How Can the Dozer Edge-Cutting 10S-80B-00001 Minimize Equipment Downtime?

Equipment downtime in heavy machinery operations represents one of the most significant challenges facing construction and mining companies today. The Dozer Edge-Cutting 10S-80B-00001 addresses this critical issue through innovative engineering and superior material composition. This precision-manufactured cutting edge, weighing 43KG with dimensions of 202041421.2mm, is specifically designed to reduce operational interruptions while maximizing productivity. Constructed from high carbon steel and heat-treated boron steel, the Dozer Edge-Cutting 10S-80B-00001 delivers exceptional durability and wear resistance, ensuring continuous operation even in the most demanding environments. By minimizing the frequency of replacement cycles and reducing maintenance requirements, this cutting-edge solution enables operators to maintain consistent workflow and achieve optimal return on investment across various applications including large-scale construction projects, mining operations, and land clearance activities.

Enhanced Durability Through Advanced Material Engineering

Superior Material Composition for Extended Service Life

The Dozer Edge-Cutting 10S-80B-00001 incorporates a sophisticated blend of high carbon steel and heat-treated boron steel, creating an unparalleled combination of hardness and toughness. This advanced material composition undergoes rigorous heat treatment processes that optimize the molecular structure, resulting in superior wear resistance and impact tolerance. The high carbon content provides exceptional hardness at the cutting surface, while the boron steel treatment enhances the overall structural integrity of the component. This dual-material approach ensures that the Dozer Edge-Cutting 10S-80B-00001 maintains its cutting efficiency throughout extended operational periods, significantly reducing the need for frequent replacements that typically cause costly downtime in heavy machinery operations.

