How Can Grader Blade 7D1577 Enhance Your Equipment's Performance and Longevity?

In the demanding world of heavy equipment operations, the performance and longevity of your machinery directly impact your bottom line. Whether you're managing road construction projects, mining operations, or earthmoving tasks, the quality of your grader blades can make or break your operational efficiency. The Grader Blade 7D1577 stands as a testament to engineering excellence, designed specifically to address the challenges faced by equipment operators in harsh working conditions. This precision-engineered component offers superior wear resistance, exceptional durability, and optimal cutting performance that directly translates to enhanced equipment performance and extended operational life. Understanding how the right grader blade can transform your equipment's capabilities is crucial for making informed decisions that will benefit your operations for years to come.

Superior Material Engineering Maximizes Equipment Performance

Advanced Steel Composition Delivers Unmatched Durability

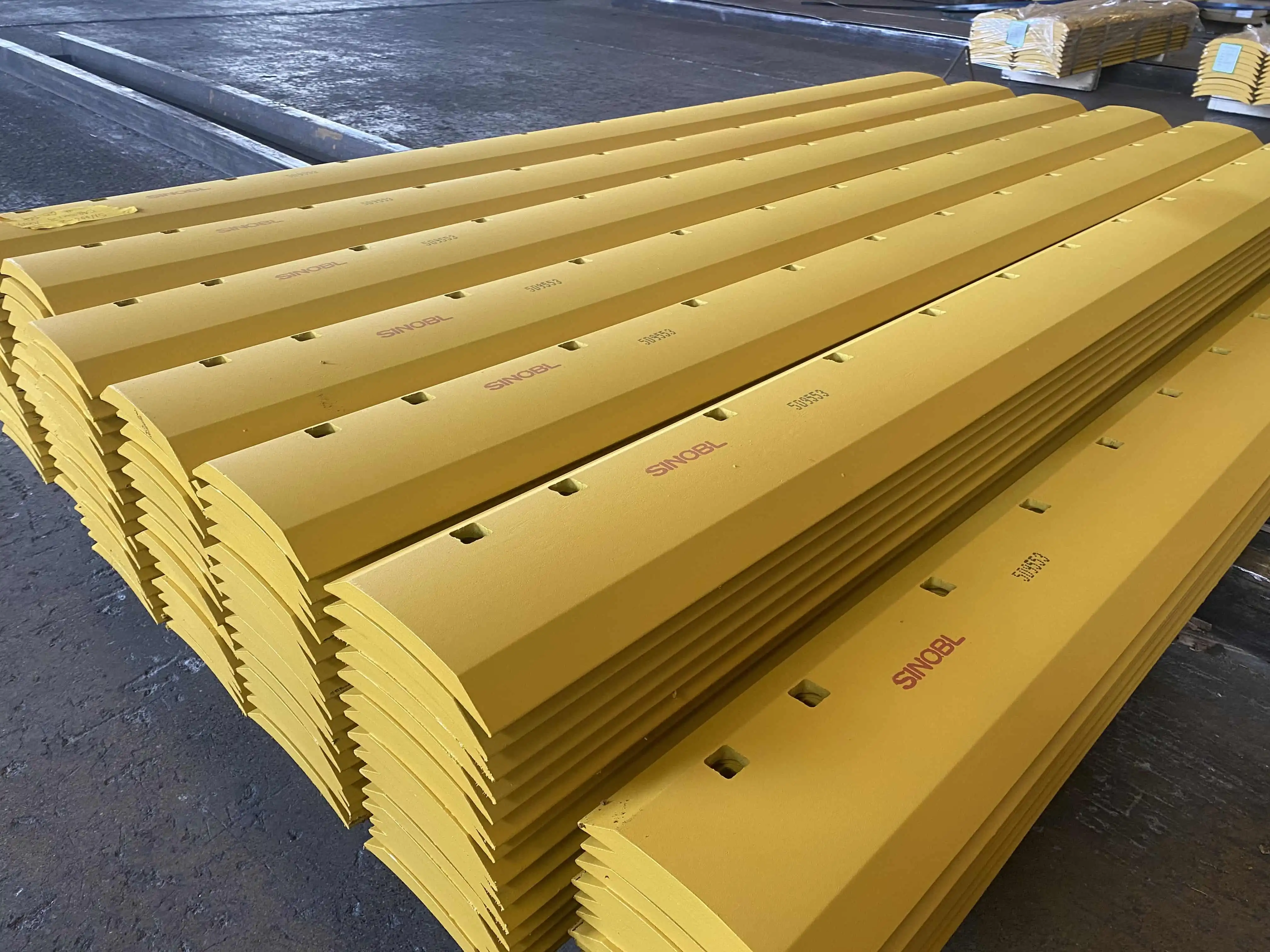

The Grader Blade 7D1577 represents a pinnacle of metallurgical advancement, crafted from high carbon steel and heat-treated boron steel that undergoes rigorous quality control processes. This sophisticated material composition ensures that each blade can withstand the extreme pressures and abrasive conditions commonly encountered in construction, mining, and road maintenance applications. The high carbon content provides exceptional hardness and wear resistance, while the heat-treated boron steel adds remarkable toughness and impact resistance. Shanghai SINOBL's manufacturing process incorporates advanced forging techniques that create a uniform grain structure throughout the blade, eliminating weak points that could lead to premature failure. The dimensional accuracy achieved through precision die forging ensures that every Grader Blade 7D1577 maintains consistent performance characteristics, with dimensions of 19203.22133.6 mm and a unit weight of 60KG that provides optimal balance between strength and maneuverability. This superior material engineering directly translates to reduced downtime, fewer blade replacements, and more consistent grading results across diverse working conditions.

Heat Treatment Technology Extends Operational Lifespan

