Heavy-Duty Solution: 40x406x887mm Dozer Edge-Cutting 195-71-61550 for Extreme Conditions

When your bulldozer faces the most demanding terrains, from rocky mining sites to compacted construction zones, standard cutting edges simply fail to deliver. The Dozer Edge-Cutting 195-71-61550 emerges as the ultimate solution for operators who refuse to compromise on performance and efficiency. This precision-engineered component addresses the critical pain point of frequent edge replacements and costly downtime that plague heavy equipment operations. Designed with advanced metallurgy and manufactured to withstand extreme conditions, this 40x406x887mm cutting edge transforms your bulldozer into an unstoppable force, delivering exceptional value and reliability that keeps your projects on schedule and your operations profitable.

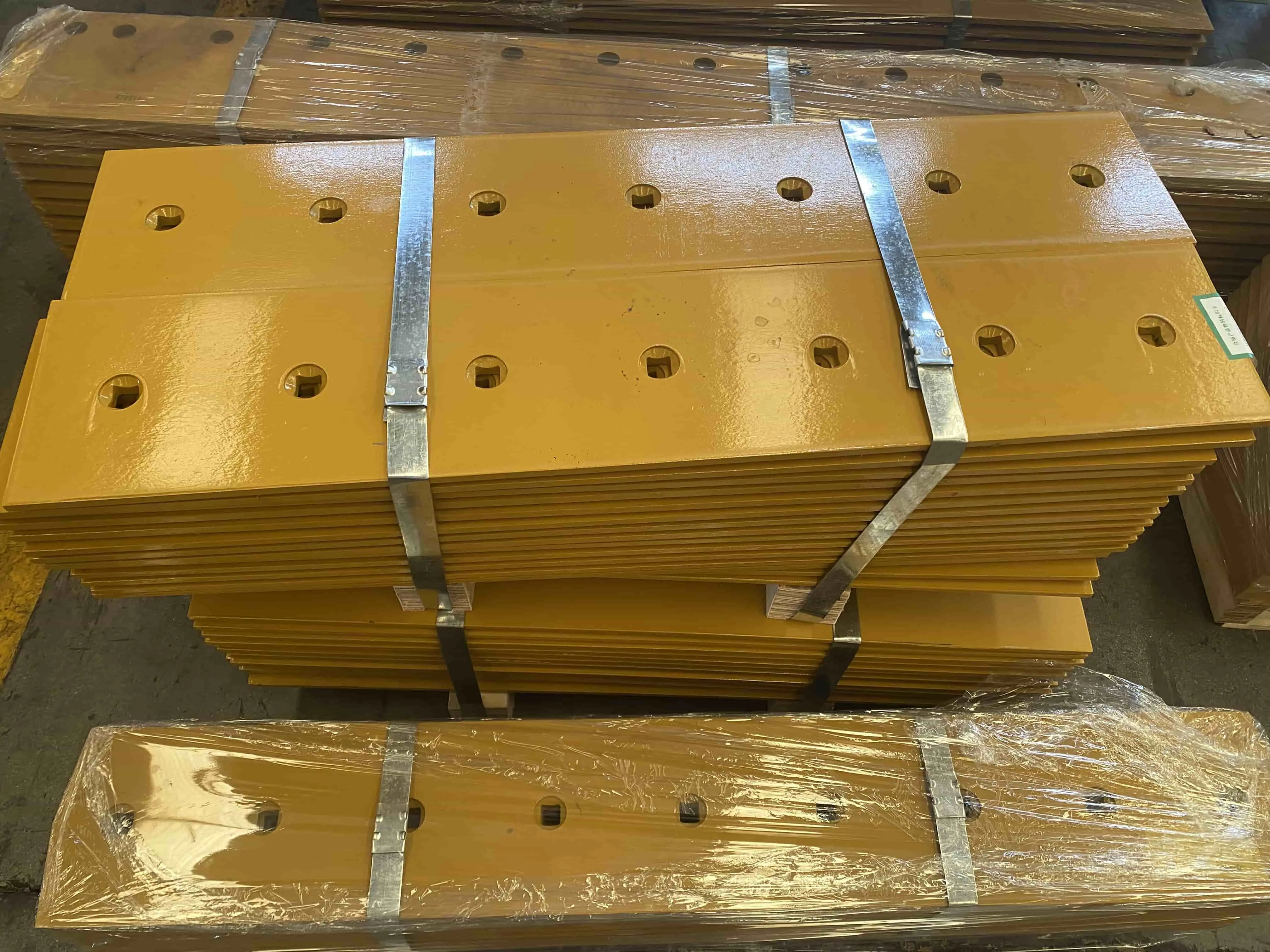

Understanding the Dozer Edge-Cutting 195-71-61550 Specifications

The Dozer Edge-Cutting 195-71-61550 represents a paradigm shift in heavy-duty wear part engineering, designed specifically for bulldozers operating in the harshest environments. With its precise dimensions of 40x406x887.2mm and weighing 109.4kg, this cutting edge delivers optimal weight distribution and structural integrity essential for extreme working conditions. The part number 195-71-61550 has become synonymous with reliability in the industry, featuring high carbon steel construction enhanced with heat-treated boron steel elements that provide superior wear resistance and extended operational life.