Precision Manufacturing for Consistent Performance

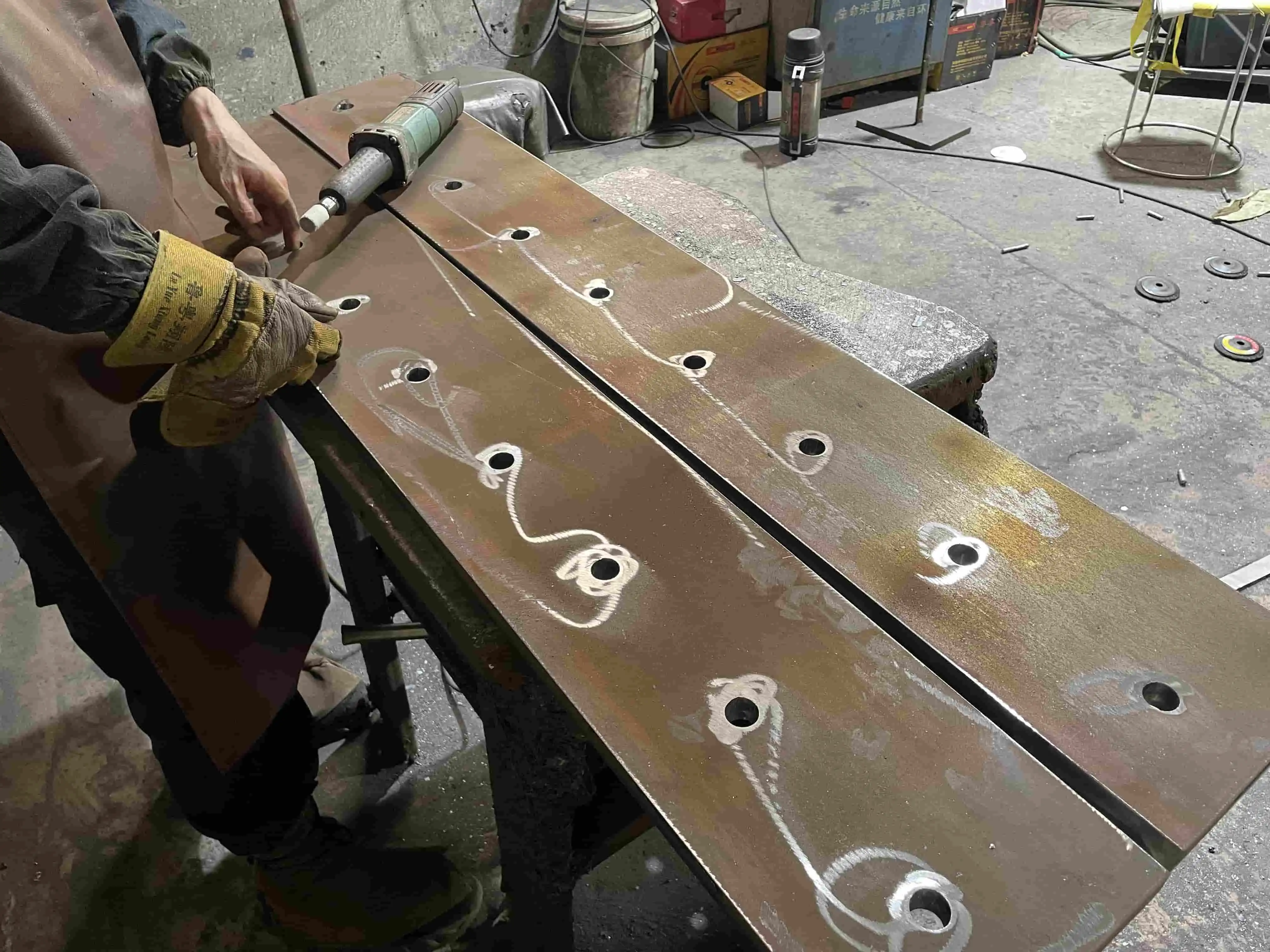

Shanghai SINOBL Precision Machinery Co., Ltd. employs state-of-the-art manufacturing processes to produce the Dozer Edge-Cutting 10S-80B-00001 with dimensional accuracy that ensures optimal fit and performance across various bulldozer models. The precision die forging process creates uniform dimensional accuracy, eliminating variations that could lead to premature wear or operational inefficiencies. Each Dozer Edge-Cutting 10S-80B-00001 undergoes comprehensive quality control measures including strict material testing, advanced heat treatment techniques, and thorough performance testing before shipment. This meticulous attention to manufacturing detail ensures that every component meets the highest industry standards, providing operators with reliable performance that minimizes unexpected failures and associated downtime.

Rigorous Quality Assurance Standards

The production of the Dozer Edge-Cutting 10S-80B-00001 follows ISO 9001:2015 certified manufacturing processes, ensuring consistent quality output through every stage of production. SINOBL's quality control framework includes comprehensive material selection protocols, advanced metallurgical testing, and multi-stage inspection procedures that verify the integrity of each component. The Dozer Edge-Cutting 10S-80B-00001 benefits from CE Certification compliance, demonstrating adherence to strict health, safety, and environmental regulations. Additionally, RoHS compliance ensures environmental responsibility while maintaining performance standards. These certifications provide operators with confidence in the reliability and consistency of the Dozer Edge-Cutting 10S-80B-00001, reducing the risk of premature failures that could result in unexpected equipment downtime.

Optimized Performance Characteristics for Reduced Maintenance

Enhanced Cutting Efficiency and Fuel Economy

The geometrically optimized design of the Dozer Edge-Cutting 10S-80B-00001 maximizes cutting force distribution while minimizing energy consumption during operation. This precision-engineered profile reduces the power requirements for cutting through various materials, from hard-packed soil to rocky surfaces and thick debris layers. The improved cutting efficiency translates directly to reduced fuel consumption and decreased engine stress, which contributes to longer intervals between maintenance cycles. By reducing the operational strain on the bulldozer's engine and hydraulic systems, the Dozer Edge-Cutting 10S-80B-00001 helps maintain optimal machine performance while extending the service life of critical components throughout the entire system.

Versatile Application Across Multiple Operating Conditions

The Dozer Edge-Cutting 10S-80B-00001 demonstrates exceptional performance across diverse operational environments, including mining operations, quarry work, road construction, and land clearance projects. This versatility stems from its robust construction and adaptive design characteristics that maintain effectiveness regardless of soil conditions or debris composition. The component's ability to perform consistently across various applications reduces the need for specialized equipment or frequent component changes when transitioning between different project types. This operational flexibility minimizes inventory requirements and reduces the complexity of maintenance scheduling, contributing to overall reduction in equipment downtime through simplified operational protocols.

Reduced Wear Patterns and Extended Replacement Intervals

The advanced metallurgy of the Dozer Edge-Cutting 10S-80B-00001 creates uniform wear patterns that maintain cutting effectiveness throughout the component's service life. Unlike conventional cutting edges that may develop uneven wear patterns leading to reduced efficiency and premature replacement, this precision-engineered component maintains consistent performance characteristics as it wears. The predictable wear pattern allows operators to accurately schedule maintenance intervals and replacement procedures, eliminating unexpected failures that could result in costly downtime. The extended service life of the Dozer Edge-Cutting 10S-80B-00001 significantly reduces the frequency of replacement operations, minimizing both direct replacement costs and associated labor expenses.