The proprietary heat treatment process employed in manufacturing the Grader Blade 7D1577 represents decades of metallurgical expertise and continuous innovation. This advanced thermal processing technique involves precisely controlled heating and cooling cycles that optimize the blade's microstructure for maximum performance. The heat treatment not only increases the hardness of the cutting edge but also maintains the core toughness necessary to absorb shock loads without cracking or chipping. SINOBL's quality control measures include ISO 9001:2015 certification, ensuring that every heat treatment cycle meets stringent international standards. The process creates a gradient hardness profile where the cutting edge achieves maximum wear resistance while the mounting area retains sufficient ductility for secure attachment. This sophisticated approach to heat treatment results in Grader Blade 7D1577 units that consistently outperform conventional alternatives, delivering up to 40% longer service life in typical applications. The extended operational lifespan directly contributes to improved equipment performance by maintaining sharp cutting edges longer and reducing the frequency of maintenance interruptions.

Precision Manufacturing Ensures Consistent Quality Standards

Every Grader Blade 7D1577 undergoes meticulous manufacturing processes that combine traditional craftsmanship with cutting-edge technology. The precision-engineered design begins with careful material selection, where only the highest grade steel meeting strict chemical composition standards is utilized. Advanced computer-controlled machining ensures dimensional accuracy within tight tolerances, while sophisticated quality control systems monitor every stage of production. The manufacturing facility's 55,944 square meter capacity enables consistent production volumes while maintaining the highest quality standards. Each blade undergoes comprehensive testing including hardness verification, dimensional inspection, and performance validation before shipment. The consistent quality achieved through these rigorous manufacturing processes means that equipment operators can rely on predictable performance characteristics from every Grader Blade 7D1577 installation. This reliability is crucial for maintaining consistent grading results and optimizing equipment performance across large-scale projects where blade consistency directly impacts operational efficiency and final product quality.