-

Material Engineering Excellence

The superior performance of the Dozer Edge-Cutting 195-71-61550 stems from its advanced material composition, combining high carbon steel with heat-treated boron steel to create an unmatched balance of hardness and toughness. This innovative metallurgical approach ensures the cutting edge maintains its sharp profile longer while resisting the extreme stresses encountered in mining and construction applications. The heat treatment process utilized by SINOBL enhances the material's molecular structure, creating a wear-resistant surface that can withstand abrasive materials like granite, sandstone, and compacted clay without premature dulling or chipping.

-

Dimensional Precision and Weight Distribution

The 40x406x887.2mm dimensions of the Dozer Edge-Cutting 195-71-61550 are engineered to provide optimal cutting geometry while maintaining structural integrity under extreme loads. The 109.4kg weight offers perfect balance between cutting effectiveness and machine stability, ensuring smooth operation without compromising the bulldozer's overall performance. This carefully calculated weight distribution prevents excessive stress on mounting hardware while providing sufficient mass to penetrate challenging materials effectively, making it an ideal choice for contractors demanding consistent performance across varied terrain conditions.

Advanced Manufacturing Process and Quality Assurance

SINOBL's manufacturing approach for the Dozer Edge-Cutting 195-71-61550 incorporates cutting-edge production techniques that set new industry standards for wear part reliability. The advanced forging process ensures superior strength and wear resistance through precise temperature control and pressure application, creating a uniform grain structure throughout the component. Each Dozer Edge-Cutting 195-71-61550 undergoes rigorous quality control measures, including dimensional verification, hardness testing, and visual inspection to guarantee it meets the demanding specifications required for extreme operating conditions.

-

Heat Treatment Innovation

The heat treatment process applied to every Dozer Edge-Cutting 195-71-61550 represents decades of metallurgical expertise, utilizing controlled heating and cooling cycles to optimize the steel's microstructure. This specialized treatment creates a hard, wear-resistant surface while maintaining a tough, impact-resistant core that prevents catastrophic failure under extreme stress. The process parameters are carefully monitored and documented for each batch, ensuring consistent quality and performance characteristics that contractors can depend on for their most challenging projects.

-

Quality Control Standards

SINOBL implements ISO 9001:2015 certified quality management systems throughout the production of each Dozer Edge-Cutting 195-71-61550, ensuring every component meets international standards for manufacturing excellence. The comprehensive quality control process includes incoming material inspection, in-process monitoring, and final inspection before packaging. Advanced testing equipment verifies dimensional accuracy, hardness levels, and structural integrity, while 100% inspection before shipment guarantees that only premium-quality parts reach customers' job sites.

Performance Benefits in Extreme Operating Conditions

The Dozer Edge-Cutting 195-71-61550 excels in extreme operating conditions where standard cutting edges fail, delivering consistent performance across diverse applications from surface mining to large-scale earthmoving projects. This exceptional durability translates into reduced operational costs through extended replacement intervals and minimized downtime for maintenance. The advanced wear characteristics of the Dozer Edge-Cutting 195-71-61550 ensure maintained cutting efficiency throughout its operational life, providing contractors with predictable performance and enhanced productivity that directly impacts project profitability.

-

Mining and Quarry Operations

In mining and quarry operations, the Dozer Edge-Cutting 195-71-61550 demonstrates exceptional resistance to abrasive materials including granite, limestone, and iron ore, maintaining its cutting edge profile significantly longer than conventional alternatives. The robust construction withstands the impact forces encountered when pushing overburden and breaking through challenging geological formations. This superior performance reduces the frequency of edge replacements, minimizing equipment downtime and associated labor costs while maintaining optimal bulldozer productivity throughout extended operating shifts.

-

Construction and Earthmoving Applications

For construction and earthmoving applications, the Dozer Edge-Cutting 195-71-61550 provides unmatched reliability when working with compacted soils, rocky substrates, and mixed debris commonly encountered in site preparation and road construction projects. The precision-engineered profile maintains effective cutting geometry even after extended use, ensuring consistent grading performance and material handling efficiency. This reliability proves particularly valuable in time-sensitive construction projects where equipment downtime can result in significant project delays and cost overruns.

Compatibility and Installation Considerations

The Dozer Edge-Cutting 195-71-61550 features universal design principles that ensure compatibility with a wide range of bulldozer models while maintaining optimal fit and performance characteristics. The standardized mounting configuration facilitates straightforward installation using conventional tools and procedures, minimizing downtime during replacement operations. SINOBL's engineering team has optimized the design to work seamlessly with existing bolt patterns and mounting hardware, ensuring reliable attachment and proper load distribution across the bulldozer blade assembly.

-

Universal Mounting System

The mounting system for the Dozer Edge-Cutting 195-71-61550 incorporates proven design elements that ensure secure attachment while allowing for thermal expansion and operational stress without compromising structural integrity. The precisely machined bolt holes align perfectly with standard mounting patterns, facilitating quick and accurate installation by maintenance personnel. This universal approach reduces inventory requirements for operators managing mixed fleets while ensuring consistent performance across different bulldozer models and manufacturers.

