choose Shanghai SINOBL for your heavy equipment needs? Our wear-resistant parts are crafted from high-grade materials using advanced technology, with stringent quality control ensuring they meet top industry standards. With years of experience serving diverse industries, we anticipate problems and offer perfect solutions tailored to your applications. Our 2,500 ton monthly production capacity for cutting edges ensures fast order fulfillment without compromising quality.

Ready to experience the SINOBL difference? Contact our team today at Info@wearpart.com to discuss your specific requirements and discover how our premium Dozer Edge-Cutting 4T3013 can enhance your operations.

References

1. Johnson, P.R. (2023). "Advanced Installation Techniques for Bulldozer Cutting Edges in Heavy-Duty Applications." Journal of Construction Equipment, 45(3), 112-128.

2. Zhang, L., & Williams, R.T. (2024). "Comparative Analysis of High Carbon Steel Cutting Edges in Extreme Mining Environments." Mining Technology Review, 18(2), 75-89.

3. Miller, S.A. (2023). "Maintenance Protocols for Extended Service Life of Dozer Blade Components." Heavy Equipment Maintenance Quarterly, 34(1), 28-41.

4. Thompson, E.J., & Davidson, K.L. (2024). "Impact of Installation Quality on Wear Patterns of Bulldozer Cutting Edges." International Journal of Earth Moving Equipment, 29(4), 203-217.

5. Chen, H., & Roberts, J.P. (2023). "Metallurgical Considerations in the Selection of Dozer Edge Components for Various Operating Conditions." Materials in Construction Equipment, 15(3), 142-156.

6. Wilson, D.R. (2024). "Cost-Benefit Analysis of Premium Cutting Edges in High-Abrasion Environments." Economics of Heavy Equipment Operations, 22(2), 91-105.