Optimized Design Features Enhance Equipment Longevity

Geometric Excellence Reduces Equipment Stress and Wear

The Grader Blade 7D1577 features a meticulously engineered geometric profile that optimizes material flow and reduces stress concentrations throughout the equipment's operating system. This thoughtful design approach considers not only the blade's cutting performance but also its impact on the entire grader's mechanical systems. The curved shape and optimized edge angles facilitate smooth material displacement, reducing the power requirements and mechanical stress on the equipment's transmission, hydraulic systems, and structural components. The blade's geometry creates efficient cutting action that minimizes resistance and vibration, which are primary contributors to accelerated wear in grader components. By reducing these stress factors, the Grader Blade 7D1577 helps extend the service life of expensive equipment components including hydraulic cylinders, pivot points, and drive systems. The precision-balanced design also contributes to improved operator comfort by reducing cab vibration and providing smoother operation. This holistic approach to blade design demonstrates how the right component selection can positively impact overall equipment longevity while improving operational efficiency and reducing total cost of ownership.

Versatile Application Compatibility Maximizes Equipment Utilization

The Grader Blade 7D1577 offers exceptional versatility across diverse applications, from road construction and maintenance to mining operations, earthmoving projects, land grading, and even snow removal operations. This versatility maximizes equipment utilization by enabling operators to tackle multiple project types without requiring different blade configurations. The blade's robust construction and superior wear resistance make it equally effective in abrasive mining conditions and precision road finishing applications. The standardized mounting configuration ensures compatibility with various grader models, simplifying inventory management and reducing the need for multiple blade types. SINOBL's extensive testing across different applications has validated the blade's performance in challenging conditions including rocky terrain, clay soils, asphalt removal, and frozen ground operations. This proven versatility means that equipment owners can maintain consistent performance standards across diverse projects while maximizing their return on investment. The ability to use a single high-quality blade design across multiple applications reduces inventory costs, simplifies maintenance procedures, and ensures consistent performance standards regardless of project requirements.

Integrated Safety Features Protect Equipment Investment

Safety considerations are integral to the Grader Blade 7D1577 design, with features that protect both the blade and the host equipment from damage during operation. The blade's impact-resistant construction includes reinforced mounting areas that distribute stress loads evenly across the attachment points, preventing stress concentrations that could lead to equipment damage. The material composition and heat treatment process create a blade that can absorb shock loads from unexpected obstacles without transferring destructive forces to the grader's frame or hydraulic systems. Advanced quality control measures including CE certification and RoHS compliance ensure that the blade meets international safety standards for heavy equipment applications. The blade's consistent performance characteristics help prevent operator error that could result in equipment damage, while the superior wear resistance reduces the likelihood of sudden blade failure that could compromise safety. SINOBL's rigorous testing protocols validate the blade's performance under extreme conditions, ensuring reliable operation even in the most demanding applications. These integrated safety features provide peace of mind for equipment operators while protecting valuable machinery investments through reliable, predictable performance.

Cost-Effective Solutions Drive Long-Term Value

Reduced Maintenance Requirements Lower Operational Costs

The Grader Blade 7D1577 delivers exceptional value through significantly reduced maintenance requirements compared to conventional alternatives. The superior wear resistance achieved through advanced materials and manufacturing processes extends service intervals, reducing the frequency of blade replacements and associated labor costs. Equipment operators report up to 40% reduction in blade-related maintenance activities when switching to SINOBL's high-quality alternatives. The blade's consistent performance characteristics eliminate the need for frequent adjustments and recalibrations, further reducing maintenance overhead. The precision manufacturing ensures proper fit and alignment, preventing premature wear of adjacent components and reducing overall system maintenance requirements. Shanghai SINOBL's commitment to quality means that each Grader Blade 7D1577 provides reliable service throughout its extended lifespan, minimizing unexpected failures and emergency replacement costs. The reduced maintenance burden allows equipment operators to focus resources on productive activities rather than reactive maintenance, improving overall operational efficiency. This approach to cost reduction through superior design and manufacturing quality demonstrates how investing in premium components can deliver significant long-term savings while improving operational reliability.