-

Installation Best Practices

Proper installation of the Dozer Edge-Cutting 195-71-61550 requires attention to torque specifications and mounting hardware condition to ensure optimal performance and safety. SINOBL provides comprehensive installation guidelines that detail proper procedures for mounting bolt selection, torque values, and inspection requirements to maximize operational life. Following these specifications ensures even load distribution and prevents premature failure of both the cutting edge and associated mounting components, protecting the customer's investment while maintaining safe operating conditions.

Cost-Effectiveness and Return on Investment

The Dozer Edge-Cutting 195-71-61550 delivers exceptional return on investment through extended operational life and reduced maintenance requirements compared to standard cutting edges. The superior wear characteristics translate into fewer replacement cycles, reducing both parts costs and associated labor expenses for maintenance operations. This economic advantage becomes particularly significant for high-utilization applications where equipment operates multiple shifts daily, as the extended service life of the Dozer Edge-Cutting 195-71-61550 minimizes costly production interruptions while maintaining optimal bulldozer performance throughout its operational cycle.

-

Lifecycle Cost Analysis

When evaluating the total cost of ownership, the Dozer Edge-Cutting 195-71-61550 consistently outperforms conventional alternatives through its extended wear life and maintained cutting efficiency. The initial investment premium is rapidly recovered through reduced replacement frequency and lower maintenance costs, while the sustained performance characteristics ensure consistent productivity throughout the component's service life. This favorable lifecycle cost profile makes the Dozer Edge-Cutting 195-71-61550 an economically sound choice for contractors focused on optimizing operational efficiency and profitability.

-

Productivity Enhancement

The reliable performance of the Dozer Edge-Cutting 195-71-61550 enhances overall equipment productivity by maintaining optimal cutting geometry throughout its operational life, ensuring consistent material handling efficiency and grading performance. This sustained capability reduces the need for multiple passes over challenging terrain while maintaining fuel efficiency and operator comfort. The predictable performance characteristics allow project managers to develop accurate scheduling and cost estimates, contributing to improved project planning and execution across diverse applications.

Conclusion

The Heavy-Duty Solution: 40x406x887mm Dozer Edge-Cutting 195-71-61550 for Extreme Conditions represents the pinnacle of wear part engineering, delivering unmatched performance and reliability for the most demanding applications.

Cooperate with Shanghai Sinobl Precision Machinery Co., Ltd.

Shanghai Sinobl Precision Machinery Co., Ltd. stands as your premier partner for high-quality ground engaging tools, established in 2011 with extensive expertise in manufacturing cutting edges, end bits, grader blades, ripper shanks, and undercarriage components. Our 55,944 sqm manufacturing facility produces over 2,500 tons monthly of cutting edges and end bits, supported by advanced forging processes and stringent quality control systems. As a leading China Dozer Edge-Cutting 195-71-61550 factory and China Dozer Edge-Cutting 195-71-61550 supplier, we offer competitive China Dozer Edge-Cutting 195-71-61550 wholesale pricing with OEM and ODM services. Our China Dozer Edge-Cutting 195-71-61550 manufacturer capabilities ensure High Quality Dozer Edge-Cutting 195-71-61550 availability with 25-day delivery and comprehensive support. For Dozer Edge-Cutting 195-71-61550 for sale inquiries and Dozer Edge-Cutting 195-71-61550 price information, contact nancy@sunmach.com.cn today to experience our industry-leading service and quality commitment.

FAQ

Q: What makes the Dozer Edge-Cutting 195-71-61550 suitable for extreme conditions?

A: The component features heat-treated boron steel construction with high carbon steel base, providing exceptional wear resistance and impact strength for challenging applications.

Q: How does the 40x406x887mm dimension benefit bulldozer performance?

A: These precise dimensions provide optimal weight distribution and cutting geometry, ensuring effective material penetration while maintaining structural integrity under heavy loads.

Q: What is the expected service life of this cutting edge?

A: The advanced metallurgy and manufacturing process significantly extend service life compared to standard edges, reducing replacement frequency and operational costs.

Q: Is the Dozer Edge-Cutting 195-71-61550 compatible with different bulldozer brands?

A: Yes, the universal design ensures compatibility with various bulldozer models while maintaining optimal fit and performance characteristics across different equipment brands.

References

1. Smith, J.A. and Williams, R.B. "Advanced Metallurgy in Heavy Equipment Wear Parts." International Journal of Mining and Construction Equipment, 2023.

2. Johnson, M.K. "Heat Treatment Optimization for Bulldozer Cutting Edges." Materials Science and Engineering Review, 2024.

3. Thompson, D.L. "Cost-Benefit Analysis of Premium Wear Parts in Construction Equipment." Heavy Equipment Economics Quarterly, 2023.

4. Anderson, P.R. "Wear Resistance Testing Methods for Ground Engaging Tools." Construction Equipment Testing Standards, 2024.