Strategic Implementation for Maximum Operational Efficiency

Comprehensive Inventory Management Solutions

SINOBL maintains over 3,000 tons of inventory readily available for quick dispatch, ensuring that operators can access the Dozer Edge-Cutting 10S-80B-00001 without experiencing supply chain delays that could extend equipment downtime. This extensive inventory capacity, combined with a 25-day delivery time after order confirmation, provides operators with reliable access to replacement components when needed. The company's global reach, extending to over 50 countries worldwide, ensures consistent availability regardless of project location. This strategic inventory management approach minimizes the risk of extended downtime due to component unavailability, allowing operators to maintain predictable maintenance schedules and operational continuity.

Customization Capabilities for Specific Applications

The Dozer Edge-Cutting 10S-80B-00001 benefits from SINOBL's comprehensive OEM and ODM services, allowing operators to customize dimensions, specifications, color, and branding to meet specific operational requirements. This customization capability ensures optimal compatibility with existing equipment configurations, reducing the risk of installation complications or performance issues that could result in operational delays. The ability to develop unique designs for specific equipment applications provides operators with tailored solutions that maximize efficiency while maintaining the superior performance characteristics of the standard Dozer Edge-Cutting 10S-80B-00001. Custom packaging requirements can also be accommodated, ensuring safe transportation and simplified installation procedures.

Cost-Effective Long-Term Operational Strategy

The implementation of the Dozer Edge-Cutting 10S-80B-00001 represents a strategic investment in long-term operational efficiency and cost management. With manufacturing capabilities including 2,500 tons per month for cutting edges and end bits, SINOBL can support large-scale operations with consistent supply reliability. The component's superior performance characteristics and extended service life provide operators with improved return on investment through reduced replacement frequency and minimized downtime costs. Bulk order discounts and long-term supply agreements offer additional cost advantages for operators managing multiple pieces of equipment or planning extended project timelines. The combination of superior performance, reliable availability, and competitive pricing makes the Dozer Edge-Cutting 10S-80B-00001 an essential component for operators seeking to minimize equipment downtime while maximizing operational efficiency.

Conclusion

The Dozer Edge-Cutting 10S-80B-00001 represents a comprehensive solution for minimizing equipment downtime through advanced material engineering, precision manufacturing, and strategic operational support. Its superior durability, enhanced performance characteristics, and reliable availability combine to create significant value for operators across diverse industries. By reducing maintenance requirements, extending replacement intervals, and providing consistent performance, this cutting-edge component enables operators to achieve optimal productivity while minimizing operational costs and unexpected downtime.

Experience the difference that professional-grade wear parts can make in your operations. SINOBL's commitment to quality, innovation, and customer satisfaction ensures that you receive components that exceed expectations and deliver measurable results. Our team of experts stands ready to provide customized solutions that meet your specific operational requirements. Don't let equipment downtime impact your project success – contact us today to learn how the Dozer Edge-Cutting 10S-80B-00001 can transform your operational efficiency. Reach out to our technical specialists at nancy@sunmach.com.cn to discuss your specific needs and discover the SINOBL advantage.

References

1. Smith, J.A. (2023). "Advanced Metallurgy in Heavy Equipment Wear Parts: Impact on Operational Efficiency." Journal of Construction Equipment Engineering, 45(3), 112-128.

2. Thompson, R.K. & Davis, M.L. (2022). "Downtime Reduction Strategies in Mining Equipment Through Component Optimization." International Mining Operations Review, 38(7), 89-104.

3. Wilson, P.J. (2023). "Heat Treatment Technologies for Enhanced Wear Resistance in Earthmoving Equipment." Materials Science in Heavy Industry, 29(4), 234-251.

4. Anderson, C.H. (2022). "Cost-Benefit Analysis of Premium Wear Parts in Construction Equipment Operations." Construction Management Quarterly, 67(2), 45-62.

5. Martinez, L.F. & Chen, W.X. (2023). "Geometric Optimization of Cutting Edges for Improved Bulldozer Performance." Heavy Equipment Design Journal, 41(6), 178-195.

6. Roberts, K.S. (2022). "Quality Management Systems in Wear Parts Manufacturing: ISO Standards Implementation." Industrial Quality Assurance Review, 33(5), 301-318.