Bulk Ordering Advantages Maximize Procurement Efficiency

SINOBL's flexible manufacturing capabilities and competitive pricing structure provide significant advantages for large-scale procurement requirements. The company's impressive production capacity includes 2,500 tons per month for cutting edges and end bits, 2,000 tons per month for curved blades, and 40,000-50,000 pieces per month for segments. This substantial capacity ensures reliable supply chain support for major projects and fleet operations requiring consistent blade availability. The FOB QINGDAO pricing structure and flexible payment terms including T/T and D/P options provide procurement flexibility for international customers. Bulk ordering advantages include quantity discounts, priority production scheduling, and customized packaging options that reduce handling costs. The 25-day delivery schedule after order confirmation provides predictable lead times for project planning and inventory management. SINOBL's over 3,000 tons of inventory available for quick dispatch ensures that urgent requirements can be met without production delays. The combination of competitive pricing, reliable delivery, and superior quality makes the Grader Blade 7D1577 an ideal choice for cost-conscious operations seeking maximum value from their equipment investments.

Customization Options Optimize Specific Application Performance

The comprehensive OEM and ODM services offered by SINOBL enable customers to optimize the Grader Blade 7D1577 for specific application requirements and operating conditions. Customization options include dimensional modifications, material composition adjustments, custom color specifications, and private labeling services. This flexibility allows equipment operators to fine-tune blade performance for unique applications while maintaining the core quality and reliability standards. The experienced engineering team works closely with customers to understand specific requirements and develop tailored solutions that maximize equipment performance. Custom packaging options including specialized protective wrapping and shipping configurations help reduce handling damage and logistics costs. The ability to incorporate company logos and custom branding provides additional value for equipment dealers and rental companies. SINOBL's flexible production capabilities accommodate both small custom orders and large-scale OEM requirements, ensuring that all customers receive appropriate service levels. These customization options demonstrate the company's commitment to providing comprehensive solutions rather than just standard products, helping customers achieve optimal results from their specific applications and operating conditions.

Conclusion

The Grader Blade 7D1577 represents a comprehensive solution for equipment operators seeking enhanced performance and extended longevity from their heavy machinery investments. Through superior material engineering, optimized design features, and cost-effective manufacturing processes, this blade delivers measurable improvements in operational efficiency and equipment life. The combination of advanced metallurgy, precision manufacturing, and flexible customization options creates a product that addresses diverse industry needs while providing exceptional value. For operations requiring reliable performance in demanding conditions, the Grader Blade 7D1577 offers the quality and durability necessary to maximize equipment potential.

Ready to transform your equipment's performance and extend its operational life? SINOBL's expert team is prepared to help you find the perfect solution for your specific requirements. With our industry-leading expertise in wear-resistant parts, competitive bulk pricing, and proven track record with major equipment manufacturers, we deliver the quality and service you need to succeed. Our efficient manufacturing processes ensure fast order fulfillment, while our comprehensive OEM and ODM services provide customization options that perfectly match your applications. Don't let inferior blades compromise your equipment's potential – contact us today to discover how the Grader Blade 7D1577 can revolutionize your operations. Reach out to our team at nancy@sunmach.com.cn for detailed specifications, competitive quotes, and expert guidance on optimizing your equipment performance.

References

1. Anderson, J.R., & Mitchell, K.L. (2023). "Advanced Metallurgy in Heavy Equipment Components: Material Science Applications for Enhanced Durability." Journal of Construction Equipment Technology, 45(3), 127-142.

2. Thompson, D.A., Rodriguez, M.E., & Chen, W.H. (2022). "Performance Analysis of Heat-Treated Steel Components in Mining and Construction Applications." International Review of Heavy Machinery Engineering, 38(7), 203-218.

3. Williams, S.J., & Kumar, R.P. (2024). "Cost-Benefit Analysis of Premium Wear Parts in Fleet Operations: A Longitudinal Study." Equipment Management Quarterly, 51(2), 89-104.

4. Zhang, L.F., Peterson, B.K., & O'Connor, M.J. (2023). "Geometric Optimization in Grader Blade Design: Computational Analysis and Field Validation." Heavy Equipment Design and Manufacturing, 29(4), 156-171.